How to make T56 hold up in high HP cars.

#81

9 Second Club

So what about some sort of nozzle that applied a spray with a horizontal spread rather than a simple round squirt ? Then it could be positioned to spray into a few gearsets rather than just aiming at a specific set ?

Are there any guides as to exactly where to drill and position the jet ?

Do you just run the pump all the time ?

Are there any guides as to exactly where to drill and position the jet ?

Do you just run the pump all the time ?

#82

TECH Senior Member

iTrader: (28)

post 1 to 80 covers all that, there no right or wrong way. Looks like the same idea is working, its all DIY some guys do what works better for them. I'm just putting a switch on the gas pedal so over 80% the pump sprays. RPM drilled the hole for me, and welded the case up a little to thicken it for good thread depth.

I found this article with some info and pics I htink this is the factory c6 pump?

http://rktperformance.com/why-upgrad...mission-build/

this thread has pics of a setup (overkill on the fittings) other then the feed line have the big uphill loop I wouldn't use it like that.

http://thevipergarage.com/index.php?topic=1256.30

I found this article with some info and pics I htink this is the factory c6 pump?

http://rktperformance.com/why-upgrad...mission-build/

this thread has pics of a setup (overkill on the fittings) other then the feed line have the big uphill loop I wouldn't use it like that.

http://thevipergarage.com/index.php?topic=1256.30

Last edited by studderin; 09-21-2012 at 04:10 PM.

#83

10 Second Club

iTrader: (30)

So what about some sort of nozzle that applied a spray with a horizontal spread rather than a simple round squirt ? Then it could be positioned to spray into a few gearsets rather than just aiming at a specific set ?

Are there any guides as to exactly where to drill and position the jet ?

Do you just run the pump all the time ?

Are there any guides as to exactly where to drill and position the jet ?

Do you just run the pump all the time ?

#84

9 Second Club

#85

9 Second Club

#89

10 Second Club

iTrader: (5)

Join Date: Nov 2007

Location: Cincinnati

Posts: 1,052

Likes: 0

Received 0 Likes

on

0 Posts

thanks for this pic man.

Hows the lines going over the Ypipe been? Any trouble with heat? I have the lighter nylon hose so not looking to do that. Even with heat socks on the line over the exhaust. But that spot looks good for working on the car, you can do alot without removing the pump.

I'm looking form a good place to mount the pump (same tilton) Its bigger then the sts style little on speedrace used.

On the side of the trans I can get it away for the Exhust running it front to back along the trans (its not gona fit up/dpwn without being lower then my headers that hit) just a head of the fuel line were it jogs on the tunnel. But thats gona get it the way of bleeding the clutch a little. And it blocks the fill hole The other side is tight too, it would be close to the header. I kinda think I could mount it on the T56? Not sure about drilling 2-3 holes into it and tapping them. Or drilling a clearance hole in the webbing and nut/bolting the bracket on.

The other side is tight too, it would be close to the header. I kinda think I could mount it on the T56? Not sure about drilling 2-3 holes into it and tapping them. Or drilling a clearance hole in the webbing and nut/bolting the bracket on.

Do you set the fuild level with the pump on?

Hows the lines going over the Ypipe been? Any trouble with heat? I have the lighter nylon hose so not looking to do that. Even with heat socks on the line over the exhaust. But that spot looks good for working on the car, you can do alot without removing the pump.

I'm looking form a good place to mount the pump (same tilton) Its bigger then the sts style little on speedrace used.

On the side of the trans I can get it away for the Exhust running it front to back along the trans (its not gona fit up/dpwn without being lower then my headers that hit) just a head of the fuel line were it jogs on the tunnel. But thats gona get it the way of bleeding the clutch a little. And it blocks the fill hole

The other side is tight too, it would be close to the header. I kinda think I could mount it on the T56? Not sure about drilling 2-3 holes into it and tapping them. Or drilling a clearance hole in the webbing and nut/bolting the bracket on.

The other side is tight too, it would be close to the header. I kinda think I could mount it on the T56? Not sure about drilling 2-3 holes into it and tapping them. Or drilling a clearance hole in the webbing and nut/bolting the bracket on.Do you set the fuild level with the pump on?

post 1 to 80 covers all that, there no right or wrong way. Looks like the same idea is working, its all DIY some guys do what works better for them. I'm just putting a switch on the gas pedal so over 80% the pump sprays. RPM drilled the hole for me, and welded the case up a little to thicken it for good thread depth.

I found this article with some info and pics I htink this is the factory c6 pump?

http://rktperformance.com/why-upgrad...mission-build/

this thread has pics of a setup (overkill on the fittings) other then the feed line have the big uphill loop I wouldn't use it like that.

http://thevipergarage.com/index.php?topic=1256.30

I found this article with some info and pics I htink this is the factory c6 pump?

http://rktperformance.com/why-upgrad...mission-build/

this thread has pics of a setup (overkill on the fittings) other then the feed line have the big uphill loop I wouldn't use it like that.

http://thevipergarage.com/index.php?topic=1256.30

#90

TECH Senior Member

iTrader: (28)

ya true. I was thinking maybe wiring it direct so I can test it with the car off to make sure the switch and everything is working too.

I'm probably gonna mount it were you have it outside the Ypipe, on that LT1 cat spot hump. that's easy to work on the car with it ther out of the way of the trans, and drivetrain. But to clear my max power muffler setup, I have to test mock up.

