Strange Lean condition with plate kit

#1

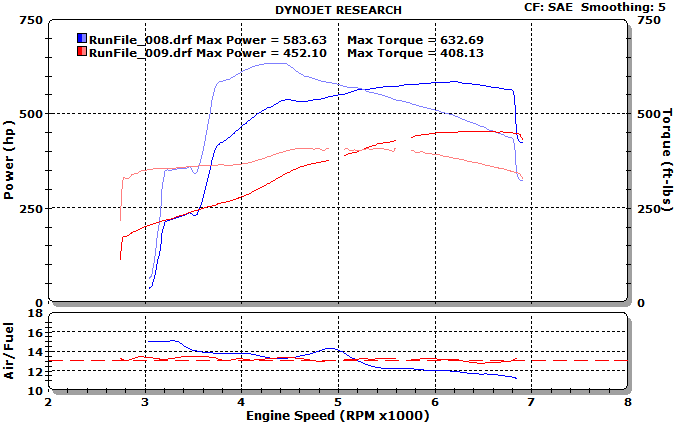

I'm tuning a c5 zo6 vette that has a 102mm Nick Williams TB and a 102mm plate kit on it. It is jetted for a 150 shot. The car makes pretty much exactly the hp and tq I would expect but it is extremely lean from initial hit up to 4500 rpms or so and then from their the afr falls like a rock to about 11.0:1 at 6800 rpms. The AFR starts out at around 14.0:1 and maintains till 4500 rpms or so like clockwork.

It is so lean I'm afraid to keep testing it, but its so rich at the top making a jet change will actually make it stupid rich. I'd like to have a steady 12:1 AFR but that isn't going to happen with a jet change. The AFR on motor is a rock solid 12.8:1 across the entire rpm range at wot....

I have verified the AFR on both the dynojets wideband as well as my NGK afx wideband logged with HPT. I have changed the plate to a different brand (both spray from the top of the plate) with no difference in the afr and I have changed the fuel solenoid with no change as well. I have changed the fuel line from the rail from hard stainless to braided and I have measured a rock solid 58 lbs of fuel pressure at the rail during a run. The pressure does nothing more than a quick flicker on the initial hit....so fast you barely even see it. The car has a brand new Racetronix pump.

The car makes a clean power curve on the dyno with just over 600 rwtq and 580 rwhp (stock bottomend LS6 with as cast TFS heads and moderate cam). No misfiring or anything like that and it has BR7EF plugs. 22 degrees of timing. I even purged the bottle and re-filled it from a completely different mother tank...

I have changed the location of the solenoids ground with no change. All wire sizing is more than adequate for the draw of these solenoids. I'm finding that the nitrous solenoid should draw about 17 amps and the fuel solenoid only 3 or 4.... We have a 40/60 relay on it supplied with the kit and a NOS tps/window switch. It hits at the specified rpm and shuts off at the specified rpm just as it should. Everything works just like it should, it just has no control whatsoever over the afr.

Has anyone else had this issue with a 102 plate that sprays from the top? I don't think this should have any affect really, but the blade of the throttle body passes right into the path of the spray coming from the plate. As in the plate is spraying right against the tb blade.

I'm at a loss for what to try. I would think if we had a wiring issue the hp would be inconsistent, low, or if anything the nitrous side would act up since that is the solenoid with the most draw and we would be rich at the hit. I really hate to keep testing this because it seems that its only a matter of time before it pops with such a lean afr right in the range where its most likely to knock.... I have installed a bunch of nitrous kits and never seen an issue like this.

It is so lean I'm afraid to keep testing it, but its so rich at the top making a jet change will actually make it stupid rich. I'd like to have a steady 12:1 AFR but that isn't going to happen with a jet change. The AFR on motor is a rock solid 12.8:1 across the entire rpm range at wot....

I have verified the AFR on both the dynojets wideband as well as my NGK afx wideband logged with HPT. I have changed the plate to a different brand (both spray from the top of the plate) with no difference in the afr and I have changed the fuel solenoid with no change as well. I have changed the fuel line from the rail from hard stainless to braided and I have measured a rock solid 58 lbs of fuel pressure at the rail during a run. The pressure does nothing more than a quick flicker on the initial hit....so fast you barely even see it. The car has a brand new Racetronix pump.

