Torque arm relocation fitment question

#1

I currently have a Spohn tunnel mount adjustable torque arm.

Mods - see link.

American racing headers with their cats and and merge pipe(s) attached to a Magnaflow catback.

Peformabilt A4

PST 3 1/2 inch aluminum driveshaft.

I am tired of the clunk when the auto loads and unloads and also the whine transmitted from the rearend because of the Spohn torque arm. It has been modified with their spherical delrin joint as well.

Whine and clunking occurred immediatly after installing with stock 10 bolt. Removed and installed a Moser. Whine clunking got worse.

Removed and re-installed a heavily modified 10 bolt again. Whine still perisists (3.23 motive gears).

I can deal with the whine but want to get rid of the clunking so am considering the BMR tunnel mounted Torque arm. My concern is clearance because of the design of the American racing exhaust pipes where they merge.

I have spoken to Erik at BMR - he seems to think that their kit will fit. Not to doubt but when I compare the tunnel mount of the Spohn (curved at bottom to accomodate AR exhaust pipe end) and the straight BMR bracket I don't think it will clear.

https://www.bmrsuspension.com/?page=...481&superpro=0

My Spohn kit - note curve on bracket.

BTW - there is no up or down adjustment for the AR exhaust pipe where it merges.

Anybody out there who has the BMR kit (TA013) as well as American racing headers and does the BMR TA013 kit fit without rubbing or touching the BRM straight lower tubes of their tunnel mount bracket?

Mods - see link.

American racing headers with their cats and and merge pipe(s) attached to a Magnaflow catback.

Peformabilt A4

PST 3 1/2 inch aluminum driveshaft.

I am tired of the clunk when the auto loads and unloads and also the whine transmitted from the rearend because of the Spohn torque arm. It has been modified with their spherical delrin joint as well.

Whine and clunking occurred immediatly after installing with stock 10 bolt. Removed and installed a Moser. Whine clunking got worse.

Removed and re-installed a heavily modified 10 bolt again. Whine still perisists (3.23 motive gears).

I can deal with the whine but want to get rid of the clunking so am considering the BMR tunnel mounted Torque arm. My concern is clearance because of the design of the American racing exhaust pipes where they merge.

I have spoken to Erik at BMR - he seems to think that their kit will fit. Not to doubt but when I compare the tunnel mount of the Spohn (curved at bottom to accomodate AR exhaust pipe end) and the straight BMR bracket I don't think it will clear.

https://www.bmrsuspension.com/?page=...481&superpro=0

My Spohn kit - note curve on bracket.

BTW - there is no up or down adjustment for the AR exhaust pipe where it merges.

Anybody out there who has the BMR kit (TA013) as well as American racing headers and does the BMR TA013 kit fit without rubbing or touching the BRM straight lower tubes of their tunnel mount bracket?

#2

Launching!

iTrader: (6)

Join Date: Nov 2014

Location: Spring TX

Posts: 271

Likes: 0

Received 0 Likes

on

0 Posts

I am also running AR 1 7/8, their catless y-pipe, and a Magnaflow cat back. I also am using a short TA so our set ups are pretty similar but I am using BMRs TA. I fought this battle too. Originally I had a UMI TA set up which was really nice and their TA bracket cleared everything very nicely but dropped too low where it cleared the exhaust and it hit on everything (my car is lowered 1.25"-ish). I sold that set up on here and bought the BMR set up that I run now.

In my experience the TA013 kit will not work. Its not going to clear your exhaust. I went with the TA012. With that kit the TA mounting bracket runs over the exhaust instead of under it. Its pretty nice because it does not reduce the ground clearance.

It did cause another issue though as it was a tight fit. The exhaust pipe was binding up and touching the TA mounting bracket. That obviously transmitted quite a bit of noise into the cabin. I took it to the guy who does my exhaust stuff (I dont know how to weld ) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

My S60 is as quiet as a mouse so no issue with whine.

In my experience the TA013 kit will not work. Its not going to clear your exhaust. I went with the TA012. With that kit the TA mounting bracket runs over the exhaust instead of under it. Its pretty nice because it does not reduce the ground clearance.

