[pics] Damaged lifter... have questions :(

#1

On The Tree

Thread Starter

iTrader: (2)

Join Date: Nov 2008

Location: South Florida

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Timeline Cliffnotes:

(1) ~April 2008, car runs really rough and choppy. Swap plugs/wires problem solved.

(2) ~August 2008, driving in a parking garage I notice a lot more engine noise 'ticking' noise up top that doesn't go away when engine warmed.

(3) August-December 2008, car parked and not driven.

(4) ~ December 2008, decide to swap valve springs as its about that time anyway and to look for a cause of the ticking.

(5) ~Decmeber 2008, Find one damaged valve tip & damaged rocker (see pic below)

(6) ~ January 2009, order parts plan on swapping valves when the same lifter that controls the valve that was damaged above is very damaged.

--------------------------------------------------------------

Pictures of the damaged stuff:

Damaged valve tip:

Damaged rocker:

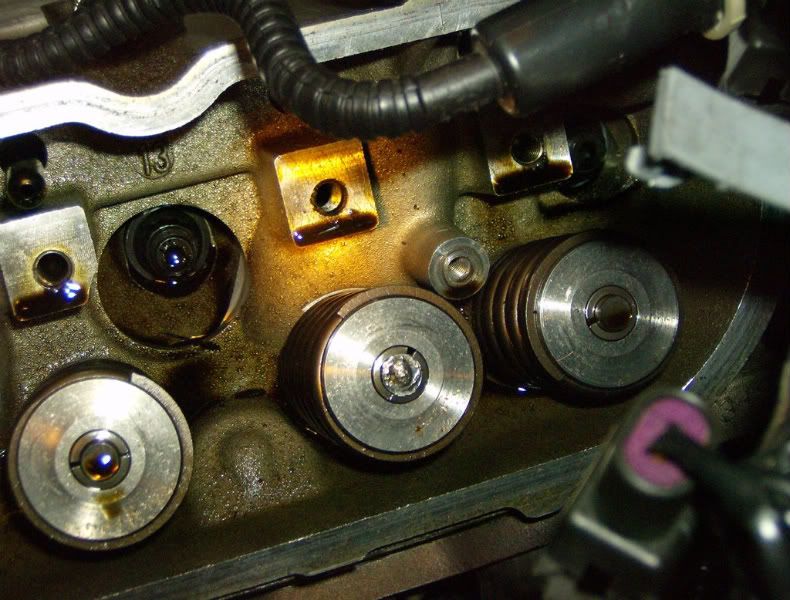

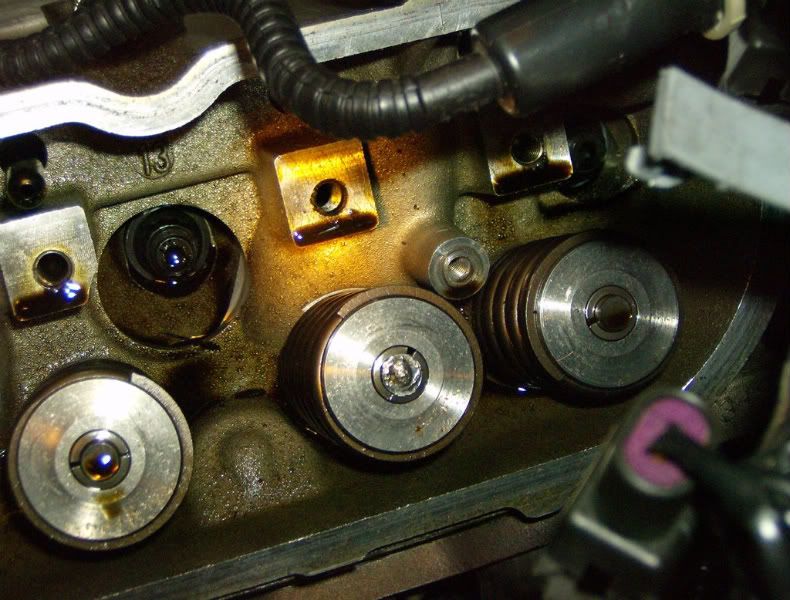

Damaged lifter:

----------------------------------------------------------------

The meat of the thread:

The heads look ok, the pistons and bores all look good. But as you can see that lifter is SERIOUSLY damaged. It didn't really want to come out of the hole. Also one side of the lifter, part of the wheel, is entirely ground down. The part that is not ground down is seriously metal fatigued with chips and pieces missing off it. It didn't want to spin at all; looks like it got shook up then just got stuck in that one position and continued to grind down.

