Hydraulic Plumbing (as in lowriders)

#21

The reason I need that is that is because of how the electronics work. Since I'm adapting a air bag electronic controller it will have 4 output wires to lift and 4 wires to drop. Normally they would go to the 8 air solenoids. That way if you get out of the car or a passenger gets in, the system will equalize itself instead of a corner sitting lower than it should.

you are asking a lot here. there is no need to equalize a side because a passenger got out. it happens all the time to non adjustable suspensioned cars. weight difference with passengers load on the vehicle will be nothing to be concerned about unless your suspension is sloppy to start with.

This doesn't make sense?

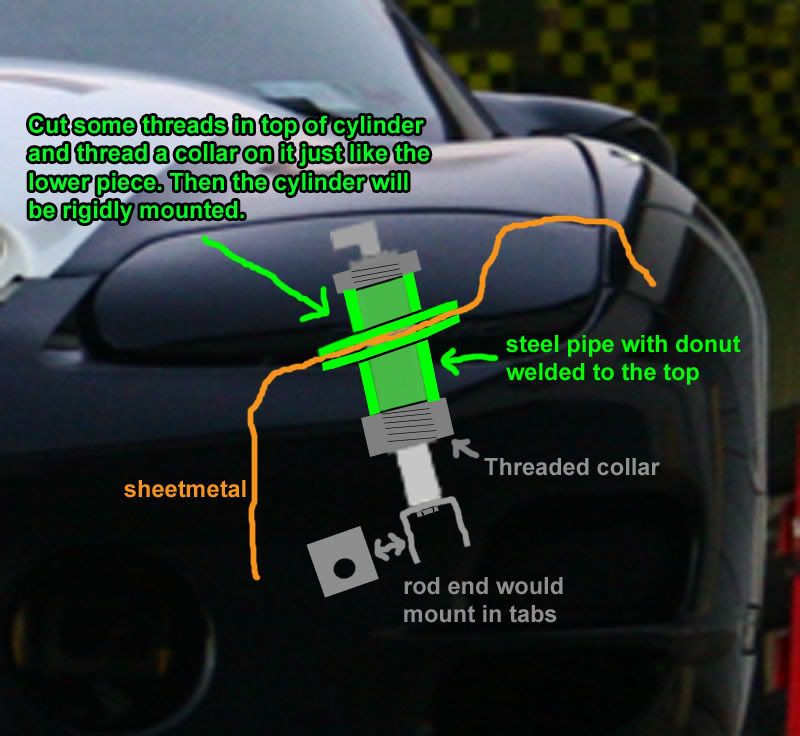

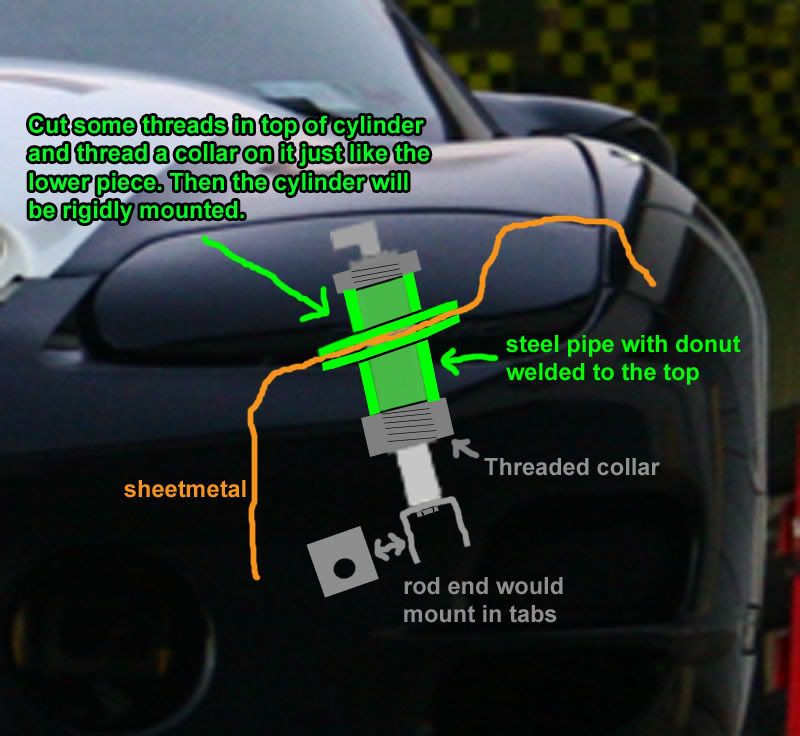

The donut would need to be welded to the cylinder at about the halfway point. Or I could add a sleeve between the cylinder cap about 2"? long and weld it on. If I remember right, there is about 4" from the sheetmetal to the hood, so figure 3" of cylinder and the last inch for the fitting. I'm assuming the cylinders can be welded on. If not, I'll have to space it and just tack the donut on it so it doesn;t drop down and then make the donut bolt onto the car.

welding to a cylinder is a "NO NO". there is a high chance that the cylinder will warp thus causing the inside of the cylinder to hurt the oring as the stroke moves in and out. which will cause a leak. it is possible to make a good weld on to the cylinder and not affect the integrity of the cylinder but would be very hard to do. cylinder casings seem to be a soft mild metal. i've welded onto the collar of a cylinder and came very close to warping the inside. i didn't warp it because i had yet to get a good weld on the cylinder. i thought about having threads made on the outside of the cylinder and using 2 bolts threaded onto it to hold a donut in place. this is costly to find a machine shop to do this.

I'll try and do a close up drawing of how the cylinder will mount through the metal.

you are asking a lot here. there is no need to equalize a side because a passenger got out. it happens all the time to non adjustable suspensioned cars. weight difference with passengers load on the vehicle will be nothing to be concerned about unless your suspension is sloppy to start with.

This doesn't make sense?

