Does Anyone Make Drop Spindles For Our Cars?

#2

12 Second Club

iTrader: (5)

Join Date: Aug 2002

Location: Middleville, Michigan

Posts: 1,789

Likes: 0

Received 0 Likes

on

0 Posts

I hope you like running 22's on your car then. There's not 1.5" of room between the lower control arm and the wheel with 17's. How do you plan on making cast iron spindles? You got a factory in your basement to make a mold and pour the molten iron?

#3

Man, your getting a little irritating. I'm not being funny, I'm dead serious. I'm not running 22's, I'm running 19's. As you can see in this pic I have plenty of room for a mere 1.5" drop.

I am also not going to cast new spindles. I don't even know why you would think such a thing. Maybe if my last name was Edelbrock, but it's not. I have a plan that may utilize the stock spindles, but it would change the camber curve. I also have another idea, but it would require cutting and welding on the upper part of the spindle. Nothing is finalized yet.

I am also not going to cast new spindles. I don't even know why you would think such a thing. Maybe if my last name was Edelbrock, but it's not. I have a plan that may utilize the stock spindles, but it would change the camber curve. I also have another idea, but it would require cutting and welding on the upper part of the spindle. Nothing is finalized yet.

#7

12 Second Club

iTrader: (5)

Join Date: Aug 2002

Location: Middleville, Michigan

Posts: 1,789

Likes: 0

Received 0 Likes

on

0 Posts

You're capable of asking a lot of dumb questions. If you're so smart, DO IT then show us what you did. You have to watch the clearance issues with your tie rod arm when you move the where the hub mounts on the spindle. If you move the wheel up 1.5" you'll have the tie rod end closer to the wheel. With your 19's you may have more room. All the drop and lift spindles I have ever seen are of cast iron material. I don't see how you're going to modify your stock spindle and move it up 1.5" and then somehow weld it back together. You'd have more luck spacing the lower ball joint up and figuring out a way to flip the ball joint to the top on the upper spindle. But then you'd have clearance issues with the top of the fenderwell. If you think you can do it, go for it and show us when you're done. I don't know you but I know you come up with a LOT of goofy ideas and I've YET to see ONE of them be completed.

Trending Topics

#8

I didn't plan this thread to go into detail about how I'm going to make them. I just wanted to know what was out there already.

I just thought of this like 2 days ago, so I can't just "do it" when I get the urge. It takes a lot of thought, measuring, experimenting, etc... to even make sure it's going to work. Then what if I find out some company X already makes them. Well, I'd have wasted my time wouldn't I?

I get a lot of ideas all the time, but most get shot down. Some have a poor cost/benefit/performance ratio. Some are real good, like the 14"rotor/4 piston Brembo front brake idea, but sometimes my money gets low. Right now my rear end just went out, so my brake money will probably go towards that. Very few ideas actually make it to the car. The last idea that actually made it were the 19" rims I put on last week. More info here:

https://ls1tech.com/forums/wheels-tires/687848-my-adventures-moving-19-c6-s.html

It is due to the rims that I decided to go with the big brakes. Due to the short sidewalls I decided I want to squeeze out 1.5" of additional travel on the compression side just as a precaution in case I hit a bump or pothole at speed. Due to the larger brakes I needed to come up with a different spare tire to fit over them. This led to a full sized 19" spare. This led to me redesigning my subwoofer setup to make room for the larger spare.

Plus I have tons of ideas for non-suspension related items. I work full time and get little time to mess with this stuff, but I do what I can and with what money I have.

As for the drop spindle design. One potential way IS with a taller lower balljoint. I still haven't found one yet, so I may have to modify the actual spindle. It depends on what I can find and whether or not I can find a good welder for these particular metals. I can't just crank up the MIG and go to town. It's a special welding process that I'm not capable of. I'm talking to welders right now about it.