It did cause another issue though as it was a tight fit. The exhaust pipe was binding up and touching the TA mounting bracket. That obviously transmitted quite a bit of noise into the cabin. I took it to the guy who does my exhaust stuff (I dont know how to weld

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.My S60 is as quiet as a mouse so no issue with whine.

Last edited by Mike TA; 07-27-2017 at 11:55 AM.

#3

Launching!

iTrader: (6)

Join Date: Nov 2014

Location: Spring TX

Posts: 271

Likes: 0

Received 0 Likes

on

0 Posts

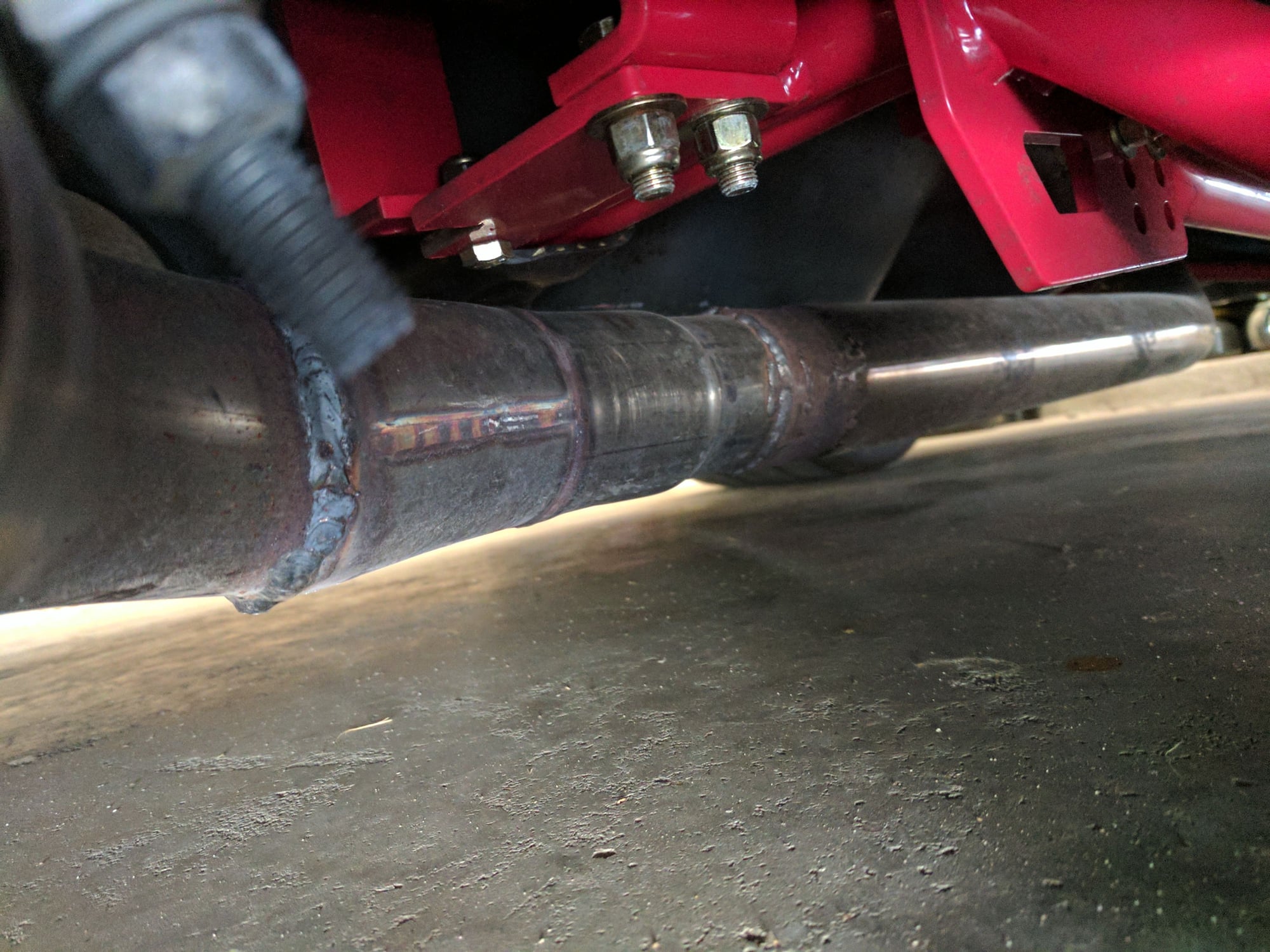

Didnt have any pics so I just crawled under it real fast.