The car makes a clean power curve on the dyno with just over 600 rwtq and 580 rwhp (stock bottomend LS6 with as cast TFS heads and moderate cam). No misfiring or anything like that and it has BR7EF plugs. 22 degrees of timing. I even purged the bottle and re-filled it from a completely different mother tank...

I have changed the location of the solenoids ground with no change. All wire sizing is more than adequate for the draw of these solenoids. I'm finding that the nitrous solenoid should draw about 17 amps and the fuel solenoid only 3 or 4.... We have a 40/60 relay on it supplied with the kit and a NOS tps/window switch. It hits at the specified rpm and shuts off at the specified rpm just as it should. Everything works just like it should, it just has no control whatsoever over the afr.

Has anyone else had this issue with a 102 plate that sprays from the top? I don't think this should have any affect really, but the blade of the throttle body passes right into the path of the spray coming from the plate. As in the plate is spraying right against the tb blade.

I'm at a loss for what to try. I would think if we had a wiring issue the hp would be inconsistent, low, or if anything the nitrous side would act up since that is the solenoid with the most draw and we would be rich at the hit. I really hate to keep testing this because it seems that its only a matter of time before it pops with such a lean afr right in the range where its most likely to knock.... I have installed a bunch of nitrous kits and never seen an issue like this.

#4

Just something that pops into my head. I had to trace down an electrical problem in my mustang. I had a diode burn out on my alternator and gave me absolute hell tuning. It was triggering the cam and crank position sensors to give false codes. Have you checked the charging system to make sure that the right voltage is being supplied and it clean.

#5

FormerVendor

iTrader: (25)

Jonathan,

I have been going messaging Martin on facebook. Have your tried everything on the list I gave you to test? If so can you email me the results? info@nitrousoutlet.com

Thanks

Dave

I have been going messaging Martin on facebook. Have your tried everything on the list I gave you to test? If so can you email me the results? info@nitrousoutlet.com

Thanks

Dave

#7

Everything works great....the afr just looks like crap.

I tried another bottle from my own car and a brand new feed line with no change. I have visually looked at all of the wiring and the connections are good....the wire isn't excessively long or too small for the load. There is no reason I can see why this thing isn't working as it should unless the design of the plate isn't happy with the throttle body....and that seems far fetched as I'm sure there are more than a few dbw cars running a plate kit with a NW tb.

I have seen cars with relay issues, intermittent connections, window switches set right on the edge, and power wires too small for the current draw. I have yet to see one I couldn't figure out but this one has me stumped...

My next plan is to wire a quick push button setup completely isolated from the rest of the wiring on the car. No NOS window switch, no fpss, nothing. Just a momentary that can handle the load slamming power right to the noids. If it still does it the wiring isn't the issue.

Trending Topics

#8

Jonathan,

I have been going messaging Martin on facebook. Have your tried everything on the list I gave you to test? If so can you email me the results? info@nitrousoutlet.com

Thanks

Dave

I have been going messaging Martin on facebook. Have your tried everything on the list I gave you to test? If so can you email me the results? info@nitrousoutlet.com

Thanks

Dave

Martin probably got busy and forgot to give it to me...

#10

I've changed everything but the nitrous noid and the wiring. The main power for the solenoids is 12 gauge and only about a foot long to the relay. There is maybe 3 feet of 16 gauge wire feeding each solenoid from the relay. In other words, 16 gauge times two. The ground side is basically just the two wires from the noids just like they came...no wire has even been added. The relay coil is grounded about 3" from the relay straight to a clean spot on the frame and the NOS window provides power to the relay coil...pretty straight forward and it all works.

#11

FormerVendor

iTrader: (25)

Jonathan, I am stuck in the back plumbing intakes trying to meet deadlines. Can you get Martin to print our messages back and forth.

Ill try to shoot you an email this afternoon with a step by step things to check and explain why I am suggesting checking them.

Sorry you guys are having a hard time. I know it sucks.

Dave

Ill try to shoot you an email this afternoon with a step by step things to check and explain why I am suggesting checking them.

Sorry you guys are having a hard time. I know it sucks.

Dave

#12

FormerVendor

iTrader: (25)

Looking at the dyno graph I see few possible things that are usually the issue. Here are some common issues that usually give the results you are seeing.

