Home built 416

#21

ModSquad

iTrader: (6)

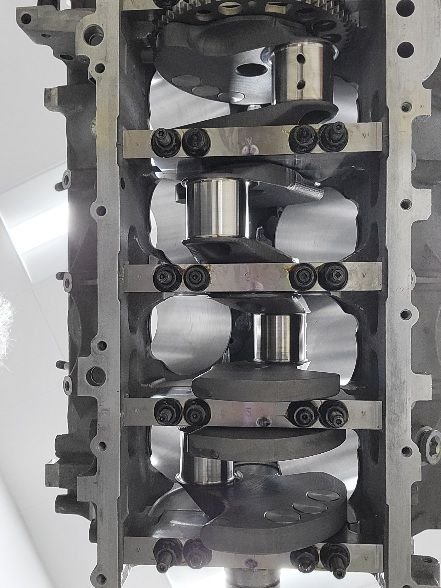

Question.....I installed #1 piston and rotated the crank over expecting for the rod bolts to hit the bottom of the cylinders. It had a ton of clearance....is that normal????

also have some x bearings coming for the rods to try and get that clearance opened up closer to .0025

also have some x bearings coming for the rods to try and get that clearance opened up closer to .0025

The following users liked this post:

65LSXNOVA (01-21-2024)

The following users liked this post:

grinder11 (01-21-2024)

