Oil pressure gauge moving opposite direction..

#1

Hi so I'm stumped on relocating my oil pressure sender.. here's the story..

I have a 64 Nova with an LS1, and I have a classic industries guage cluster that uses the bell style sending unit with 1/8npt male fitting. When I emailed them about location they said just use the rear passenger port with an adapter. So that's what I did but because of it's size and my fast intake I had to use an adapter that out it out at a 45*. After about 500 miles I noticed it was leaking from the adapter on the block to the 45* angle fitting and nowhere else. Tried another fitting, tried 3 different sealant types. Still had a leak. So I decided to remote mount it from the oil filter adapter plate (using a moroso f-body pan). Got the proper earl fittings to run it 90* and up via steel braided line. When I tested the remote setup, the needle moved opposite direction, like it isn't grounding. So I took off the hose thinking it was that. Mounted it straight off the port with an adapter and made a new wire to the guage wire. Still the needle goes down when starting up...

The fittings I used for the original location were brass, with Teflon tape and they read 50+psi. The fittings for the lower pan mount were aluminum earls with tape and without tape. I'm thinking I just have to go back to mounting from top location and double up on Teflon even though it says not to... Running out of ideas. Anyone got any suggestions? Thanks you.

I have a 64 Nova with an LS1, and I have a classic industries guage cluster that uses the bell style sending unit with 1/8npt male fitting. When I emailed them about location they said just use the rear passenger port with an adapter. So that's what I did but because of it's size and my fast intake I had to use an adapter that out it out at a 45*. After about 500 miles I noticed it was leaking from the adapter on the block to the 45* angle fitting and nowhere else. Tried another fitting, tried 3 different sealant types. Still had a leak. So I decided to remote mount it from the oil filter adapter plate (using a moroso f-body pan). Got the proper earl fittings to run it 90* and up via steel braided line. When I tested the remote setup, the needle moved opposite direction, like it isn't grounding. So I took off the hose thinking it was that. Mounted it straight off the port with an adapter and made a new wire to the guage wire. Still the needle goes down when starting up...

The fittings I used for the original location were brass, with Teflon tape and they read 50+psi. The fittings for the lower pan mount were aluminum earls with tape and without tape. I'm thinking I just have to go back to mounting from top location and double up on Teflon even though it says not to... Running out of ideas. Anyone got any suggestions? Thanks you.

#2

ModSquad

iTrader: (6)

Show a couple pics of what you’ve done here. I’ve seen guys drill and tap the plate there to feed a turbo. In doing so, the fitting screwed in too far and blocked the oil flow there, starving the engine of oil. Maybe the Moroso pan has a different block-off plate? Pictures please…

#3

Show a couple pics of what you’ve done here. I’ve seen guys drill and tap the plate there to feed a turbo. In doing so, the fitting screwed in too far and blocked the oil flow there, starving the engine of oil. Maybe the Moroso pan has a different block-off plate? Pictures please…