1. Fuel supply issue- Usually when you see a air fuel graph start off lean and gradually get richer throughout the pass it is a fuel delivery issue. The most common issue is that the application does not have enough fuel pump to support the demand. The only way to know if you are running out of fuel pump is to watch a fuel pressure gauge on the car. If the fuel pressure drops and slowly recovers you do not have enough fuel pump or in some cases there is a restriction such as dirty fuel filter or kinked fuel line etc. The next issue in fuel delivery could be a faulty fuel solenoid. Make sure the fuel solenoid is opening and flowing fuel like it should be. Some old style fuel solenoids have a piston material that will swell with today's pump gas. Check with the system manufacture to make sure you have a fuel solenoid designed for today's fuels.( Note: If the car has a fuel pressure safety switch check and make sure it is set correctly. Do not bypass it without verifying fuel pressure first. It may be doing its job.)

2. Nitrous flow delivery issue- If fuel pressure is solid the next common issue is a restriction in the nitrous flow. Most common issues found are trash in the solenoid blocking the inlet port, Kinked nitrous line, Teflon slither in nitrous line, bad bottle fill, etc. The best way to test the system for a nitrous flow issue is to do a flow consumption test. In order to do this test you will need a stop watch, fresh bottle fill and a good digital scale. You will take the nitrous bottle and place it on the scale. With the main feed line hooked to the bottle you will then purge all the air out of the main feed line. After purging the air out of the system, write down the weight of the nitrous bottle. You will need to run the solenoids power and ground wire straight to the battery during the test. You can just hold the wires to power and ground through the blast or you can wire in a push button. You will blast the nitrous system for 10 seconds using your stop watch. (Please keep in mind if you blasted the nitrous through the system into the engine do not crank the engine or you will have an explosion. You will need to unplug the coils and turn the engine over, cycling the nitrous through the engine and out of the exhaust before cranking the engine.) After your 10 second blast you will write down the weight of the nitrous bottle. Using this formula 1lb per every 10 seconds equals 100 hp, you will determine if the system flowed the right amount of nitrous for the power level. (So if 200 pills are in the system you should flow 2 lbs in 10 seconds)

3. Voltage issue- If fuel delivery and nitrous flow are not an issue the next common issue is voltage in the car. If the cars voltage is low the solenoids may not function properly not to mention the cars computer can do weird things. Check the data logs to see what the voltage is doing.

4. Ignition- Ignition spark is important. Spark plug choice and spark plug gap are important. If the gap is spread too far out you can blow the fire out from the spark being too weak. If the gap is to close together there may not be enough open area to ignite the air fuel mixture. If plug gap is not an issue make sure your coils are not breaking down.

5. Wiring- If everything else test good the issue is probably in the wiring. Check the gauge wire size and make sure it is capable of supplying the amp draw of the system. The longer the wire is the bigger the gauge wire needs to be used. Check all your grounds and wire connection points. If you have a nitrous controller make sure it has its own grounding point. Most controller manufactures suggest grounding them away from other grounds so that the controller does not get feedback. Also make sure the controller is capable of supplying the amperage the nitrous solenoids draw.

1. Fuel supply issue- Usually when you see a air fuel graph start off lean and gradually get richer throughout the pass it is a fuel delivery issue. The most common issue is that the application does not have enough fuel pump to support the demand. The only way to know if you are running out of fuel pump is to watch a fuel pressure gauge on the car. If the fuel pressure drops and slowly recovers you do not have enough fuel pump or in some cases there is a restriction such as dirty fuel filter or kinked fuel line etc. The next issue in fuel delivery could be a faulty fuel solenoid. Make sure the fuel solenoid is opening and flowing fuel like it should be. Some old style fuel solenoids have a piston material that will swell with today's pump gas. Check with the system manufacture to make sure you have a fuel solenoid designed for today's fuels.( Note: If the car has a fuel pressure safety switch check and make sure it is set correctly. Do not bypass it without verifying fuel pressure first. It may be doing its job.)

