7000 rpm on a arp bolt rebuild

#61

TECH Fanatic

iTrader: (1)

Very valuable info, Ed! Thanks for sharing all of that.

All of my comments were aimed at the guy running a HR cam in a 350/355 motor, based on experience with my own and what we've tried on other guys' cars.

Not everybody is willing to dial in the rest of the car to make use of the motor's potential like you and the other fast guys do. In fact most of them have no clue how important that really is, even though they might say so.

All of my comments were aimed at the guy running a HR cam in a 350/355 motor, based on experience with my own and what we've tried on other guys' cars.

Not everybody is willing to dial in the rest of the car to make use of the motor's potential like you and the other fast guys do. In fact most of them have no clue how important that really is, even though they might say so.

#62

9-Second Club

iTrader: (1)

Run less spring on the profiles we are running and you will tear up more **** than you could haul off in a big truck. Not enough spring and you beat everything To death. The valve needs to stay on the seat when it closes, and not loft too far off the nose of the cam. # 1356 PACs are about the least anybody uses around here. Oval track guys & bracket racers use different (milder) profiles and less spring. Different world.

The better cylinder head shops replace the seats anyway. Especially if ports are welded. Inter locking seats like Brodix does are probably safest. That's what my new set will have. I'm restricted to stock valve diameters, but if you want to take advantage of big valves you have to replace the seats anyway.

The better cylinder head shops replace the seats anyway. Especially if ports are welded. Inter locking seats like Brodix does are probably safest. That's what my new set will have. I'm restricted to stock valve diameters, but if you want to take advantage of big valves you have to replace the seats anyway.

#64

11 Second Club

iTrader: (1)

Things change. I know one of the dragweek class winners and his 8500rpm solid roller with a quarter inch more lift than my setup has uses less seat pressure than my setup and held together well enough to win his class on dragweek. It is titanium valves which certainly helps but it is as I said a quarter inch more lift and sees 8500rpm.

#66

Very valuable info, Ed! Thanks for sharing all of that.

All of my comments were aimed at the guy running a HR cam in a 350/355 motor, based on experience with my own and what we've tried on other guys' cars.

Not everybody is willing to dial in the rest of the car to make use of the motor's potential like you and the other fast guys do. In fact most of them have no clue how important that really is, even though they might say so.

All of my comments were aimed at the guy running a HR cam in a 350/355 motor, based on experience with my own and what we've tried on other guys' cars.

Not everybody is willing to dial in the rest of the car to make use of the motor's potential like you and the other fast guys do. In fact most of them have no clue how important that really is, even though they might say so.

#67

TECH Fanatic

iTrader: (1)

I find this a big ******* insult. Some of us don't have all the time, fund or resources to pull all of the tricks out of our asses that MOST of us have learned over the years from people like Ed and many others. For many it's a hobby and for someone like myself I don't have constant access to a dyno or even a local racetrack to even test out what I've built.

Nothing was aimed at you, but if you think the shoe fits......

The fact is, MOST are not going to be able to wring out from an engine what he and SOME others do.

#70

TECH Fanatic

iTrader: (1)

I was thinking of the OP when I said that. Not insulting him at all, just being realistic to what MOST are willing to do to their car to get the potential out of the motor. I could be wrong, but I lumped him into the general multi-purpose car category, not purpose built to chase records.

#71

I was thinking of the OP when I said that. Not insulting him at all, just being realistic to what MOST are willing to do to their car to get the potential out of the motor. I could be wrong, but I lumped him into the general multi-purpose car category, not purpose built to chase records.

#74

9-Second Club

iTrader: (1)

1: There is absolutely nothing wrong with 240 plus degree 355" with the factory PCM. I have tuned several. Some are pretty good running cars. One customer's 355" had a 230-236 then put the 242-248 I pulled out of mine. Picked up on the dyno & track. He would drive it to the track then run mid-high tens @ 124-125.

