Cover above oil filter....

#1

Launching!

Thread Starter

Join Date: Jan 2009

Location: Mead, WA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

...What is it for? Is it a 'cap' for an oil pressure port? Where I could possibly screw in a sender?

Reason I ask, is I need to run a oil pressure gauge and I need to find a place to put the oil pressure sender.

Reason I ask, is I need to run a oil pressure gauge and I need to find a place to put the oil pressure sender.

#3

It should take 15 minutes to tap, drill, install the sender.

#4

Launching!

Thread Starter

Join Date: Jan 2009

Location: Mead, WA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

Ok, I'm lost.... Let's see if I got this right?

Take the cover off and toss it in the garbage, right?

Under the cover there is already a 1/8" PT?

That tapped hole doesn't go all the way through to the block and will need to be opened up?

Take the cover off and toss it in the garbage, right?

Under the cover there is already a 1/8" PT?

That tapped hole doesn't go all the way through to the block and will need to be opened up?

#5

Yep, your lost, way lost.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Look at the part, you're going to see a .332 diameter hole drilled down almost all the way. Now why did they drill it partially. I have no idea, but if they went all the way they'd have to plug it because it would not cover the oil hole in the block.

Now thats your job--drill it the rest of the way. I'd suggest a .125 to .250 hole, you're only reading pressure so it doesn't need to be huge for flow.

Now run a tap through it (the factory predrilled hole, not your hole), just like you'd tap any aluminum part.

Clean it up.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

You should at least test fit the sender, I'd suggest installing it into the part, and then putting it back on the block.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Look at the part, you're going to see a .332 diameter hole drilled down almost all the way. Now why did they drill it partially. I have no idea, but if they went all the way they'd have to plug it because it would not cover the oil hole in the block.

Now thats your job--drill it the rest of the way. I'd suggest a .125 to .250 hole, you're only reading pressure so it doesn't need to be huge for flow.

Now run a tap through it (the factory predrilled hole, not your hole), just like you'd tap any aluminum part.

Clean it up.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

You should at least test fit the sender, I'd suggest installing it into the part, and then putting it back on the block.

#7

Launching!

Thread Starter

Join Date: Jan 2009

Location: Mead, WA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

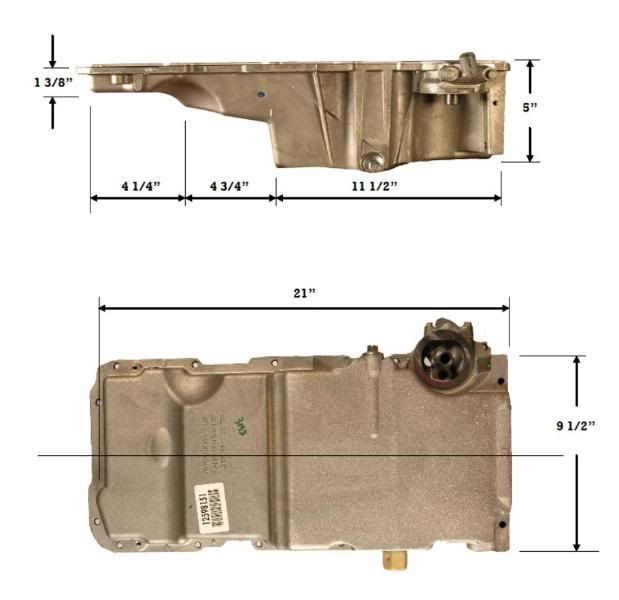

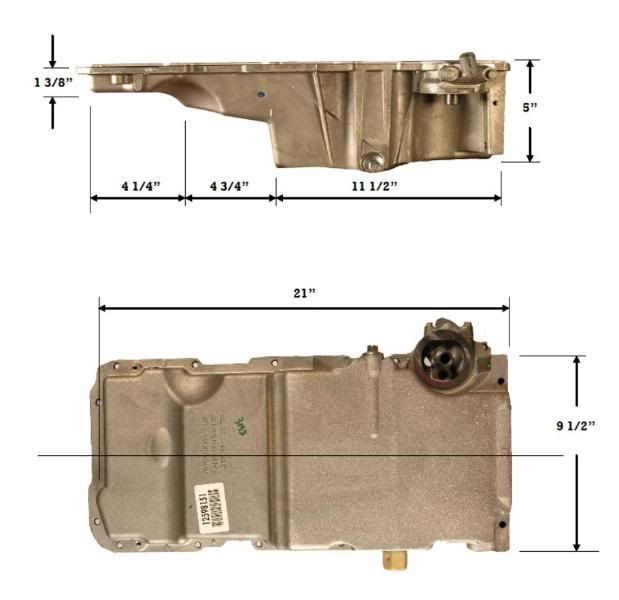

lol Now to fawk it up more, the part I'm talking about is on the oil pan. Top right in this picture.

Is this same thing you speak of? I'm confused, because you are talking about a plate on the block and I'm talking about one on the pan.

