Air Ride Using YOUR Front Shocks for $350

#61

TECH Enthusiast

iTrader: (15)

BTW the plane in my avatar does individual kneeling of each landing gear independently, or you can kneel the entire jet forward or backwards for loading. I do it all the time but it is a whole different ballgame. It works with hydraulic driven motors that turn jackscrews, and the struts are pneudraulic.

If someone is interested in using a similiar setup LMK

Once again sorry for

If someone is interested in using a similiar setup LMK

Once again sorry for

#63

Don't mean to hijack but bare with me, (novice)

i want ride approx 1"-1.5" lower all the time

i want to be able to lift for driveways (hell even higher than stock would be nice)

couldn't care less about "laying frame"

don't want handling like a waterbed

air ride technologies is to expensive

yes or no, is this a viable/practical/economical option?

i want ride approx 1"-1.5" lower all the time

i want to be able to lift for driveways (hell even higher than stock would be nice)

couldn't care less about "laying frame"

don't want handling like a waterbed

air ride technologies is to expensive

yes or no, is this a viable/practical/economical option?

I did find a pretty neat device that works with coilover springs that will raise a lowered car up without effecting the spring rate or anything else. They are kind of pricy and are mostly used on exotic cars like Lambo's, Ferrari's, etc...

It's from a Japanese company called Roberuta and it's called the Roberuta Cup. It just a little cup that sits on the shock and when filled with air it will raise the car.

As you can see, it is a nice design, but the stroke is pretty short. It does give low cars an unfair advantage, though. It's just too expensive and height limited for my use, but I thought you guys should know about them.

It's from a Japanese company called Roberuta and it's called the Roberuta Cup. It just a little cup that sits on the shock and when filled with air it will raise the car.

As you can see, it is a nice design, but the stroke is pretty short. It does give low cars an unfair advantage, though. It's just too expensive and height limited for my use, but I thought you guys should know about them.

http://www.topsecretjpn.com/roberuta.shtml

It looks great, but I think it's still really expensive, maybe $2000 or so. It also uses a compresor and air tank. There are 6 pages of pics here.

http://www.roberuta.com/file/index.html

Last edited by JasonWW; 11-15-2007 at 11:30 PM.

#64

BTW the plane in my avatar does individual kneeling of each landing gear independently, or you can kneel the entire jet forward or backwards for loading. I do it all the time but it is a whole different ballgame. It works with hydraulic driven motors that turn jackscrews, and the struts are pneudraulic.

If someone is interested in using a similiar setup LMK

Once again sorry for

If someone is interested in using a similiar setup LMK

Once again sorry for

#65

TECH Enthusiast

iTrader: (15)

Pneudralic is just a combination of air and hydro fluid. Our struts (the plane again) are fully extended under a no load condition, filled with hydraulic fluid to a certain point, and then inflated with gaseous nitrogen. It doesn't sound like it makes any sense i'll get a parts breakdown if your interested in seeing the inner workings.

I was kidding about actually using an aircraft like setup for the record. But hey maybe you can come up with something new!

I was kidding about actually using an aircraft like setup for the record. But hey maybe you can come up with something new!

#66

Pneudralic is just a combination of air and hydro fluid. Our struts (the plane again) are fully extended under a no load condition, filled with hydraulic fluid to a certain point, and then inflated with gaseous nitrogen. It doesn't sound like it makes any sense i'll get a parts breakdown if your interested in seeing the inner workings.

I was kidding about actually using an aircraft like setup for the record. But hey maybe you can come up with something new!

I was kidding about actually using an aircraft like setup for the record. But hey maybe you can come up with something new!

I'm using the GC coilover conversions which means the whole spring/shock assembly is connected to the car in one mount, not 2 like the stock setup. The stock setup has the spring resting on the rubber mount and the shock going to the center. Anyway, with the single mounting point I wish I could just raise and lower it.

Imagine a hydraulic cylinder running almost side by side to the shock/spring assembly. At the top they would be connected by a rocker assembly.