And the pump is just 3/8 NPT so I might make up some 3/8 brake line and run some steel line off the pump and get the lines over by the tunnel tight on the floor, over the exhust. I dont want to set it up with the light nylon black ProClassic line running over the exhaust. Thats gonna be bad if that hose ever gets loose or something and touches, when it gets hot WOT..... F that

Then loose flair nut and flair the lines, and put a 3/8 double flair seat brass fitting to 3/8 npt. then put my 3/8npt to -6 AN fitting on that.

Or see if I can get steel -6 an ends I can weld right on the lines. Think Newera might have some for N20 stuff, I can grab tomarrow,

I'm probably gonna mount it were you have it outside the Ypipe, on that LT1 cat spot hump. that's easy to work on the car with it ther out of the way of the trans, and drivetrain. But to clear my max power muffler setup, I have to test mock up.

And the pump is just 3/8 NPT so I might make up some 3/8 brake line and run some steel line off the pump and get the lines over by the tunnel tight on the floor, over the exhust. I dont want to set it up with the light nylon black ProClassic line running over the exhaust. Thats gonna be bad if that hose ever gets loose or something and touches, when it gets hot WOT..... F that

Then loose flair nut and flair the lines, and put a 3/8 double flair seat brass fitting to 3/8 npt. then put my 3/8npt to -6 AN fitting on that.

Or see if I can get steel -6 an ends I can weld right on the lines. Think Newera might have some for N20 stuff, I can grab tomarrow,

#91

9 Second Club

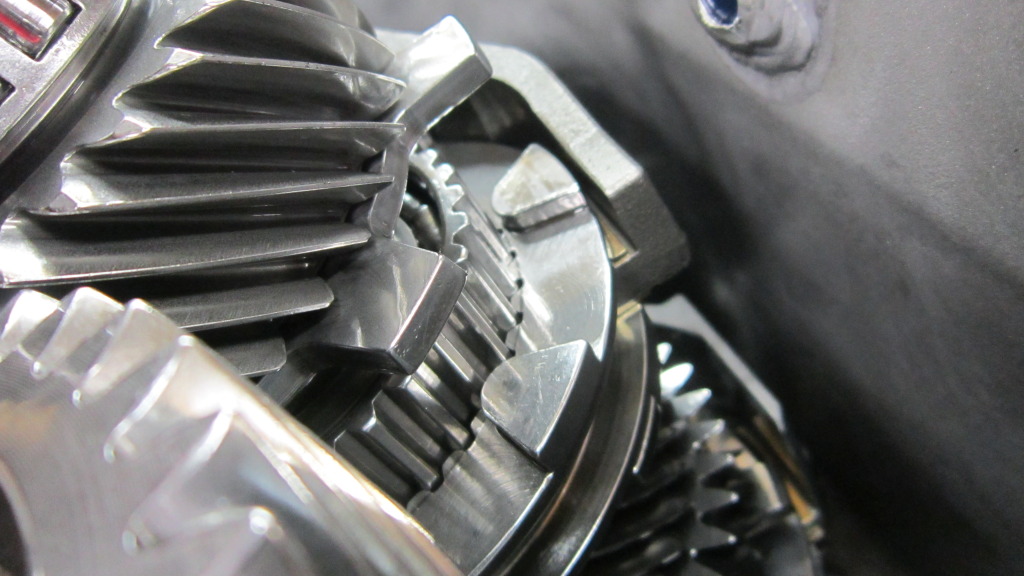

I would nearly be inclined just to use some -3 or -4 fittings into the box, and direct oil at the input shaft interface and 1-2 gears too.

1-2 seem pretty close together, so could be achieved with a single fitting

1-2 seem pretty close together, so could be achieved with a single fitting

#93

TECH Fanatic

iTrader: (24)

damn I am glad my trans held up without an issue. and its in another guys car and shift 10 times better with a centerforce DFX in front of it, than it did trying to shift with a Sof Loc clutch. I am pretty sure if I could of gotton the car to 60ft like it did with the Sof loc, but actually have a clutch that let me shift going down track, I bet a 8.60's range wouldn't have been out of the question.

I sure do miss banging those gears! dont miss messing with the trans and clutch all the time and not being able to focus on the chassis and other things.

I sure do miss banging those gears! dont miss messing with the trans and clutch all the time and not being able to focus on the chassis and other things.

#94

9 Second Club

iTrader: (4)

^^^ I'm with ya there! Never had any issues with my tranny either. I wish I still had my entire setup up and going. There was ALOT left in it and I never pushed it hard.

I'm still gonna be banging gears sometime in the next bit though, I upgraded to a GTO tranny that I'm putting the 32spline SSR mainshaft in. Hopefully I can get the turbo spooled with a 2step and some fuel/timing trickery.

I'm still gonna be banging gears sometime in the next bit though, I upgraded to a GTO tranny that I'm putting the 32spline SSR mainshaft in. Hopefully I can get the turbo spooled with a 2step and some fuel/timing trickery.

#96

9 Second Club

Very neat. The pumps all look quite big. Has anyone used this newer more compact pump ?

http://www.merlinmotorsport.co.uk/p1...duct_info.html

I dont think they create a lot of pressure, although it shouldnt need to for this application.

Claims about 8psi at 160 litres per hour. Which is a lot of flow.

http://www.merlinmotorsport.co.uk/p1...duct_info.html

I dont think they create a lot of pressure, although it shouldnt need to for this application.

Claims about 8psi at 160 litres per hour. Which is a lot of flow.

#97

10 Second Club

iTrader: (30)

If anyone is looking for one of these setups mine is for sale BNIB never used. Deeply discounted from new.

https://ls1tech.com/forums/parts-cla...nge-setup.html

https://ls1tech.com/forums/parts-cla...nge-setup.html