2: That 402' drag week car did not have the same series Comp Cam's lobes we run or he would have torn **** up with less spring pressure. Would anybody with any sense run the series lobes many if us run on something we were going to drive on the highway? Hell no! I have been trying to explain to you it's different engines. Guys run lobes like I do because we have found them to be faster. COMP has a series of lobes with a lot of lift but not much dwell which does not use much spring. You can not just take spring away from just any series lobes.

2: That 402' drag week car did not have the same series Comp Cam's lobes we run or he would have torn **** up with less spring pressure. Would anybody with any sense run the series lobes many if us run on something we were going to drive on the highway? Hell no! I have been trying to explain to you it's different engines. Guys run lobes like I do because we have found them to be faster. COMP has a series of lobes with a lot of lift but not much dwell which does not use much spring. You can not just take spring away from just any series lobes.

Last edited by Ed Wright; 01-07-2013 at 09:06 AM.

#76

11 Second Club

iTrader: (1)

Ed, 3700lbs averaging 9.9 driving over 1000miles in the south in September so not cold weather glory runs. Sounds fast and durable to me.

Far as the lobes yes you are right not Comp catalog lobes, the cam was specifically designed for this engine, and was Spintron tested to make sure the springs and all were perfect.

My point was not that all solid roller cams can use low spring pressure but rather that some shops are beginning to design solid roller cams that are fast and use low spring pressure.

We have more options than ever before and people should be aware of them before choosing the most popular one.

Far as the lobes yes you are right not Comp catalog lobes, the cam was specifically designed for this engine, and was Spintron tested to make sure the springs and all were perfect.

My point was not that all solid roller cams can use low spring pressure but rather that some shops are beginning to design solid roller cams that are fast and use low spring pressure.

We have more options than ever before and people should be aware of them before choosing the most popular one.

#77

9-Second Club

iTrader: (1)

Shops don't design roller cams, they pick lobes out of the Master Reference Catalog. I run the HXL series lobes because my car goes down the race track faster with lobes with more dwell. There are other solid roller cams same size at .050", and ten degrees or more smaller at .100" lift. Hydraulic cams way more than that. The HXL has more valve open area at the same or less seat timing. More air flow without loosing cylinder pressure.

If you aren't limited to 10.5-1 compression as I, it's not that big a deal. Guys are losing seats from aluminium LTX heads with a lot less spring that I use. I posted that about replacing stock seats to maybe prevent somebody else having the same kind of carnage I had at Houston last Sept when mine lost a valve seat.

401", no limitations on compression, cylinder heads or throttle body? You are much more impressed with that car that I.

If you aren't limited to 10.5-1 compression as I, it's not that big a deal. Guys are losing seats from aluminium LTX heads with a lot less spring that I use. I posted that about replacing stock seats to maybe prevent somebody else having the same kind of carnage I had at Houston last Sept when mine lost a valve seat.

401", no limitations on compression, cylinder heads or throttle body? You are much more impressed with that car that I.

#79

Shops don't design roller cams, they pick lobes out of the Master Reference Catalog. I run the HXL series lobes because my car goes down the race track faster with lobes with more dwell. There are other solid roller cams same size at .050", and ten degrees or more smaller at .100" lift. Hydraulic cams way more than that. The HXL has more valve open area at the same or less seat timing. More air flow without loosing cylinder pressure.

If you aren't limited to 10.5-1 compression as I, it's not that big a deal. Guys are losing seats from aluminium LTX heads with a lot less spring that I use. I posted that about replacing stock seats to maybe prevent somebody else having the same kind of carnage I had at Houston last Sept when mine lost a valve seat.

401", no limitations on compression, cylinder heads or throttle body? You are much more impressed with that car that I.

If you aren't limited to 10.5-1 compression as I, it's not that big a deal. Guys are losing seats from aluminium LTX heads with a lot less spring that I use. I posted that about replacing stock seats to maybe prevent somebody else having the same kind of carnage I had at Houston last Sept when mine lost a valve seat.

401", no limitations on compression, cylinder heads or throttle body? You are much more impressed with that car that I.

