My 416 Build

#21

Moderator

iTrader: (20)

His comment was non-objective and his comment appears biased to me. I was hoping for a response to your question to put my mind at ease.

I just got my first cam from Cam Motion. I wasn't real pleased w/the performance from my last cam, so when I had the engine and cam removed, I had the old cam degreed first. It was a comp cam and was dead nuts on. After installing my Cam Motion cam, I was told it was off 1 degree using the same exact chain set. This is still not conclusive data, but it is more likely than not this cam is off 1 degree. It was 3 instead of 4 degrees advanced.

As for Cam Motion, he seems like a stand up guy. What I would like to hear from Cam Motion, Kip, is how in his opinion as a grinder, can the advance be off a degree? What causes this? And can I be sure the rest of the cam's parameters are as expected?

I just got my first cam from Cam Motion. I wasn't real pleased w/the performance from my last cam, so when I had the engine and cam removed, I had the old cam degreed first. It was a comp cam and was dead nuts on. After installing my Cam Motion cam, I was told it was off 1 degree using the same exact chain set. This is still not conclusive data, but it is more likely than not this cam is off 1 degree. It was 3 instead of 4 degrees advanced.

As for Cam Motion, he seems like a stand up guy. What I would like to hear from Cam Motion, Kip, is how in his opinion as a grinder, can the advance be off a degree? What causes this? And can I be sure the rest of the cam's parameters are as expected?

#22

I've had a few weird timing sets and the crank key could be a wee bit off on an aftermarket crank or a stock one for that matter probably.

There is also some play in the timing sets to the cam pin and the bolts to the top gear as you can shift the gear a little forward or backwards before tightening the cam bolts too of course.

Basically you could have all sorts of issues if you don't really degree the cam in so do it if at all possible so you know what's really going on no matter what is at fault if it's off you'll at least know and fix it.

The last three Cam Motion cams I've gotten wouldn't fit aftermarket gears even though OEM GM, Comp and Bullet did just fine.

I'm not saying the Cam Motion pin was off degree wise but it was certainly off as far as how far in or out it was machined. It only fit a stock slotted gear so I slotted the aftermarket top gear a little further till it would go on.

There is also some play in the timing sets to the cam pin and the bolts to the top gear as you can shift the gear a little forward or backwards before tightening the cam bolts too of course.

Basically you could have all sorts of issues if you don't really degree the cam in so do it if at all possible so you know what's really going on no matter what is at fault if it's off you'll at least know and fix it.

The last three Cam Motion cams I've gotten wouldn't fit aftermarket gears even though OEM GM, Comp and Bullet did just fine.

I'm not saying the Cam Motion pin was off degree wise but it was certainly off as far as how far in or out it was machined. It only fit a stock slotted gear so I slotted the aftermarket top gear a little further till it would go on.

#23

I've had a few weird timing sets and the crank key could be a wee bit off on an aftermarket crank or a stock one for that matter probably.

There is also some play in the timing sets to the cam pin and the bolts to the top gear as you can shift the gear a little forward or backwards before tightening the cam bolts too of course.

Basically you could have all sorts of issues if you don't really degree the cam in so do it if at all possible so you know what's really going on no matter what is at fault if it's off you'll at least know and fix it.

The last three Cam Motion cams I've gotten wouldn't fit aftermarket gears even though OEM GM, Comp and Bullet did just fine.

I'm not saying the Cam Motion pin was off degree wise but it was certainly off as far as how far in or out it was machined. It only fit a stock slotted gear so I slotted the aftermarket top gear a little further till it would go on.

There is also some play in the timing sets to the cam pin and the bolts to the top gear as you can shift the gear a little forward or backwards before tightening the cam bolts too of course.

Basically you could have all sorts of issues if you don't really degree the cam in so do it if at all possible so you know what's really going on no matter what is at fault if it's off you'll at least know and fix it.

The last three Cam Motion cams I've gotten wouldn't fit aftermarket gears even though OEM GM, Comp and Bullet did just fine.

I'm not saying the Cam Motion pin was off degree wise but it was certainly off as far as how far in or out it was machined. It only fit a stock slotted gear so I slotted the aftermarket top gear a little further till it would go on.

Why didn't the cams fit the aftermarket gears? Pin length, location?

#24

Super Hulk Smash

iTrader: (7)

I had that issue on my Rollmaster too with the Cam Motion cam. The holes did not line up. Well technically, two lined up and one was slightly off. But we're talking barely off. I hit it with the drill to open up the timing set. It was still a tight fit. But it wasn't going on with the cam gear unless I modified it.

#25

Kip, what is the explanation for the holes not aligning? Is this all your cams?

What are you doing in these cases?

Is it possible the cam gear could loosen since it is theoretically possible 1 bolt may not be taking as much of the side loading of the gear?

What are you doing in these cases?

Is it possible the cam gear could loosen since it is theoretically possible 1 bolt may not be taking as much of the side loading of the gear?

#26

TECH Apprentice

His comment was non-objective and his comment appears biased to me. I was hoping for a response to your question to put my mind at ease.

I just got my first cam from Cam Motion. I wasn't real pleased w/the performance from my last cam, so when I had the engine and cam removed, I had the old cam degreed first. It was a comp cam and was dead nuts on. After installing my Cam Motion cam, I was told it was off 1 degree using the same exact chain set. This is still not conclusive data, but it is more likely than not this cam is off 1 degree. It was 3 instead of 4 degrees advanced.

