csi water pump failed - low voltage?

#1

UPDATE: Check my most recent post on page 2. I copied it below because this is more relevant.

I posted a quick summary below this post to summarize these two pages so you can ignore reading it.

I got my new pig tail from CSR as I though that was the problem. I put the new harness on and same thing, pump wont go on. Put my jerry rigged wiring back in and the pump wont turn on. What? it just worked last time..

Took my battery to autozone and had it recharged to rule that out - battery was low, but they recharged it.

Hard wired the battery direct to the pump and the pump turns on!

Okay this is the weirdest part.. When I have everything wired up and I stuck the postive tester in the back of my test wire at the pumps harness (last point in the electrical system before the pump) and the negative end to a different clean ground bolt(same result as using the pump ground, but I wanted to rule out a grounding issue, which I found it doesnt have). With it like this I get pretty much no voltage, but the moment I take the postive test terminal off the pump, I get 12v, put the terimnal back on pump, no voltage.

Wtf is going on? I am at my whits end, this doesnt make sense to me. Kind of at the point of ripping out all the wiring and putting it all in brand new, or going back to mechanical again.

----------------------------------------------------------------------

Okay I need help with an EWP electrical gremlin.

I will try to summarize best I can.

Was driving around and my CSR ewp turn off. Towed it home.

Started testing everything (new replay, hardwired pump to battery to make sure the pump was not fried) And thought it was the car side of the CSR pigtail in the end. Cut off the car side connector, made some jerry rigged wiring and basically sliced in two wires and used a female blade connector to complete the circuit. Pumped worked fine for a few days of testing in the garage. Left it like that until I ordered new harness.

Order new pigtail from CSR. Put the harness on and now the pump does not turn on. Put my jerry rigged wiring back in. Pump does not turn on. Hardwired pump to battery, pump turns on.

Put harness back in, jammed my meter test leads into the back of the harness. With harness connected and car on accessory, I get no voltage. The moment I take the harness off the pump, I get 12v, put harness back on pump (with the system live), voltage goes back to 0, take the harness back out and 12v!

Wtf is going on? Im about to just rip out all the current EWP wiring (done by the last owner) and start fresh..

How is it that it worked with my ghetto wiring, and now it doesnt. But when I stick my test leads on the end of the wires, it DOES show 12v, but the moment those 12v wires touch the pump leads, it goes to zero. And the pump still works if I give it direct 12v from the batter bypassing all the wiring.

I posted a quick summary below this post to summarize these two pages so you can ignore reading it.

I got my new pig tail from CSR as I though that was the problem. I put the new harness on and same thing, pump wont go on. Put my jerry rigged wiring back in and the pump wont turn on. What? it just worked last time..

Took my battery to autozone and had it recharged to rule that out - battery was low, but they recharged it.

Hard wired the battery direct to the pump and the pump turns on!

Okay this is the weirdest part.. When I have everything wired up and I stuck the postive tester in the back of my test wire at the pumps harness (last point in the electrical system before the pump) and the negative end to a different clean ground bolt(same result as using the pump ground, but I wanted to rule out a grounding issue, which I found it doesnt have). With it like this I get pretty much no voltage, but the moment I take the postive test terminal off the pump, I get 12v, put the terimnal back on pump, no voltage.

Wtf is going on? I am at my whits end, this doesnt make sense to me. Kind of at the point of ripping out all the wiring and putting it all in brand new, or going back to mechanical again.

----------------------------------------------------------------------

Okay I need help with an EWP electrical gremlin.

I will try to summarize best I can.

Was driving around and my CSR ewp turn off. Towed it home.

Started testing everything (new replay, hardwired pump to battery to make sure the pump was not fried) And thought it was the car side of the CSR pigtail in the end. Cut off the car side connector, made some jerry rigged wiring and basically sliced in two wires and used a female blade connector to complete the circuit. Pumped worked fine for a few days of testing in the garage. Left it like that until I ordered new harness.

Order new pigtail from CSR. Put the harness on and now the pump does not turn on. Put my jerry rigged wiring back in. Pump does not turn on. Hardwired pump to battery, pump turns on.

Put harness back in, jammed my meter test leads into the back of the harness. With harness connected and car on accessory, I get no voltage. The moment I take the harness off the pump, I get 12v, put harness back on pump (with the system live), voltage goes back to 0, take the harness back out and 12v!

Wtf is going on? Im about to just rip out all the current EWP wiring (done by the last owner) and start fresh..

How is it that it worked with my ghetto wiring, and now it doesnt. But when I stick my test leads on the end of the wires, it DOES show 12v, but the moment those 12v wires touch the pump leads, it goes to zero. And the pump still works if I give it direct 12v from the batter bypassing all the wiring.

Last edited by timaishu; 07-22-2017 at 02:14 PM.

#3

#4

Interesting, so I tested all the relay wires coming out the bottom and they were 12v. So I put the meter back on the pump wire and now it shows 12v. Still doesnt work though.