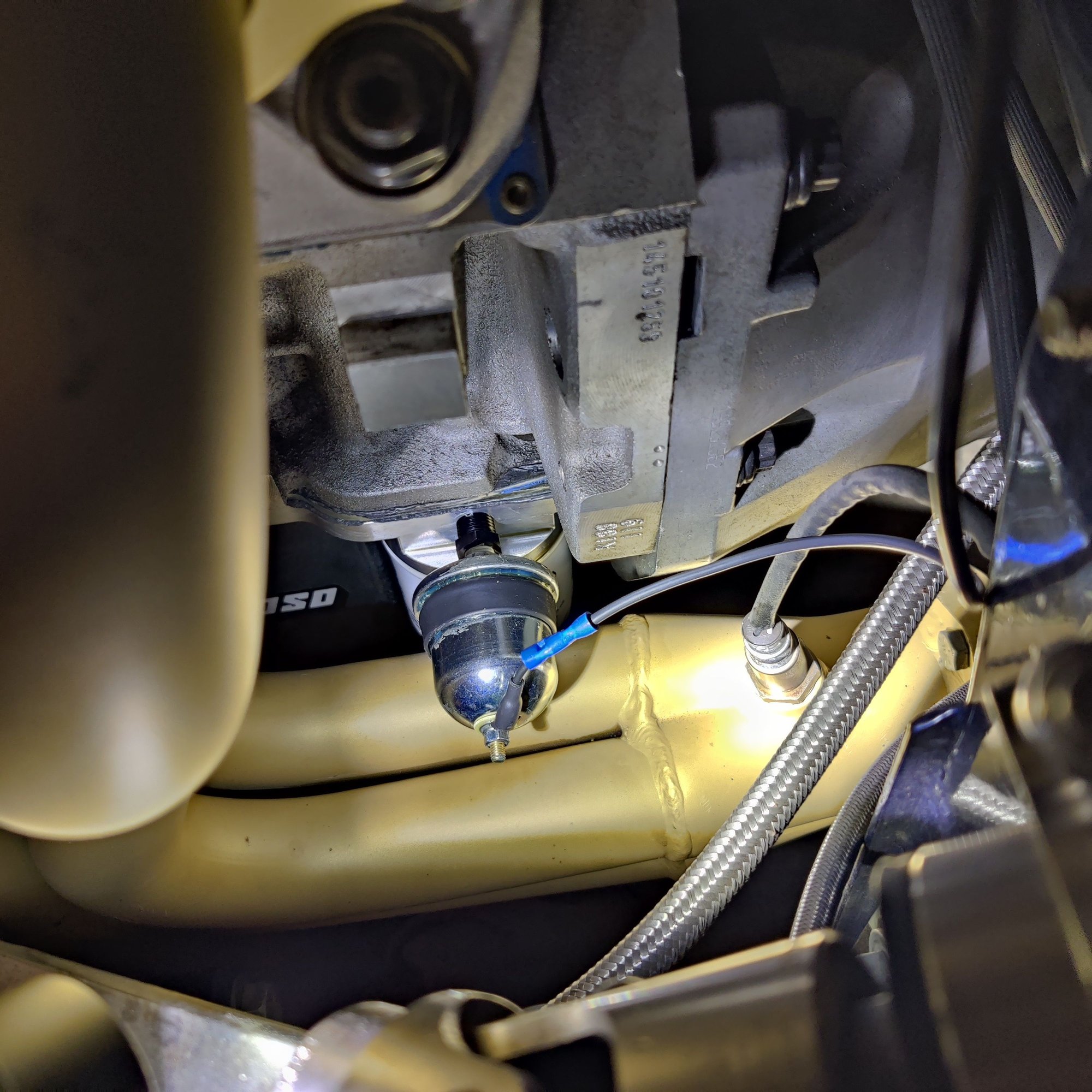

This is where I originally had the sender mounted using extensions because there's no room to go straight down with my manifold.

This is the current location off the oil filter adapter plate from the moroso pan

