Just got done with a 454 tonight---Pics inside

#41

TECH Resident

iTrader: (14)

Ed,

Not sure why the hostility..

The lifter bores are different. My original post was incorrect and it was brought to my attention. I admitted that. My intent with the original post was that the way the lifter sits on the cam doesn't differ. You could pick any angle around the 360* circumference and as long as the centerline of the lifter aligns with the centerline of the cam bore, the angle isn't a factor. The particular angle used in a BBC is to align the lifters with the pushrods for the canted valve head. You know this, I know this, and anybody that sat down and thought about it could understand it.

Now,

If you think the anlge is a factor, please explain. I'm more than willing to learn and listen.

Where did I down talk someone else experience? I think maybe the lack of tone on the internet is making you think I'm downtalking your experience, and I do disagree with the "doomsday" theory on BBC flat tappets but two professionals can disagree. I see no problem with a roller cam and for the customer who has the cash, it has advantages. I just find it hard to believe that all of the sudden something that has worked OK since 1965 isn't viable. I (and I'm sure you) have worked on BBC's with 200,000 miles on them and the cams be OK, as in rebuilding the motor and the cam is still in good enough shape to turn in as a core for regrind.

Other than the location of the main galley, what is different about the oiling system on a BBC, as far as how it oils?

I believe the Gen V BBCs went to the cam placement, and the Bowtie blocks even earlier if my memory is correct.

I also own a small shop specializing in performance work, and nowadays mostly performance GM automatic transmissions.

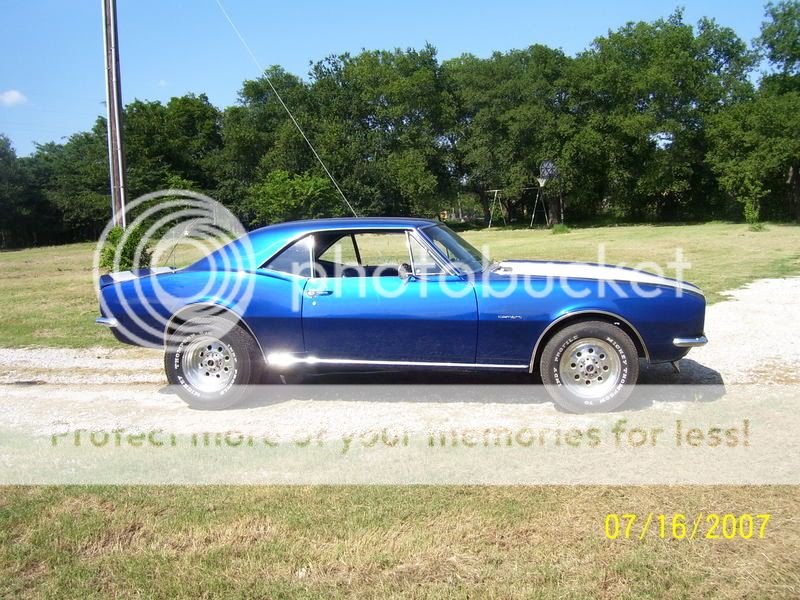

This was 2 weekends ago, quick project for a long distance customer.

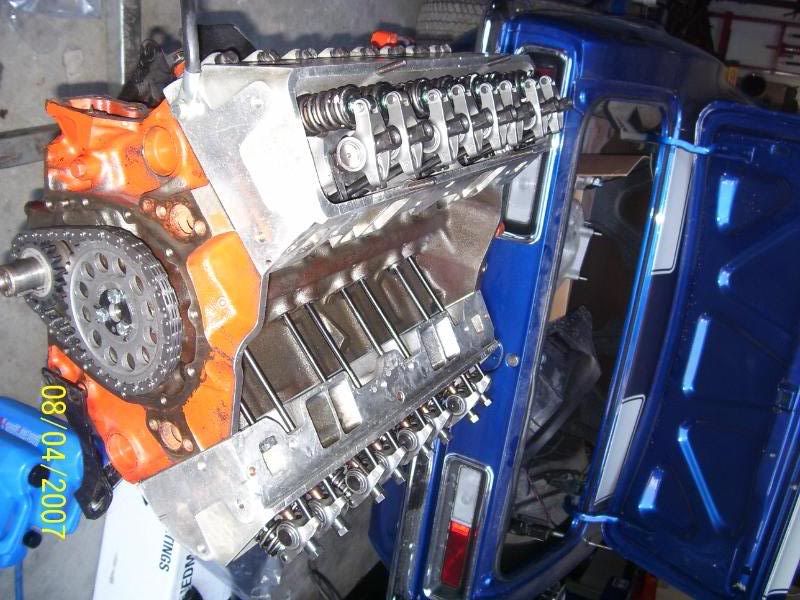

This is the current project. 200-4R swap and fixing the engine built by a race shop. Double roller timing chain rubbing the block, too much compression for a street motor, too aggressive springs for a flat tappet cam, dome hitting the chamber, etc. So yeah, I'm familiar with fixing the problems other "experts" can't get right.