Maybe a combination of bad wiring fried the pump cause the voltage dropped?

Maybe a combination of bad wiring fried the pump cause the voltage dropped?

#5

You may have a "corrupted" wire/connection causing intermittent voltage readings.

If the EWP was only getting 9vdc....it likely did not like that and burned up...or the motor just died.

I would get the Meziere EWP. Mine is now 18 years old with about 95k mi on it. YMMV

If the EWP was only getting 9vdc....it likely did not like that and burned up...or the motor just died.

I would get the Meziere EWP. Mine is now 18 years old with about 95k mi on it. YMMV

#6

Im thinking about that, but this event leaves me feeling a little paranoid.. I kind of want to go back to mechanical so I don't have to worry about it cutting out. Definitely a ymmv situation like my case. My pump is maybe 8-10 years old, but only has like 4k miles on it.

Trending Topics

#8

Im thinking about that, but this event leaves me feeling a little paranoid.. I kind of want to go back to mechanical so I don't have to worry about it cutting out. Definitely a ymmv situation like my case. My pump is maybe 8-10 years old, but only has like 4k miles on it.

IMHO the Meziere is a better unit than the CSR. However if the circuit to it is not perfect it to will fail as a result

Back when I went EWP I had the feeling that I would get 3 years/20k mi max because its a electric motor. I did the EWP in 99 after my 96 went out of warranty....and after dealer replaced 8 Opti & WP because the mechanical WP weep hole is directly in front of the Opti and it got nailed with coolant. I even bought a spare a few years later so I would have one on hand when mine went out. Now 18 years and 95k mi later I have as much confidence as a mechanical WP. If it died tomorrow, no problem as it has had a long life. The spare is in the trunk and it would take just a few minutes to replace. Meziere will rebuild them for around $100

A solid relay/fuse wiring to the EWP is critical to having a trouble free EWP

#9

From your initial VDC being 9,,,,then 12v you either have a intermittent wiring issue or your DVM is on the fritz. You need to confirm the wiring/fuse/relay is solid.

IMHO the Meziere is a better unit than the CSR. However if the circuit to it is not perfect it to will fail as a result

Back when I went EWP I had the feeling that I would get 3 years/20k mi max because its a electric motor. I did the EWP in 99 after my 96 went out of warranty....and after dealer replaced 8 Opti & WP because the mechanical WP weep hole is directly in front of the Opti and it got nailed with coolant. I even bought a spare a few years later so I would have one on hand when mine went out. Now 18 years and 95k mi later I have as much confidence as a mechanical WP. If it died tomorrow, no problem as it has had a long life. The spare is in the trunk and it would take just a few minutes to replace. Meziere will rebuild them for around $100

A solid relay/fuse wiring to the EWP is critical to having a trouble free EWP

IMHO the Meziere is a better unit than the CSR. However if the circuit to it is not perfect it to will fail as a result

Back when I went EWP I had the feeling that I would get 3 years/20k mi max because its a electric motor. I did the EWP in 99 after my 96 went out of warranty....and after dealer replaced 8 Opti & WP because the mechanical WP weep hole is directly in front of the Opti and it got nailed with coolant. I even bought a spare a few years later so I would have one on hand when mine went out. Now 18 years and 95k mi later I have as much confidence as a mechanical WP. If it died tomorrow, no problem as it has had a long life. The spare is in the trunk and it would take just a few minutes to replace. Meziere will rebuild them for around $100

A solid relay/fuse wiring to the EWP is critical to having a trouble free EWP

Only thing that will be tough is I need to locate the spline coupler from block to pump as the original owner didnt have it.

BUT, before I go ahead and buy anything, one last check I want to do is direct wire the pump to my battery as a test, if it doesnt turn on like that, then it must be fried. if it works, then I will troubleshoot the wiring as that would be cheaper than a new EWP or mechanical pump.

#12

I direct wired the pump and it worked fine. So somewhere along the way the wiring has gone bad.

What is strange is the pig tail connector, depsite the weird 9v reading does show 12 now. So does that mean maybe just a bad ground? I mean, if 12v is coming out that + wire, then it has to be good right? Then just a bad ground? I will see about moving the ground and see what happens. I will be back..

Edit :I cant for sure diagnose the ground as bad, but I keep getting different readings making me feel like its loose, but I cant get the pump to turn on despite jiggling and pushing on it etc.

Edit2: I think I will try and source a replacement harness as I feel like thats got to be the problem somehow.

Edit3: Pretty sure its the harness some way some how. I ordered a replacement from CSR. I will report back once I have it and tested. If not, I will look into a new wiring kit if its not too expensive.

What is strange is the pig tail connector, depsite the weird 9v reading does show 12 now. So does that mean maybe just a bad ground? I mean, if 12v is coming out that + wire, then it has to be good right? Then just a bad ground? I will see about moving the ground and see what happens. I will be back..

Edit :I cant for sure diagnose the ground as bad, but I keep getting different readings making me feel like its loose, but I cant get the pump to turn on despite jiggling and pushing on it etc.

