So i Finally bought an 8.8!

#101

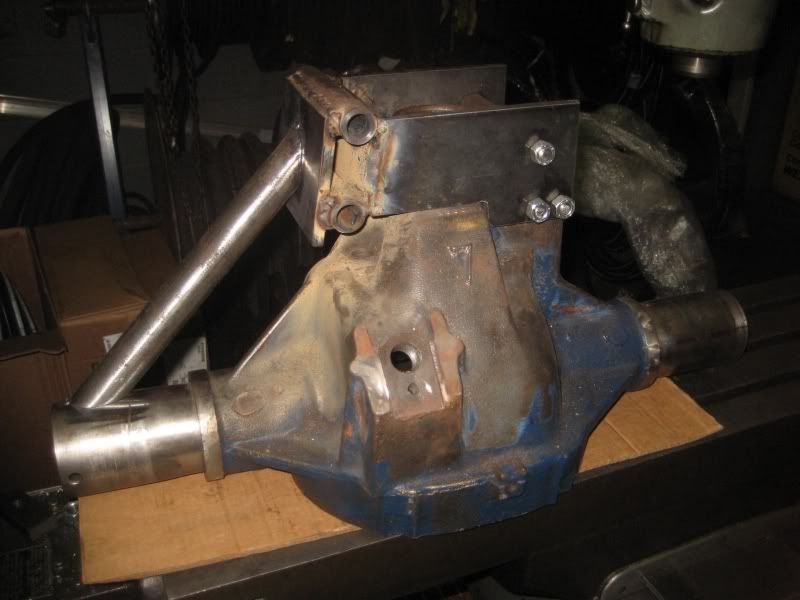

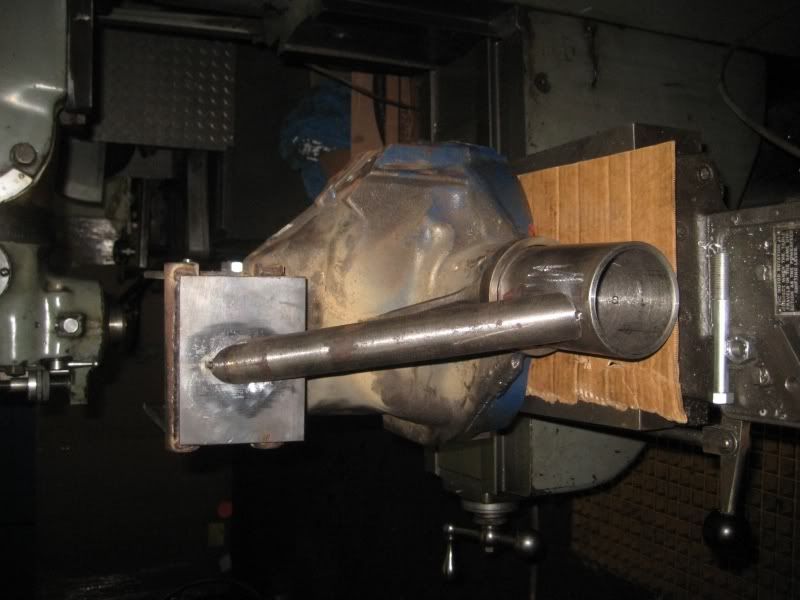

Ah... Nearly forgot. Im going to be fabricating axle tube connectors to slip on the inside. I was going to slip the 10-bolt tubes into the 8.8 tubes. But i feel there is just abit to much movement between the too. That could possibly cause the welds to crack, causing catastrophic failure. Ill be making up the sleeves to go in around 3" on both tubes having a near press fit on the ID to keep it straight and true.

#103

Just like the rep at Moser said. "youll see them by friday." That was exactly 1 week prior to me receiving my custom axles.

Spec's

-Stock Length (32")

-31 Spline

-Stock bolt pattern with stock lugs & 1/2" Screw in 3" studs

The total was around $450. That included, The Axles, Both bolt patterns with studs, and a stud kit for my 8.8 pumpkin.

I am impressed with the speed that i received them, aswell as the quality. There are afew small burrs on the axle flange where they threaded it for the 1/2" studs. But other then that there really nice. for the record aswell, there customer service was Very helpful and nice. Ive heard horror stories about people ordering things from moser. I didnt have any of that.

Here are afew pictures of how they look. Ive also talked to my boss about what i was planning on doing with my axle tubes. Ill explain that more when i do it :p

pics:

The excitement is coming to a head!