I'm not here to "impress" anyone.

To most viewers here, they have no way of knowing what the real qualifications are of anyone posting on an internet site. I'm well respected on other sites that I frequent I just don't have a big post count here.

Not sure why the hostility..

The lifter bores are different. My original post was incorrect and it was brought to my attention. I admitted that. My intent with the original post was that the way the lifter sits on the cam doesn't differ. You could pick any angle around the 360* circumference and as long as the centerline of the lifter aligns with the centerline of the cam bore, the angle isn't a factor. The particular angle used in a BBC is to align the lifters with the pushrods for the canted valve head. You know this, I know this, and anybody that sat down and thought about it could understand it.

Now,

If you think the anlge is a factor, please explain. I'm more than willing to learn and listen.

Where did I down talk someone else experience? I think maybe the lack of tone on the internet is making you think I'm downtalking your experience, and I do disagree with the "doomsday" theory on BBC flat tappets but two professionals can disagree. I see no problem with a roller cam and for the customer who has the cash, it has advantages. I just find it hard to believe that all of the sudden something that has worked OK since 1965 isn't viable. I (and I'm sure you) have worked on BBC's with 200,000 miles on them and the cams be OK, as in rebuilding the motor and the cam is still in good enough shape to turn in as a core for regrind.

Other than the location of the main galley, what is different about the oiling system on a BBC, as far as how it oils?

I believe the Gen V BBCs went to the cam placement, and the Bowtie blocks even earlier if my memory is correct.

I also own a small shop specializing in performance work, and nowadays mostly performance GM automatic transmissions.

This was 2 weekends ago, quick project for a long distance customer.

This is the current project. 200-4R swap and fixing the engine built by a race shop. Double roller timing chain rubbing the block, too much compression for a street motor, too aggressive springs for a flat tappet cam, dome hitting the chamber, etc. So yeah, I'm familiar with fixing the problems other "experts" can't get right.

I'm not here to "impress" anyone.

To most viewers here, they have no way of knowing what the real qualifications are of anyone posting on an internet site. I'm well respected on other sites that I frequent I just don't have a big post count here.

#43

Banned

iTrader: (10)

Originally Posted by jakeshoe

Ed,

Not sure why the hostility..

The lifter bores are different. My original post was incorrect and it was brought to my attention. I admitted that. My intent with the original post was that the way the lifter sits on the cam doesn't differ. You could pick any angle around the 360* circumference and as long as the centerline of the lifter aligns with the centerline of the cam bore, the angle isn't a factor. The particular angle used in a BBC is to align the lifters with the pushrods for the canted valve head. You know this, I know this, and anybody that sat down and thought about it could understand it.

Now,

If you think the anlge is a factor, please explain. I'm more than willing to learn and listen.

Not sure why the hostility..

The lifter bores are different. My original post was incorrect and it was brought to my attention. I admitted that. My intent with the original post was that the way the lifter sits on the cam doesn't differ. You could pick any angle around the 360* circumference and as long as the centerline of the lifter aligns with the centerline of the cam bore, the angle isn't a factor. The particular angle used in a BBC is to align the lifters with the pushrods for the canted valve head. You know this, I know this, and anybody that sat down and thought about it could understand it.

Now,

If you think the anlge is a factor, please explain. I'm more than willing to learn and listen.

And again, if you dont know tha track record of BBcs with flat tappets, I assume you dont have near the experience you think you do.

Its more than just a lifter bore issue. Its shitty material issues. It zinc levels in motor oil issues.

Give you a for instance.....About 5 years ago, I built twins for a Sea Ray. 454s. Nothing special about them. At the time, the customer wanted to put new cams in. I told him I wouldnt without going roller. He didnt want to spend the money. We ended up reusing the original cams, taking care to keep the lifters in order.

The engine runs fine to this day. Why? And why is this pertinent? The difference in cam core and lifter materials over the past few years has gone right to ****.

