flywheel bolts!?!?

#1

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

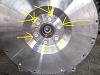

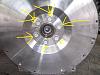

alright so im changing the clutch in my 01 camaro ss..i got a monster cluth stage 2 and a new 28lb flywheel.. soo i go to bolt up the flywheel and the bolts arent sitting flush with the flywheel!! the very edge of all 6 bolts are hitting the the part of the flywheel that starts to protrude out by like 1mm its very little but doesnt look right.. see attchment  its bending the flat parts of the bolt out.. is this gunna be a problem?? or should i just torque the suckers down with locktight and call it good ?

its bending the flat parts of the bolt out.. is this gunna be a problem?? or should i just torque the suckers down with locktight and call it good ?

its bending the flat parts of the bolt out.. is this gunna be a problem?? or should i just torque the suckers down with locktight and call it good ?

its bending the flat parts of the bolt out.. is this gunna be a problem?? or should i just torque the suckers down with locktight and call it good ?

#3

if it were me, I would contact Monster. Did they include FW bolts?

The bolt should sit flush.

you could get grade 8 bolts that did not have the flat outer skirt part that is extending onto the angled part of your FW

The bolt should sit flush.

you could get grade 8 bolts that did not have the flat outer skirt part that is extending onto the angled part of your FW

#5

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

ya i contacted monster.. they said they have never heard of that problem.. told me to send pictures.. they said that my stock ones are TTY anyways and i need new ones but i know for a fact they are not  and i really want to get this thing goin tonight so i can drive it tomo so im thinking of just grinding the shoulder/washer part off the bolt so it doesnt hit the angled part of the flywheel which is barely anything (1/2mm) locktight torque em and call it good what do you think.. opinion?

and i really want to get this thing goin tonight so i can drive it tomo so im thinking of just grinding the shoulder/washer part off the bolt so it doesnt hit the angled part of the flywheel which is barely anything (1/2mm) locktight torque em and call it good what do you think.. opinion?

#6

TECH Fanatic

iTrader: (20)

ya i contacted monster.. they said they have never heard of that problem.. told me to send pictures.. they said that my stock ones are TTY anyways and i need new ones but i know for a fact they are not  and i really want to get this thing goin tonight so i can drive it tomo so im thinking of just grinding the shoulder/washer part off the bolt so it doesnt hit the angled part of the flywheel which is barely anything (1/2mm) locktight torque em and call it good what do you think.. opinion?

and i really want to get this thing goin tonight so i can drive it tomo so im thinking of just grinding the shoulder/washer part off the bolt so it doesnt hit the angled part of the flywheel which is barely anything (1/2mm) locktight torque em and call it good what do you think.. opinion?

Trending Topics

#8

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

the flywheel surface is perfectly flat.. its just the fact that the edges of the bolts skirts/washer/shoulder part is hitting where the flywheel starts to curve up to where the clutch disc sits.. i already grinded down the washer/shoulder of the bolts and installed them with locktight. i also smoothed out the surcface if the bolt that sits on the flywheels everything sat flush and torqued nicely, i am breaking in my clutch now.. my only concern is that i reduced the clamping surface of the bolts?? and affected clamping force?? but besides that im feeling pretty confident about it...

I would prob notice if the flywheel started to come loose wouldn't I?

I would prob notice if the flywheel started to come loose wouldn't I?

#10

TECH Senior Member

iTrader: (28)

Is is just thous top bolts "hitting" on the top of the bolt shoulder?

do you have the flywheel tight on the crank yet?

I bet you just noticed its the side of those 2 top bolt because you have the FW just started on the crank register and it tipped in at the bottom more still so only thous 2 top bolt look to be hitting. And the bottom bolts are hitting on the top (inside) more too.

If so, and the FW is not drawn on the crank yet. Get it seated all the way and see if the bolts still look tipped

do you have the flywheel tight on the crank yet?

I bet you just noticed its the side of those 2 top bolt because you have the FW just started on the crank register and it tipped in at the bottom more still so only thous 2 top bolt look to be hitting. And the bottom bolts are hitting on the top (inside) more too.

If so, and the FW is not drawn on the crank yet. Get it seated all the way and see if the bolts still look tipped

#11

TECH Senior Member

iTrader: (28)

heads up,.... you can reuse the stock flywheel bolt. I just clean them good (wire wheel) put some red locktight on them, tq is a X pattern ect like normal. Used my stock 2001s something like 15 times we counted once, lol. Just been using some stock take offs a newer LS2 car from the shop. I few of mine were getting rounded off a little. Personally I like using them over ARP, only downside in the head on stocks is short, so when you break them loose you need to have the socket on them square. But other then that there shorter then arps, (well years ago I saw alot of cars with arp FW bolts that had a shoulder and were taller head they stocks, I think not most places are selling the lower head ones) on some twin and triple clutch setups need to room. And the arps hit and cause problems. Your more likely to have a 6point 15mm socket for the stocks over a 12 point (think there 3/4, 19mm?) the arps are. its easier and faster to get stock, I think cheaper too

#12

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

im pretty sure your supposed to use blue lock tight.. and i dont think your understanding me correctly... the flywheel is completely on the crank sitting perfectly flush with the crank it just pretty much slipped right on.. didnt have to use the bolts to draw it on.. but on the surface of the flywheel where the bolts go, that circle is too small causing all the bolts shoulder to hit that outer circle where the surface starts inclining to the surface of the clutch disc.. i pointed to it and circled it in the pictures i posted i tried to make it as clear as possible.. i should have just took an actual picture of it but its too late now i got it all bolted up and am driving it now on this beautiful day in colorado  .

.

.

.

#13

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

the pictures that i posted arent actual pictures of my flywheel i just pulled them off google. on my flywheel the outer circle that i pointed to in the pictures is alot closer to the bolt holes///cause the shoulder washer part of the bolts to hit the incline.... make more sense???

#14

TECH Senior Member

iTrader: (28)

gotcha,

ya I was guessing the 2 bolts circled were just the 2 top stops of contact. And it was something simple like that, your tired working on the car in the dark and cold and overlooked something like that, it happens. I know what your saying, the FW radius corner going up to the disc raised surface, the bolt shoulders were hitting the start of the radius. Never seen that too, not this has anything to do with that but only seen the aftermarket cranks not fitting flywheels as "good"... The OEM holes are all over, the aftermarket is tighter and run into problems

ya I was guessing the 2 bolts circled were just the 2 top stops of contact. And it was something simple like that, your tired working on the car in the dark and cold and overlooked something like that, it happens. I know what your saying, the FW radius corner going up to the disc raised surface, the bolt shoulders were hitting the start of the radius. Never seen that too, not this has anything to do with that but only seen the aftermarket cranks not fitting flywheels as "good"... The OEM holes are all over, the aftermarket is tighter and run into problems

Last edited by studderin; 01-21-2013 at 02:40 PM.

#17

Teching In

Thread Starter

iTrader: (2)

Join Date: Dec 2011

Location: Longmont, CO

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

i have no pics and dont plan on taking it apart just to take pics.. and no your not missing what i am saying the pictures i posted are clear as day just look in the little yellow circles.. where is starts to incline is where my bolts were hitting

#20

TECH Junkie

iTrader: (18)

Join Date: Aug 2005

Location: Amsterdam Ny, the good part

Posts: 3,398

Likes: 0

Received 64 Likes

on

51 Posts

ive read this over many times and have no idea whats going on . I used a speed inc flywheel and new gm bolts and had no problems . its almost 10 im going to bed im confused.