2. Nitrous flow delivery issue- If fuel pressure is solid the next common issue is a restriction in the nitrous flow. Most common issues found are trash in the solenoid blocking the inlet port, Kinked nitrous line, Teflon slither in nitrous line, bad bottle fill, etc. The best way to test the system for a nitrous flow issue is to do a flow consumption test. In order to do this test you will need a stop watch, fresh bottle fill and a good digital scale. You will take the nitrous bottle and place it on the scale. With the main feed line hooked to the bottle you will then purge all the air out of the main feed line. After purging the air out of the system, write down the weight of the nitrous bottle. You will need to run the solenoids power and ground wire straight to the battery during the test. You can just hold the wires to power and ground through the blast or you can wire in a push button. You will blast the nitrous system for 10 seconds using your stop watch. (Please keep in mind if you blasted the nitrous through the system into the engine do not crank the engine or you will have an explosion. You will need to unplug the coils and turn the engine over, cycling the nitrous through the engine and out of the exhaust before cranking the engine.) After your 10 second blast you will write down the weight of the nitrous bottle. Using this formula 1lb per every 10 seconds equals 100 hp, you will determine if the system flowed the right amount of nitrous for the power level. (So if 200 pills are in the system you should flow 2 lbs in 10 seconds)

3. Voltage issue- If fuel delivery and nitrous flow are not an issue the next common issue is voltage in the car. If the cars voltage is low the solenoids may not function properly not to mention the cars computer can do weird things. Check the data logs to see what the voltage is doing.

4. Ignition- Ignition spark is important. Spark plug choice and spark plug gap are important. If the gap is spread too far out you can blow the fire out from the spark being too weak. If the gap is to close together there may not be enough open area to ignite the air fuel mixture. If plug gap is not an issue make sure your coils are not breaking down.

5. Wiring- If everything else test good the issue is probably in the wiring. Check the gauge wire size and make sure it is capable of supplying the amp draw of the system. The longer the wire is the bigger the gauge wire needs to be used. Check all your grounds and wire connection points. If you have a nitrous controller make sure it has its own grounding point. Most controller manufactures suggest grounding them away from other grounds so that the controller does not get feedback. Also make sure the controller is capable of supplying the amperage the nitrous solenoids draw.

#15

So to update this thread, I still haven't had any luck with this issue. Today I bypassed all of the wiring and powered the solenoids directly with a momentary push button. No change.

I then mounted a fogger nozzle into a 4" piece of aluminum tubing about 5" inches before the tb. New lines to hook it up and used the same jets still. No change.

I even made a pull with a battery charger on the car and running while making a pull. No change.

The voltage drops from 13.9 to 12.9 or so on the hit but recovers to 13.7 for the duration of the run. The voltage didn't really even drop on the run with the charger hooked up.

I'm at a complete loss on what could be causing this.... It isn't safe to run and I have lost a TON of money chasing this problem.

The fogger nozzle did seem to be a tiny bit better in terms of going lean....and if anything the fuel line was longer. The fogger nozzle also produced the most torque when compared to the plates... Probably due to the slighter richer afr. It is still right at 14:1 from the hit until 4500 rpms. All I know to do is put a bigger fuel jet in it and see where it goes on the hit and just let it ride out the top of the pull around 10:1.

I then mounted a fogger nozzle into a 4" piece of aluminum tubing about 5" inches before the tb. New lines to hook it up and used the same jets still. No change.

I even made a pull with a battery charger on the car and running while making a pull. No change.

The voltage drops from 13.9 to 12.9 or so on the hit but recovers to 13.7 for the duration of the run. The voltage didn't really even drop on the run with the charger hooked up.

I'm at a complete loss on what could be causing this.... It isn't safe to run and I have lost a TON of money chasing this problem.

The fogger nozzle did seem to be a tiny bit better in terms of going lean....and if anything the fuel line was longer. The fogger nozzle also produced the most torque when compared to the plates... Probably due to the slighter richer afr. It is still right at 14:1 from the hit until 4500 rpms. All I know to do is put a bigger fuel jet in it and see where it goes on the hit and just let it ride out the top of the pull around 10:1.

#16

11 Second Club

iTrader: (13)

Join Date: Oct 2003

Location: apoopka, fl

Posts: 1,414

Likes: 0

Received 0 Likes

on

0 Posts

if the fuel line is longer, you found your problem.

On lines over 8" i tend to run a 2" shorter fuel line. That difference grows as length does. This gets missed a lot, especially on dyno's with widebands. But get a datalogger and 02's in every exhaust runner and it becomes more apparent.

On lines over 8" i tend to run a 2" shorter fuel line. That difference grows as length does. This gets missed a lot, especially on dyno's with widebands. But get a datalogger and 02's in every exhaust runner and it becomes more apparent.

