Home built 416

#41

ModSquad

iTrader: (6)

Personally I’d go with DuraBond CH-23’s. The 25’s are designed for heavy valvespring pressures…not needed. You need to carefully check for any burrs from removing the cam bearings. Every time cam bearings come out, the parting seam of the bearing leaves marks in the aluminum. The marks make burrs which will distort the new bearing going in. The tricky part here is that if you try and remove the raised places (burrs) in the cam journals, you can remove too much material and hinder the new bearings from the proper amount of crush that they need to stay put. You’ve installed cam bearings before, so you prolly already know this.

If that camshaft is bent in the least, it won’t go in. And if it does, it won’t turn right. I talk about bent cams here all the time. You need to set that cam up in a fixture and put a dial indicator on it as you turn it to see if it’s bent. They leave the dealer straight, and then the shipping company throws it around like a football. You can’t see a bent cam with your naked eyes. Well…unless it’s realllllllly bent….

If that camshaft is bent in the least, it won’t go in. And if it does, it won’t turn right. I talk about bent cams here all the time. You need to set that cam up in a fixture and put a dial indicator on it as you turn it to see if it’s bent. They leave the dealer straight, and then the shipping company throws it around like a football. You can’t see a bent cam with your naked eyes. Well…unless it’s realllllllly bent….

#42

Personally Iíd go with DuraBond CH-23ís. The 25ís are designed for heavy valvespring pressuresÖnot needed. You need to carefully check for any burrs from removing the cam bearings. Every time cam bearings come out, the parting seam of the bearing leaves marks in the aluminum. The marks make burrs which will distort the new bearing going in. The tricky part here is that if you try and remove the raised places (burrs) in the cam journals, you can remove too much material and hinder the new bearings from the proper amount of crush that they need to stay put. Youíve installed cam bearings before, so you prolly already know this.

If that camshaft is bent in the least, it wonít go in. And if it does, it wonít turn right. I talk about bent cams here all the time. You need to set that cam up in a fixture and put a dial indicator on it as you turn it to see if itís bent. They leave the dealer straight, and then the shipping company throws it around like a football. You canít see a bent cam with your naked eyes. WellÖunless itís realllllllly bentÖ.

If that camshaft is bent in the least, it wonít go in. And if it does, it wonít turn right. I talk about bent cams here all the time. You need to set that cam up in a fixture and put a dial indicator on it as you turn it to see if itís bent. They leave the dealer straight, and then the shipping company throws it around like a football. You canít see a bent cam with your naked eyes. WellÖunless itís realllllllly bentÖ.

I think the next set I try I want to loctite in with 680. Do I apply it to the backside of cam bearing or do you apply after install along the edges??? Might be a dumb question 😕

#43

I don't believe the cam is bent as the stock cam locks up in the position at #2 bearing. Also back in October this cam slide in this block with different ch-25 bearing installed and spun very freely. Only thing different from then to now is different cam bearings and block was align honed, decked, cylinders torque plate honed .005 over

#44

TECH Apprentice

V blocks, a good indicator and 15 minutes of your time

I've heard the cam bearings are honed after installation from GM. I don't know for sure. I've personally had issues installing the cam on fresh bearings and we either lightly sanded the back of the bearing (OD), or polished the journals on the cam

I've heard the cam bearings are honed after installation from GM. I don't know for sure. I've personally had issues installing the cam on fresh bearings and we either lightly sanded the back of the bearing (OD), or polished the journals on the cam

The following users liked this post:

65LSXNOVA (01-22-2024)

#46

ModSquad

iTrader: (6)

I have a set in the shop and didn’t know they have been discontinued for now. You can grab the chp-23t’s which are the same, only coated with Teflon. If you are gonna loctite them, it goes on the back of the shell, but I don’t recommend it. If your having to use loctite to hold a cam bearing from turning or walking, then there are other issues.

#47

I have a set in the shop and didnít know they have been discontinued for now. You can grab the chp-23tís which are the same, only coated with Teflon. If you are gonna loctite them, it goes on the back of the shell, but I donít recommend it. If your having to use loctite to hold a cam bearing from turning or walking, then there are other issues.

The following users liked this post:

DualQuadDave (01-23-2024)

#48

Alright I got some measurements for the cam bore and bearings.

block cam bore diameter (all about .001 big)

#1. 2.3470

#2. 2.3269

#3. 2.3077

#4. 2.3274

#5. 2.3467

Outside cam bearing diameter (was installed and taken out)

#1. 2.3452

#2. 2.3250

#3. 2.3030

#4. 2.3250

#5. 2.3452

Inside cam bearing installed diameter

#1. 2.1688

#2. 2.1665

#3. 2.1661

#4. 2.1661

#5. 2.1678

Cam journal diameter

1-5 all measured 2.1650

block cam bore diameter (all about .001 big)

#1. 2.3470

#2. 2.3269

#3. 2.3077

#4. 2.3274

#5. 2.3467

Outside cam bearing diameter (was installed and taken out)

#1. 2.3452

#2. 2.3250

#3. 2.3030

#4. 2.3250

#5. 2.3452

Inside cam bearing installed diameter

#1. 2.1688

#2. 2.1665

#3. 2.1661

#4. 2.1661

#5. 2.1678

Cam journal diameter

1-5 all measured 2.1650

#50

Got the x bearings today. Rods are now coming out between .0025-.0027 This weekend i plan on getting the crank pistons and rods installed and measuring deck height. After that will be disassembly for cleaning and hopefully final assembly.

