TFS Heads, FAST and ECS Cam Install Pics

#42

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by pdd

looks great, so you sanded the block with 800 grit sand paper, then went over it with rubbing alcohol?

#43

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by BriancWS6

Very nice man! Your car looks like a pleasure to work on...all nice and clean like they should all be. Your garage and everything looks like a great place to wrench with everything neat and organized. What size cam are you going with incase I missed that somewhere?

#45

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

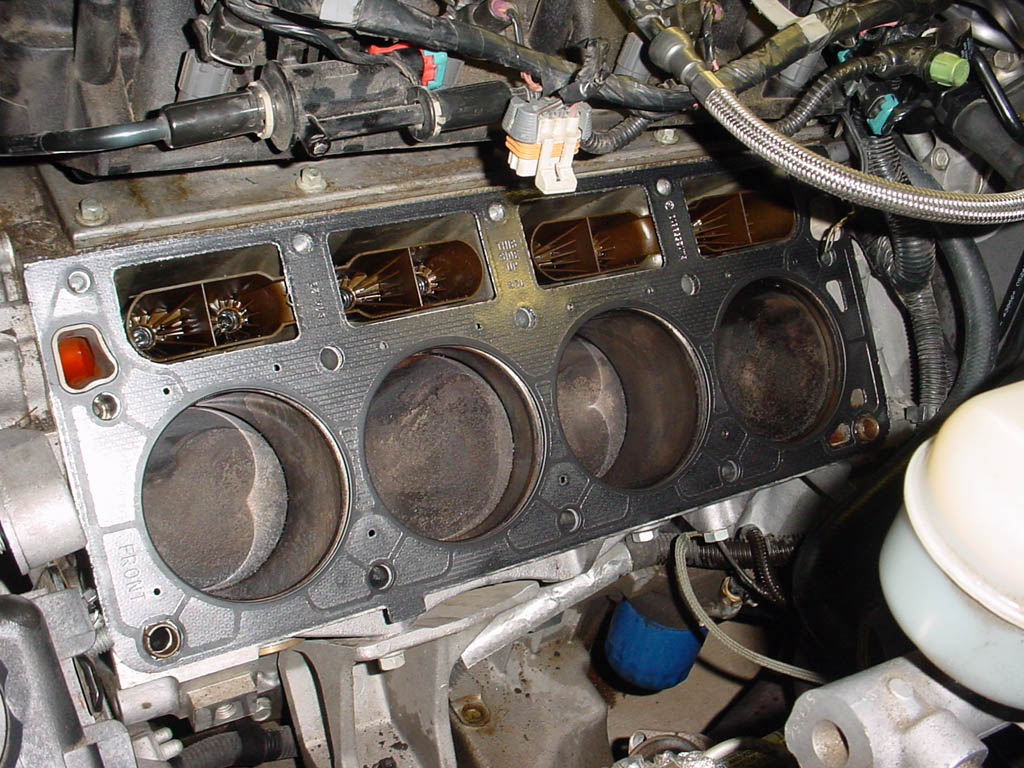

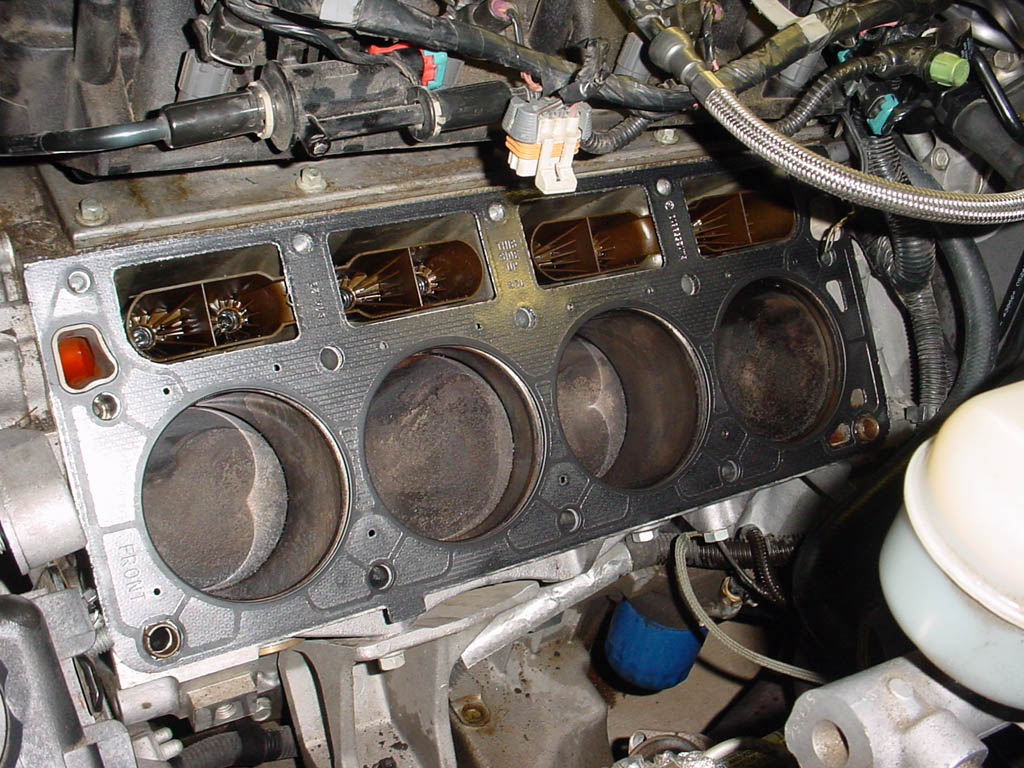

Ok...no my gaskets only seemed like they had an orientation. Meaning they could only face the correct way. I didn't see a 'This Side Up' on those. They are the 02 gaskets. They looked different then these.

Mine looked like this....

I didn't see a 'This Side Up' face........

Then I read this from LS1howto.com........ If you got the new 02+ style head gaskets, they are identical so just make sure you have the right side facing up. The gaskets will line up with the dowels discussed above.

Can anyone tell me if my gaskets are 'upside down' from the pictures? The good news is the heads are not torqued down beyond 22 foot pounds so I guess I can take them off if I have too and depending on how compressed the gaskets are re-use them. Worst case situation order/buy new ones.

I hope somebody that's built a few LS1's can help me here!

Mine looked like this....

I didn't see a 'This Side Up' face........

Then I read this from LS1howto.com........ If you got the new 02+ style head gaskets, they are identical so just make sure you have the right side facing up. The gaskets will line up with the dowels discussed above.

Can anyone tell me if my gaskets are 'upside down' from the pictures? The good news is the heads are not torqued down beyond 22 foot pounds so I guess I can take them off if I have too and depending on how compressed the gaskets are re-use them. Worst case situation order/buy new ones.

I hope somebody that's built a few LS1's can help me here!

#49

10 Second Club

iTrader: (11)

Join Date: Dec 2003

Location: Joplin, Missouri

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

Look like they are stock head gaskets.

What pushrods did you heads come with? I have my heads milled down to 59cc and I have Morel lifters and I was just wanting to know if I got the pushrods.

What pushrods did you heads come with? I have my heads milled down to 59cc and I have Morel lifters and I was just wanting to know if I got the pushrods.

#50

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 02Z28