Spec's

-Stock Length (32")

-31 Spline

-Stock bolt pattern with stock lugs & 1/2" Screw in 3" studs

The total was around $450. That included, The Axles, Both bolt patterns with studs, and a stud kit for my 8.8 pumpkin.

I am impressed with the speed that i received them, aswell as the quality. There are afew small burrs on the axle flange where they threaded it for the 1/2" studs. But other then that there really nice. for the record aswell, there customer service was Very helpful and nice. Ive heard horror stories about people ordering things from moser. I didnt have any of that.

Here are afew pictures of how they look. Ive also talked to my boss about what i was planning on doing with my axle tubes. Ill explain that more when i do it :p

pics:

The excitement is coming to a head!

#110

Just like the rep at Moser said. "youll see them by friday." That was exactly 1 week prior to me receiving my custom axles.

Spec's

-Stock Length (32")

-31 Spline

-Stock bolt pattern with stock lugs & 1/2" Screw in 3" studs

The total was around $450. That included, The Axles, Both bolt patterns with studs, and a stud kit for my 8.8 pumpkin.

I am impressed with the speed that i received them, aswell as the quality. There are afew small burrs on the axle flange where they threaded it for the 1/2" studs. But other then that there really nice. for the record aswell, there customer service was Very helpful and nice. Ive heard horror stories about people ordering things from moser. I didnt have any of that.

Here are afew pictures of how they look. Ive also talked to my boss about what i was planning on doing with my axle tubes. Ill explain that more when i do it :p

pics:

The excitement is coming to a head!

Spec's

-Stock Length (32")

-31 Spline

-Stock bolt pattern with stock lugs & 1/2" Screw in 3" studs

The total was around $450. That included, The Axles, Both bolt patterns with studs, and a stud kit for my 8.8 pumpkin.

I am impressed with the speed that i received them, aswell as the quality. There are afew small burrs on the axle flange where they threaded it for the 1/2" studs. But other then that there really nice. for the record aswell, there customer service was Very helpful and nice. Ive heard horror stories about people ordering things from moser. I didnt have any of that.

Here are afew pictures of how they look. Ive also talked to my boss about what i was planning on doing with my axle tubes. Ill explain that more when i do it :p

pics:

The excitement is coming to a head!

#111

OMG progress! I got sick and tired of not having time. So i canceled plans with my girl to work on the rear  Not awhole lot. But its the little tedious **** that really bothers me.

Not awhole lot. But its the little tedious **** that really bothers me.

I bought some threaded rod to finish the mock up before i weld everything together. Ill get grade 8 bolts when im ready for final build.

Not awhole lot. But its the little tedious **** that really bothers me.

Not awhole lot. But its the little tedious **** that really bothers me.

I bought some threaded rod to finish the mock up before i weld everything together. Ill get grade 8 bolts when im ready for final build.

#114

#115

I'm curious to see how you TA bracket comes out. Right now I don't see it lasting long. Not saying you did a bad job, but you could break that cast part of the housing off with a small hammer and a good whack.

I'm setting mine up with a 4 link and getting rid of the TA, but keeping my UMI arm around incase I ever change my mind.

The build is looking good though man, I wish I had all the parts you do, but I keep spending my money on other things my car needs

I'm setting mine up with a 4 link and getting rid of the TA, but keeping my UMI arm around incase I ever change my mind.

The build is looking good though man, I wish I had all the parts you do, but I keep spending my money on other things my car needs

#116

I'm curious to see how you TA bracket comes out. Right now I don't see it lasting long. Not saying you did a bad job, but you could break that cast part of the housing off with a small hammer and a good whack.

I'm setting mine up with a 4 link and getting rid of the TA, but keeping my UMI arm around incase I ever change my mind.

The build is looking good though man, I wish I had all the parts you do, but I keep spending my money on other things my car needs

I'm setting mine up with a 4 link and getting rid of the TA, but keeping my UMI arm around incase I ever change my mind.

The build is looking good though man, I wish I had all the parts you do, but I keep spending my money on other things my car needs

My new year resolution is to finish the rear by early spring

#117

Thanks, once im 100$ done with the TA mount youll understand that itll be strong enough. Way stronger then welding to the housing. Even if you do everything required to weld mild steel to cast. It will never be as strong as mild steel to mild steel. Ive been on vacation since last week, and i had Zero time the past 2 weeks.

My new year resolution is to finish the rear by early spring

My new year resolution is to finish the rear by early spring

I have 90% of my suspension parts then I'm going to build the rear axle. Still have to get gears, axles, trac lok rebuild kit, bearings and seals, and brakes.

I'm curious to see how the car feels with a 4 link, hopefully I'll like it LOL

Keep up the good work man

#120