I didn't notice any serious engine issues with these damaged parts other then the noise... :*****: Averaged ~18-19mpg to the tank, 30mpg highway.

http://www.youtube.com/watch?v=Dh3hoMvxM8g

Video taken when the parts would have been damaged but before I knew this.

----------------------------------------------------------

Questions:

What should I be doing at this point? I had already ordered new lifters, lifter trays etc before I knew about this. But is there anything else that can be damaged? What about the cam? I can only see it through the hole for the lifter and it looks ok. Where did all the metal shavings go!? :*****:

What caused this and how do I make sure it doesn't happen again?

I think as far as 'testing' the cam to be sure its ok I can stick a lifter in that hole and in another and slowly crank the engine by hand and measure the highest and lowest points. Then compare them with a known good lobe and the lobe where all this damaged stuff was located.

My simple weekend valvespring swap has turned into one hell of a project. :ack:

(1) ~April 2008, car runs really rough and choppy. Swap plugs/wires problem solved.

(2) ~August 2008, driving in a parking garage I notice a lot more engine noise 'ticking' noise up top that doesn't go away when engine warmed.

(3) August-December 2008, car parked and not driven.

(4) ~ December 2008, decide to swap valve springs as its about that time anyway and to look for a cause of the ticking.

(5) ~Decmeber 2008, Find one damaged valve tip & damaged rocker (see pic below)

(6) ~ January 2009, order parts plan on swapping valves when the same lifter that controls the valve that was damaged above is very damaged.

--------------------------------------------------------------

Pictures of the damaged stuff:

Damaged valve tip:

Damaged rocker:

Damaged lifter:

----------------------------------------------------------------

The meat of the thread:

The heads look ok, the pistons and bores all look good. But as you can see that lifter is SERIOUSLY damaged. It didn't really want to come out of the hole. Also one side of the lifter, part of the wheel, is entirely ground down. The part that is not ground down is seriously metal fatigued with chips and pieces missing off it. It didn't want to spin at all; looks like it got shook up then just got stuck in that one position and continued to grind down.

I didn't notice any serious engine issues with these damaged parts other then the noise... :*****: Averaged ~18-19mpg to the tank, 30mpg highway.

http://www.youtube.com/watch?v=Dh3hoMvxM8g

Video taken when the parts would have been damaged but before I knew this.

----------------------------------------------------------

Questions:

What should I be doing at this point? I had already ordered new lifters, lifter trays etc before I knew about this. But is there anything else that can be damaged? What about the cam? I can only see it through the hole for the lifter and it looks ok. Where did all the metal shavings go!? :*****:

What caused this and how do I make sure it doesn't happen again?

I think as far as 'testing' the cam to be sure its ok I can stick a lifter in that hole and in another and slowly crank the engine by hand and measure the highest and lowest points. Then compare them with a known good lobe and the lobe where all this damaged stuff was located.

My simple weekend valvespring swap has turned into one hell of a project. :ack:

#2

TECH Addict

iTrader: (24)

Ouch.

Do the following if you want to do it right.

Replace the Cam

Replace lifters with Morels

Replace lifter trays

Replace Valve

Replace the Locks and Retainer on that valve

Replace all valve seals

Replace Rocker arm

Looks like the lifter roller seized up because of too much force or maybe valve float. This caused lots of pressures on the valve tip and rocker tip causing the metal fatigue and failure. Thats my guess. Make sure you replace the cam, I'm sure there is lots of heat damage to the lobe which will weaken it.

Best of luck to you!

Do the following if you want to do it right.

Replace the Cam

Replace lifters with Morels

Replace lifter trays

Replace Valve

Replace the Locks and Retainer on that valve

Replace all valve seals

Replace Rocker arm

Looks like the lifter roller seized up because of too much force or maybe valve float. This caused lots of pressures on the valve tip and rocker tip causing the metal fatigue and failure. Thats my guess. Make sure you replace the cam, I'm sure there is lots of heat damage to the lobe which will weaken it.

Best of luck to you!

#3

On The Tree

Thread Starter

iTrader: (2)

Join Date: Nov 2008

Location: South Florida

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Ouch.

Do the following if you want to do it right.

Replace the Cam

Replace lifters with Morels

Replace lifter trays

Replace Valve

Replace the Locks and Retainer on that valve

Replace all valve seals

Replace Rocker arm

Looks like the lifter roller seized up because of too much force or maybe valve float. This caused lots of pressures on the valve tip and rocker tip causing the metal fatigue and failure. Thats my guess. Make sure you replace the cam, I'm sure there is lots of heat damage to the lobe which will weaken it.

