Plastigage vs Mic readings

#1

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

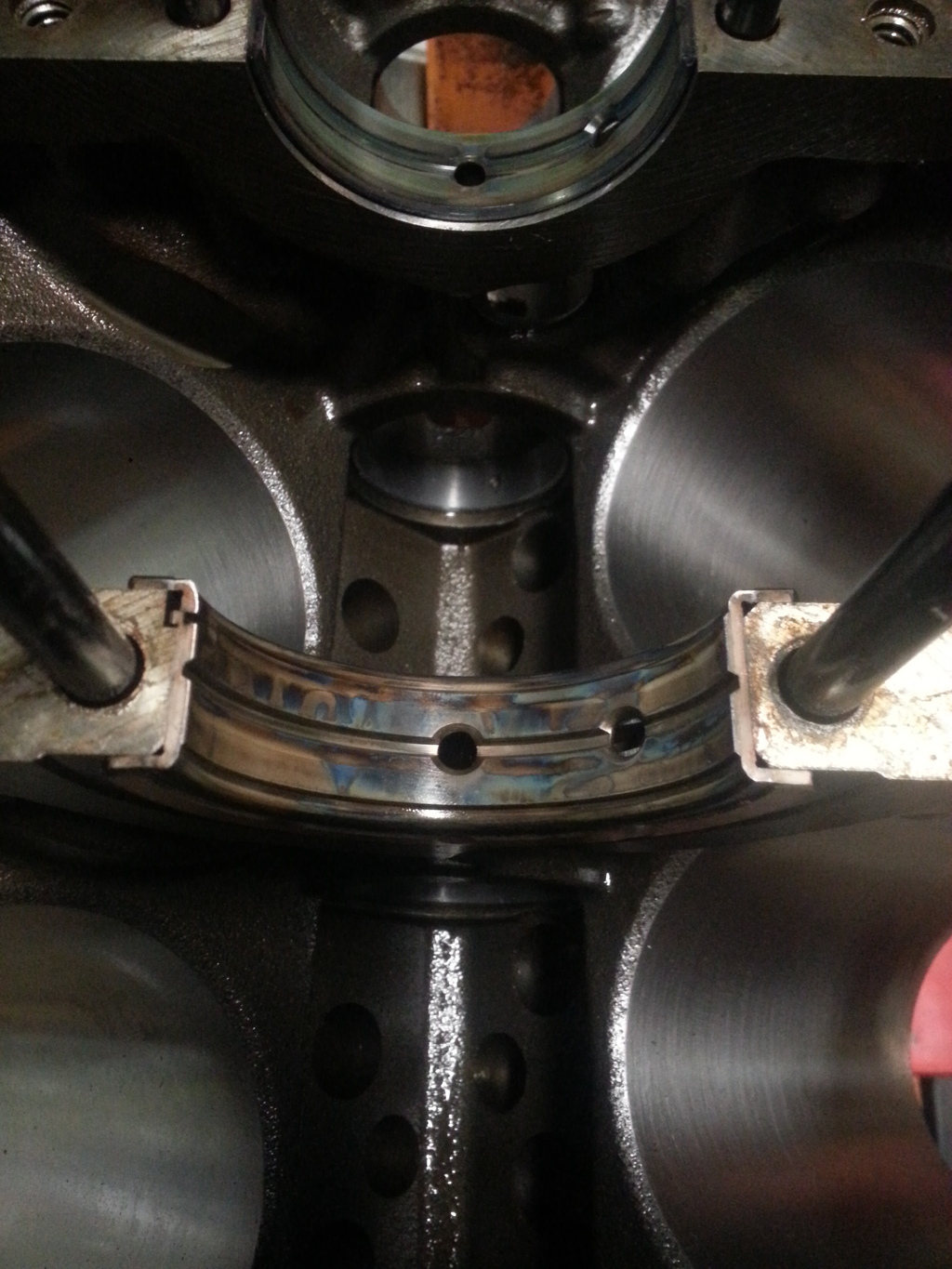

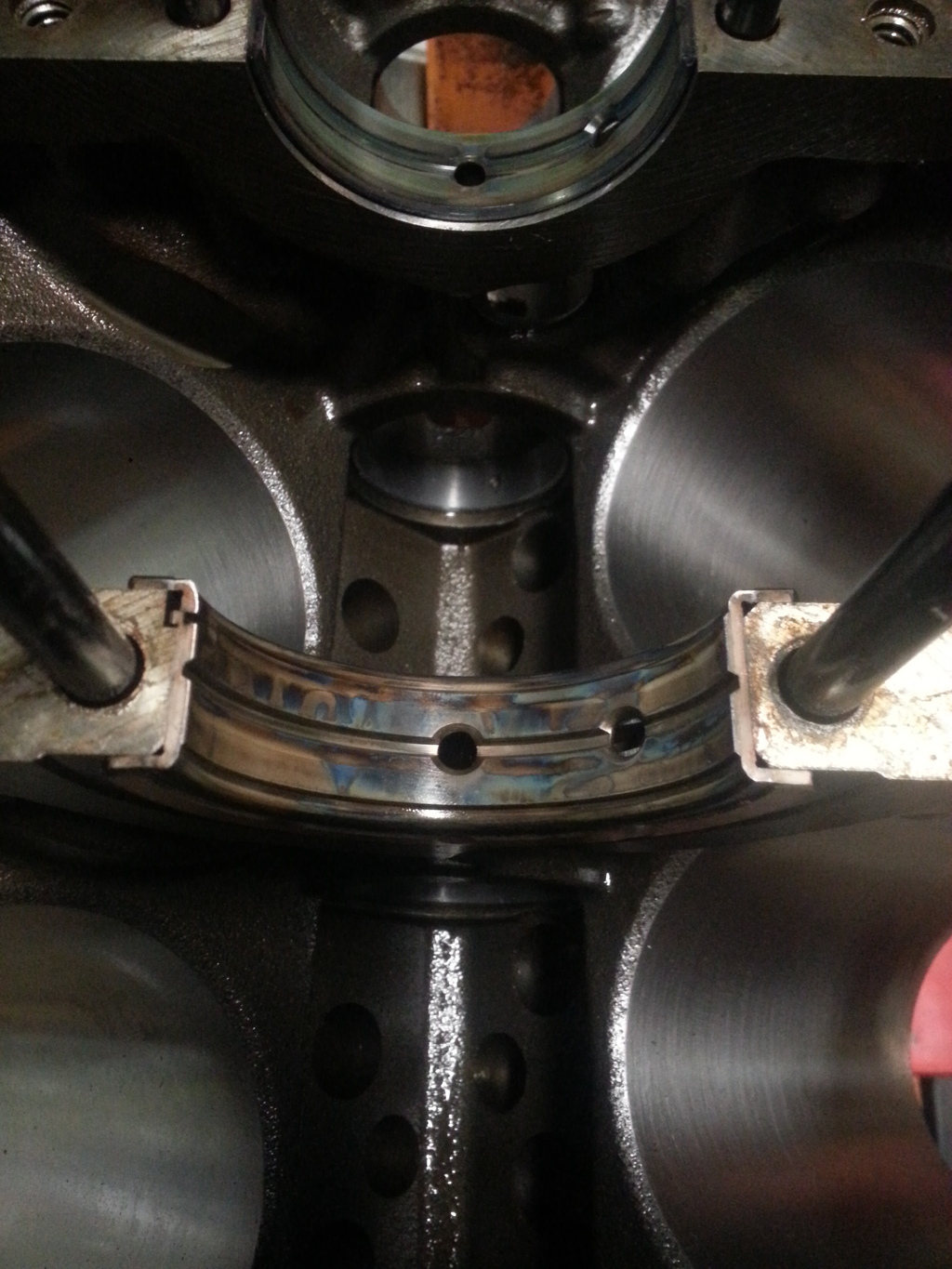

I'm in assembly stage of an Iron 5.3, Stock crank. Turbo build, this is essentially my 4th LS engine in less than 2 yrs. So I am attempting to be as meticulous as I possibly can so I KNOW its right.

Here is where im at.

