F'ing needle bearings!

#1

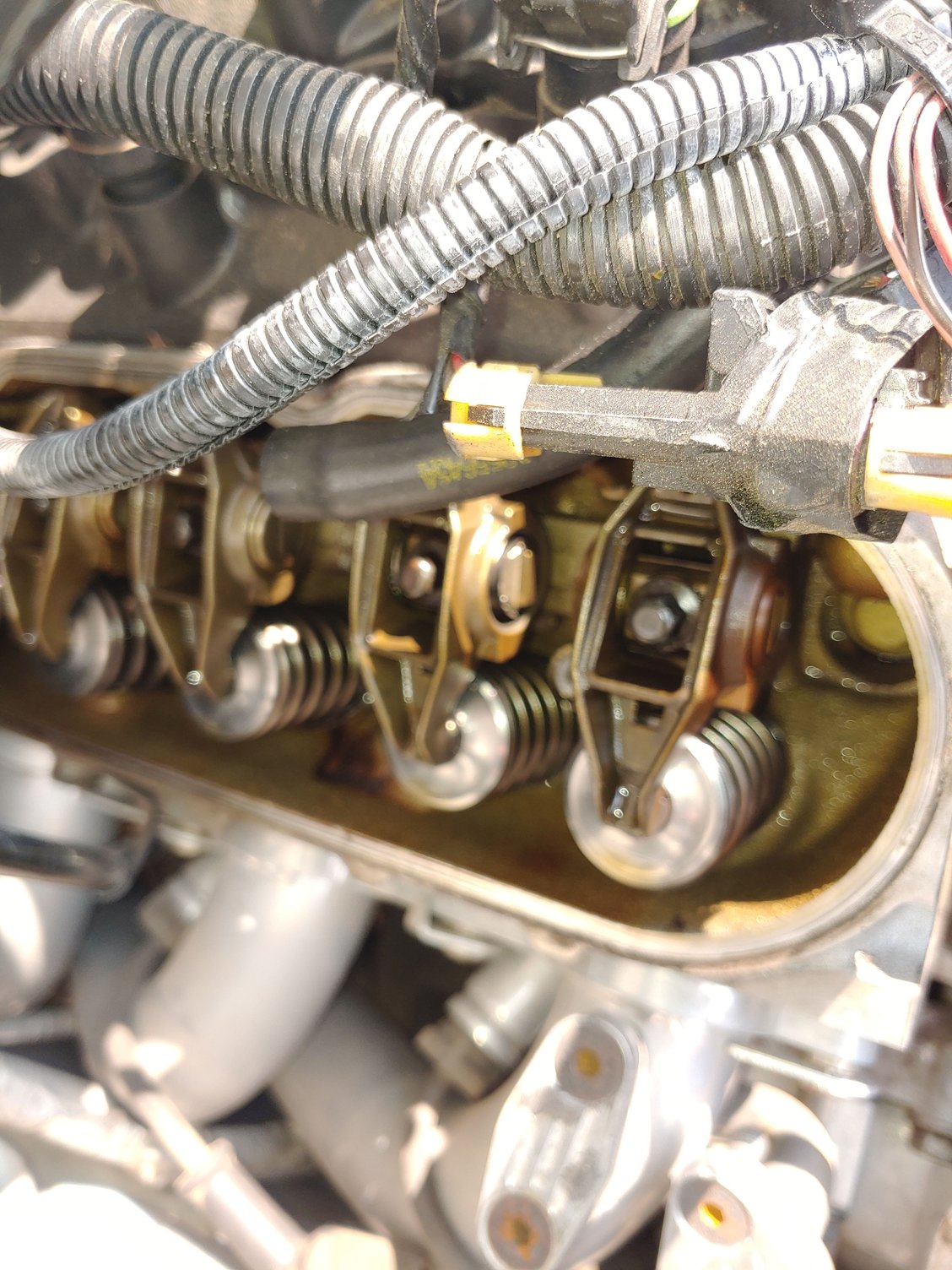

Welp... add me to the list of victims of "The Great LS1 Rocker Needle Bearing Migration". Oil change today revealed needle bearings on the magnet and in the drain pan. Luckily, I had not heard anything that made me think there was something wrong with the motor, so I think I dodged a bullet!

Ordered the RPM Speed Max Effort rockers from WS6 Store. Add that to the new tires and front end alignment, and this has been an expensive week!

Ordered the RPM Speed Max Effort rockers from WS6 Store. Add that to the new tires and front end alignment, and this has been an expensive week!

The following users liked this post:

G Atsma (09-11-2020)

#5

Statistically, the stock rockers with the uncaged needle bearings are a non-issue.

#6

Are you gonna chance it and simply put new bushed rockers in it or tear it down to make sure you removed all foreign material? Sucks to be you right now but I'd pull it apart to make certain. You could possibly figure out how many needles are in each rocker and do some math.

#7

Trending Topics

#8

Are you gonna chance it and simply put new bushed rockers in it or tear it down to make sure you removed all foreign material? Sucks to be you right now but I'd pull it apart to make certain. You could possibly figure out how many needles are in each rocker and do some math.

If I have to tear the motor down, it will be to ditch the LS1 block and heads anyway.

Last edited by FCar2000TA; 09-12-2020 at 09:14 PM.

#10

As soon as someone says statistics implys that there are failures not just here. Have seen it several times with my own eyes. That is all I need to make my opinion. Have never seen a bushed lifter come apart and they have been around forever. If you actually go to the track on a regular basis you will seen them too. I'm sure the OP didn't make it up. When you spend the crazy money we do to build a high end motor, why would you even take a chance on it when it has absolutely no benefits.

#11

I have seen many lifters break in half at the trunion on crazy *** boosted motors. What do you think happens to the needle bearings? Bushed lifters just need to be swapped out. Unless there is a way to account for every needle like that has been already stated. There is no way I would run that motor without tearing it apart. Who knows though, you may get lucky.

#12

I did not mean to say it does not happen. But you make it sound like a common disease with all stock rockers.

If you narrow it down to higher ("competition level") performance situations, THEN it is an issue.

If you narrow it down to higher ("competition level") performance situations, THEN it is an issue.

#13

Stock trunnions come apart with a hammer and chisel. The max effort rockers will not come apart unless you damage the rocker, like cut it open to remove the trunnion. If this happens in your engine, it wouldnt matter what you were using, engine is kaput. Needle bearings have less surface area that means less friction and less heat. Bushed materials are more for race applications where bushings are inspected and changed often.

#14

Stock trunnions come apart with a hammer and chisel. The max effort rockers will not come apart unless you damage the rocker, like cut it open to remove the trunnion. If this happens in your engine, it wouldnt matter what you were using, engine is kaput. Needle bearings have less surface area that means less friction and less heat. Bushed materials are more for race applications where bushings are inspected and changed often.

The following users liked this post:

G Atsma (09-13-2020)

The following users liked this post:

G Atsma (09-13-2020)

#17

#18

Had the same issue with the com cam trunion upgraded rockers and went back to OEM. Bought a bunch of neodyium magnets on extensions. I start my needle bearing hunt next week. Tentative plan is pull valve covers, intake/valley cover, and oil pan.