Uh oh...ls7 lifter stuck in bore.

#1

Well my usual yearly may curse strikes again where Im tearing the motor down. Last yr i thought I covered all my bases on having a stout reliable setup built after having 2 engine failures before the season even started. I pennied up and did a forged piston/rod setup from dssracing, btr 660 dual spring setup,ljms stg 2 turbo cam, trunion bushings,hardened pushrods, new bearings etc. car ran great and made good power for pushing pump gas with lil meth on deka 80s and intank pump from my t4 turbo and restrictive exhaust. I was happy. Put the car away for winter saving up to get my dana s60 and installed it. had some minor hiccups with that also but nothing I couldnt move on and be confident to start making passes. The day before i was about to head to an armdrop event. My motor started singing a familiar lifter tune!

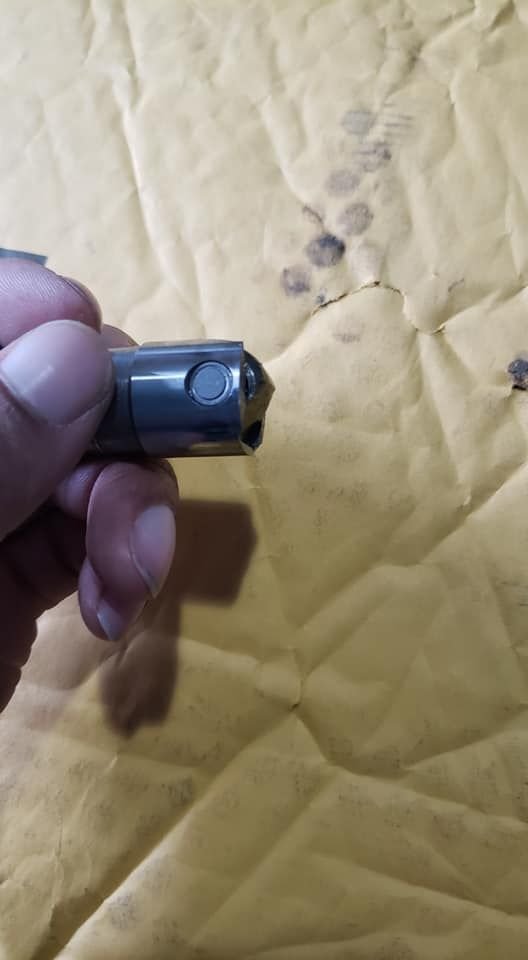

I did all the simple checks,dumped oil..cut the filter, checked the rockers..puhsrods etc. nothing wrong their. Called another tech friend of mine to listen to it run as it ran mint..but ticking was awful and he said what i thought...bad lifter. So here we are 2 weeks later i had time to dig in and pull off just the bare stuff to get the heads off and pull the lifters. Passenger side everything came out easy..0 sign of an issues where I had thought for sure the sound was coming from. Driver side..not so much.. 2 of the "ls7" lifters did not want to come out. 1 of them took some paced pulling bit by bit. the last one..is still in its bore with limited travel. I can see a piece on the bottm of that lifter has broken off but the roller is intact. The lifter seems to be stuck partially up so the cam lobe seems to be fine luckily. However it seems the lifter has mushroomed. I either force it out from the top or bottom..it gets stuck either way.

Taking the cam out and getting the lifter to drop usually is the answer and most have no issues..well since this 1 lifter doesnt want to do that either it appears I will be ruining the block from what Ive found in searches..the bore will get scored and possibly need to be sleeved/honed. how easy is it to damage the lifter bore forcing out a lifter? To the eye..the lifter shouldnt be fighting me this hard on either end..its not that ballooned at all. i was able to take the valve out and thought I could pull it out with visegrips. So im at a stand still. This was going to be a quick easy lifter swap,disassembly today..re-assembly tomorrow as i have new johnson lifters ready to go in..gaskets..etc. I might borrow a lifter removal tool and try my luck..either way I do it or a machine shop regardless and see how the bore survives. has anyone removed a stuck lifter and the bore really wasnt all that bad?

