408 lt1

#1

TECH Apprentice

Thread Starter

Just wondering if anyone has built any 408 LT1. I would think if u were gonna build a 396 why not go ahead and put the extra 1/8 inch stroke and make it a 408.

#3

TECH Apprentice

Thread Starter

Shouldnt cost that much more. If u order the rotating assm. that way it should be about the same from eagle. Only problem would be cam clearance. The way i wanna build one will be more expensive. I wanna run a Callies crank with the 1.88 honda rodbearing jounals, to cut down on rotating weight and to get precious clearance. And i would like to run the 1.5, 1.5, 3MM ring package to cut down on ring tension. Getting the compression down would be the next hurdle. But i was thinking with 11.5:1 compression i could run a cam with around 238/244 degrees at .050 int/exh with an lsa of around 114 should keep the cyl pressure down. I think that would make a pretty wicked street motor that would knock dwn some 10 sec quarters with ease.

#4

Shouldnt cost that much more. If u order the rotating assm. that way it should be about the same from eagle. Only problem would be cam clearance. The way i wanna build one will be more expensive. I wanna run a Callies crank with the 1.88 honda rodbearing jounals, to cut down on rotating weight and to get precious clearance. And i would like to run the 1.5, 1.5, 3MM ring package to cut down on ring tension. Getting the compression down would be the next hurdle. But i was thinking with 11.5:1 compression i could run a cam with around 238/244 degrees at .050 int/exh with an lsa of around 114 should keep the cyl pressure down. I think that would make a pretty wicked street motor that would knock dwn some 10 sec quarters with ease.

Have you seen the clearancing first hand for a 396? It is pretty easy to hit water...even a 383 can punch into the jacket pretty quickly with the wrong rod/bolt combo.

You would most likely have to go through more then one block to cherry pick a usable one, shave the rod bolts, clearance the hell out of it, and still have to at least half fill the block...then if you are lucky you'll end up with a usable 408.

1/8" sounds so small on paper until you get in there and realize how much that extra 1/8" clearance would help...it really is not worth the extra cost and risk.

#6

8 Second 6 Speed Director

iTrader: (6)

Join Date: May 2002

Location: windsor, ont. canada - Home of the fastest LT1 6spd.

Posts: 3,293

Likes: 0

Received 1 Like

on

1 Post

yeah what he said, lol!!!

The extra cost is exactly what you just mentioned - clearancing and machine work.

Have you seen the clearancing first hand for a 396? It is pretty easy to hit water...even a 383 can punch into the jacket pretty quickly with the wrong rod/bolt combo.

You would most likely have to go through more then one block to cherry pick a usable one, shave the rod bolts, clearance the hell out of it, and still have to at least half fill the block...then if you are lucky you'll end up with a usable 408.

1/8" sounds so small on paper until you get in there and realize how much that extra 1/8" clearance would help...it really is not worth the extra cost and risk.

Have you seen the clearancing first hand for a 396? It is pretty easy to hit water...even a 383 can punch into the jacket pretty quickly with the wrong rod/bolt combo.

You would most likely have to go through more then one block to cherry pick a usable one, shave the rod bolts, clearance the hell out of it, and still have to at least half fill the block...then if you are lucky you'll end up with a usable 408.

1/8" sounds so small on paper until you get in there and realize how much that extra 1/8" clearance would help...it really is not worth the extra cost and risk.

Trending Topics

#8

TECH Apprentice

Thread Starter

The extra cost is exactly what you just mentioned - clearancing and machine work.

Have you seen the clearancing first hand for a 396? It is pretty easy to hit water...even a 383 can punch into the jacket pretty quickly with the wrong rod/bolt combo.

You would most likely have to go through more then one block to cherry pick a usable one, shave the rod bolts, clearance the hell out of it, and still have to at least half fill the block...then if you are lucky you'll end up with a usable 408.

1/8" sounds so small on paper until you get in there and realize how much that extra 1/8" clearance would help...it really is not worth the extra cost and risk.

Have you seen the clearancing first hand for a 396? It is pretty easy to hit water...even a 383 can punch into the jacket pretty quickly with the wrong rod/bolt combo.

You would most likely have to go through more then one block to cherry pick a usable one, shave the rod bolts, clearance the hell out of it, and still have to at least half fill the block...then if you are lucky you'll end up with a usable 408.

1/8" sounds so small on paper until you get in there and realize how much that extra 1/8" clearance would help...it really is not worth the extra cost and risk.

#11

TECH Apprentice

Thread Starter

Naw not eagle or callies compstar rods. We are in the process of building a roundie round motor with a callies crank and eagle rods with the honda rod bearings. The rods are alot smaller on the bigend. And they are a good bit lighter. And as far as pistons go JE makes em. They are a 1 inch compression height, and they would have to be a flattop or dome. No room for a dish. Thats the problem. If they are thick enough in the crown then i may can set em up in the lathe and put a .030 dish in them to get an extra 5 cc. If not i will just run a wider LSA cam to blead off the squeeze.

