block ready for assembly (pics)

#1

9 Second Club

Thread Starter

iTrader: (4)

Join Date: Dec 2004

Location: Cali

Posts: 2,607

Likes: 0

Received 0 Likes

on

0 Posts

well after what seems like a lifetime my engine builder called and had me come down today and see the block ready for assembly..... all the work was awesome.... took the extra time for the extra touches that make for a healthy motor.... and since we're planning to make 1000hp and run in the 8's now i'm glad he took the extra time....

so i took a couple of spy shots while i was there.... motor will start being assembled on wednesday and should be ready for the Super Victor to be plopped on top early next week..... i'll take delivery once we are sure how we want to setup the ignition (not opti but most likely crank trigger and dist)....

block with finished bores

other side/freshly hottanked and painted

polished oil galley returns in rear

deck with deck plugs installed

clearancing for the 3.75" stroker crank

just for fun plopped the AFR 227's on there

oil galley shot with heads

so i took a couple of spy shots while i was there.... motor will start being assembled on wednesday and should be ready for the Super Victor to be plopped on top early next week..... i'll take delivery once we are sure how we want to setup the ignition (not opti but most likely crank trigger and dist)....

block with finished bores

other side/freshly hottanked and painted

polished oil galley returns in rear

deck with deck plugs installed

clearancing for the 3.75" stroker crank

just for fun plopped the AFR 227's on there

oil galley shot with heads

#3

8 Second Club

iTrader: (4)

Nice! I see he plugged and drilled your upper deck cooling passages for extra strength. PortPros did mine as well. They also did a couple more little tricks to strengthen the block. How long before it is built? Mine is finished.....just need to go over and take some pics of it and pick it up. Looks like they did a great job for ya!!

#7

9-Second Club

iTrader: (1)

I like Comp Cam's little aluminum vent tubes screwed into the valley return / drain-back holes. They are the only ones I have found that clear the roller tie-bars easily. Stops oil falling on the spinning rotating assembly, yet allows crank case pressure to equalize.

Nice looking parts.

Nice looking parts.

Trending Topics

#8

9 Second Club

Thread Starter

iTrader: (4)

Join Date: Dec 2004

Location: Cali

Posts: 2,607

Likes: 0

Received 0 Likes

on

0 Posts

Nice! I see he plugged and drilled your upper deck cooling passages for extra strength. PortPros did mine as well. They also did a couple more little tricks to strengthen the block. How long before it is built? Mine is finished.....just need to go over and take some pics of it and pick it up. Looks like they did a great job for ya!!

Thanks everyone for the words....

#9

TECH Addict

iTrader: (8)

I would also have your man smooth out the two humps at the rear of the block (third picture) to aid oil return. If you are planning to run eights that's where the oil is going to be. You might also want to install a baffle at the oil pump to stop oil from riding up and hitting the rotating assembly when you launch.

Daren

Daren

#12

9 Second Club

Thread Starter

iTrader: (4)

Join Date: Dec 2004

Location: Cali

Posts: 2,607

Likes: 0

Received 0 Likes

on

0 Posts

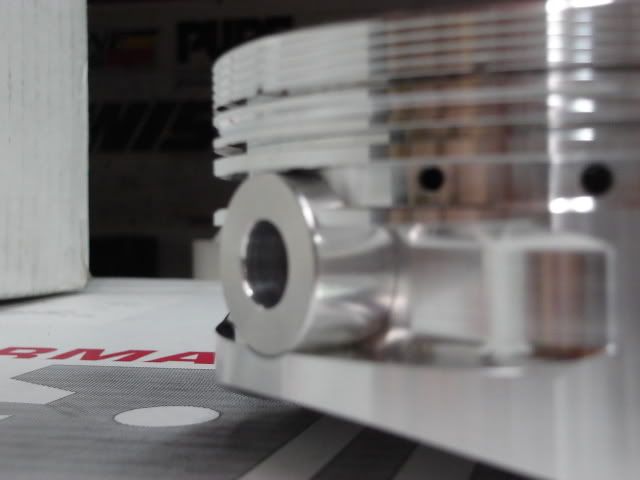

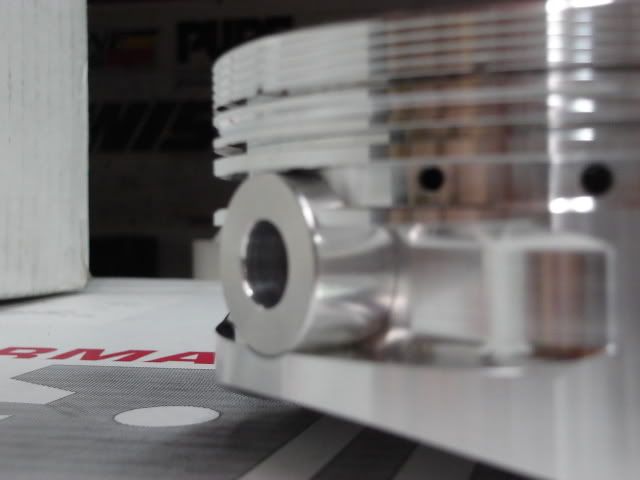

They're not the "IN" pics but you can at least get a feel for what we're running for a piston.....

gas ported JE custom nitrous flattops.... 12:1 compression with my heads, reduction grooves machined into the ringlands and these pistons were made with a 300 top ring land for large amounts of nitrous..... And I'm still going to use a 6" rod hence the wristpin "buttons" instead of spirolox....

gas ported JE custom nitrous flattops.... 12:1 compression with my heads, reduction grooves machined into the ringlands and these pistons were made with a 300 top ring land for large amounts of nitrous..... And I'm still going to use a 6" rod hence the wristpin "buttons" instead of spirolox....