I did all the simple checks,dumped oil..cut the filter, checked the rockers..puhsrods etc. nothing wrong their. Called another tech friend of mine to listen to it run as it ran mint..but ticking was awful and he said what i thought...bad lifter. So here we are 2 weeks later i had time to dig in and pull off just the bare stuff to get the heads off and pull the lifters. Passenger side everything came out easy..0 sign of an issues where I had thought for sure the sound was coming from. Driver side..not so much.. 2 of the "ls7" lifters did not want to come out. 1 of them took some paced pulling bit by bit. the last one..is still in its bore with limited travel. I can see a piece on the bottm of that lifter has broken off but the roller is intact. The lifter seems to be stuck partially up so the cam lobe seems to be fine luckily. However it seems the lifter has mushroomed. I either force it out from the top or bottom..it gets stuck either way.

Taking the cam out and getting the lifter to drop usually is the answer and most have no issues..well since this 1 lifter doesnt want to do that either it appears I will be ruining the block from what Ive found in searches..the bore will get scored and possibly need to be sleeved/honed. how easy is it to damage the lifter bore forcing out a lifter? To the eye..the lifter shouldnt be fighting me this hard on either end..its not that ballooned at all. i was able to take the valve out and thought I could pull it out with visegrips. So im at a stand still. This was going to be a quick easy lifter swap,disassembly today..re-assembly tomorrow as i have new johnson lifters ready to go in..gaskets..etc. I might borrow a lifter removal tool and try my luck..either way I do it or a machine shop regardless and see how the bore survives. has anyone removed a stuck lifter and the bore really wasnt all that bad?

#2

TECH Addict

iTrader: (32)

Ive usually knocked them out the bottom with the cam removed. Since yours is still stuck, this is what i would try.

Take the clip off the lifter end (the pushrod seat)

Remove the spring and maybe try drilling it out toward the roller tip. U can thin maybe bust it in half and it will fall out in pieces. OR weld something to the inside section and pull it out. The weld being hot should help it come out.

Either way its possible the lifter bore is messed up and will need some sort of honing or sleeve. Can be fixed, just takes time and money.

Take the clip off the lifter end (the pushrod seat)

Remove the spring and maybe try drilling it out toward the roller tip. U can thin maybe bust it in half and it will fall out in pieces. OR weld something to the inside section and pull it out. The weld being hot should help it come out.

Either way its possible the lifter bore is messed up and will need some sort of honing or sleeve. Can be fixed, just takes time and money.

#6

Well its been a week and got the car back up and running. I got into a groove just wanting to bang things out as it was pretty hot outside. I pulled the cam and polished the pitting that was on it and reassembled the entire motor. I ordered a pushrod tool that arrived literally as I was putting the rockers on. Im glad i bought the 7.350 because it was almost perfect length.If i want more preload I think going to a 7.375 would get me more into the .050-.060 range. which some say is better but Im sticking with what the specs call for. After that it was time to crank it over and build oil pressure before a first start. I put in engine flush to the existing oil just as a precaution to clean whatever else was still in there. Fired it up and carefully listened for any abnormal sounds,check leaks etc and got it upto temp.

With driving it around for a few days I slowly start getting into more boost at short street pulls, also trying to bleed the cooling system a few times to really get all the air out as my engine seemed to really be sensitive with air pockets which then lead to overheating during high boost pulls previously. The car sounds different to me especially idling and i now hear the famous sewing machine noise people mention.Throttle response feels a tad bit more crisp..power feels like it comes in harder..or im just not used to it consistently making over 700whp lol.But so far..its running like it did when it first fired up last yr.

With driving it around for a few days I slowly start getting into more boost at short street pulls, also trying to bleed the cooling system a few times to really get all the air out as my engine seemed to really be sensitive with air pockets which then lead to overheating during high boost pulls previously. The car sounds different to me especially idling and i now hear the famous sewing machine noise people mention.Throttle response feels a tad bit more crisp..power feels like it comes in harder..or im just not used to it consistently making over 700whp lol.But so far..its running like it did when it first fired up last yr.