#12

11 Second Club

iTrader: (1)

From what I see Eagle sometimes lasts in race applications where the clearances are big enough that the taper from the bad machining doesn't matter. On the street with tight clearances though I have seen a number of bearing troubles with them. The cast cranks guys use in a blind lust for displacement seem to like to crack too. Don't get me wrong I would like a 383 but I wont use a $200 crank to get there, have my eyes on the Compstar Speedpack.

Use the Compstar it is MUCH better stuff.

Use the Compstar it is MUCH better stuff.

#15

TECH Apprentice

Thread Starter

From what I see Eagle sometimes lasts in race applications where the clearances are big enough that the taper from the bad machining doesn't matter. On the street with tight clearances though I have seen a number of bearing troubles with them. The cast cranks guys use in a blind lust for displacement seem to like to crack too. Don't get me wrong I would like a 383 but I wont use a $200 crank to get there, have my eyes on the Compstar Speedpack.

Use the Compstar it is MUCH better stuff.

Use the Compstar it is MUCH better stuff.

#16

11 Second Club

iTrader: (1)

I wont be bothering with a 408 BUT hitting water is not the end of the world, little epoxy and maybe some rock block to hold it in place been done a lot of times by a lot of folks.

fergymoto, why don't you elaborate on those pics.

On the taper I was more refering too the cranks. I know local engine guys don't like Eagle because they say they go out of round after a few torquings.

fergymoto, why don't you elaborate on those pics.

On the taper I was more refering too the cranks. I know local engine guys don't like Eagle because they say they go out of round after a few torquings.

#17

12 Second Club

iTrader: (129)

fergymoto, why don't you elaborate on those pics.

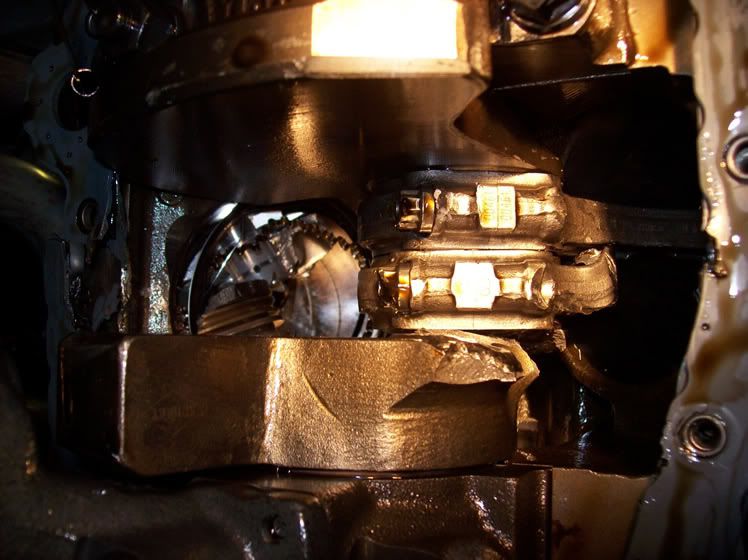

Eagle cast crank, I beam rods with ARP cap screws, KB hypereutectic pistons flat top with valve reliefs. LPE CNCd heads, 224/232 .605/.605 107.5 LSA Bret Bauer cam

4L60E, 3400 2.1 STR Fuddle converter, 3.42 10 bolt, MT ET Street Radials, 3600lbs

.0025" bearing clearance on the mains and rods, 12.2:1 compression, stock intake manifold, 58mm TB, EWP, LT headers, 3" true duals.

I ran this setup for like 700 miles. I got to go to the track with it and it was slow. It ran 12.0s at 110mph with 1.601-1.61 short times. Ran good, it just wasn't fast.

One day I was out cruising in my car and was just driving down the road going ~30mph. I hit the gas and it downshifted to first and began to accelerate and there was a pop and it started free revving. I thought my trans broke, the thing had 117k on it and it was about time. I coasted a little ways with it idling and it was still running fine and what not.

Thinking it was the transmission, I'm like "Well it's about time this thing broke. I'm going to do it in!" So I hit the gas again and it revved and all hell broke loose. I heard parts flying around and looked in the rearview to see a nice trail of smoke following me as I'm coasting down the road. The engine had stalled out.

At this point I still thought it was the tranny and that something had broke and made it stall. I turned the key and it was locked solid. I got out of the car and looked under it and my heart sunk a little bit when I didn't smell any tranny fluid. It sunk a little more when I saw the fluid on the ground was oil and not tranny fluid.

I took it home and pulled the pan off and took those pics. That's it as I found it.

I am sure that the first time I hit the gas the crank sheared off. The second time I hit the gas the crank flexed having no support back there (it broke off the counterweight behind the number 8 rod journal). Then as it was spinning down and flexing it bent the 7 & 8 rods and when it came back up with bent rods it blew the #8 rod and piston into smitherines. The #7 rod did not break but was bent quite sideways, and the piston was cracked.