Is this same thing you speak of? I'm confused, because you are talking about a plate on the block and I'm talking about one on the pan.

Yep, your lost, way lost.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Look at the part, you're going to see a .332 diameter hole drilled down almost all the way. Now why did they drill it partially. I have no idea, but if they went all the way they'd have to plug it because it would not cover the oil hole in the block.

Now thats your job--drill it the rest of the way. I'd suggest a .125 to .250 hole, you're only reading pressure so it doesn't need to be huge for flow.

Now run a tap through it (the factory predrilled hole, not your hole), just like you'd tap any aluminum part.

Clean it up.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

You should at least test fit the sender, I'd suggest installing it into the part, and then putting it back on the block.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Look at the part, you're going to see a .332 diameter hole drilled down almost all the way. Now why did they drill it partially. I have no idea, but if they went all the way they'd have to plug it because it would not cover the oil hole in the block.

Now thats your job--drill it the rest of the way. I'd suggest a .125 to .250 hole, you're only reading pressure so it doesn't need to be huge for flow.

Now run a tap through it (the factory predrilled hole, not your hole), just like you'd tap any aluminum part.

Clean it up.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

You should at least test fit the sender, I'd suggest installing it into the part, and then putting it back on the block.

Trending Topics

#9

Launching!

Thread Starter

Join Date: Jan 2009

Location: Mead, WA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

lol NICE! After I posted my last one, I went out and 'kinda' looked at the motor and didn't see anything on the block - granted, I don't have a clear view of the block, but...

Anyway! Thanks!!!!

Actually, one more question... I'm installing Autometer gauges and in the gauges, they have their own senders. I'm assuming the one on the back of the motor/intake valley is reading pressure at the cam, which is AFTER it goes through the mains? And the one we are talking about at the filter is reading pump pressure. Would it be wise to swap those? Put my Autometer gauge on the top of the motor and switch the PCM connection to read filter pressure?

Reason being, I would like to read actual engine oil pressure while in the driver seat and could care less what the PCM reads, as I don't intend on having the PCM tell me that it's wrong.

Thoughts? I'm also considering this for the water temp as well - put the Autometer sensor in the front of the motor and move the PCM sensor to the back of the motor (or anywhere else for that matter).

Anyway! Thanks!!!!

Actually, one more question... I'm installing Autometer gauges and in the gauges, they have their own senders. I'm assuming the one on the back of the motor/intake valley is reading pressure at the cam, which is AFTER it goes through the mains? And the one we are talking about at the filter is reading pump pressure. Would it be wise to swap those? Put my Autometer gauge on the top of the motor and switch the PCM connection to read filter pressure?

Reason being, I would like to read actual engine oil pressure while in the driver seat and could care less what the PCM reads, as I don't intend on having the PCM tell me that it's wrong.

Thoughts? I'm also considering this for the water temp as well - put the Autometer sensor in the front of the motor and move the PCM sensor to the back of the motor (or anywhere else for that matter).

#10

Well you may need to check my info on this, seriously now.

I know I've seen a pic of that part we were just figuring out, threaded for the factory sender. Thats the location for some application. So if you found one of those, you could put your factory sender by the oil filter. But then you'd need to find an adapter from metric to NPT to put your aftermarket sender in the original location because it's metric with a seat.

Now the water temp sensor isn't a problem, other than extending the wires.

Then use autometers adapter and special sensor where the factory sender was.

You might want to think about forgetting autometers special parts and put the supplied sensor in a tee connected inline with the throttle body bypass hose.

And just leaving the factory sensor where it is.

The reason I say all this is because I just bought all the adapters and the short sensor, busted my *** to install it in the pass side head, now it seems to read low.

I have HP Tuners scanner, the stock gauge, and the autometer giving me three different readings.

And when you look at autometers recommended adapter and sensor you will see that it doesn't have coolant flowing past it, and it's strange that on the package they call it a cylinder head temperature sensor, not coolant temp sensor.

And now you've got me thinking. My new autometer oil pressure gauge reads lower than the factory gauge at low rpm and higher at high rpm. You may get a more accurate reading with it in the factory location.

I know I've seen a pic of that part we were just figuring out, threaded for the factory sender. Thats the location for some application. So if you found one of those, you could put your factory sender by the oil filter. But then you'd need to find an adapter from metric to NPT to put your aftermarket sender in the original location because it's metric with a seat.

Now the water temp sensor isn't a problem, other than extending the wires.

Then use autometers adapter and special sensor where the factory sender was.

You might want to think about forgetting autometers special parts and put the supplied sensor in a tee connected inline with the throttle body bypass hose.

And just leaving the factory sensor where it is.

The reason I say all this is because I just bought all the adapters and the short sensor, busted my *** to install it in the pass side head, now it seems to read low.

I have HP Tuners scanner, the stock gauge, and the autometer giving me three different readings.