Here is a 90* setup, but in mine it would be a 180* setup.

All the hydraulic cylinder would do is change the ride height. The spring/shock part would work just like they always do.

What makes this setup so great is it would be fully track ready. The cylinder is narrow and can easily lift the cars weight. They are not super expensive and the hydraulics can hold the shock/spring steady in both compression and rebound. There's no guessing about spring rates as well.

#67

^^^^^^^ that is amzing i have always loved crazy suspention mods there is a toyota mini truck built by the editer of minitruck'n mag that has a full coilover suspention all around that is raised and lowered by airbags and has a locking cylinder that can lock out the coilovers at a ridehight so it will only ride on the coilovers and not the baggs. this is not in anyway feasable for an fbody but just cool

#68

^^^^^^^ that is amzing i have always loved crazy suspention mods there is a toyota mini truck built by the editer of minitruck'n mag that has a full coilover suspention all around that is raised and lowered by airbags and has a locking cylinder that can lock out the coilovers at a ridehight so it will only ride on the coilovers and not the baggs. this is not in anyway feasable for an fbody but just cool

Have any links to it?

BTW, it may be feasible to mount the hydraulic cylinders parallel to the hood and towards the front of the car then run a 90* linkage like in the pic above. These types of setup put stresses in different locations and directions, so I'd have to think about it some more. What would really be handy would be some shorter shocks. Maybe Strano knows of a much shorter shock (koni SA) that can be revalved to match the F-body units. Something similar to this.

I know Koni makes coilovers, but they are very expensive. Hmmm, maybe I could sell my GC/koni sa fronts to help offset the cost. Thay may work. Anyway, a shorter shock would open up all kinds of options to alter the ride height.

The only thing about the hydraulically adjustably ride height would be controlling it. I don't think there are digital controllers and you don't have pressure gauges to look at. Full up and full down wouldn't be a problem, but setting it in the middle for the normal ride height would be a pain in the ***. I guess you may have to add some ride height sensors just like on some air systems. They provide a variable voltage reading which can be wired to some digital voltmeter gauges.

That would probably work, but a digital controller would be nicer.

Last edited by JasonWW; 11-16-2007 at 01:09 AM.

#69

Here's a thought, since the ride height would be 4 corner controllable while driving, why not make it somewhat active? Why can't we install some inertia sensors and have the suspension lean into the turns or at least keep the car level under hard cornering? One of the big issues with hard cornering on a lowered car is that the outer suspension compresses to where you run out of travel and you hit the bumpstops which can unsettle the car. If you lift that outer side of the car you will stay off the bumpstops and maintain your cornering grip. That's how thew formula one cars worked.

Hell, let's look at all the goodies that were banned on those cars. Active aerodynamics. Why not for our cars? Or we could just tweak our cars for more down force and have the suspension compensate by lifting the car at high speeds so we maintain the proper ride height. That sounds doable. Yeah man!

.

Hell, let's look at all the goodies that were banned on those cars. Active aerodynamics. Why not for our cars? Or we could just tweak our cars for more down force and have the suspension compensate by lifting the car at high speeds so we maintain the proper ride height. That sounds doable. Yeah man!

.

Last edited by JasonWW; 11-16-2007 at 03:13 AM.

#71

TECH Enthusiast

iTrader: (15)

I was looking at the landing gear on my plane today i came up with an idea that would maintain your springs and shocks that would be actuated electrically. It's just a rough idea at this point but could work. It would be electrically actuated and would give you as much lift as the suspension would allow while maintaining the handling characteristics of whatever springs and shocks you have. (That's while it's retracted though, i wouldn't drive it much extended although your shocks/springs themselves would still be in their normal configuration, your front wheel camber would probably be out of whack.)

Might be able to keep all of the components in the fender well, but i'll have to do some more studying on that.