Edit2: I think I will try and source a replacement harness as I feel like thats got to be the problem somehow.

Edit3: Pretty sure its the harness some way some how. I ordered a replacement from CSR. I will report back once I have it and tested. If not, I will look into a new wiring kit if its not too expensive.

Last edited by timaishu; 07-16-2017 at 01:39 PM.

#14

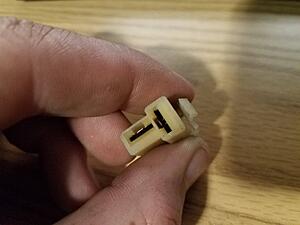

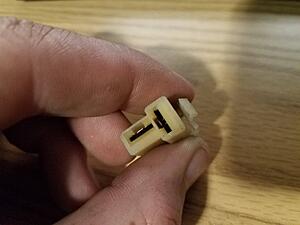

Doh! The harness I ordered is the pump side male connector. I need the female harness, which of course, is not listed on their website. I sent CSR an email to cancel my order and a general inquiry on where to get the female harness.

#15

I spoke with CSR and apparently they do not stock the female pig tail. I did some googleing and was able to come across the connector type, but I cannot find any for sale with the wires aready on it..

Anyone know where to get it? Otherwise CSR's only suggestion was to cut off the connectors and splic in new ones, they said the only way to get a new pigtail is with a new pump.... I want to have a solid connection and splicing in two more wires sounds like another opportunity for failure. Im dont know how to solder wires together either, never had luck transferring the solder into the copper wires for some reason and doing it in the engine bay sounds annoying... Any suggestions on how to add two new pig tails with solid connections?

This is what I found: http://www.mouser.com/ProductDetail/...dQuNsOeA%3D%3D

But it looks to be just the plug with no terminals or wires.

Any suggestions?

Anyone know where to get it? Otherwise CSR's only suggestion was to cut off the connectors and splic in new ones, they said the only way to get a new pigtail is with a new pump.... I want to have a solid connection and splicing in two more wires sounds like another opportunity for failure. Im dont know how to solder wires together either, never had luck transferring the solder into the copper wires for some reason and doing it in the engine bay sounds annoying... Any suggestions on how to add two new pig tails with solid connections?

This is what I found: http://www.mouser.com/ProductDetail/...dQuNsOeA%3D%3D

But it looks to be just the plug with no terminals or wires.

Any suggestions?

Last edited by timaishu; 07-17-2017 at 01:08 PM.

#17

What about something like this?

Then some real solid butt heat shrunk butt connectors and then a tube of traditional head sink on top?

Last edited by timaishu; 07-17-2017 at 08:14 PM.

#18

IDK what connector type the CSR uses but if it's not a weatherPak type than change connectors and make new wire runs as needed.

Solder, don't use butt connectors. Practice on pieces of wire. Use some heat shrink over any in-line solder connection. You can use a heat gun...or Bic lighter to shrink it

You can buy a WeatherPac pigtail M & F and solder splice in the wires

I buy just the connectors and crimp the pins on wire and insert pins in connector for a "factory" install.

Solder, don't use butt connectors. Practice on pieces of wire. Use some heat shrink over any in-line solder connection. You can use a heat gun...or Bic lighter to shrink it

You can buy a WeatherPac pigtail M & F and solder splice in the wires

I buy just the connectors and crimp the pins on wire and insert pins in connector for a "factory" install.

#19

Couldnt let it go so I went back out (11pm) and cut the connector off I thought was bad and spliced it in dirty (this is by no means permanent) to test my theory and I was right. With this thing gone, the pump works like a charm.

The dumb thing is I tested continuity and its there on both ends, but for some reason when all is in place, it wont make a connection. No idea how this thing went bad but it surely seems to have.

Pretty sure the pump wiring is 16g as my short black runs are 14g and its a bit thicker.

Next step is to buy weather terminals as mentioned above and splice it in properly (cut off the other connector etc). Any recommendations on relatively cheaper weather pack style connectors(the example I linked above wont work as I have 16g wiring)? Do I need a special crimper?

The dumb thing is I tested continuity and its there on both ends, but for some reason when all is in place, it wont make a connection. No idea how this thing went bad but it surely seems to have.

Pretty sure the pump wiring is 16g as my short black runs are 14g and its a bit thicker.

Next step is to buy weather terminals as mentioned above and splice it in properly (cut off the other connector etc). Any recommendations on relatively cheaper weather pack style connectors(the example I linked above wont work as I have 16g wiring)? Do I need a special crimper?

Last edited by timaishu; 07-18-2017 at 01:27 AM.

#20

TECH Fanatic

Seems you are confused. The female "plug" is the one coming from the pump even though the prongs are male. The one you cut off is the male "plug" pigtail supplied with all CSR pumps. The male plug on their website is what you need according to your pictures. https://www.csr-performance.com/shop...csr-waterpumps