Experienced measurements with ID mics, not snapgauges

BORE w bearing Crank Journal Result

2.5617 2.5586 .0031

2.5621 2.5586 .0035

2.5621 2.5586 .0035

2.5617 2.5587 .0030

2.5620 2.5586 .0034

I've done 3 rounds of plastigage and majority is showing .002 and even tighter on 4/5. I'm using ACL X bearings (.001 under)

I can't dispute the Mic readings, I initially was worried that it was to tight based on my plastigage. Now with concrete measurements. Im almost thinking to loose. Goals with research were .0025ish. I am using a Melling 10296. I won't assemble this until im happy its RIGHT!

Experienced opinions on where to go? Run it? or try half standard shells?

Here is where im at.

Experienced measurements with ID mics, not snapgauges

BORE w bearing Crank Journal Result

2.5617 2.5586 .0031

2.5621 2.5586 .0035

2.5621 2.5586 .0035

2.5617 2.5587 .0030

2.5620 2.5586 .0034

I've done 3 rounds of plastigage and majority is showing .002 and even tighter on 4/5. I'm using ACL X bearings (.001 under)

I can't dispute the Mic readings, I initially was worried that it was to tight based on my plastigage. Now with concrete measurements. Im almost thinking to loose. Goals with research were .0025ish. I am using a Melling 10296. I won't assemble this until im happy its RIGHT!

Experienced opinions on where to go? Run it? or try half standard shells?

#4

On The Tree

I never use platigage, for me it is just a false sense of security. I use the mic, and "feel" of the rotating crank. If you are starting the engine soon, I would assemble with 30wt motor oil, and then you can spin the crank, and feel if it's to loose or dragging. Ive assembled a descent amount of engines, but I almost go exclusively by feel now. Mic it, then use judgement. Plastigge is completely useless on rods, as the rods "rock" and twist when torqueing.

#5

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

I never use platigage, for me it is just a false sense of security. I use the mic, and "feel" of the rotating crank. If you are starting the engine soon, I would assemble with 30wt motor oil, and then you can spin the crank, and feel if it's to loose or dragging. Ive assembled a descent amount of engines, but I almost go exclusively by feel now. Mic it, then use judgement. Plastigge is completely useless on rods, as the rods "rock" and twist when torqueing.

I've had local machinists that do the "spin" test and that's it. And I cannot leave it to that alone lol. I'm to **** this go around to not see exactly whats going on.

#7

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

Line bore was not true, chewed up bearings. Along with several other things, and never got a spec sheet from him when I got it back. Should have known it was half-assed at that point.

Trending Topics

#10

Plastigauge has its place in engine assembly but is WORTHLESS as a machinist tool.

I seen many engines check good with plastigauge that had core shifts and bent cranks, out of round journals and other issues. Its just a final check before assembly that the clearance is good but it will tell you nothing else. Personally I don't like it because it fools people into thinking they are ok when they are so far from where they need to be its insane. I seen some real effups using it.

I seen many engines check good with plastigauge that had core shifts and bent cranks, out of round journals and other issues. Its just a final check before assembly that the clearance is good but it will tell you nothing else. Personally I don't like it because it fools people into thinking they are ok when they are so far from where they need to be its insane. I seen some real effups using it.

Last edited by RockinWs6; 12-30-2015 at 08:43 AM.

#11

Spend a couple hundred on mics or.... spend nothing, throw your strip of plastic down, and possible buy a new engine in the near future...

If you don't already have some good mics, spend the money and get some. 100% worth it. When I was 16 I used the plastic on my engine (SBC 383), it checked out fine, but 5000 miles down the road, bye bye bearings and crank. On the 300+ engines I have built since then, a quality mic is all I will use. You will find out quickly that not all machine shops do things right. Sometimes it is there fault, sometimes it is the machine. That is why you always double check!

If you don't already have some good mics, spend the money and get some. 100% worth it. When I was 16 I used the plastic on my engine (SBC 383), it checked out fine, but 5000 miles down the road, bye bye bearings and crank. On the 300+ engines I have built since then, a quality mic is all I will use. You will find out quickly that not all machine shops do things right. Sometimes it is there fault, sometimes it is the machine. That is why you always double check!