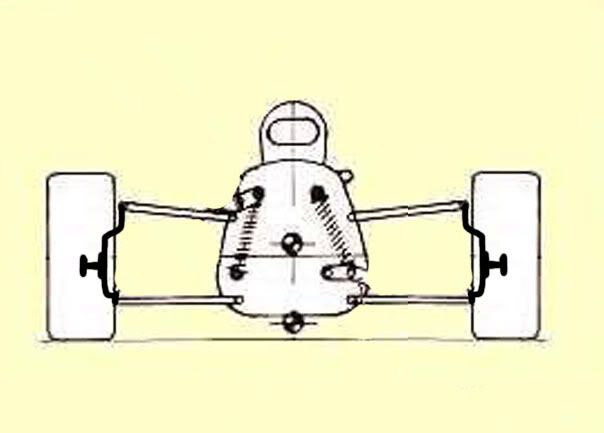

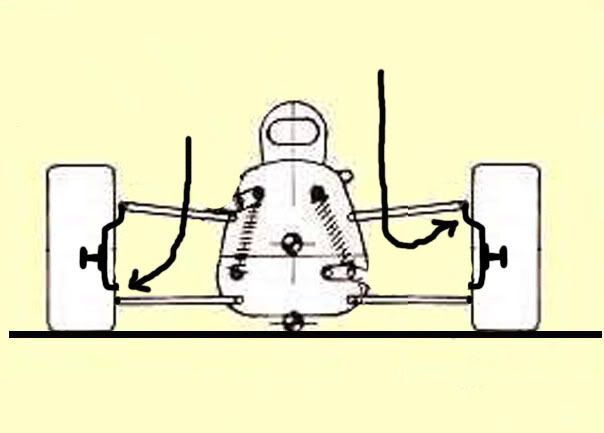

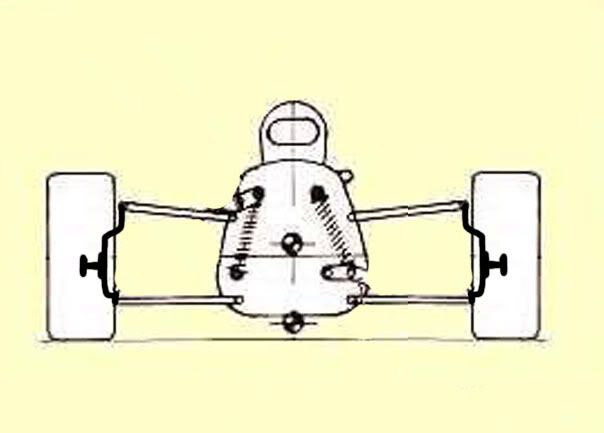

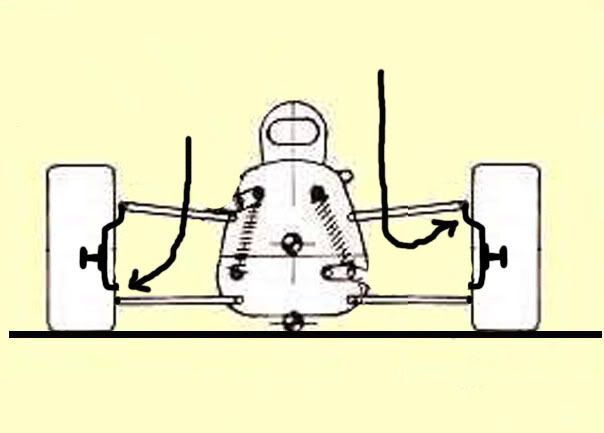

I basically want to raise the spindle 1.5" above the balljoint pivot. If I can then shorten the top of the spindle 1.5" the geometry will remain the same. The tie rods can be left alone as I know they are fine with a 2" drop, but if I wanted to I could add a bumpsteer kit.

Go from this:

To this:

And yes, I plan to brace the front subframe and then cut into the metal fenders up front to gain an extra 1.5" of room for the tire to tuck into the fender.