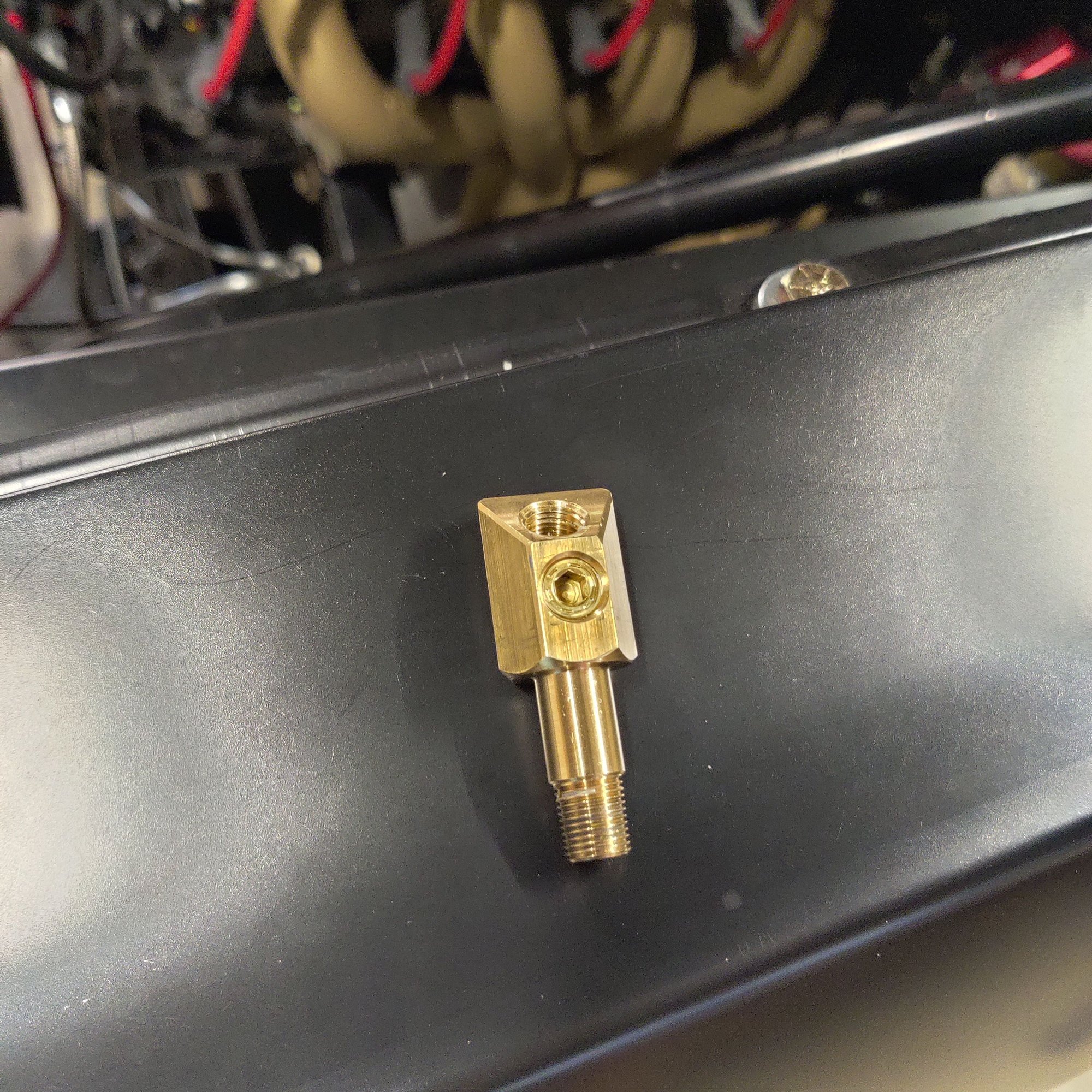

This was the extension

Running straight out as just a test, I would run a 90* elbow so it would face upwards, as well as solder that connector, the butt connector is just a place holder.

#4

More a less a guess on my part but the gauge doesn't ground from the sender. The gauge grounds off the back of the gauge to the chassis (At least on the Auto Meter gauges I've used) or where ever you have your grounds. I've always used the adapter above the oil filter to tap into for oil pressure. Bad sender?

#5

More a less a guess on my part but the gauge doesn't ground from the sender. The gauge grounds off the back of the gauge to the chassis (At least on the Auto Meter gauges I've used) or where ever you have your grounds. I've always used the adapter above the oil filter to tap into for oil pressure. Bad sender?

#6

TECH Fanatic

iTrader: (23)

I don't know about a '64 Nova, but on my '80s GM vehicle the oil gauge will peg HIGH if open circuit, and peg LOW if short circuit. In other words, the lower the electrical resistance to ground the lower the oil pressure reading on gauge. If yours is the same concept, then that suggests you've got a short to ground somewhere. Maybe check for short circuit between your terminal and the case of the sensor. Perhaps the insulator broke from being over torqued or something like that.