The donut would need to be welded to the cylinder at about the halfway point. Or I could add a sleeve between the cylinder cap about 2"? long and weld it on. If I remember right, there is about 4" from the sheetmetal to the hood, so figure 3" of cylinder and the last inch for the fitting. I'm assuming the cylinders can be welded on. If not, I'll have to space it and just tack the donut on it so it doesn;t drop down and then make the donut bolt onto the car.

welding to a cylinder is a "NO NO". there is a high chance that the cylinder will warp thus causing the inside of the cylinder to hurt the oring as the stroke moves in and out. which will cause a leak. it is possible to make a good weld on to the cylinder and not affect the integrity of the cylinder but would be very hard to do. cylinder casings seem to be a soft mild metal. i've welded onto the collar of a cylinder and came very close to warping the inside. i didn't warp it because i had yet to get a good weld on the cylinder. i thought about having threads made on the outside of the cylinder and using 2 bolts threaded onto it to hold a donut in place. this is costly to find a machine shop to do this.

I'll try and do a close up drawing of how the cylinder will mount through the metal.

xxxxx

#22

as far as alignment, i would have my car aligned when it is all the way down. i plan to ride around at this height the most. when my car is the lowest, i would make sure that i could still get around if a system failure were to occur. this height will scrape over speed bumps but i can still make it home. this is very important to me. i try to plan for the worst case scenario. i'm not into laying the unibody on the ground. as it is now, i have my lowest point on the car at around 2.5". that is plenty low to scrape on already. i'm on 215/40/18's up front and 245/35/20's in the back. the back can only safely go lower 1" after i take out the bumpstops. and the front could go 1" lower and be safe on 90% of road conditions.

#23

What ever happened to that air bag idea you had a while back, I quite liked those universal air strut type sleeves for the front and if you wanted to get super fancy with it you could always run linear potentiometers to measure your wheel travel and adjust air in each corner accordingly, could even have it setup to dump air pressure in the outer side of the car in a turn to help out the sway bars. Hydraulics just seem... heavy.

https://ls1tech.com/forums/suspension-brakes/803631-air-ride-using-your-front-shocks-350-a.html

That's still a good setup, but I was concerned about the spring rates. It's just hard to say what you'll end up with. It may be fine, but I didn't want to take the chance.