Just remeber that this is just an idea i came up with while on my lunch break so it's WAY to soon to come up with specifics, and it may not even be feasible. Also I have little experience on automotive suspensions aside from typical maintenance like replacing shocks, springs, struts, rod ends etc, but have worked on aircraft landing gear for about 8 years. Kinda bass ackwards! Anyway here's what i came up with so far

JG adj lift mod (i wanted to have a cool mod named after me)

pro's:

-no bulky air or fluid reservoirs

-no lines that could break or leak

-no valves that could fail

-no noisy pumps

-wouldn't affect handling characteristics (while in normal mode)

-no costly pressure guages or control systems

-one switch operate it

-no one has ever seen anything like it before (as far as i know)

cons

-availability and price of actuators

-would involve some cutting and fabrication

-depeding on which type of actuation you chose, your electrical supply system would probably have to be upgraded

-unsure of price right now

-may have to keep the engine running for operation due to electrical demand

- overall system weight would more than an air setup

-no one has ever seen anything like it before (as far as i know)

im looking into 2 different variations right now. One would involve relocating more than i would like in the engine bay, but would be easier to acquire than the other. The 2nd would be a cleaner, less noticable look but a couple of the parts may be hard to find for the right price. I know what it costs for the military to buy these parts but you've all heard the stories of $300 toilet seats so it would involve a little more searching for a cheaper vendor!

Anyhow just thought i would throw in some ideas

Might be able to keep all of the components in the fender well, but i'll have to do some more studying on that.

Just remeber that this is just an idea i came up with while on my lunch break so it's WAY to soon to come up with specifics, and it may not even be feasible. Also I have little experience on automotive suspensions aside from typical maintenance like replacing shocks, springs, struts, rod ends etc, but have worked on aircraft landing gear for about 8 years. Kinda bass ackwards! Anyway here's what i came up with so far

JG adj lift mod (i wanted to have a cool mod named after me)

pro's:

-no bulky air or fluid reservoirs

-no lines that could break or leak

-no valves that could fail

-no noisy pumps

-wouldn't affect handling characteristics (while in normal mode)

-no costly pressure guages or control systems

-one switch operate it

-no one has ever seen anything like it before (as far as i know)

cons

-availability and price of actuators

-would involve some cutting and fabrication

-depeding on which type of actuation you chose, your electrical supply system would probably have to be upgraded

-unsure of price right now

-may have to keep the engine running for operation due to electrical demand

- overall system weight would more than an air setup

-no one has ever seen anything like it before (as far as i know)

im looking into 2 different variations right now. One would involve relocating more than i would like in the engine bay, but would be easier to acquire than the other. The 2nd would be a cleaner, less noticable look but a couple of the parts may be hard to find for the right price. I know what it costs for the military to buy these parts but you've all heard the stories of $300 toilet seats so it would involve a little more searching for a cheaper vendor!

Anyhow just thought i would throw in some ideas

#72

TECH Resident

iTrader: (6)

Join Date: Aug 2006

Location: Hampstead, MD

Posts: 766

Likes: 0

Received 0 Likes

on

0 Posts

Once Grainger gets a part number for toilet seats then they'll buy cheaper ones.

So this actuator, I assume its like an pneumatic one and pushes or retracts a rod? How will normal operation not be compromised?

So this actuator, I assume its like an pneumatic one and pushes or retracts a rod? How will normal operation not be compromised?

#73

TECH Enthusiast

iTrader: (15)

It involves moving the surface that the top of the shock/spring mounts to up and down. The actuator itself would be located on the other end of a swing arm type setup, with a pivit point somewhere in the middle. The actuator (still deciding on which type and where to locate it) would move the inboard end of the arm up, pushing the outboard end down, therefore pushing the whole strut down. With the upper mounting surface always being the same distance from the lower surface, shock performance should remain unaffected. The "arm" would have to have some bend in it so the inboard end could mounted lower, while keeping the actuator parallel to the strut. Don't want the thing going through the hood!

To simplify, you have an actuator "rod" that is moved in and out by a rotating flexshaft. The motor is attached to the other end of the flexshaft.