That being said, I figured I would clear up a little of the spin, you have so nicely bestowed upon my N/A 402.

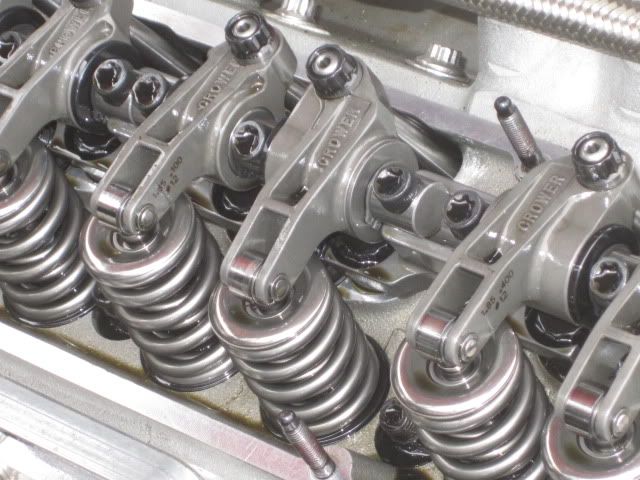

For the record......."shops" do have their own "lobes" designed. You just don't have access to them. My lobe is 301/272/201....... .468 lobe with a 1.85 ratio rocker arm. And uses a 1575ML spring from PSI. 1.400 OD in at 2.020 with 135lbs seat and 580lbs open. All on a factory ductile iron seat from Dart. This is not new tech...........Cup shops have been doing it for years. I have 11,000 miles on my turd right now. It is in for a hone and rings.

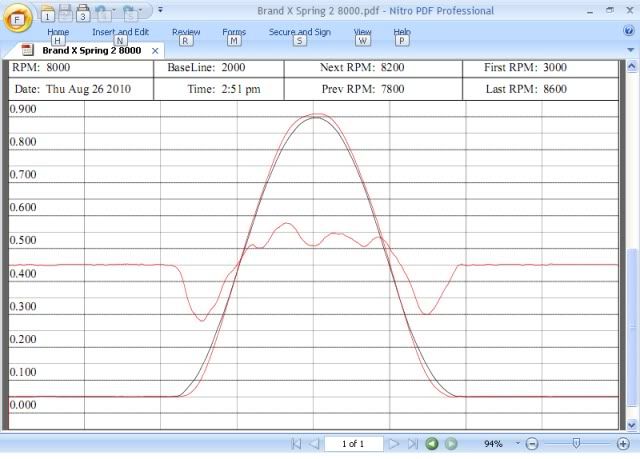

Here are some videos of it on the spintron stable to 9000rpm.

And a screenshot of the valve trace around peak HP. Note deflection and Loft......the entire valvetrain was designed to loft. Unloading the system over the nose where forces are at their highest.....

Seemed to work very well...........I run a 4.88 gear........so cruising on the highway at 65mph while pulling my trailer is done at 4000rpm. Drag Week this year was also 1400miles........not 1000.

Coming into Memphis......Day 3.....

Day 1 on the way to Dallas......

And yes......there are limitations on compression. I am not made of money so it needs to run on 91. 11.7:1 compression is what I am running. Also, the cylinder heads. They are a stock configuration 23 degree non-raised runner Dart Pro 1. Our engines are probably more similar than you’d like to lead others to believe.

Car has been 9.71 @ just shy of 137 on some glory runs. 1000ft DA at a bracket race in May......

No Video of the 9.71......sorry....

Here are some mid .70passes.....

No big wheelie.....no drama......through the mufflers with the trailer hitch on it.

No big wheelie.....no drama......through the mufflers with the trailer hitch on it.So lets get this straight..........facts........no spin.

9.91 at 3200lbs….329D/A 383 Fuel Injected 23 Degree head

9.71 at 3700lbs…1000D/A 402 Carb’d 23 Degree head

Ill be at Drag Week next year to Defend my Title…….you are welcome to bring your junk. Show me how its done.