Look like they are stock head gaskets.

What pushrods did you heads come with? I have my heads milled down to 59cc and I have Morel lifters and I was just wanting to know if I got the pushrods.

What pushrods did you heads come with? I have my heads milled down to 59cc and I have Morel lifters and I was just wanting to know if I got the pushrods.

That information is at home. I can check back for you and re-post.

#55

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, the valve angles are different. I'll be checking pre-load tomorrow when I buy a 6mm hex drive socket (which I lost I guess) and will KNOW for sure. But TEA put this package together and they are not a fly-by-night group of guys. they know their business.

#56

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

No pictures tonight guys  There isn't much to see because all I did was Torque the head bolts down and then I got stuck because I don't have Thread Sealant here or a 6mm hex 3/8 drive. Should have some nice pics tomorrow night.

There isn't much to see because all I did was Torque the head bolts down and then I got stuck because I don't have Thread Sealant here or a 6mm hex 3/8 drive. Should have some nice pics tomorrow night.

There isn't much to see because all I did was Torque the head bolts down and then I got stuck because I don't have Thread Sealant here or a 6mm hex 3/8 drive. Should have some nice pics tomorrow night.

There isn't much to see because all I did was Torque the head bolts down and then I got stuck because I don't have Thread Sealant here or a 6mm hex 3/8 drive. Should have some nice pics tomorrow night.

#59

9 Second Club

iTrader: (17)

Join Date: Nov 2002

Location: New Braunfels ,Tx

Posts: 4,997

Likes: 0

Received 0 Likes

on

0 Posts

You used the stock bolts? Not ARPs ? Just asking. Looks good and you should try to tune the TB and not just jump on the wagon and drill it. Try to tune it first. Ive have had to drill only one. All the rest of them was taking the time to get it done.  Looks like your almost there

Looks like your almost there

Looks like your almost there

Looks like your almost there

Last edited by JMBLOWNWS6; 12-14-2006 at 04:11 AM.

#60

TECH Resident

Thread Starter

iTrader: (6)

Join Date: May 2006

Location: ATX

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by JMBLOWNWS6

You used the stock bolts? Not ARPs ? Just asking. Looks good and you should try to tune the TB and not just jump on the wagon and drill it. Try to tune it first. Ive have had to drill only one. All the rest of them was taking the time to get it done.  Looks like your almost there

Looks like your almost there

Looks like your almost there

Looks like your almost there