0411

#1

Teching In

Thread Starter

Join Date: Oct 2017

Location: south carolina

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

I have e 99 bird that I got as a roller. I want to put in a 468 Pontiac motor and make it efi. I also picked up a 4l80e out of a van to put behind my motor. I was seeing if I could use a 0411 pcm with a express van tune and change stuff around. the van and the Pontiac motor have the same firing order but the Pontiac is counter clock on the dist. I have done the 0411 swap in my s10 with lextech wiring and express tune. just seeing if I can use the 0411 before going with high dollar efi control for motor and trans.

#2

TECH Senior Member

How are you going to bolt the trans to the Poncho mill? Different bellhousing patterns...

#4

TECH Senior Member

How are you going to use a distributor? LS's do not have them. Are you using some sort of coil-on-plug ignition?

#5

TECH Fanatic

The biggest issue will be TPS and RPM. Just an initial thought as I read your plan. I'm not sure what you are planning on doing for the other problems that might occur.

How are you going to get RPM signal with a distributor to the 0411? Are you going to add a signal wire to tell it what RPM it has? It will need this to shift properly at WOT. The 4l80, and others all use TPS signal for all part throttle shifting. Are you adding a TPS as well?

This sounds like a fun venture, but likely more complicated than it needs to be.

How are you going to get RPM signal with a distributor to the 0411? Are you going to add a signal wire to tell it what RPM it has? It will need this to shift properly at WOT. The 4l80, and others all use TPS signal for all part throttle shifting. Are you adding a TPS as well?

This sounds like a fun venture, but likely more complicated than it needs to be.

#7

Teching In

Thread Starter

Join Date: Oct 2017

Location: south carolina

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

I am going to use a ls1 style throttle body and injectors on a efi intake. I have a built Pontiac motor and that's what I know and have a bunch of parts for. its just the efi conversion is what I having a hard time with. after it is all up and running I am going to add a 88mm turbo and don't want to mess with a blowthru carb.

Trending Topics

#8

The ONLY thing you would have to figure out will be mounting the crank sensor. You will have to fab up some type of crank trigger system and have a reluctor wheel machined to mount to your balancer (assuming you run it external). If you wanted an internal(protected) reluctor wheel I'm sure you could fab something up to read off the torq converter similar to how Chrysler does theirs off the flex plate.

If you wanted to avoid the whole distributor thing you could modify the distributor pickup coil to read as a 1x cam sensor, make it a 24 tooth reluctor and go to coil on plug ignition. You could adjust the firing order in the tune or you could change it when you wired the coils up.

Getting the tps signal will be the least of your concerns, there are a number of ways you could do that.

Adjusting idle speed can be done with out an IAC using the spark tables to control the idle from park to drive. Assuming your not talking about a heavy cam'd engine....you can only get so much out of the spark tables this way.

If your able to figure out a crank sensor your idea would work just fine.

If you wanted to avoid the whole distributor thing you could modify the distributor pickup coil to read as a 1x cam sensor, make it a 24 tooth reluctor and go to coil on plug ignition. You could adjust the firing order in the tune or you could change it when you wired the coils up.

Getting the tps signal will be the least of your concerns, there are a number of ways you could do that.

Adjusting idle speed can be done with out an IAC using the spark tables to control the idle from park to drive. Assuming your not talking about a heavy cam'd engine....you can only get so much out of the spark tables this way.

If your able to figure out a crank sensor your idea would work just fine.

#9

TECH Fanatic

I suppose the real problem will be getting that intake to mount to those heads. I have never even thought to try something like this, so now I'm more curious than anything to see how this thing comes together.

I suppose it is possible to do without the rpm signal, since you can just use your part throttle shift tables to account for that. You just won't have a WOT shift point. Something tells me though that it may not ever shift correctly at WOT. If the requirements are not met, it just won't shift. I don't think this is something you can bypass. The PCM must interpret the RPM from somewhere. It's an electronic transmission. I know the distributor has a sending unit, but what type of reference signal does it produce would be the question. 5v? PW? 24x, 58x, etc... Using the 0411 you will absolutely need this. I'm not really sure what they used before 97 to control the 80e, but that I would be looking into if I were you.

I want this to work, because it's definitely something crazy I have never heard of or even thought of.

I suppose it is possible to do without the rpm signal, since you can just use your part throttle shift tables to account for that. You just won't have a WOT shift point. Something tells me though that it may not ever shift correctly at WOT. If the requirements are not met, it just won't shift. I don't think this is something you can bypass. The PCM must interpret the RPM from somewhere. It's an electronic transmission. I know the distributor has a sending unit, but what type of reference signal does it produce would be the question. 5v? PW? 24x, 58x, etc... Using the 0411 you will absolutely need this. I'm not really sure what they used before 97 to control the 80e, but that I would be looking into if I were you.

I want this to work, because it's definitely something crazy I have never heard of or even thought of.