So what I came up with is a mix of lowrider hydraulic parts and high performance coilovers. I like this idea for several reasons.

One, it should be cheaper than an air setup.

Two, your spring rate will never change so you know your going to get the same great grip you have now (assuming you already have a good setup)

Three, I should be able to get more range of suspension travel.

Four, it takes up less space as you don't need a big air tank.

#24

this looks good but i'm assuming that the a arm is now held in place by the original top of the stru assembly correct and that the hydraulic cylinder is now angled to go through the engine bay at a point different from the original strut mount. if so....there is not enough room to do that. a hydraulic cylinder will have to go through the engine at the same point that the original strut mount due to space restraints.

I don't understand what you mean here. The connection between the shaft and the shock can't be fixed. As the shock moves up and down from the road surface the angle of the shock changes very slightly. So you have to have a pivot in there somewhere to allow fot that. The rodend will act just like a powerball. It will be a solid connection, but allow for angle changes.

#25

as far as alignment, i would have my car aligned when it is all the way down. i plan to ride around at this height the most. when my car is the lowest, i would make sure that i could still get around if a system failure were to occur. this height will scrape over speed bumps but i can still make it home. this is very important to me. i try to plan for the worst case scenario. i'm not into laying the unibody on the ground. as it is now, i have my lowest point on the car at around 2.5". that is plenty low to scrape on already. i'm on 215/40/18's up front and 245/35/20's in the back. the back can only safely go lower 1" after i take out the bumpstops. and the front could go 1" lower and be safe on 90% of road conditions.

If you want to lower the car more, you'll need to tub it.

This is my car and as it sits, I have 2" of travel front and rear before it rubs on the sheetmetal up front or the torque arm hits the sheetmetal in the back.

With 550lb front and 150lb rear springs combined with koni shocks it rides real well at this height. I really can't go lower without hurting the ride quality. Or I could tub it and set the suspension up for the same 2" of compression travel.

Once these cars are tubbed, you can really tuck the rims like so.

Then you can set your ride height for say 2.5", have 2" of travel and still have 1/2" before touching the ground. You'll need to tuck your exhaust up higher, though.

#26

If you can't weld the cylinder in place, what keeps it from moving around or being pulled straight down? For my idea to work the cylinder has to resist being pushed up as well as pulled down. It has to act just like a rigid mount.

Do you have any pics of how the cylinders are mounted?

If the donut holds them, then the weight of the car is resting on the threads of the cylinder that the collar is screwed onto, right?

I may be able to slide some thick pipe over the cylinder and then put the donut on top of it to space the cylinder lower down to clear the hood.

If I understand right, on a regular lowrider the the cylinder shafts are bolted firmly to a normal spring cup of some sort and when the spring compresses the whole cylinder may rock a little back and forth?

If I can't do it my way, I can bolt the cylinder directly to the shock and then make a pivot mount for the cylinder so it can rock, but not be pulled down through the hole. I'll weld the pivots to the steel pipe sleeve I mentioned, but I'll still need to tack the cylinder to the pipe to keep it from sliding down.

Or I could have the top of the cylinder threaded, then screw down on the pipe sleeve to firmly hold the cylinder from the top and the bottom while still allowing it to pivot.

I'll draw up a picture later.

Do you have any pics of how the cylinders are mounted?

If the donut holds them, then the weight of the car is resting on the threads of the cylinder that the collar is screwed onto, right?

I may be able to slide some thick pipe over the cylinder and then put the donut on top of it to space the cylinder lower down to clear the hood.

If I understand right, on a regular lowrider the the cylinder shafts are bolted firmly to a normal spring cup of some sort and when the spring compresses the whole cylinder may rock a little back and forth?