If you look at that last picture you can see where originally I had to cut a chunk off of the driveshaft loop mounting bracket. That is where the exhaust was bound up. It was so tight that I was afraid that corner was going to wear a hole in the exhaust pipe. Now it clears fine. I have a new bracket to replace it but it honestly hasnt given me any trouble so I let it ride. Next time I have to get under the car I will probably switch it out.

#4

I am also running AR 1 7/8, their catless y-pipe, and a Magnaflow cat back. I also am using a short TA so our set ups are pretty similar but I am using BMRs TA. I fought this battle too. Originally I had a UMI TA set up which was really nice and their TA bracket cleared everything very nicely but dropped too low where it cleared the exhaust and it hit on everything (my car is lowered 1.25"-ish). I sold that set up on here and bought the BMR set up that I run now.

In my experience the TA013 kit will not work. Its not going to clear your exhaust. I went with the TA012. With that kit the TA mounting bracket runs over the exhaust instead of under it. Its pretty nice because it does not reduce the ground clearance.

It did cause another issue though as it was a tight fit. The exhaust pipe was binding up and touching the TA mounting bracket. That obviously transmitted quite a bit of noise into the cabin. I took it to the guy who does my exhaust stuff (I dont know how to weld ) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

In my experience the TA013 kit will not work. Its not going to clear your exhaust. I went with the TA012. With that kit the TA mounting bracket runs over the exhaust instead of under it. Its pretty nice because it does not reduce the ground clearance.

It did cause another issue though as it was a tight fit. The exhaust pipe was binding up and touching the TA mounting bracket. That obviously transmitted quite a bit of noise into the cabin. I took it to the guy who does my exhaust stuff (I dont know how to weld

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.

) and the solution was pretty simple but I am not sure if I can explain it well. Basically, he made a cut on each side of the y-pipe and rotated everything down a little so that it didnt bind up on the TA mount. I also wrapped that side on the mount in heavy rubber hose in case it ended up making contact which it hasnt. I have had it like that for a year with no issues. I think he charged me $30 to fix the exhaust. No banging and Im no longer getting exhaust noise transmitted through the TA. I will trying to see if I have any pics to post.The BMR TA013 I think would provide enough clearance if the horizontal tubes were flat bar steel (at least 1/2 inch) but perhaps tubing has more structural integrity than a flat piece of 1/4 bar steel.

Adding two pieces of flat bar steel or aluminum between the floor mounting bracket perhaps would allow about another 1/4 inch of clearance with the TA013 and yet not drop the bracket down too much. As you can see the Spohn TA also hits speed bumps etc. Thankfully I haven't knocked it off yet.

I have Koni adjustable shocks in front which lowered the car about 3/4 inch and Sam Strano lowering spring on the rear lowering the car about an 1 inch plus.

Going back the the stock transmission mounted TA is out because of my hp level (565 rwhp). I don't want to break the transmission tailshaft.

I also have an oversized driveshaft - PST 3.5 inches so the mounting pedestal on the TA013 might be an issue too even without the optional driveshaft loop.

Finding a good exhaust welder based on past experience - I don't even want to go there about some of the past welding jobs done on two previous exhaust systems. I didn't appreciate the BFH method used to get some clearance by one shop.

The American racing and Magnaflow system I have now is excellent and I want to leave it that way.

BTW - Spohn doesn't make a compatible front bracket like mine for a TA that is similar to the UMI and BMR brackets (TA013 and TA012) that slide vs the pivit joint on front of Spohn TA that is causing clunking when it loads and unloads under power.