The following users liked this post:

Homer_Simpson (01-28-2022)

#12

10 Second Club

iTrader: (18)

This is one of the best simple articles out there that I refer folks to a lot.

http://www.hotrod.com/how-to/engine/...arance-basics/

I'd use a half bearing the next size down. 30s is probably a little looser then you want

http://www.hotrod.com/how-to/engine/...arance-basics/

I'd use a half bearing the next size down. 30s is probably a little looser then you want

#13

10 Second Club

iTrader: (37)

This is one of the best simple articles out there that I refer folks to a lot.

http://www.hotrod.com/how-to/engine/...arance-basics/

I'd use a half bearing the next size down. 30s is probably a little looser then you want

http://www.hotrod.com/how-to/engine/...arance-basics/

I'd use a half bearing the next size down. 30s is probably a little looser then you want

Good reading, thanks.

Good reading, thanks.

#14

"Too loose you know, too tight the world knows." Although .003 starts entering the too loose range (thicker oil would allow it to live, but really just a bandaid). I'd shoot to keep it under .003. In my performance builds, my ideal target is .0027 (rod and main, iron blocks), in stock rebuilds, anything between .002 and .003 will fly for me. I always use a mic and a dial bore gauge (Mit and Starrett for me), and follow up with the feel spins to make sure there are no dragging spots. I also use a beam-style torque wrench to record how much torque it takes to spin the motor over without the heads on.

#15

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the comments guys.

Luckily for me my Dad has Mics that are calibrated on a fairly regular basis by an outside company sourced through his job.

Right now, I need to borrow a dial bore gauge. See what that tells me. Then looks like im gonna need to order a standard set of bearings and use half of them to get me in my goal range of .0023-28.

Luckily for me my Dad has Mics that are calibrated on a fairly regular basis by an outside company sourced through his job.

Right now, I need to borrow a dial bore gauge. See what that tells me. Then looks like im gonna need to order a standard set of bearings and use half of them to get me in my goal range of .0023-28.

#16

TECH Regular

iTrader: (9)

You should be close between plastigage and a good set of micrometers. There is no substitute for the right tool, however.

I can make a mic read what ever i want and many inexperienced people use mics like they are a c-clamp. How experienced are you at using them? Did your dad double check?

You measured the bore with inside mics not that digital caliper correct? Although these tools you said were calibrated at your dad's employer did you check the inside mic with the outside mic, do you have a set of standards to check against?

Good luck with your build, take your time, do it right the first time.

I can make a mic read what ever i want and many inexperienced people use mics like they are a c-clamp. How experienced are you at using them? Did your dad double check?

You measured the bore with inside mics not that digital caliper correct? Although these tools you said were calibrated at your dad's employer did you check the inside mic with the outside mic, do you have a set of standards to check against?

Good luck with your build, take your time, do it right the first time.

#17

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

You should be close between plastigage and a good set of micrometers. There is no substitute for the right tool, however.

I can make a mic read what ever i want and many inexperienced people use mics like they are a c-clamp. How experienced are you at using them? Did your dad double check?

You measured the bore with inside mics not that digital caliper correct? Although these tools you said were calibrated at your dad's employer did you check the inside mic with the outside mic, do you have a set of standards to check against?

Good luck with your build, take your time, do it right the first time.

I can make a mic read what ever i want and many inexperienced people use mics like they are a c-clamp. How experienced are you at using them? Did your dad double check?

You measured the bore with inside mics not that digital caliper correct? Although these tools you said were calibrated at your dad's employer did you check the inside mic with the outside mic, do you have a set of standards to check against?

Good luck with your build, take your time, do it right the first time.

I'm not a skilled user of said micrometers, so my pops does it on the daily. And yes we have standards to check accuracy. And no calipers have been used at all.

I just snagged a dial bore gauge I will cross reference the mic readings with. See how close the 2 tools are.

#18

TECH Regular

Thread Starter

iTrader: (2)

Join Date: Sep 2013

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

"In other words, if you’re using one-unders with standards for your main bearings, put all the one-unders in the cap with the standards in the block side of the housing bore, or vice versa. So with that said, let’s get on with it"

Nice bit of info I snagged out of that article. I would have left my X bearing shells in block side otherwise.

Nice bit of info I snagged out of that article. I would have left my X bearing shells in block side otherwise.