If I can't do it my way, I can bolt the cylinder directly to the shock and then make a pivot mount for the cylinder so it can rock, but not be pulled down through the hole. I'll weld the pivots to the steel pipe sleeve I mentioned, but I'll still need to tack the cylinder to the pipe to keep it from sliding down.

Or I could have the top of the cylinder threaded, then screw down on the pipe sleeve to firmly hold the cylinder from the top and the bottom while still allowing it to pivot.

I'll draw up a picture later.

#27

caliswangin916, if it's just the strut looking shock setup that is holding you back, have you considered seperating the 2 pieces. You can move the shock over to the side and mount whatever spring you want.

Here is Slammed1500's (Kenny) camaro with air ride:

I don't have room for a shock on the side as I'm running wide 285 front tires, but since yours are skinnier, you may have room.

The trick is getting a shocked valved properly. Kenny, said his setup didn't ride that good due the shock. He plans to switch over to the Air Ride one piece units. If you run a good quality shock it may be fine for your use and ride good.

Here are 2 threads of his. They show the tubbed front and rear wheel wells as well as the rear tunnel, etc... The gas tank may also be in the way. Kenny plans to have a custom one made. I plan to swap over to a IRS so the gas tank won't be a problem for me.

https://ls1tech.com/forums/tools-fabrication/801893-tubed-camaro-pics.html

https://ls1tech.com/forums/appearance-detailing/787832-project-obsessed.html

On my own setup, if I can't work out all the details, like no extra batteries, mounting the cylinders like I want and having the Controller think it's working an air suspension, then I may have to go back to the air strut bag idea I had. Each have pros and cons and now they are starting to even out.

Here is Slammed1500's (Kenny) camaro with air ride:

I don't have room for a shock on the side as I'm running wide 285 front tires, but since yours are skinnier, you may have room.

The trick is getting a shocked valved properly. Kenny, said his setup didn't ride that good due the shock. He plans to switch over to the Air Ride one piece units. If you run a good quality shock it may be fine for your use and ride good.

Here are 2 threads of his. They show the tubbed front and rear wheel wells as well as the rear tunnel, etc... The gas tank may also be in the way. Kenny plans to have a custom one made. I plan to swap over to a IRS so the gas tank won't be a problem for me.

https://ls1tech.com/forums/tools-fabrication/801893-tubed-camaro-pics.html

https://ls1tech.com/forums/appearance-detailing/787832-project-obsessed.html

On my own setup, if I can't work out all the details, like no extra batteries, mounting the cylinders like I want and having the Controller think it's working an air suspension, then I may have to go back to the air strut bag idea I had. Each have pros and cons and now they are starting to even out.

#28

My brains kicking in now. You know how on a big rig with air suspension, they don't run a bunch of electric pumps. They run an engine mounted pump. Lets say we ditch all the extra batteries and multiple pump assemblies and just mount a single extra power steering pump on the front of the engine. If we feed it to a larger reservoir and mount it low it may work fine. We could even install an electric clutch on it like an A/C compressor so that most of the time it's just free wheeling. If this idea really did work, then we could ditch the extra batteries, chargers, pumps, pump motors, all that weight and expense. Now the obvious trade off would be that the car could only lift when the engine was running. That's fine by me. I plan to have it set up to automatically lower to the ground when I turn the engine off, then lift back up once I crank it up again.

I think the stock pump uses a pressure bypass valve so it recirculates the fluid. That may be an acceptable solution to an electric clutch on the pump. Or we could install a dump valve between the high pressure side and the low pressure side. The pump would be pumping, but under low pressure conditions just recirculating the fluid. Only when that valved open would it build the real pressure to lift the car. If we don't have enough pressure at idle we could install a smaller pulley to speed it up. All the dump valves and so forth could be mounted underhood or in the fenders.