Or.... maybe you really do have low oil pressure at the gauge.

Maybe wise to double check with a mechanical gauge at the top of the block.

Or.... maybe you really do have low oil pressure at the gauge.

Maybe wise to double check with a mechanical gauge at the top of the block.

#7

I don't know about a '64 Nova, but on my '80s GM vehicle the oil gauge will peg HIGH if open circuit, and peg LOW if short circuit. In other words, the lower the electrical resistance to ground the lower the oil pressure reading on gauge. If yours is the same concept, then that suggests you've got a short to ground somewhere. Maybe check for short circuit between your terminal and the case of the sensor. Perhaps the insulator broke from being over torqued or something like that.

Or.... maybe you really do have low oil pressure at the gauge.

Maybe wise to double check with a mechanical gauge at the top of the block.

Or.... maybe you really do have low oil pressure at the gauge.

Maybe wise to double check with a mechanical gauge at the top of the block.

Yeah gonna double check my connections. I highly doubt it went from perfectly good pressure at idle (50+) to 0 after simply sitting in the same spot for a week. Like I said the needle actually forces itself downward on startup. My fuel gauge did the same until I grounded the fuel cell properly. So I think it's conductivity related. I read that anodized fittings don't conduct electricity and that's what I've been testing off of...so I ordered a brass elbow adapter and will try again with that. Brass is what I was using for the adapter fittings up top.

Trending Topics

#8

TECH Fanatic

iTrader: (23)

My fuel gauge did the same until I grounded the fuel cell properly. So I think it's conductivity related. I read that anodized fittings don't conduct electricity and that's what I've been testing off of...so I ordered a brass elbow adapter and will try again with that. Brass is what I was using for the adapter fittings up top.

Last edited by QwkTrip; 03-07-2023 at 11:36 PM.

#9

Fuel gauge also pegs LOW (empty) when there is a short to ground, and goes HIGH (full) when electrical resistance is high. What exactly did you do with grounding to make the fuel gauge work right? What you're saying is confusing to me because my intuition would predict the opposite. Seems this same weird behavior is happening with your oil gauge too.

In the case of my oil pressure sender, it was working just fine with the ground going from my block ground straps, I presume, to the negative firewall terminal. The wire going from the sending unit provided the cluster with the other end of the circuit, at least from what I understand. When I moved the sender to the pan port, I used anodized fittings instead of brass, so that's where I believe my issue is now coming from. I read that anodized fittings don't conduct electricity. So that's sort of where I'm at. I'm also not an experienced electrician or even builder. This is my first build so forgive my ignorance.

#10

TECH Fanatic

iTrader: (23)

I guess I'm still confused how your fuel gauge went LOW when the ground was omitted, I would have thought it goes HIGH. But that's history, not worthwhile spending more time on that.

Oil pressure gauge gets +12V from the battery and has 2 grounds. One ground is at the gauge cluster (I hope you hooked that up). Other ground is the oil pressure sender. The pressure sender is basically a variable resistor dependent on oil pressure, which causes the gauge needle to move with changes in oil pressure. The higher the current draw through the pressure sender, the lower the needle will read in the gauge. So there are two ways that needle might be pulled low:

(1) Short circuit in the circuit to the sender.

(2) Poor or no ground at gauge cluster (the other ground i talked about for the gauge).

Oil pressure gauge gets +12V from the battery and has 2 grounds. One ground is at the gauge cluster (I hope you hooked that up). Other ground is the oil pressure sender. The pressure sender is basically a variable resistor dependent on oil pressure, which causes the gauge needle to move with changes in oil pressure. The higher the current draw through the pressure sender, the lower the needle will read in the gauge. So there are two ways that needle might be pulled low:

(1) Short circuit in the circuit to the sender.

(2) Poor or no ground at gauge cluster (the other ground i talked about for the gauge).

The following users liked this post:

jarrett wininger (03-07-2023)

#11

I guess I'm still confused how your fuel gauge went LOW when the ground was omitted, I would have thought it goes HIGH. But that's history, not worthwhile spending more time on that.