The rod pushes/pulls one end of an arm creating a seesaw type action.

I know it sounds complicated but i personally would find the welding part of everything more intimidating than laying out the rest of the system.

#74

On The Tree

Join Date: Apr 2007

Location: Way Out In The Boonies Chasin' Hill Billies, North GA

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

^^^^^^^ that is amzing i have always loved crazy suspention mods there is a toyota mini truck built by the editer of minitruck'n mag that has a full coilover suspention all around that is raised and lowered by airbags and has a locking cylinder that can lock out the coilovers at a ridehight so it will only ride on the coilovers and not the baggs. this is not in anyway feasable for an fbody but just cool

Too bad we can't find any spring rates on any of these set-ups. Somewhere there has to be some information on this.....If not, there is a niche in the suspension market that needs to be filled.

#75

It involves moving the surface that the top of the shock/spring mounts to up and down. The actuator itself would be located on the other end of a swing arm type setup, with a pivit point somewhere in the middle. The actuator (still deciding on which type and where to locate it) would move the inboard end of the arm up, pushing the outboard end down, therefore pushing the whole strut down. With the upper mounting surface always being the same distance from the lower surface, shock performance should remain unaffected. The "arm" would have to have some bend in it so the inboard end could mounted lower, while keeping the actuator parallel to the strut. Don't want the thing going through the hood!

To simplify, you have an actuator "rod" that is moved in and out by a rotating flexshaft. The motor is attached to the other end of the flexshaft.

The rod pushes/pulls one end of an arm creating a seesaw type action.

I know it sounds complicated but i personally would find the welding part of everything more intimidating than laying out the rest of the system.

To simplify, you have an actuator "rod" that is moved in and out by a rotating flexshaft. The motor is attached to the other end of the flexshaft.

The rod pushes/pulls one end of an arm creating a seesaw type action.

I know it sounds complicated but i personally would find the welding part of everything more intimidating than laying out the rest of the system.

Does anyone know where to get those rocker arm assemblies the race cars use in a pushrod setup?

I think there woukld be room to move the whole koni/GC setup upper mount to the front or rear an inch or 2 and then place the cylinder ram on the opposite side and weld it to the K-member. Then mount a lever with the pivot in the locaton the shock used to mount in. When the ram pushes up, the lever will push the whole shock down and raise the car. Plus I could tweak the lecer lengths to change the ratios if need be. I just need to learn more about hydro systems and find a place to get the pivots from. The rest of the joints would be rod ends. It's pretty easy to swap a rod end joint to the top of the Koni shock.

I'll draw up a picture tommorrow.

#76

I would like to experiment with a setup like this, with a set of Koni SAs. You could use a set of the slip on adjustable coil-over sleeves, and set the air spring on top of it. That way, you could optimize the spring rate for performance (set at a specified PSI for the desired spring rate, once that is achieved adjust the ride hight by changing the spring perch).

That's why the hydrualic setup would work well. It will hold the top of the shock/spring firmly under both compression and extension. An air bag can not do that. If you look at the Roberuta Cup from above you will notice that the shock goes through it to mount solidly to the car. Only the coil spring is pushed when air is added.

#77

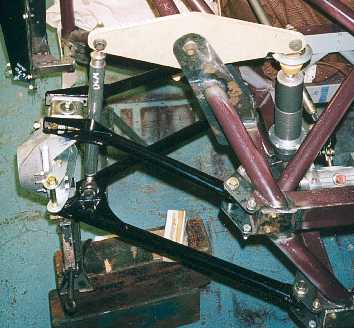

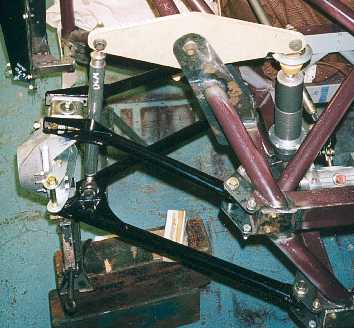

See this pic?