And when you look at autometers recommended adapter and sensor you will see that it doesn't have coolant flowing past it, and it's strange that on the package they call it a cylinder head temperature sensor, not coolant temp sensor.

And now you've got me thinking. My new autometer oil pressure gauge reads lower than the factory gauge at low rpm and higher at high rpm. You may get a more accurate reading with it in the factory location.

#11

Launching!

Thread Starter

Join Date: Jan 2009

Location: Mead, WA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

This motor is a 2008, and I don't see the coolant hose your talking about. I know very little about the LS engines, but I believe the coolant going into the TB was before DBW?

I'll have to look at the sender that came with the Autometer temp gauge and see what it looks like... That would suck if what you say is true. If I wanted a head temp gauge I woudl have bought one

Talked to my dad about this.... The plug we're talking about by the filter will be pump pressure as will the one in the intake valley on top of the rear main. The front plug on the driver side between the crank and cam is the front plug that I was thinking about (had front/rear reversed) that shows pressure after goign through the main and rods. HOWEVER! The LS motors have priority oiling. Meaning that along the sides? (I know on the driver, not sure about passneger) are oil gallies that feed the main bearings first, from teh side, then they feed the cam bearings/lifters above. So that plug on the front side of the motor should also be pump pressure.

So I think I'll leave the stock sender where it is, and tap that plug we've been talking about for the Autometer gauge.

Unless... Looking at the stock sender, it's three wire. Does that mean it can be used for the gauge and PCM?

I'll have to look at the sender that came with the Autometer temp gauge and see what it looks like... That would suck if what you say is true. If I wanted a head temp gauge I woudl have bought one

Talked to my dad about this.... The plug we're talking about by the filter will be pump pressure as will the one in the intake valley on top of the rear main. The front plug on the driver side between the crank and cam is the front plug that I was thinking about (had front/rear reversed) that shows pressure after goign through the main and rods. HOWEVER! The LS motors have priority oiling. Meaning that along the sides? (I know on the driver, not sure about passneger) are oil gallies that feed the main bearings first, from teh side, then they feed the cam bearings/lifters above. So that plug on the front side of the motor should also be pump pressure.

So I think I'll leave the stock sender where it is, and tap that plug we've been talking about for the Autometer gauge.

Unless... Looking at the stock sender, it's three wire. Does that mean it can be used for the gauge and PCM?

Well you may need to check my info on this, seriously now.

I know I've seen a pic of that part we were just figuring out, threaded for the factory sender. Thats the location for some application. So if you found one of those, you could put your factory sender by the oil filter. But then you'd need to find an adapter from metric to NPT to put your aftermarket sender in the original location because it's metric with a seat.

Now the water temp sensor isn't a problem, other than extending the wires.

Then use autometers adapter and special sensor where the factory sender was.

You might want to think about forgetting autometers special parts and put the supplied sensor in a tee connected inline with the throttle body bypass hose.

And just leaving the factory sensor where it is.

The reason I say all this is because I just bought all the adapters and the short sensor, busted my *** to install it in the pass side head, now it seems to read low.

I have HP Tuners scanner, the stock gauge, and the autometer giving me three different readings.

And when you look at autometers recommended adapter and sensor you will see that it doesn't have coolant flowing past it, and it's strange that on the package they call it a cylinder head temperature sensor, not coolant temp sensor.

And now you've got me thinking. My new autometer oil pressure gauge reads lower than the factory gauge at low rpm and higher at high rpm. You may get a more accurate reading with it in the factory location.

I know I've seen a pic of that part we were just figuring out, threaded for the factory sender. Thats the location for some application. So if you found one of those, you could put your factory sender by the oil filter. But then you'd need to find an adapter from metric to NPT to put your aftermarket sender in the original location because it's metric with a seat.

Now the water temp sensor isn't a problem, other than extending the wires.

Then use autometers adapter and special sensor where the factory sender was.

You might want to think about forgetting autometers special parts and put the supplied sensor in a tee connected inline with the throttle body bypass hose.

And just leaving the factory sensor where it is.

The reason I say all this is because I just bought all the adapters and the short sensor, busted my *** to install it in the pass side head, now it seems to read low.

I have HP Tuners scanner, the stock gauge, and the autometer giving me three different readings.

And when you look at autometers recommended adapter and sensor you will see that it doesn't have coolant flowing past it, and it's strange that on the package they call it a cylinder head temperature sensor, not coolant temp sensor.

And now you've got me thinking. My new autometer oil pressure gauge reads lower than the factory gauge at low rpm and higher at high rpm. You may get a more accurate reading with it in the factory location.

#12

Yep, your lost, way lost.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

Take that part off your block, use a 10mm wrench and remove the two bolts.

You can take the part to china if you want, just so you're not tempted to drill your block while you've got a drill in your hand.

Now, you'll need to decide whether or not you want to install the sender now, or when you get back to your home country where the vehicle is located.

ROFLMAO! Thanks, I just sprayed coffee all over my new monitor...

it is on the pan lol.

it is on the pan lol.