Best of luck to you!

Do the following if you want to do it right.

Replace the Cam

Replace lifters with Morels

Replace lifter trays

Replace Valve

Replace the Locks and Retainer on that valve

Replace all valve seals

Replace Rocker arm

Looks like the lifter roller seized up because of too much force or maybe valve float. This caused lots of pressures on the valve tip and rocker tip causing the metal fatigue and failure. Thats my guess. Make sure you replace the cam, I'm sure there is lots of heat damage to the lobe which will weaken it.

Best of luck to you!

I'm hearing from other people I may need to tear apart the engine because of metal shavings being somewhere in there. Tha'ts probably too much project for me.

#4

TECH Addict

iTrader: (24)

I would say tearing the motor down is probably true, but if you have a magnetic drain plug, it'll catch most of it.

Did you buy ALL new valves? Or just a replacement? Make sure you take your heads in and have the valves properly installed. Otherwise they may not seal properly.

Also, make sure you replace that cam. You don't want to go through all of that work to find out the cam finally failed, take care of it now.

Adrian

Did you buy ALL new valves? Or just a replacement? Make sure you take your heads in and have the valves properly installed. Otherwise they may not seal properly.

Also, make sure you replace that cam. You don't want to go through all of that work to find out the cam finally failed, take care of it now.

Adrian

#5

TECH Regular

Join Date: Jan 2005

Location: Orlaanndoooo

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

I'm not sure if I would trust the old oil pump after that. You know if some metal went into the pan it was going through that pump as well. The pump will be off when you do a cam swap, won't it?

Then it gets into....if the pump shows damage how much are you going to trust those main and rod bearings?

What was first...the roller siezing up and grinding away...or maybe valve float causing the valve to smack a piston, tear up some valve tip & rocker arm, and fracture some roller needle bearings? Not saying it hasta be one of those two, but you'll have the heads off so it would show any evidence of the piston forcing the valve closed. Exploratory surgery!

Then it gets into....if the pump shows damage how much are you going to trust those main and rod bearings?

What was first...the roller siezing up and grinding away...or maybe valve float causing the valve to smack a piston, tear up some valve tip & rocker arm, and fracture some roller needle bearings? Not saying it hasta be one of those two, but you'll have the heads off so it would show any evidence of the piston forcing the valve closed. Exploratory surgery!

#6

11 Second Club

iTrader: (24)

Your oil is probably like fine metalic paint. I would definately pull the motor down. All of that metal went through every nook and crany of the motor. What if you put a fine powder in your oil and ran it? If you want to sleep at night, rings, bearings, seals, cam, total scrub down, etc. Inspect the oil pump and pick up. Get the engine brushes with warm soap and water and scrub block and disassembled heads. You had a lifter fail. The valve tip and rocker are the recipient. Get Morel lifters or the new Comp Short Travel lifters. I already had the GM lifters come apart with mild spring pressures. They need to figure out the problem. You are looking for long term reliability, don't short cut yourself. Good luck.

#7

On The Tree

Thread Starter

iTrader: (2)

Join Date: Nov 2008

Location: South Florida

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Just wanted to add a few pics and info:

I put one of the good lifters in the hole where the damaged one came out of and it slid in and out just fine and I don't see any damaged in the lifter bore. It looks like the intake valve (where all the damaged came from) slightly scuffed the piston inside the valve reliefs.

Here are some pics:

You can see just a light line at the top of the valve relief where its a golden color.

Looking down the lifter bores, top one is the where the damaged intake valve parts were.

General look at that side of the engine.

------------------------------------

I'm just kind of thinking out loud here but I was thinking about dropping the oil pan so I can get a look at the underside of the engine and the parts. Now assuming I don't see any damage I may still want to 'clean' it a bit. Is there a solvent type wash I can run through the engine (not actually running, while its torn apart) to help clear it out. Then maybe run some oil through it to rinse any loose stuff to the bottom? Maybe a seafoam like equivalent, where I could pour some in and manually spin the crank? Then once its together I'll run it for ~150 miles or so then change the oil again.

I put one of the good lifters in the hole where the damaged one came out of and it slid in and out just fine and I don't see any damaged in the lifter bore. It looks like the intake valve (where all the damaged came from) slightly scuffed the piston inside the valve reliefs.

Here are some pics:

You can see just a light line at the top of the valve relief where its a golden color.

Looking down the lifter bores, top one is the where the damaged intake valve parts were.

General look at that side of the engine.