Any questions?

#18

TECH Apprentice

Thread Starter

383"

Eagle cast crank, I beam rods with ARP cap screws, KB hypereutectic pistons flat top with valve reliefs. LPE CNCd heads, 224/232 .605/.605 107.5 LSA Bret Bauer cam

4L60E, 3400 2.1 STR Fuddle converter, 3.42 10 bolt, MT ET Street Radials, 3600lbs

.0025" bearing clearance on the mains and rods, 12.2:1 compression, stock intake manifold, 58mm TB, EWP, LT headers, 3" true duals.

I ran this setup for like 700 miles. I got to go to the track with it and it was slow. It ran 12.0s at 110mph with 1.601-1.61 short times. Ran good, it just wasn't fast.

One day I was out cruising in my car and was just driving down the road going ~30mph. I hit the gas and it downshifted to first and began to accelerate and there was a pop and it started free revving. I thought my trans broke, the thing had 117k on it and it was about time. I coasted a little ways with it idling and it was still running fine and what not.

Thinking it was the transmission, I'm like "Well it's about time this thing broke. I'm going to do it in!" So I hit the gas again and it revved and all hell broke loose. I heard parts flying around and looked in the rearview to see a nice trail of smoke following me as I'm coasting down the road. The engine had stalled out.

At this point I still thought it was the tranny and that something had broke and made it stall. I turned the key and it was locked solid. I got out of the car and looked under it and my heart sunk a little bit when I didn't smell any tranny fluid. It sunk a little more when I saw the fluid on the ground was oil and not tranny fluid.

I took it home and pulled the pan off and took those pics. That's it as I found it.

I am sure that the first time I hit the gas the crank sheared off. The second time I hit the gas the crank flexed having no support back there (it broke off the counterweight behind the number 8 rod journal). Then as it was spinning down and flexing it bent the 7 & 8 rods and when it came back up with bent rods it blew the #8 rod and piston into smitherines. The #7 rod did not break but was bent quite sideways, and the piston was cracked.

Any questions?

Eagle cast crank, I beam rods with ARP cap screws, KB hypereutectic pistons flat top with valve reliefs. LPE CNCd heads, 224/232 .605/.605 107.5 LSA Bret Bauer cam

4L60E, 3400 2.1 STR Fuddle converter, 3.42 10 bolt, MT ET Street Radials, 3600lbs

.0025" bearing clearance on the mains and rods, 12.2:1 compression, stock intake manifold, 58mm TB, EWP, LT headers, 3" true duals.

I ran this setup for like 700 miles. I got to go to the track with it and it was slow. It ran 12.0s at 110mph with 1.601-1.61 short times. Ran good, it just wasn't fast.

One day I was out cruising in my car and was just driving down the road going ~30mph. I hit the gas and it downshifted to first and began to accelerate and there was a pop and it started free revving. I thought my trans broke, the thing had 117k on it and it was about time. I coasted a little ways with it idling and it was still running fine and what not.

Thinking it was the transmission, I'm like "Well it's about time this thing broke. I'm going to do it in!" So I hit the gas again and it revved and all hell broke loose. I heard parts flying around and looked in the rearview to see a nice trail of smoke following me as I'm coasting down the road. The engine had stalled out.

At this point I still thought it was the tranny and that something had broke and made it stall. I turned the key and it was locked solid. I got out of the car and looked under it and my heart sunk a little bit when I didn't smell any tranny fluid. It sunk a little more when I saw the fluid on the ground was oil and not tranny fluid.

I took it home and pulled the pan off and took those pics. That's it as I found it.

I am sure that the first time I hit the gas the crank sheared off. The second time I hit the gas the crank flexed having no support back there (it broke off the counterweight behind the number 8 rod journal). Then as it was spinning down and flexing it bent the 7 & 8 rods and when it came back up with bent rods it blew the #8 rod and piston into smitherines. The #7 rod did not break but was bent quite sideways, and the piston was cracked.

Any questions?

#19

TECH Apprentice

Thread Starter

Haha i see what killed it. Look in the 4th pic down and u will see ur spiral lock layin in the bottom of the pan. That will kill the **** out of a motor. But i would still bet that detonation played into it with the combinaton u were running. Man that thing had to have a ton of cyl pressure with that 107 LSA.

#20

for the additional costs of internals and difficulty of clearancing and machining an extra 12 cubes wouldnt be worth it (for the 408 vs the 396).

personally i would love to see an aftermarket lt1 block with a 4.125 bore like the 400SBC with the LT1 water passages, etc. stroke that out to 434+ cubes. it probably wouldnt be cost effective but it would be badass.

personally i would love to see an aftermarket lt1 block with a 4.125 bore like the 400SBC with the LT1 water passages, etc. stroke that out to 434+ cubes. it probably wouldnt be cost effective but it would be badass.