Ever heard of Shubeck? I think I spelled it right. Do a google. They are a lifter company that was born out of nothing more than the fact that most flat tappet lifters are terrible pieces of ****. Their flat tappet lifters are like 600 bucks. Most of the Super Stock drag racers use them.

Originally Posted by jakeshoe

I just find it hard to believe that all of the sudden something that has worked OK since 1965 isn't viable. I (and I'm sure you) have worked on BBC's with 200,000 miles on them and the cams be OK, as in rebuilding the motor and the cam is still in good enough shape to turn in as a core for regrind.

Originally Posted by jakeshoe

Other than the location of the main galley, what is different about the oiling system on a BBC, as far as how it oils?

I believe the Gen V BBCs went to the cam placement, and the Bowtie blocks even earlier if my memory is correct.

I believe the Gen V BBCs went to the cam placement, and the Bowtie blocks even earlier if my memory is correct.

Originally Posted by jakeshoe

I also own a small shop specializing in performance work, and nowadays mostly performance GM automatic transmissions.

This was 2 weekends ago, quick project for a long distance customer

This is the current project. 200-4R swap and fixing the engine built by a race shop. Double roller timing chain rubbing the block, too much compression for a street motor, too aggressive springs for a flat tappet cam, dome hitting the chamber, etc. So yeah, I'm familiar with fixing the problems other "experts" can't get right.

This was 2 weekends ago, quick project for a long distance customer

This is the current project. 200-4R swap and fixing the engine built by a race shop. Double roller timing chain rubbing the block, too much compression for a street motor, too aggressive springs for a flat tappet cam, dome hitting the chamber, etc. So yeah, I'm familiar with fixing the problems other "experts" can't get right.

Originally Posted by jakeshoe

I'm not here to "impress" anyone.

To most viewers here, they have no way of knowing what the real qualifications are of anyone posting on an internet site. I'm well respected on other sites that I frequent I just don't have a big post count here.

To most viewers here, they have no way of knowing what the real qualifications are of anyone posting on an internet site. I'm well respected on other sites that I frequent I just don't have a big post count here.

And its not about post count. I've jumped guys with alot higher post counts when they post some bullshit info or numbers they pull out of their ***. Search my posts. You'll see. Had a really heated debate with a guy not long ago on here. They locked the thread.

We dont need to continue this. We're pretty far off topic, and I dont wanna get this one locked down.

I only hope for the best for the OP.

Take care, Jake, and good luck in your business. Turn out quality and everything else will work itself out.

#45

TECH Resident

iTrader: (14)

Materials may not be as good, I know from my cam grinder that there have been some cheap lifters getting out. They sell Elgin, which I don't believe Elgin manufactures but I've never had issue with them.

One thing I do usually do on a SBC or BBC, for several reasons, is use a reground cam.

It is a proven core if it came out of an engine and isn't flat. We know it is hardened. Cam regrinders ( I use a specific one, and at least in their case) aren't welding up Chevy V8 cam cores for re-use.

But I have also used off the shelf new cams and not had any issues. I've also used 15-40 diesel grade oils in hot rods for years, I was doing this before I even knew what zinc was, just because the diesels see extended service intervals, heavy loads, and I know of a couple of very high milage SBC's that ran it and on teardown needed NOTHING. 250K+ miles in a 4x4 3/4 ton truck and the pistons were even re-used they were in such good shape. This was years ago, but it convinced me that it was good enough oil for me to use.

I guess the future may be motorcycle grade oils. Harley 20W-50?

My personal BBC runs a mild older design flat tappet, I installed it when I freshened it about 3 yrs ago. No issues with it. It had a regrind in it before that with 2-3 years of HARD use. It was still in excellent shape when I pulled it out.

There have been runs of factory defects before. The 4100 was before my time, I haven't messed with them much. I have been under the hood of the 4.5 and 4.9's a bit.

I am well aware of Shubeck. They had a neat product, their more innovative product was the "Roller-X" lifters which were a roller-less lightweight lifter for roller cam setups that could supposedly withstand extreme pressures and no worries of roller bearing failure. Last I heard the company was belly up or at least in some re-structuring.

Their solid flat tappets were supposed to be very light.

I've worked for and with others who have the certs too. For the most part they were brilliant guys. I've been master certified for 10 years (and let it expire), and got the L1 and machinist while I was working at a GM dealership.