Imagine the spring/shock on the outboard side like stock and the pushrod on the inboard side. Just like that it wouldn't do anything. All the linkage stuff is extra complication not needed. But if we replace the solid rod with a hydrualic rod capable of extending and contracting, then we have a adjustable ride height device that still relies on the spring/shock for all the performance duties.

With a shorter lever the whole thing should fit under the wheel well.

Imagine the spring/shock on the outboard side like stock and the pushrod on the inboard side. Just like that it wouldn't do anything. All the linkage stuff is extra complication not needed. But if we replace the solid rod with a hydrualic rod capable of extending and contracting, then we have a adjustable ride height device that still relies on the spring/shock for all the performance duties.

With a shorter lever the whole thing should fit under the wheel well.

Last edited by JasonWW; 11-16-2007 at 10:51 PM.

#78

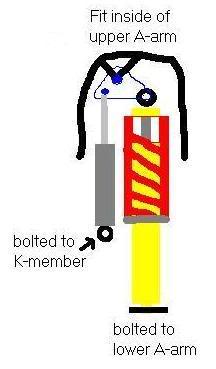

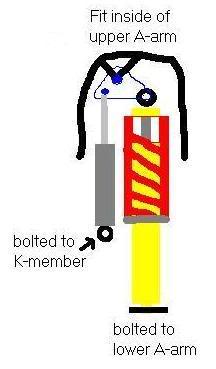

I only had access to MS Paint at the moment, so here is a quick diagram.

Has anyone actually thought about how much travel we should have? Stock is about 8 inches with the stock ride height in the middle. I'm lowered about 2" and have about 2" on compression travel with 6" of extension travel. Should we stick to 8" of travel to jack the car way up when needed? I guess if it can be done, why not?

Has anyone actually thought about how much travel we should have? Stock is about 8 inches with the stock ride height in the middle. I'm lowered about 2" and have about 2" on compression travel with 6" of extension travel. Should we stick to 8" of travel to jack the car way up when needed? I guess if it can be done, why not?

#79

I trhink this is the cheapest digital air ride controller I've seen.

http://store.summitracing.com/partde...5&autoview=sku

Air Lift Easy Street AutoPilot $477.

http://store.summitracing.com/partde...5&autoview=sku

Air Lift Easy Street AutoPilot $477.

#80

I was just checking out Prohopper dot com and saw an entry level kit for $750.

Hell of a lot cheaper than an air setup, but probably heavier with the 2 pumps. I wonder if you can get by with a single pump?

EDIT, looks like a single pump setup might allow the car to lean in a corner. I'm guessing the fluid is not isolated between the front 2 cylinders. Hmmm, a 2 pump setup would fix this, but add more weight. I'll have to do some more research.

I bet I could fool some people into thinking I "ruined" the car with hydrualics when in fact it will be a serious cornering machine. I can just see the look on their face when they hear the pump and see the car start dancing around. Maybe even 3 wheel it. It wouldn't jump due to the coilovers suspension, but hey, a little dancing around would be cool.

It wouldn't jump due to the coilovers suspension, but hey, a little dancing around would be cool.

Check out layitlow dot com. It's cool stuff.

Hell of a lot cheaper than an air setup, but probably heavier with the 2 pumps. I wonder if you can get by with a single pump?

EDIT, looks like a single pump setup might allow the car to lean in a corner. I'm guessing the fluid is not isolated between the front 2 cylinders. Hmmm, a 2 pump setup would fix this, but add more weight. I'll have to do some more research.

I bet I could fool some people into thinking I "ruined" the car with hydrualics when in fact it will be a serious cornering machine. I can just see the look on their face when they hear the pump and see the car start dancing around. Maybe even 3 wheel it.

It wouldn't jump due to the coilovers suspension, but hey, a little dancing around would be cool.

It wouldn't jump due to the coilovers suspension, but hey, a little dancing around would be cool.Check out layitlow dot com. It's cool stuff.

Last edited by JasonWW; 11-17-2007 at 04:50 AM.