------------------------------------

I'm just kind of thinking out loud here but I was thinking about dropping the oil pan so I can get a look at the underside of the engine and the parts. Now assuming I don't see any damage I may still want to 'clean' it a bit. Is there a solvent type wash I can run through the engine (not actually running, while its torn apart) to help clear it out. Then maybe run some oil through it to rinse any loose stuff to the bottom? Maybe a seafoam like equivalent, where I could pour some in and manually spin the crank? Then once its together I'll run it for ~150 miles or so then change the oil again.

Trending Topics

#9

thats pretty bad, hope you get it running soon, here are few of my observations,

1) retainers dont seem like they are properly matched to the spring

2) damage seems likely to be a result of coil bind

3) lifter may have turned in its bore

hope this helps

1) retainers dont seem like they are properly matched to the spring

2) damage seems likely to be a result of coil bind

3) lifter may have turned in its bore

hope this helps

#10

It definatly looks like the lifter turned in its bore. Def going to have to change cams and since youre in that general area of the motor its only cheap insurance to change oil pumps. It also wouldnt be a bad idea like others have said to tear the motor down to be safe, depending on how much metal came off the cam and lifter it could have damaged the parts on the bottom end. It would also be good to mic that piston to see how bad it is, chances are that its fine, but why cut corners now.

#14

On The Tree

Thread Starter

iTrader: (2)

Join Date: Nov 2008

Location: South Florida

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Don't know for sure. It has about ~30k miles on it. It was in another car briefly before they damaged that car. It was put into another FRC been through 2 owners and now me.

Rough specs:

6.0 iron block

4 callies crank

eagle rods

diamond pistons

ATI damper pulley

Absolute speed heads W/ 2.08 1.60? valves flow 325+

custom ground cam its a 244 248, 61x 61x 114

Comp r lifters

Hardened push rods (7.350" trick flow)

C.R 11.6

90mm fast intake and TPIS 90MM TB.

38# injectors

Granettelli maf

Racetronix hot wire kit with 255 pump.

LG long tube headers W/ X pipe 3

Rough specs:

6.0 iron block

4 callies crank

eagle rods

diamond pistons

ATI damper pulley

Absolute speed heads W/ 2.08 1.60? valves flow 325+

custom ground cam its a 244 248, 61x 61x 114

Comp r lifters

Hardened push rods (7.350" trick flow)

C.R 11.6

90mm fast intake and TPIS 90MM TB.

38# injectors

Granettelli maf

Racetronix hot wire kit with 255 pump.

LG long tube headers W/ X pipe 3

Last edited by OutKlast; 01-27-2009 at 11:19 PM.

#16

How long had the engine sat idle before you started running it?

That damage is very similar to what I've seen several times on Gen 6 454 irrigation engines that are allowed to set for several months without running. Farmers change the oil, then fire them up for the season. A couple of theories are that since the engines are at full operating temp when shut down, the thin oil drains completely back to the pan and the rollers get almost dry, particularly those with a bit more clearance in the roller area. Another theory is that that the oil gels/thickens in the roller area over the winter and since the engines are fired up and immediately run, the affected lifter(s) - it's generally not more than one or two - skid on the cam and never actually roll. Once they get hot from friction, the roller actually locks down and the damage is accelerated. The cam lobes end up with what amounts to a notch in them and that ends up totally destroying the lifter, exactly like the one you show. The engines I'm referring to definitely didn't go into valve float, most are never run over about 2500 - 3000 rpms.

I'm not saying I'm sure that's what happened to yours, but it looks exactly like what I've seen. What they've found for a cure is either going to flat tappet cams (not acceptable to me) or starting them and only allowing them to run for about 30 seconds at a time and doing this 3 or 4 times. The heat slowly melts the gel or thins the oil, or allows enough time for oil to penetrate the rollers, whichever is happening in the roller area, and then the engine is fired up and run normally. It seems to work, the farmers that take the time to do this have eliminated the problem.

Just a thought...

At any rate, yours is in line for a complete tear-down and thorough cleaning. Make sure you have a shop check the block closely in the area of the affected lifter, it's been whacked very hard and the lifter bore should be checked for dimension and roundness and the surrounding area should be checked for cracks.

That damage is very similar to what I've seen several times on Gen 6 454 irrigation engines that are allowed to set for several months without running. Farmers change the oil, then fire them up for the season. A couple of theories are that since the engines are at full operating temp when shut down, the thin oil drains completely back to the pan and the rollers get almost dry, particularly those with a bit more clearance in the roller area. Another theory is that that the oil gels/thickens in the roller area over the winter and since the engines are fired up and immediately run, the affected lifter(s) - it's generally not more than one or two - skid on the cam and never actually roll. Once they get hot from friction, the roller actually locks down and the damage is accelerated. The cam lobes end up with what amounts to a notch in them and that ends up totally destroying the lifter, exactly like the one you show. The engines I'm referring to definitely didn't go into valve float, most are never run over about 2500 - 3000 rpms.