I just thought of this like 2 days ago, so I can't just "do it" when I get the urge. It takes a lot of thought, measuring, experimenting, etc... to even make sure it's going to work. Then what if I find out some company X already makes them. Well, I'd have wasted my time wouldn't I?

I get a lot of ideas all the time, but most get shot down. Some have a poor cost/benefit/performance ratio. Some are real good, like the 14"rotor/4 piston Brembo front brake idea, but sometimes my money gets low. Right now my rear end just went out, so my brake money will probably go towards that. Very few ideas actually make it to the car. The last idea that actually made it were the 19" rims I put on last week. More info here:

https://ls1tech.com/forums/wheels-tires/687848-my-adventures-moving-19-c6-s.html

It is due to the rims that I decided to go with the big brakes. Due to the short sidewalls I decided I want to squeeze out 1.5" of additional travel on the compression side just as a precaution in case I hit a bump or pothole at speed. Due to the larger brakes I needed to come up with a different spare tire to fit over them. This led to a full sized 19" spare. This led to me redesigning my subwoofer setup to make room for the larger spare.

Plus I have tons of ideas for non-suspension related items. I work full time and get little time to mess with this stuff, but I do what I can and with what money I have.

As for the drop spindle design. One potential way IS with a taller lower balljoint. I still haven't found one yet, so I may have to modify the actual spindle. It depends on what I can find and whether or not I can find a good welder for these particular metals. I can't just crank up the MIG and go to town. It's a special welding process that I'm not capable of. I'm talking to welders right now about it.

I basically want to raise the spindle 1.5" above the balljoint pivot. If I can then shorten the top of the spindle 1.5" the geometry will remain the same. The tie rods can be left alone as I know they are fine with a 2" drop, but if I wanted to I could add a bumpsteer kit.

Go from this:

To this:

And yes, I plan to brace the front subframe and then cut into the metal fenders up front to gain an extra 1.5" of room for the tire to tuck into the fender.

#9

It's amazing that a simple question turns into me typing for what seems like an hour going into all kinds of details I never wanted to get into here. A simple "yeah, so and so makes them" or "nope, never seen them for our cars" would suffice.

Just be glad I'm not focussing my attention on how to build these cars:

https://ls1tech.com/forums/showpost....2&postcount=20

Just be glad I'm not focussing my attention on how to build these cars:

https://ls1tech.com/forums/showpost....2&postcount=20

#10

12 Second Club

iTrader: (5)

Join Date: Aug 2002

Location: Middleville, Michigan

Posts: 1,789

Likes: 0

Received 0 Likes

on

0 Posts

DONK's are more about looks than actual safety and drive ability. I would be scared to see what kind of mods they did to get that thing up that high. There are no dropped spindles for our cars. There are for the 67-81 cars since they have a more traditional spindle setup and are shared across other GM cars so there are multiple fit applications for the investment of creating a dropped spindle. Our cars are unique and there isn't a demand to go that low when you can find lowering springs all day that give from 3/4" - 2" of drop. Are you planning on running stock height springs or lowered springs? I don't see what you're trying to accomplish with all this extra work.

After looking at my car you're going to have to relocate the fuse boxes underhood to gain any type of clearance in the area you're talking about in front of the strut tower. You're looking at basically reconstructing the entire front suspension and unibody structure. I honestly don't see the point of all this work for a slight increase in suspension travel on a street car.

After looking at my car you're going to have to relocate the fuse boxes underhood to gain any type of clearance in the area you're talking about in front of the strut tower. You're looking at basically reconstructing the entire front suspension and unibody structure. I honestly don't see the point of all this work for a slight increase in suspension travel on a street car.

#11

Yeah, I realize there isn't a real demand for these, plus the cars are out of production so we'll probably never see dropped spindles in the future. I was pretty sure no one made any, but I just wanted to ask first.