If I post something that is misinformation, by all means, call me on it but I don't feel that a BBC with a flat tappet cam is an issue IF you take care of the potential problems. Use quality parts (my main concern is the lifters), do proper assembly lube and break-in, don't use too heavy of a valve spring, take care of the oil issue, and the important one, inspect the lifter bores...

What I have seen is lifter bores that have been burred from someone pulling a lifter out (forcing it) that was high mileage, carboned, had a burr, etc and raised a burr on the lifter bore edge.

Then a typical run of the mill machine shop machines the block, never inspects or hones the lifter bores, and often uses the "shake-n-bake" cleaning method.

Customer assembles the engine, or sometimes even the machine shop, lifter bores are too tight, have a burr, etc, and the lifter has resistance or can't spin, you will have a flat cam in short order. The cam company will get the blame.

I just haven't seen the huge issues with a BBC specifically. I was building about 2 engines a week while in the military and working in a machine shop too for additional income. I did quite a few of the marine BBC's, mostly the 330 hp Mercruiser 454's. I often used the Summit brand generic cams in those or a regrind. I also built who knows how many basic SBC 350 street engines and quite a few circle track motors at that time. I never had ANY issues that I know of.

I honestly got bored/burnt out on the engine building, and started getting into the transmissions and have more or less made that my specialty.

However in the last week I've assembled two engines and I would say I still average about 1 a month these days, usually a more drag racing oriented motor, 400+ cube SBCs and 454-496 BBC's. Many of these are roller setups just because max power is the name of the game.

383 I fixed that was built by a semi-local race engine builder. All types of issues with this one that most backyard builders wouldn't have fouled up

I'm almost done with a 1969 351W for a customer's Mach 1. Just rebuilt to stock specs, nothing fancy.

I've got a 505 BBC that parts all arrived this week that will be getting a solid roller pulled out and a hydraulic flat tappet installed. Customer doesn't want to mess with lash adjustments, valve spring checks and replacing, etc. That one is going to be fun... In car valve spring change with the solid roller valve springs.

You are right about owning your own shop. It is rewarding and frustrating at times.

One thing I do usually do on a SBC or BBC, for several reasons, is use a reground cam.

It is a proven core if it came out of an engine and isn't flat. We know it is hardened. Cam regrinders ( I use a specific one, and at least in their case) aren't welding up Chevy V8 cam cores for re-use.

But I have also used off the shelf new cams and not had any issues. I've also used 15-40 diesel grade oils in hot rods for years, I was doing this before I even knew what zinc was, just because the diesels see extended service intervals, heavy loads, and I know of a couple of very high milage SBC's that ran it and on teardown needed NOTHING. 250K+ miles in a 4x4 3/4 ton truck and the pistons were even re-used they were in such good shape. This was years ago, but it convinced me that it was good enough oil for me to use.

I guess the future may be motorcycle grade oils. Harley 20W-50?

My personal BBC runs a mild older design flat tappet, I installed it when I freshened it about 3 yrs ago. No issues with it. It had a regrind in it before that with 2-3 years of HARD use. It was still in excellent shape when I pulled it out.

There have been runs of factory defects before. The 4100 was before my time, I haven't messed with them much. I have been under the hood of the 4.5 and 4.9's a bit.

I am well aware of Shubeck. They had a neat product, their more innovative product was the "Roller-X" lifters which were a roller-less lightweight lifter for roller cam setups that could supposedly withstand extreme pressures and no worries of roller bearing failure. Last I heard the company was belly up or at least in some re-structuring.

Their solid flat tappets were supposed to be very light.

I've worked for and with others who have the certs too. For the most part they were brilliant guys. I've been master certified for 10 years (and let it expire), and got the L1 and machinist while I was working at a GM dealership.

If I post something that is misinformation, by all means, call me on it but I don't feel that a BBC with a flat tappet cam is an issue IF you take care of the potential problems. Use quality parts (my main concern is the lifters), do proper assembly lube and break-in, don't use too heavy of a valve spring, take care of the oil issue, and the important one, inspect the lifter bores...

What I have seen is lifter bores that have been burred from someone pulling a lifter out (forcing it) that was high mileage, carboned, had a burr, etc and raised a burr on the lifter bore edge.

Then a typical run of the mill machine shop machines the block, never inspects or hones the lifter bores, and often uses the "shake-n-bake" cleaning method.

Customer assembles the engine, or sometimes even the machine shop, lifter bores are too tight, have a burr, etc, and the lifter has resistance or can't spin, you will have a flat cam in short order. The cam company will get the blame.