#54

#55

ModSquad

iTrader: (6)

I like the 10296 pumps on most performance builds. It’s not a whole lot more volume, but it’s enough to help keep bearings cooler. Most folks get caught up in the pressure numbers. Yes, pressure matters, but pressure is just a measure of hydraulic resistance. It’s the flow that actually lubricates. A higher volume oil pump will produce LOWER oil temps in the engine than a pump of less flow, in a performance build. These LS engines really don’t need a ton of pressure to keep them alive.

#56

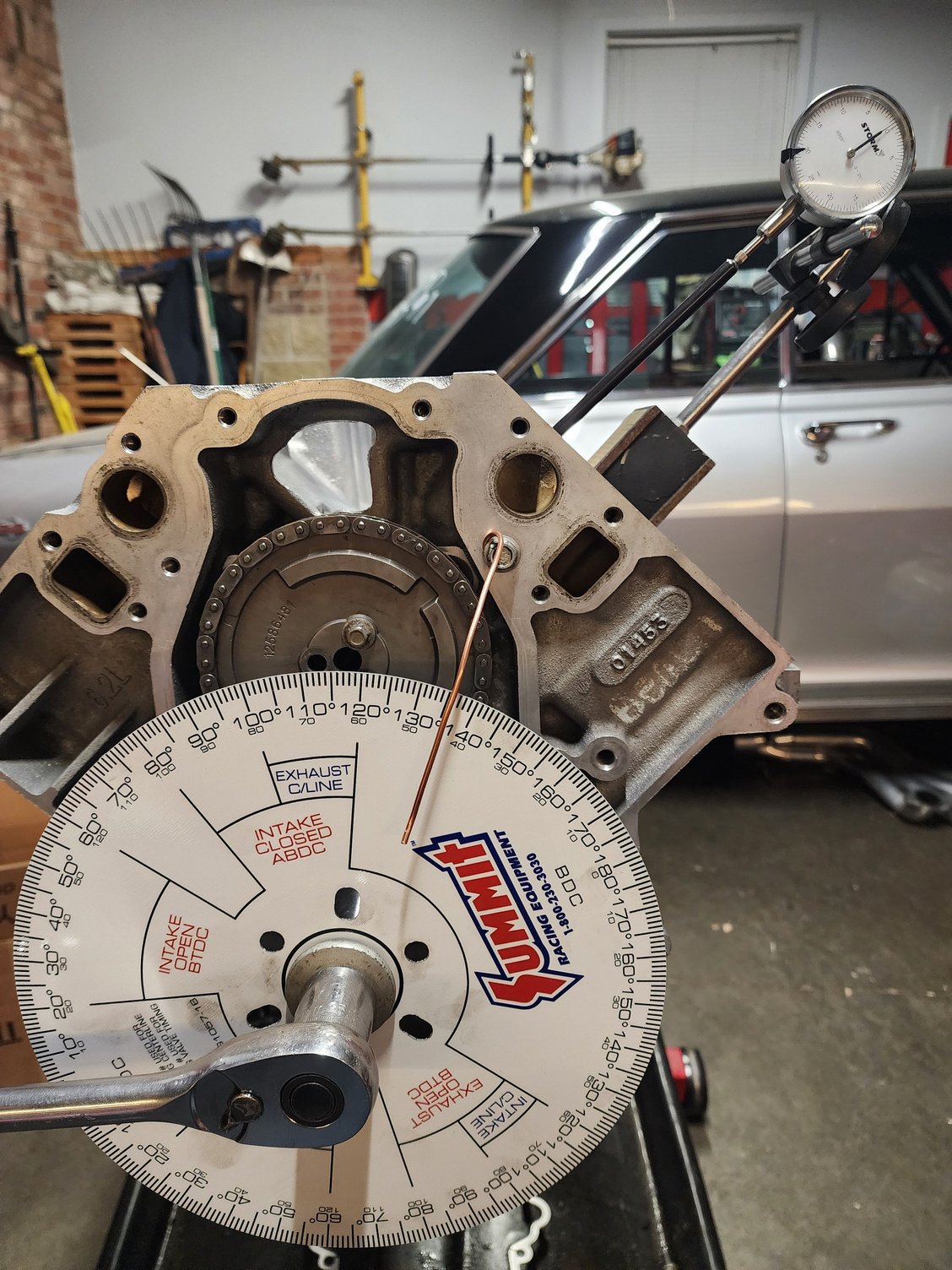

Got this cam a few years ago (used) and was going to use it in the SBE 6.2. No cam card so this is where im at.

.050. 240/247

IVO 12

IVC 48

EVO 60

EVC 7

INTAKE C/L 108

LSA. 112

These cam events where found with the timing set dot to dot

The following users liked this post:

slowride (01-28-2024)

#58

#59

#60

Got the car running today and let it idle for about 30 minutes between 160-190 degrees. Oil pressure at idle starts cold at 60 psi and ends up at 46 psi at idle warm.