I think the stock pump uses a pressure bypass valve so it recirculates the fluid. That may be an acceptable solution to an electric clutch on the pump. Or we could install a dump valve between the high pressure side and the low pressure side. The pump would be pumping, but under low pressure conditions just recirculating the fluid. Only when that valved open would it build the real pressure to lift the car. If we don't have enough pressure at idle we could install a smaller pulley to speed it up. All the dump valves and so forth could be mounted underhood or in the fenders.

#30

Here is a mounting arraignment I think will work.

The steel pipe lengths and the donuts could probably be welded to the car as well then the cylinder slid into place. Or you could just weld the pipe to the donut so it won't try to rock. Either way it should be plenty strong.

Tell me what you think.

The steel pipe lengths and the donuts could probably be welded to the car as well then the cylinder slid into place. Or you could just weld the pipe to the donut so it won't try to rock. Either way it should be plenty strong.

Tell me what you think.

#31

The first part is correct, but the cylinder will be mounted at the same angle as the shock. Just as the above pic shows. There is room to change the angle of the cylinder, but I want to keeps any side loads off the cylinder as much as I can.

I don't understand what you mean here. The connection between the shaft and the shock can't be fixed. As the shock moves up and down from the road surface the angle of the shock changes very slightly. So you have to have a pivot in there somewhere to allow fot that. The rodend will act just like a powerball. It will be a solid connection, but allow for angle changes.

I don't understand what you mean here. The connection between the shaft and the shock can't be fixed. As the shock moves up and down from the road surface the angle of the shock changes very slightly. So you have to have a pivot in there somewhere to allow fot that. The rodend will act just like a powerball. It will be a solid connection, but allow for angle changes.

/

\

#32

Even at it's lowest ride height you need about 2" of compression travel just so your not rubbing the tires on the sheetmetal up front or hitting the gas tank ot center tunnel in the back. To ride around at your low setting with your current tires, you'll need to tub the wheel wells. Do you want to do that or not? If not, then you want to pull the plastic fenderwell trim out of one of the wheel wells and measure how much space you have between the tire and the sheetmetal. You can lower the car until you have only a 2" gap. At that point, with 500lb springs and better shocks, you should have a pretty good ride. Going lower will make it ride rough. I think 2" of compression travel is about minimal for a decent ride.

If you want to lower the car more, you'll need to tub it.

This is my car and as it sits, I have 2" of travel front and rear before it rubs on the sheetmetal up front or the torque arm hits the sheetmetal in the back.

With 550lb front and 150lb rear springs combined with koni shocks it rides real well at this height. I really can't go lower without hurting the ride quality. Or I could tub it and set the suspension up for the same 2" of compression travel.

Once these cars are tubbed, you can really tuck the rims like so.

Then you can set your ride height for say 2.5", have 2" of travel and still have 1/2" before touching the ground. You'll need to tuck your exhaust up higher, though.

If you want to lower the car more, you'll need to tub it.

This is my car and as it sits, I have 2" of travel front and rear before it rubs on the sheetmetal up front or the torque arm hits the sheetmetal in the back.

With 550lb front and 150lb rear springs combined with koni shocks it rides real well at this height. I really can't go lower without hurting the ride quality. Or I could tub it and set the suspension up for the same 2" of compression travel.

Once these cars are tubbed, you can really tuck the rims like so.

Then you can set your ride height for say 2.5", have 2" of travel and still have 1/2" before touching the ground. You'll need to tuck your exhaust up higher, though.

as the car sits on 215/40/18's, the center of my fender is 25", i still have about 3" more before the top of the tire hits the iinner fender well cover. but it is likely that i will max out the upper a arm before that. meaning the upper a arm(the end with the ball joint) will sit up against the fender well top.

tubbing is not an option for me. i don't want to lay unibody or even close to it. my lowest will still be drivable if there is a system failure and i'm 600 miles away from home.

#33

That shaft should be a lot stronger than that. It obviously handles side loads pretty well considering they use them to hop the cars. While driving it will only be extanded about half way. It will only be extended fully when I'm driving real slow over a steep driveway. The cylinder will be fixed at it's angle. No way the shaft would bend or the cylinder would bend. Those parts can't be as weak as your saying.