Right know I have the GC coilovers and Koni SA shocks.

http://img.photobucket.com/albums/v3...A/5a76fbce.jpg

The issue with them is not the spring, but the shock. It has internal stops that prevent the shock from compressing too much. I basically need it to compress more than it does right now in order to get the extra travel I want. Now I can modify the upper mount, the lower mount or shorten the shock. The drop spindle idea was suggested to me, but I blew it off. Later I started really thinking about it. I had a set on my old Chevy PU and they were great. I was low on stock springs and it rode real nice. It's pretty much perfect.

I won't have to move any fuse boxes. I'll just cut a flap of metal about 16" long right above the tire and push it up. I can then weld it back in place if I want to. In honesty, I'd rather just cut out the room I need and leave it like that and then add some cross bracing for the front subframe. The way these cars are put together there has to be some flex already there. Even if I weren't cutting the fenders I would still add the braces. It's kind of like adding a SFC. The car will function without them, but when you stiffen the unibody it allows the suspension to work so much better and feel more stable.

If you don't understand why I would want to do all this work, then that's OK. You can't understand all human nature. We'll just leave it at that.

Oh yeah, I did find a guy here in Houston who can do the welding. It's probably made of 4140 cast steel, but he'll have to see it first to make sure. He specializes in heliarc welding exotic metals and he has done several one off projects like this for other folks. He doesn't charge much either. Shortening the spindles would probably run about $50ea. If I can get the taller ball joints, I'll use them. If not, I can fab up a new lower mount or lower the existing one. Either way, I'm getting closer to a solution.

Right know I have the GC coilovers and Koni SA shocks.

http://img.photobucket.com/albums/v3...A/5a76fbce.jpg

The issue with them is not the spring, but the shock. It has internal stops that prevent the shock from compressing too much. I basically need it to compress more than it does right now in order to get the extra travel I want. Now I can modify the upper mount, the lower mount or shorten the shock. The drop spindle idea was suggested to me, but I blew it off. Later I started really thinking about it. I had a set on my old Chevy PU and they were great. I was low on stock springs and it rode real nice. It's pretty much perfect.

I won't have to move any fuse boxes. I'll just cut a flap of metal about 16" long right above the tire and push it up. I can then weld it back in place if I want to. In honesty, I'd rather just cut out the room I need and leave it like that and then add some cross bracing for the front subframe. The way these cars are put together there has to be some flex already there. Even if I weren't cutting the fenders I would still add the braces. It's kind of like adding a SFC. The car will function without them, but when you stiffen the unibody it allows the suspension to work so much better and feel more stable.

If you don't understand why I would want to do all this work, then that's OK. You can't understand all human nature. We'll just leave it at that.

Oh yeah, I did find a guy here in Houston who can do the welding. It's probably made of 4140 cast steel, but he'll have to see it first to make sure. He specializes in heliarc welding exotic metals and he has done several one off projects like this for other folks. He doesn't charge much either. Shortening the spindles would probably run about $50ea. If I can get the taller ball joints, I'll use them. If not, I can fab up a new lower mount or lower the existing one. Either way, I'm getting closer to a solution.

Last edited by JasonWW; 04-12-2007 at 12:28 PM.

#15

12 Second Club

iTrader: (5)

Join Date: Aug 2002

Location: Middleville, Michigan

Posts: 1,789

Likes: 0

Received 0 Likes

on

0 Posts

A drop spindle is the hub is moved up higher on the actual spindle. It's common on trucks to lower them and they are now offering them for many older muscle cars. No one home makes them though. They need to be cast from iron generally.

#16

Originally Posted by GETGONE

You just stated that your shocks are your limiting factor. How are you going to get around that?

Now I want to cut out the sheetmetal an extra 1.5" of space for the tire to go up into. When I install the 1.5" drop spindle, my car will be super low and have 0.5" of space from the tire to the factory sheetmetal. I will them raise the car back up through the spring adjustment so that I am back to having a 2" gap. Now the suspension geometry and spring length will almost be stock, but it will have the ability to put the tire 1.5" higher than it did before. So then I will cut out the sheetmetal in the fenders. Does that make sense?