#5

Launching!

iTrader: (6)

Join Date: Nov 2014

Location: Spring TX

Posts: 271

Likes: 0

Received 0 Likes

on

0 Posts

I also thought about just having some fabrication changes to the TA mounting bracket but after visiting my exhaust guy what we did seemed like the best and most cost effective options. I wouldn't want anyone putting a hammer to the bottom of my car either, especially if it looked as clean as yours. I am with you on the exhaust set up, I love mine. It sounds great at idle and bad *** at WOT. I am not a huge fan of really damn loud exhaust and I love this set up. Unfortunately it seems that there just really isn't a true bolt-on-and-go tunnel mounted TA set up for this though. Everything requires some modification somewhere. Post back up if you find a solution. I would love to see it.

#6

I suppose one could order the BMR TA013 front bracket and cut off the veritical

TA mounting bracket and butcher the same on my Spohn bracket leaving just the horizontal tubes from the Spohn. But very expensive.

Then marry the two together - Spohn tubes on the bottom and BMR mounting bracket welded to it. Too bad BMR doesn't bend the horizontal tubes like my Spohn tubes.

Or Spohn make two versions - one with a pivot mount like I currently have and another using the clamshell design like the BMR (getting rid of the clunk as the joint loads and unloads).

Or BMR make two versions - one with the tubes straight like their TA013 and another with the tubes bent down like the Spohn.

TA mounting bracket and butcher the same on my Spohn bracket leaving just the horizontal tubes from the Spohn. But very expensive.

Then marry the two together - Spohn tubes on the bottom and BMR mounting bracket welded to it. Too bad BMR doesn't bend the horizontal tubes like my Spohn tubes.

Or Spohn make two versions - one with a pivot mount like I currently have and another using the clamshell design like the BMR (getting rid of the clunk as the joint loads and unloads).

Or BMR make two versions - one with the tubes straight like their TA013 and another with the tubes bent down like the Spohn.

Trending Topics

#8

LS1Tech Premium Sponsor

iTrader: (40)

It's difficult with these, I have seen it work both ways with ARH headers. They seem to fall right in the same real estate that our crossmember uses. Most long tubes hang lower and most stock exhausts run higher. I have had people run the TA011/TA103 style crossmember and space it down a little, and I have had some like Mike TA posted and run the TA012/TA014 style crossmember with some modification to the y pipe.

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

#9

It's difficult with these, I have seen it work both ways with ARH headers. They seem to fall right in the same real estate that our crossmember uses. Most long tubes hang lower and most stock exhausts run higher. I have had people run the TA011/TA103 style crossmember and space it down a little, and I have had some like Mike TA posted and run the TA012/TA014 style crossmember with some modification to the y pipe.

Maybe BMR can do the same with their TA013 and we can compare. It might be closed enough where two 1/4 to 5/16 inch bar steel plates mounted between the crossmember and the tunnel mount brackets would lower the crossmember just enough for clearance for my ARH y pipe.

I have a Miller Plasma cutter so making the plates isn't difficult. But removing the crossmember tubes and welding in a staight 1/4 - 3/8 inch of flat bar steel that would replace the crossmember tubes would gain at least an additional 1/2 inch of clearance - but that would require a professional welder. And would it be as strong as the tubes - don't know?

I might have to bite the bullet and order the TA013 and then modify it with the tubes off of the Spohn crossmember.

#10

LS1Tech Premium Sponsor

iTrader: (40)

I think we may still have some spacer left from the first design of these crossmembers. They were 1/4" thick aluminum. If I still have some I can include them with yours to save you some work. As for the noise reduction though, you will definitely see a difference in that due to the difference in bushing design.

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

#11

I think we may still have some spacer left from the first design of these crossmembers. They were 1/4" thick aluminum. If I still have some I can include them with yours to save you some work. As for the noise reduction though, you will definitely see a difference in that due to the difference in bushing design.

One way or another I am sure I can get your kit (TA013) to work.