I just haven't seen the huge issues with a BBC specifically. I was building about 2 engines a week while in the military and working in a machine shop too for additional income. I did quite a few of the marine BBC's, mostly the 330 hp Mercruiser 454's. I often used the Summit brand generic cams in those or a regrind. I also built who knows how many basic SBC 350 street engines and quite a few circle track motors at that time. I never had ANY issues that I know of.

I honestly got bored/burnt out on the engine building, and started getting into the transmissions and have more or less made that my specialty.

However in the last week I've assembled two engines and I would say I still average about 1 a month these days, usually a more drag racing oriented motor, 400+ cube SBCs and 454-496 BBC's. Many of these are roller setups just because max power is the name of the game.

383 I fixed that was built by a semi-local race engine builder. All types of issues with this one that most backyard builders wouldn't have fouled up

I'm almost done with a 1969 351W for a customer's Mach 1. Just rebuilt to stock specs, nothing fancy.

I've got a 505 BBC that parts all arrived this week that will be getting a solid roller pulled out and a hydraulic flat tappet installed. Customer doesn't want to mess with lash adjustments, valve spring checks and replacing, etc. That one is going to be fun... In car valve spring change with the solid roller valve springs.

You are right about owning your own shop. It is rewarding and frustrating at times.

#53

Launching!

Join Date: Feb 2006

Location: North Star, Ohio

Posts: 216

Likes: 0

Received 0 Likes

on

0 Posts

*sigh*...

First off, don't let these guys scare you about the non-roller cams. While it is true that the cores being used today are much softer and prone to wiped lobes, they are not as hopeless as this bunch makes it sound. No offense but if you guys are having such big problems then you should be the ones rethinking your process, cause you're obviouslly not doing something right. Thousands of cams are installed daily in BBC's and live just fine.

Theres a few simple things you can do to help better your odds when breaking in your non-roller cam.

Since GM discontinued E.O.S, I recommend this http://www.acdelco.com/html/pi_vehcare_lub.htm

Also make sure you use a Moly based lube for your break in. They are the best for the first few minutes.

Zinc, zddp, and phosphrous (if that's not the same as zddp) are important additives, creating a "sacrificial barrier" between the lifter and camshaft that is vital to the cam's longevity

Most modern oils are contributing to these cam failures. The lower zinc levels are the culprit. Valvolines racing oil (not the stuff sol in stores) has high levels of zinc. Shell rotella also has high zinc content, though I have heard even they are reformulating their oils to reduce zinc levels.

If you want to save a few bucks and still get the good stuff, check out Napas 20/50 oil. I've heard from many including some napa employees that is nothing more than repackaged Valvoline VR-1 oil. Redline oils also have the right amount of zddp.

As I said, if you follow the accepted break in procedure and have a quality oil with high zinc content, you will 99% of the time be fine. Also the advice about removing the inner springs is wise advice and cheap insurance. Otherwise I wouldn't fret over it despite what you are told on here.

First off, don't let these guys scare you about the non-roller cams. While it is true that the cores being used today are much softer and prone to wiped lobes, they are not as hopeless as this bunch makes it sound. No offense but if you guys are having such big problems then you should be the ones rethinking your process, cause you're obviouslly not doing something right. Thousands of cams are installed daily in BBC's and live just fine.

Theres a few simple things you can do to help better your odds when breaking in your non-roller cam.

Since GM discontinued E.O.S, I recommend this http://www.acdelco.com/html/pi_vehcare_lub.htm

Also make sure you use a Moly based lube for your break in. They are the best for the first few minutes.

Zinc, zddp, and phosphrous (if that's not the same as zddp) are important additives, creating a "sacrificial barrier" between the lifter and camshaft that is vital to the cam's longevity

Most modern oils are contributing to these cam failures. The lower zinc levels are the culprit. Valvolines racing oil (not the stuff sol in stores) has high levels of zinc. Shell rotella also has high zinc content, though I have heard even they are reformulating their oils to reduce zinc levels.

If you want to save a few bucks and still get the good stuff, check out Napas 20/50 oil. I've heard from many including some napa employees that is nothing more than repackaged Valvoline VR-1 oil. Redline oils also have the right amount of zddp.

As I said, if you follow the accepted break in procedure and have a quality oil with high zinc content, you will 99% of the time be fine. Also the advice about removing the inner springs is wise advice and cheap insurance. Otherwise I wouldn't fret over it despite what you are told on here.