#25

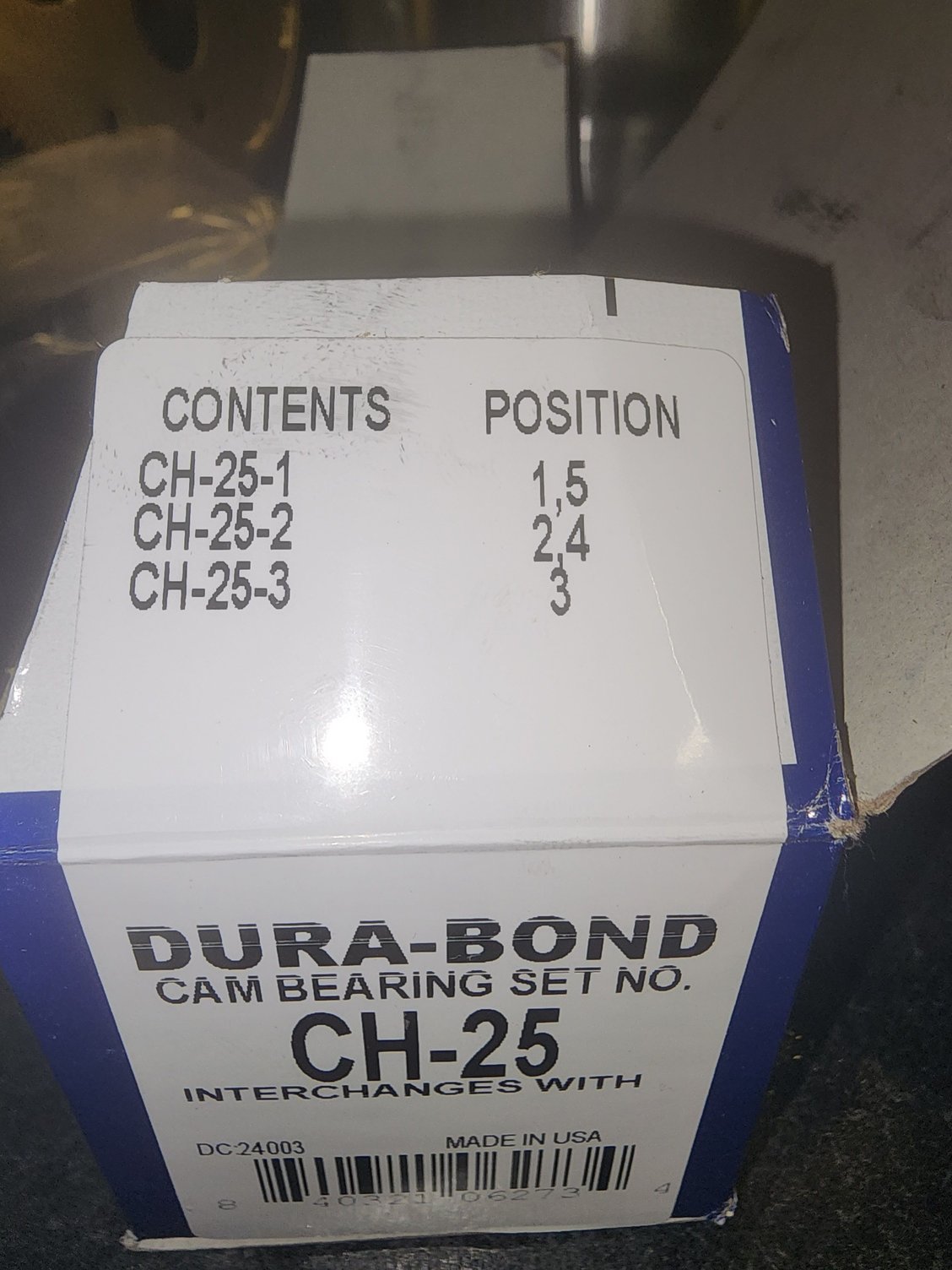

This is the 4th or 5th set of cam bearings ive installed on a LS in the past 25 yrs. I know the ch-25 are wider than the ch-23 but damn i think they could make the ch-25 even wider if they wanted.

Installation Using one of summits cam bearing installers. Works pretty darn good.

Finished product. Used a allen wrench and stuck it thru cam bearing oil feed hole to comfirm oil hole alignment.

#26

More bearing troubles.....started measuring bearing clearances and #1 cam bear i was coming up with .0035(not bad) #2 im getting .0005 and i confirmed it as i can get the cam to even attempt to go into cam bearing #2. I do have a brand new set of ch-23 here i might give a try.

#28

#30

Only thing I'm thinking is maybe I need the main caps installed and torqued

The following users liked this post:

Double06 (01-21-2024)

#31

TECH Junkie

iTrader: (28)

Should be fun! What heads are you going to run and target compression ratio? We did an 11:1 91 octane 416ci LS3 with 100% stock LS3 heads/intake and BTR either Stg3 or 4 cam and it made 560rwhp thru a T56 Magnum, McLeod alum flywheel/RST and 12 bolt with 335/30/18 out back. It had crappy mid length headers and a crush bent 2.5" exhaust also. Customer then had the heads ported, ported the intake with rod mod, custom cam, redone exhaust with dual 3" mandrel bent and LOTS of tuning where it made just under 600rwhp. This is a C10 AutoX Optima Challenge truck! It now has a 9" rear IRS setup ($$$$) in it and a whole bunch of front end aero plus some more out back. High dollar evolution build of the entire truck that does well in the truck class for sure.

Last edited by gnx7; 01-21-2024 at 05:37 PM.

The following users liked this post:

Woodylyf767 (01-22-2024)

#32

Should be fun! What heads are you going to run and target compression ratio? We did an 11:1 91 octane 416ci LS3 with 100% stock LS3 heads/intake and BTR either Stg3 or 4 cam and it made 560rwhp thru a T56 Magnum, McLeod alum flywheel/RST and 12 bolt with 335/30/18 out back. It had crappy mid length headers and a crush bent 2.5" exhaust also. Customer then had the heads ported, ported the intake with rod mod, custom cam, redone exhaust with dual 3" mandrel bent and LOTS of tuning where it made just under 600rwhp. This is a C10 AutoX Optima Challenge truck! It now has a 9" rear IRS setup ($$$$) in it and a whole bunch of front end aero plus some more out back. High dollar evolution build of the entire truck that does well in the truck class for sure.

https://www.youtube.com/watch?v=59J_fsC_D5s

https://www.youtube.com/watch?v=59J_fsC_D5s

#33

Well I torqued the mains down and reinstalled the cam bearings with the same results. Can't get this cam or the factory cam to even start to go into the 2nd cam bearing. Guess I'm ordering new cam bearings. I've never had this much trouble with bearings in the past....wonder if quality control is nonexistent anymore???

#35

The following users liked this post:

Woodylyf767 (01-22-2024)

#39