I'm not saying I'm sure that's what happened to yours, but it looks exactly like what I've seen. What they've found for a cure is either going to flat tappet cams (not acceptable to me) or starting them and only allowing them to run for about 30 seconds at a time and doing this 3 or 4 times. The heat slowly melts the gel or thins the oil, or allows enough time for oil to penetrate the rollers, whichever is happening in the roller area, and then the engine is fired up and run normally. It seems to work, the farmers that take the time to do this have eliminated the problem.

Just a thought...

At any rate, yours is in line for a complete tear-down and thorough cleaning. Make sure you have a shop check the block closely in the area of the affected lifter, it's been whacked very hard and the lifter bore should be checked for dimension and roundness and the surrounding area should be checked for cracks.

#17

Teching In

Join Date: Jan 2005

Location: Tallahassee FL/ Fort Stewart, GA

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

Yeah your best bet is a teardown and replace all questionable parts during the rebuild. If for some reason you cant, at least take all precautions to gunk in the crankcase...drain and refill, magnetic plugs, filtermag, drop the pan and clean it out as well as the bottom end (check bearings while you are in there) and after you start it let it run for a few seconds and change the oil again, then again soon afterwards.

#18

Ahhhh,way to familiar of a scenario.Several years ago I had a technician that worked for me perform a heads/cam swap(big mistake,should have made the time to do it myself)on my 2000 WS6.Well,he didn't have a lifter in the tray properly & it turned.Needless to say it looks just like yours.I removed the heads & found the lifter sideways.At that point I replaced the cam,oil pump & lifters.It made it about 2 months before oil pressure dropped & the motor started to really consume oil.After a real teardown & inspection I found the bottom of the lifter bore damaged(no machinist would even touch it) & the metal had made its way through the motor(scarred cylinders & rings).I think the best thing to do is completely disassemble the engine,take the crank,rods & pistons to a machine shop & prepare to upgrade your block.Not going this route will only be a temporary fix.Don't feel to bad,it happened to me & Im sure plenty of others.The good news is the car now runs 10's,stock weigh, all motor.Broken parts are the best excuse to go faster!!!!!If your married,sometimes it can be the only excuse to go faster.Best of luck.

#19

Hello Outklast,

The cam will have suffered wear for sure. Roller cams don't mate very well with a locally-made flat tappet lifter!

The needle roller inside the lifter will have more than likely failed to have caused this in the first place, so your sump is probably full of 5mm long needle bearings.

What cam are you running out of interest? As this looks like the result of too much lift and aggressive ramp rates.

The Callaway C4B was prone to do this very thing because of the same reason.

If you want piece of mind you are going to have to get it stripped and fully cleaned and checked again.

Or do it cheaply and more than likely pay twice.

The cam will have suffered wear for sure. Roller cams don't mate very well with a locally-made flat tappet lifter!

The needle roller inside the lifter will have more than likely failed to have caused this in the first place, so your sump is probably full of 5mm long needle bearings.

What cam are you running out of interest? As this looks like the result of too much lift and aggressive ramp rates.

The Callaway C4B was prone to do this very thing because of the same reason.

If you want piece of mind you are going to have to get it stripped and fully cleaned and checked again.

Or do it cheaply and more than likely pay twice.

#20

Hello Outklast,

The cam will have suffered wear for sure. Roller cams don't mate very well with a locally-made flat tappet lifter!

The needle roller inside the lifter will have more than likely failed to have caused this in the first place, so your sump is probably full of 5mm long needle bearings.

What cam are you running out of interest? As this looks like the result of too much lift and aggressive ramp rates.

The Callaway C4B was prone to do this very thing because of the same reason.

If you want piece of mind you are going to have to get it stripped and fully cleaned and checked again.

Or do it cheaply and more than likely pay twice.

The cam will have suffered wear for sure. Roller cams don't mate very well with a locally-made flat tappet lifter!

The needle roller inside the lifter will have more than likely failed to have caused this in the first place, so your sump is probably full of 5mm long needle bearings.

What cam are you running out of interest? As this looks like the result of too much lift and aggressive ramp rates.

The Callaway C4B was prone to do this very thing because of the same reason.

If you want piece of mind you are going to have to get it stripped and fully cleaned and checked again.

Or do it cheaply and more than likely pay twice.