#54

Banned

iTrader: (10)

Originally Posted by 383LT1S10

*sigh*...

First off, don't let these guys scare you about the non-roller cams. While it is true that the cores being used today are much softer and prone to wiped lobes, they are not as hopeless as this bunch makes it sound. No offense but if you guys are having such big problems then you should be the ones rethinking your process, cause you're obviouslly not doing something right. Thousands of cams are installed daily in BBC's and live just fine.

Theres a few simple things you can do to help better your odds when breaking in your non-roller cam.

Since GM discontinued E.O.S, I recommend this http://www.acdelco.com/html/pi_vehcare_lub.htm

Also make sure you use a Moly based lube for your break in. They are the best for the first few minutes.

Zinc, zddp, and phosphrous (if that's not the same as zddp) are important additives, creating a "sacrificial barrier" between the lifter and camshaft that is vital to the cam's longevity

Most modern oils are contributing to these cam failures. The lower zinc levels are the culprit. Valvolines racing oil (not the stuff sol in stores) has high levels of zinc. Shell rotella also has high zinc content, though I have heard even they are reformulating their oils to reduce zinc levels.

If you want to save a few bucks and still get the good stuff, check out Napas 20/50 oil. I've heard from many including some napa employees that is nothing more than repackaged Valvoline VR-1 oil. Redline oils also have the right amount of zddp.

As I said, if you follow the accepted break in procedure and have a quality oil with high zinc content, you will 99% of the time be fine. Also the advice about removing the inner springs is wise advice and cheap insurance. Otherwise I wouldn't fret over it despite what you are told on here.

First off, don't let these guys scare you about the non-roller cams. While it is true that the cores being used today are much softer and prone to wiped lobes, they are not as hopeless as this bunch makes it sound. No offense but if you guys are having such big problems then you should be the ones rethinking your process, cause you're obviouslly not doing something right. Thousands of cams are installed daily in BBC's and live just fine.

Theres a few simple things you can do to help better your odds when breaking in your non-roller cam.

Since GM discontinued E.O.S, I recommend this http://www.acdelco.com/html/pi_vehcare_lub.htm

Also make sure you use a Moly based lube for your break in. They are the best for the first few minutes.

Zinc, zddp, and phosphrous (if that's not the same as zddp) are important additives, creating a "sacrificial barrier" between the lifter and camshaft that is vital to the cam's longevity

Most modern oils are contributing to these cam failures. The lower zinc levels are the culprit. Valvolines racing oil (not the stuff sol in stores) has high levels of zinc. Shell rotella also has high zinc content, though I have heard even they are reformulating their oils to reduce zinc levels.

If you want to save a few bucks and still get the good stuff, check out Napas 20/50 oil. I've heard from many including some napa employees that is nothing more than repackaged Valvoline VR-1 oil. Redline oils also have the right amount of zddp.

As I said, if you follow the accepted break in procedure and have a quality oil with high zinc content, you will 99% of the time be fine. Also the advice about removing the inner springs is wise advice and cheap insurance. Otherwise I wouldn't fret over it despite what you are told on here.

And its a wide spread problem, documented by machine shop after machine shop.

There are lotsa reasons, most have been covered here.

Cam cores, lifter material, oils, lifter bore problems. They all add up to conspire against you. To me its a risk not worth taking. Simple as that.....

#55

TECH Fanatic

iTrader: (2)

Join Date: Nov 2006

Location: Aztec, NM

Posts: 1,360

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by edcmat-l1

*sigh*....

And its a wide spread problem, documented by machine shop after machine shop.

There are lotsa reasons, most have been covered here.

Cam cores, lifter material, oils, lifter bore problems. They all add up to conspire against you. To me its a risk not worth taking. Simple as that.....

And its a wide spread problem, documented by machine shop after machine shop.

There are lotsa reasons, most have been covered here.

Cam cores, lifter material, oils, lifter bore problems. They all add up to conspire against you. To me its a risk not worth taking. Simple as that.....

#60

what a great thread! I personally would love to see other member's shops and current projects, but it might be a problem if they're not a sponsor. This Guy's Garage is one of my favorite sections in Car Craft and this thread turned into that real quick.

Ed, Jake - looks like an agree to disagree situation here- its nice to see professionals who act like it.

Ed, Jake - looks like an agree to disagree situation here- its nice to see professionals who act like it.

Especially 396s. Too small for their weight

Especially 396s. Too small for their weight