Oil pressure gauge gets +12V from the battery and has 2 grounds. One ground is at the gauge cluster (I hope you hooked that up). Other ground is the oil pressure sender. The pressure sender is basically a variable resistor dependent on oil pressure, which causes the gauge needle to move with changes in oil pressure. The higher the current draw through the pressure sender, the lower the needle will read in the gauge. So there are two ways that needle might be pulled low:

(1) Short circuit in the circuit to the sender.

(2) Poor or no ground at gauge cluster (the other ground i talked about for the gauge).

Oil pressure gauge gets +12V from the battery and has 2 grounds. One ground is at the gauge cluster (I hope you hooked that up). Other ground is the oil pressure sender. The pressure sender is basically a variable resistor dependent on oil pressure, which causes the gauge needle to move with changes in oil pressure. The higher the current draw through the pressure sender, the lower the needle will read in the gauge. So there are two ways that needle might be pulled low:

(1) Short circuit in the circuit to the sender.

(2) Poor or no ground at gauge cluster (the other ground i talked about for the gauge).

#12

TECH Fanatic

iTrader: (23)

No, you haven't lost your mind.  You've got some good ideas to look into. Sorry I couldn't be of more help. I'm still wrestling with this in my mind too. Things are acting the opposite of how my mind thinks they should act, which makes me wonder if the adapter really is choking oil flow (resulting in low pressure). If changing materials doesn't work then I'd maybe consider next step to use a mechanical gauge at top of the valley to verify whether the numbers are real.

You've got some good ideas to look into. Sorry I couldn't be of more help. I'm still wrestling with this in my mind too. Things are acting the opposite of how my mind thinks they should act, which makes me wonder if the adapter really is choking oil flow (resulting in low pressure). If changing materials doesn't work then I'd maybe consider next step to use a mechanical gauge at top of the valley to verify whether the numbers are real.

#13

No, you haven't lost your mind.  You've got some good ideas to look into. Sorry I couldn't be of more help. I'm still wrestling with this in my mind too. Things are acting the opposite of how my mind thinks they should act, which makes me wonder if the adapter really is choking oil flow (resulting in low pressure). If changing materials doesn't work then I'd maybe consider next step to use a mechanical gauge at top of the valley to verify whether the numbers are real.

You've got some good ideas to look into. Sorry I couldn't be of more help. I'm still wrestling with this in my mind too. Things are acting the opposite of how my mind thinks they should act, which makes me wonder if the adapter really is choking oil flow (resulting in low pressure). If changing materials doesn't work then I'd maybe consider next step to use a mechanical gauge at top of the valley to verify whether the numbers are real.

#17

TECH Resident

Been doing this for a looonng time. Have never found an anodized fitting not grounding.

"The fittings I used for the original location were brass, with Teflon tape and they read 50+psi. The fittings for the lower pan mount were aluminum earls with tape and without tape".

We use liquid teflon on the fittings. Never an issue.

We've also used plumbers liquid seal on water system fittings with a high success rate.

Good that it's solved.

"The fittings I used for the original location were brass, with Teflon tape and they read 50+psi. The fittings for the lower pan mount were aluminum earls with tape and without tape".

We use liquid teflon on the fittings. Never an issue.

We've also used plumbers liquid seal on water system fittings with a high success rate.

Good that it's solved.

#18

ModSquad

iTrader: (6)

Anodizing has zero bearing on conductivity of electrons. It’s too thin to affect current. I’d say you had a loose connection and found it by accident. Either way, it’s fixed.

The following users liked this post:

G Atsma (03-14-2023)

#19

TECH Addict

iTrader: (1)

I agree with both posts above. Never any issue with anodized anything being a non conductor. As the NPT threads tighten to each other, they're an interference fit, meaning the anodizing quickly get wiped off the thread pitch diameter..

Last edited by grinder11; 03-14-2023 at 02:23 PM.