ERL Superdeck Block Head Gasket Question

#1

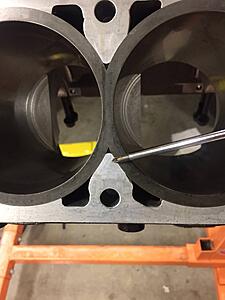

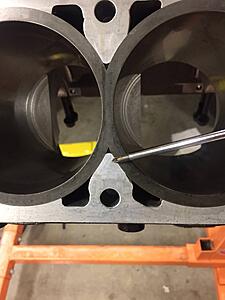

Late last night I was reading a article and there was a picture of them installing a headgasket. For whatever reason it made me think to check my headgaskets on the block. The ERL truss design blocks the coolant hole in the gasket on the exhaust side. Should I drill a hole or holes on the exhaust side like how they are poisotioned on the intake side? I would call ERL and ask them their opinion but they've shut their doors. I've seen a couple of custom LS head gaskets on google with holes on the exhaust side that are similar to the intake side holes. But all regular and OEM gaskets have the holes positioned exactly like this one on the exhaust/intake sides.

Don't mind the 6 bolt head gasket...it worked for what I wanted so that's why I got it. Fel-Pro Permatoqure MLS with the laserweld stopper layer

Don't mind the 6 bolt head gasket...it worked for what I wanted so that's why I got it. Fel-Pro Permatoqure MLS with the laserweld stopper layer

#2

Best thing to do is get in contact with the *Master himself: Steve.

http://www.raceenginedevelopment.com/contact-us/

http://www.raceenginedevelopment.com/contact-us/

#3

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

Hi Petra, YES I agree.

You need to "vent" the crankcase to let the air out, then too allowing the head to vent

The pictured area between the sleeves is a "vent", the open area.

I would connect that by a deck groove to the Head Gasket open hole.

I have done this with other engines and the LS, align steam holes.

THEN report to ERL ???, now we see the reason.

Lance

You need to "vent" the crankcase to let the air out, then too allowing the head to vent

The pictured area between the sleeves is a "vent", the open area.

I would connect that by a deck groove to the Head Gasket open hole.

I have done this with other engines and the LS, align steam holes.

THEN report to ERL ???, now we see the reason.

Lance

#4

Hi Petra, YES I agree.

You need to "vent" the crankcase to let the air out, then too allowing the head to vent

Are you referring to PCV system or coolant system?

The pictured area between the sleeves is a "vent", the open area.

Are you talking about the small space/hole between the peak of the truss and the sleeves?

I would connect that by a deck groove to the Head Gasket open hole.

I'd rather not mess with the deck. Just wondering if I need drill holes in the current head gasket or leave them be.

I have done this with other engines and the LS, align steam holes.

THEN report to ERL ???, now we see the reason.

Lance

You need to "vent" the crankcase to let the air out, then too allowing the head to vent

Are you referring to PCV system or coolant system?

The pictured area between the sleeves is a "vent", the open area.

Are you talking about the small space/hole between the peak of the truss and the sleeves?

I would connect that by a deck groove to the Head Gasket open hole.

I'd rather not mess with the deck. Just wondering if I need drill holes in the current head gasket or leave them be.

I have done this with other engines and the LS, align steam holes.

THEN report to ERL ???, now we see the reason.

Lance

#5

TECH Enthusiast

I see what you are saying here. I see the Warhawk gasket holes. I guess need to see if the hole line up in the other areas. I am wondering if you can drill small holes where the Warhawk holes are on your existing gasket. Given it is an open area on both sides would not affect the sealing if they were small holes. The one thing about the Felpro single hole it is in the highest spot so that would help with the air pockets.

Trending Topics

#8

I was hoping some more people with ERL builds would chime in. So no issues at all? And normal coolant temps etc? Did you use the suggested Evans Waterless Coolant?

Nah i didn't intend of drilling the deck at all. Maybe the head gasket or get different ones.

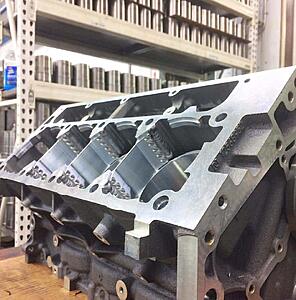

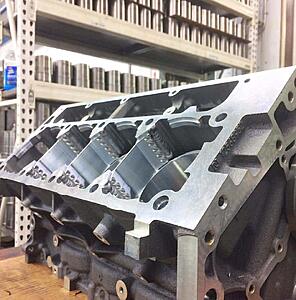

My thought process so far....The trusses themselves slightly hinder the normal flow of coolant but have holes drilled so that it's not a complete blockage (see pic). Normally it's wide open in a stock block. At the same time the trusses/sleeves allow for coolant to touch the actual liner and pass between the bores. A stock block has Siamese bores so no coolant passes between the upper part between each bore. Plus with the sleeves the coolant touches the actual liner vs the cast aluminum surrounding the liner. So there's pros and cons to each. But how important is the coolant hole on the exhaust side? Does it function to vent steam only or does it assist in parallel flow? If I leave it alone I kinda suppose the hot coolant/steam will just rise and pass between the bores and go through the holes on the intake side.

Nah i didn't intend of drilling the deck at all. Maybe the head gasket or get different ones.

My thought process so far....The trusses themselves slightly hinder the normal flow of coolant but have holes drilled so that it's not a complete blockage (see pic). Normally it's wide open in a stock block. At the same time the trusses/sleeves allow for coolant to touch the actual liner and pass between the bores. A stock block has Siamese bores so no coolant passes between the upper part between each bore. Plus with the sleeves the coolant touches the actual liner vs the cast aluminum surrounding the liner. So there's pros and cons to each. But how important is the coolant hole on the exhaust side? Does it function to vent steam only or does it assist in parallel flow? If I leave it alone I kinda suppose the hot coolant/steam will just rise and pass between the bores and go through the holes on the intake side.

#9

TECH Enthusiast

I have an ERL SD1 and no cooling temp issues. I think the steam holes just help with air pockets that might get in there. Actually based on the picture there if you drilled a hole where the gasket hole is it looks like you might hit the top water transfer hole. I think what I would do is do what the Warhawk gasket does and just drill a hole in it where the water jacket is about 1/2 inch down and 3/4 inch over from where the current steam hole is. I actually have an old head gasket which inprints the head side it is 3/4 of an inch over from the head bolt hole. I think these holes help provide an equilibrium between the head and the block and reduce air pockets and really does not do much for cooling.