#34

If you can't weld the cylinder in place, what keeps it from moving around or being pulled straight down? For my idea to work the cylinder has to resist being pushed up as well as pulled down. It has to act just like a rigid mount.

cylinders are traditionally pushed up by the spring (on the end of the cup on the end of the shaft).

Do you have any pics of how the cylinders are mounted?

If the donut holds them, then the weight of the car is resting on the threads of the cylinder that the collar is screwed onto, right?

the donut is pretty much used to be a displacement for the cylinder collaras it pushes up a frame or body point.

I may be able to slide some thick pipe over the cylinder and then put the donut on top of it to space the cylinder lower down to clear the hood.

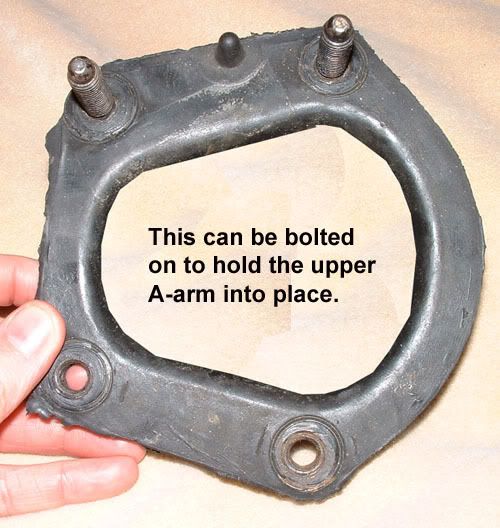

this is doable to achieve spaceing, but if you do this, you lose length availablity on the strut end. you can also use a mini spring instead of the spacer to get a spring in there. this looks like what i may try next. i made a plate to hold the upper a arm in place but didn't think to cut a hole in the plate for a cylinder since i was trying to flow my cylinder upside down. this would work for and accumulated setup.

If I understand right, on a regular lowrider the the cylinder shafts are bolted firmly to a normal spring cup of some sort and when the spring compresses the whole cylinder may rock a little back and forth?

you are correct. the cylinder will have play through the hole made for the cylinder to go through the frame/body. you can reinforce this hole with a donut welded to the frame/body to help keep the cylinder from trying to move and hurt the fram/body hole.

If I can't do it my way, I can bolt the cylinder directly to the shock and then make a pivot mount for the cylinder so it can rock, but not be pulled down through the hole. I'll weld the pivots to the steel pipe sleeve I mentioned, but I'll still need to tack the cylinder to the pipe to keep it from sliding down.

the only time i can see a cylinder pulled down is when you jack up the car with a manual jack and the cylinder shaft is fully compressed. or if you go 4 wheelin where one side of the car is on a surface 4 inches above the other. you can avoid the cylinder from trying to go down by jacking the car up at the lower a arm.

Or I could have the top of the cylinder threaded, then screw down on the pipe sleeve to firmly hold the cylinder from the top and the bottom while still allowing it to pivot.

I'll draw up a picture later.

cylinders are traditionally pushed up by the spring (on the end of the cup on the end of the shaft).

Do you have any pics of how the cylinders are mounted?

If the donut holds them, then the weight of the car is resting on the threads of the cylinder that the collar is screwed onto, right?

the donut is pretty much used to be a displacement for the cylinder collaras it pushes up a frame or body point.

I may be able to slide some thick pipe over the cylinder and then put the donut on top of it to space the cylinder lower down to clear the hood.

this is doable to achieve spaceing, but if you do this, you lose length availablity on the strut end. you can also use a mini spring instead of the spacer to get a spring in there. this looks like what i may try next. i made a plate to hold the upper a arm in place but didn't think to cut a hole in the plate for a cylinder since i was trying to flow my cylinder upside down. this would work for and accumulated setup.