It's like taking a stock car and installing the drop spindles. The car will sit 1.5" lower with no change in the suspension. The upper and lower shock mounts and the shock itself can stay the same, stock, Koni, Bilstein, whatever. Only the tire moves up or the car moves down depending on how you look at it. It really is very simple and it's an ideal way to lower a car.

As far as expense, I think I may get a set of LT1 spindles super cheap and cut off the brake lugs as I won't need then anyway. So that's maybe $30. Then have the upper section cut and welded at $50ea. So now I'm up to $130. If I'm lucky I can get some taller lower balljoints for under $80 each and install them myself. This would bring the cost to $290. If I can't find the balljoints I will have to weld on the bottom of the spindle which may run about the same as the balljoints. So we are talking roughly $300. This would be a bargain for drop spindles. I think the Belltech drop spindles I bought for my truck were about $350 back in the day. I think $300 would be extremely cheap for fabricating a drop spindle.

#17

The end result of doing these mods will allow an extremely low ride height should I choose to lower it some more as well as offer a very smooth ride at that lower height.

Here's are some pics of my car with the fender lips at 25".

I could return my car to this ride height and STILL have a 1/2 inch more suspension travel than I do right now. This would be insane. No one has a smooth ride at these heights. Plus the suspension geometry would be fine. This is pretty much unheard of.

No one has a smooth ride at these heights. Plus the suspension geometry would be fine. This is pretty much unheard of.

Here's are some pics of my car with the fender lips at 25".

I could return my car to this ride height and STILL have a 1/2 inch more suspension travel than I do right now. This would be insane.

No one has a smooth ride at these heights. Plus the suspension geometry would be fine. This is pretty much unheard of.

No one has a smooth ride at these heights. Plus the suspension geometry would be fine. This is pretty much unheard of. Last edited by JasonWW; 04-12-2007 at 08:12 PM.

#18

Can you imagine my car with these rims being lowered another 1 to 1.5 inches? Other than scraping on stuff, it would be fine.

In reality I'll probably only lower it 1/2" or so more.

My car would be able to go 1.5" lower than this attached picture at full droop.

In reality I'll probably only lower it 1/2" or so more.

My car would be able to go 1.5" lower than this attached picture at full droop.

Last edited by JasonWW; 04-12-2007 at 08:58 PM.

#19

12 Second Club

iTrader: (24)

Join Date: Jan 2005

Location: Olathe, KS

Posts: 562

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by JasonWW

Here's are some pics of my car with the fender lips at 25".

Sorry Jason, but that is the sickest ride height/stance I've seen.

Although, my heart truly lies with slicks/skinnies and a slight rake. If I could afford to have an F-bod for drag, and another for cruising/street that is exactly how I would have it sitting.

Although, my heart truly lies with slicks/skinnies and a slight rake. If I could afford to have an F-bod for drag, and another for cruising/street that is exactly how I would have it sitting.

#20

Yeah, it really did look awesome. Unfortunetely there wasn't enough suspension travel to ride well. I only had it at this height for one day, then I raised it up one inch. If I do the mods I want I can lower it back down again and have a nice smooth ride.

Going up and down steep driveways was the only down side. Most can be attacked at a 45* angle, but on some you will just scrape. There is no way to avoid it. I am considering doing like the vettes and mounting some rollers near the front and rear attached to the chassis. This would keep me from scraping the nose and tail. I could also probably make some skid rails as well to protect the underside. This would make the car very practical to drive since it is my daily driver. I'll have to consider this later on, though.

Going up and down steep driveways was the only down side. Most can be attacked at a 45* angle, but on some you will just scrape. There is no way to avoid it. I am considering doing like the vettes and mounting some rollers near the front and rear attached to the chassis. This would keep me from scraping the nose and tail. I could also probably make some skid rails as well to protect the underside. This would make the car very practical to drive since it is my daily driver. I'll have to consider this later on, though.