#17

It isn't the fuel line... The fuel line supplied with the kit from the noid to the plate is roughly 11" long. The nitrous line is about 16 or 17" long. I've changed the hard tube line to braided also still using the plate with zero change.

I installed the fogger nozzle with a much LONGER fuel line (the nitrous and fuel lines were the same length) and the problem was a tiny bit better, not worse.

I can see your theory on needing a shorter fuel line based on the fact that nitrous is under a lot more pressure and may reach the plate quicker...but this is running 58 lbs of fuel pressure and the lean condition is almost a second and a half if you look at the dyno log in "time" vs. "engine speed". There is no way that its taking over a second longer for the fuel to reach the plate than the nitrous, especially when the line is already 6" shorter.

I just made a pull and just hit the nitrous switch at 5000 rpms just to see what effect that had. The lean condition wasn't as pronounced, but still there and still unsafe. I'm going to hit the spray at 3000 next and hopefully the lean condition will be cleared up by 4000 where it really needs the fuel the most....

Thats all I know to do since literally everything has been replaced and tested. The only other thing I could figure would be something goofy going on with the tune in terms of torque management or something when the nitrous hits. I don't think so; the timing is where I'm commanding it, the fuel is commanded correctly, and the TPS stays at wot. There appears to be no clutch slip or anything like that that might make the afr appear leaner like a stall can do before it reaches the point where it grabs.

I HATE nitrous now.

I installed the fogger nozzle with a much LONGER fuel line (the nitrous and fuel lines were the same length) and the problem was a tiny bit better, not worse.

I can see your theory on needing a shorter fuel line based on the fact that nitrous is under a lot more pressure and may reach the plate quicker...but this is running 58 lbs of fuel pressure and the lean condition is almost a second and a half if you look at the dyno log in "time" vs. "engine speed". There is no way that its taking over a second longer for the fuel to reach the plate than the nitrous, especially when the line is already 6" shorter.

I just made a pull and just hit the nitrous switch at 5000 rpms just to see what effect that had. The lean condition wasn't as pronounced, but still there and still unsafe. I'm going to hit the spray at 3000 next and hopefully the lean condition will be cleared up by 4000 where it really needs the fuel the most....

Thats all I know to do since literally everything has been replaced and tested. The only other thing I could figure would be something goofy going on with the tune in terms of torque management or something when the nitrous hits. I don't think so; the timing is where I'm commanding it, the fuel is commanded correctly, and the TPS stays at wot. There appears to be no clutch slip or anything like that that might make the afr appear leaner like a stall can do before it reaches the point where it grabs.

I HATE nitrous now.

#18

10 Second Club

iTrader: (26)

A few things jump out at me. You're using the iat to adjust timing during the spray. Have you tried removing the retard from that and command it directly in the high octane spark table instead? Yes I know the car likes 28 degrees at wot na but I'd be curious to rule out the iat retard doing something goofy. Second I'd like to see what happens if you swapped fuel pumps or powered the pump via a separate source. Third, do you narrow band O2 s show the same lean dip during the pull? Do the plugs show lean after a pull?

#19

A few things jump out at me. You're using the iat to adjust timing during the spray. Have you tried removing the retard from that and command it directly in the high octane spark table instead? Yes I know the car likes 28 degrees at wot na but I'd be curious to rule out the iat retard doing something goofy. Second I'd like to see what happens if you swapped fuel pumps or powered the pump via a separate source. Third, do you narrow band O2 s show the same lean dip during the pull? Do the plugs show lean after a pull?

The fuel pump is a brand new Racetronix that we installed the same time as the nitrous kit. Power is supplied via their "hotwire" kit. Regardless, the fuel pressure has been tested at the rail between the rail and the solenoid during a full pull on the dyno. The pressure was verified to hold steady with nothing more than a brief "flicker" of the gauge.

The plugs haven't been verified to be lean. They look fine. BR7EF plugs. The thing is, its stupid lean at first and by the time the run is over it is too rich.

We have the dynojets wideband in one exhaust pipe in a rear o2's location and an NGK AFX wideband in the other rear o2's location and the car has a full exhaust system all the way out the back. No cats. The narrow band sensors do verify the lean condition as well. The way I see it there is nothing left to do but doctor up the NA tune as much as possible in the lean area and let it ride....