#14

TECH Fanatic

The ONLY thing you would have to figure out will be mounting the crank sensor. You will have to fab up some type of crank trigger system and have a reluctor wheel machined to mount to your balancer (assuming you run it external). If you wanted an internal(protected) reluctor wheel I'm sure you could fab something up to read off the torq converter similar to how Chrysler does theirs off the flex plate.

If you wanted to avoid the whole distributor thing you could modify the distributor pickup coil to read as a 1x cam sensor, make it a 24 tooth reluctor and go to coil on plug ignition. You could adjust the firing order in the tune or you could change it when you wired the coils up.

Getting the tps signal will be the least of your concerns, there are a number of ways you could do that.

Adjusting idle speed can be done with out an IAC using the spark tables to control the idle from park to drive. Assuming your not talking about a heavy cam'd engine....you can only get so much out of the spark tables this way.

If your able to figure out a crank sensor your idea would work just fine.

If you wanted to avoid the whole distributor thing you could modify the distributor pickup coil to read as a 1x cam sensor, make it a 24 tooth reluctor and go to coil on plug ignition. You could adjust the firing order in the tune or you could change it when you wired the coils up.

Getting the tps signal will be the least of your concerns, there are a number of ways you could do that.

Adjusting idle speed can be done with out an IAC using the spark tables to control the idle from park to drive. Assuming your not talking about a heavy cam'd engine....you can only get so much out of the spark tables this way.

If your able to figure out a crank sensor your idea would work just fine.

#15

TECH Fanatic

#17

You may still have to have a new reluctor machined that matches the pattern on the vortec but you have all the mounting provisions needed. If you have access to a scope get a reading from your crank sensor while cranking and compare the wave shape to a GM signal. You should be able to find wave form examples with google. As long as the #1 trigger is the same and the other 3 pulses show up in the pattern you shouldn't have any issues. If not.....new wheel and crank sensor would take care of that for sure.

I looked into doing this for a friend on a 67 Firebird with a 326 a couple of years ago, it's completely doable. He was looking to go TBI to keep it looking stock-ish....... but the ignition system would have been the same as going port injection.

Dakota Digital makes the adapter to pull speed signal off the speedo cable or they also make an adapter to drive a cable speedometer off an electronic trans so your covered either way.

I looked into doing this for a friend on a 67 Firebird with a 326 a couple of years ago, it's completely doable. He was looking to go TBI to keep it looking stock-ish....... but the ignition system would have been the same as going port injection.

Dakota Digital makes the adapter to pull speed signal off the speedo cable or they also make an adapter to drive a cable speedometer off an electronic trans so your covered either way.

#18

TECH Fanatic

So basically, as far as your original question goes, yes. You can use the 0411 to control the 80. You can send your tune in for a segment swap to support@hptuners and they can hook you up. Otherwise you need to run a relay, and a 4L60e tune. The 4L80 does not have a 3-2 downshift solenoid whereas the 60 does. If the PCM you have is set up for an 80 that's half of the battle. Then you still need to change the pins on your harness since your car never had an 80 in it. This is to "trick" the 80 into thinking it has that solenoid. If you go with the relay, you won't need the ISS, if you go with repining the connector, then you will also need to ADD the ISS to your PCM.

#19

TECH Fanatic

Simple, Run the Cam Sensor "Pick-Up Wheel" 180 degrees from the normal Chevy/Clockwise location.

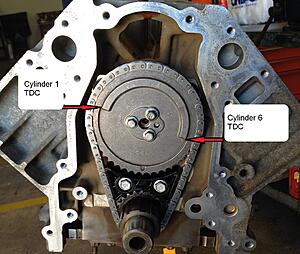

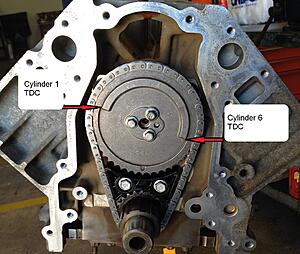

A picture to help explain as I'm terrible at explaining things......1x Cam Gear, If it were to spin counter clockwise, The raised portion of the cam gear would need to be 180 degrees from where it is now to give the same signal as before.....I hope this helps?

A picture to help explain as I'm terrible at explaining things......1x Cam Gear, If it were to spin counter clockwise, The raised portion of the cam gear would need to be 180 degrees from where it is now to give the same signal as before.....I hope this helps?

#20

So basically, as far as your original question goes, yes. You can use the 0411 to control the 80. You can send your tune in for a segment swap to support@hptuners and they can hook you up. Otherwise you need to run a relay, and a 4L60e tune. The 4L80 does not have a 3-2 downshift solenoid whereas the 60 does. If the PCM you have is set up for an 80 that's half of the battle. Then you still need to change the pins on your harness since your car never had an 80 in it. This is to "trick" the 80 into thinking it has that solenoid. If you go with the relay, you won't need the ISS, if you go with repining the connector, then you will also need to ADD the ISS to your PCM.