As for Cam Motion, he seems like a stand up guy. What I would like to hear from Cam Motion, Kip, is how in his opinion as a grinder, can the advance be off a degree? What causes this? And can I be sure the rest of the cam's parameters are as expected?

I just got my first cam from Cam Motion. I wasn't real pleased w/the performance from my last cam, so when I had the engine and cam removed, I had the old cam degreed first. It was a comp cam and was dead nuts on. After installing my Cam Motion cam, I was told it was off 1 degree using the same exact chain set. This is still not conclusive data, but it is more likely than not this cam is off 1 degree. It was 3 instead of 4 degrees advanced.

As for Cam Motion, he seems like a stand up guy. What I would like to hear from Cam Motion, Kip, is how in his opinion as a grinder, can the advance be off a degree? What causes this? And can I be sure the rest of the cam's parameters are as expected?

#27

TECH Apprentice

I had that issue on my Rollmaster too with the Cam Motion cam. The holes did not line up. Well technically, two lined up and one was slightly off. But we're talking barely off. I hit it with the drill to open up the timing set. It was still a tight fit. But it wasn't going on with the cam gear unless I modified it.

gear from GM you will see that they are slotted just a little. The reason is if the pin is off any it will not still go in the pin hole on the gear. So they slotted it to make sure the pin can be off just a little and still work. We took it a little further like .008. It works fine on the stock gears but on the aftermarket is does not fit they need a little adjusting. We have fix the problem but there are still some of those cores around. So if you have one let us know. The pin just lines the cam up it does not do any holding like some guys think. So after market gears may need to be slotted.

#29

TECH Apprentice

#31

#32

FormerVendor

iTrader: (3)

All Comp gives you is a print out of what the lobe should be based on the lobe master number and LSA/ICL. You have to order the Adcole measurement. It's listed as Part #1-125-1.

For the 399.99 custom cam price, it does not include that. Last I saw it was about $55 to run Adcole on the cam. I've never seen a vendor offer that as part of a custom Comp package. Maybe I'm wrong, but I don't recall seeing it.

It's still good to degree the cam. Especially if you have a one-off Comp custom grind. I've heard from several vendors they can be off a few degrees. However, the bulk "shelf" grinds are dead nuts. But it's still a good idea to measure to know exactly what you have. And again, stacking tolerances can add up.

For the 399.99 custom cam price, it does not include that. Last I saw it was about $55 to run Adcole on the cam. I've never seen a vendor offer that as part of a custom Comp package. Maybe I'm wrong, but I don't recall seeing it.

It's still good to degree the cam. Especially if you have a one-off Comp custom grind. I've heard from several vendors they can be off a few degrees. However, the bulk "shelf" grinds are dead nuts. But it's still a good idea to measure to know exactly what you have. And again, stacking tolerances can add up.

Doesn't mean it's ground right, but they use it.

#34

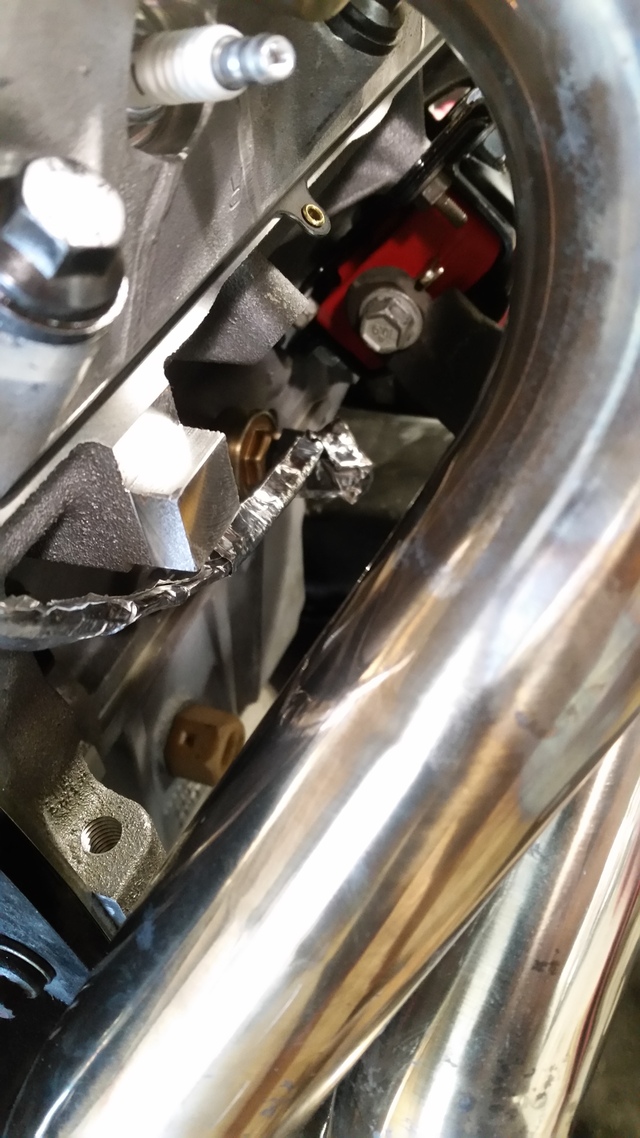

After installing the LTs & seeing how close the knock sensors were I ended up wrapping the harnesses in foil tape.

R. side knock sensor wasn't nearly as bad as the L. side

It was a very long day, getting everything fine tuned on the install but the motor is in! I gotta get the intake & MAF assembled as I'm going with an LS7 MAF & 4 inch housing to accommodate the extra airflow. Everything fits really nice & looks almost stock! Hasn't been running since last November, I cant wait to drive it!