If I understand right, on a regular lowrider the the cylinder shafts are bolted firmly to a normal spring cup of some sort and when the spring compresses the whole cylinder may rock a little back and forth?

you are correct. the cylinder will have play through the hole made for the cylinder to go through the frame/body. you can reinforce this hole with a donut welded to the frame/body to help keep the cylinder from trying to move and hurt the fram/body hole.

If I can't do it my way, I can bolt the cylinder directly to the shock and then make a pivot mount for the cylinder so it can rock, but not be pulled down through the hole. I'll weld the pivots to the steel pipe sleeve I mentioned, but I'll still need to tack the cylinder to the pipe to keep it from sliding down.

the only time i can see a cylinder pulled down is when you jack up the car with a manual jack and the cylinder shaft is fully compressed. or if you go 4 wheelin where one side of the car is on a surface 4 inches above the other. you can avoid the cylinder from trying to go down by jacking the car up at the lower a arm.

Or I could have the top of the cylinder threaded, then screw down on the pipe sleeve to firmly hold the cylinder from the top and the bottom while still allowing it to pivot.

I'll draw up a picture later.

#35

i agree that there needs to be 2" of travel for the shock/strut to be able to do work, that's why when i was planning accumulators, i bought 6" cylinders so that i could constantly have 2" of travel when the car was all the way down.

as the car sits on 215/40/18's, the center of my fender is 25", i still have about 3" more before the top of the tire hits the iinner fender well cover. but it is likely that i will max out the upper a arm before that. meaning the upper a arm(the end with the ball joint) will sit up against the fender well top.

tubbing is not an option for me.

as the car sits on 215/40/18's, the center of my fender is 25", i still have about 3" more before the top of the tire hits the iinner fender well cover. but it is likely that i will max out the upper a arm before that. meaning the upper a arm(the end with the ball joint) will sit up against the fender well top.

tubbing is not an option for me.

Your right about lowering your car another inch so you can still have 2" of travel, but not using an accumulator. A proper shock will slow down the tire from rising and help prevent bottoming out. A stiffer spring will do the same, but you don't want it too stiff. So a 500lb or so spring with a good shock will still ride good with only 2" of travel. If the accumulator can not properly control the wheel like the shock can, then you may end up needing more than 2" of travel to keep the ride quality good. I plan to have the cylinders rock solid so the spring and shock do all the work. If you use an accumulator with a shock the cylinder will move up and down and the shock will not be able to work properly.

You can get around the upper arm hitting the sheetmetal by cutting a hole in the sheetmetal. Simple as that. You can also weld a new dome shaped piece over the hole to make it look nice. If the whole arm is going to hit the fender sheetmetal then you'd need to modify the A-arm so it won't hit. That's what Kenny did.

I plan to solve the upper A-arm clearance problem with the drop spindles.

#36

caliswangin916, if it's just the strut looking shock setup that is holding you back, have you considered seperating the 2 pieces. You can move the shock over to the side and mount whatever spring you want.

Here is Slammed1500's (Kenny) camaro with air ride:

On my own setup, if I can't work out all the details, like no extra batteries, mounting the cylinders like I want and having the Controller think it's working an air suspension, then I may have to go back to the air strut bag idea I had. Each have pros and cons and now they are starting to even out.

Here is Slammed1500's (Kenny) camaro with air ride:

On my own setup, if I can't work out all the details, like no extra batteries, mounting the cylinders like I want and having the Controller think it's working an air suspension, then I may have to go back to the air strut bag idea I had. Each have pros and cons and now they are starting to even out.

i'm telling you for a decent setup, you want 2 pump and 4 batteries which will take up the hatch area. i plan to have an amp on the left side of the car and a nitrous bottle in the spare tire well so this stuff taking space is no big deal. i don't want a subbed stereo so no big deal. hydraulics is better!!!!!!

ideally what i want is a hydraulic cylinder separate of the strut assembly similar to the picture. problem is making a mount. a mount could be welded to the side of the fender well body but i don't want to have to go that route yet. i cannot fab that tubular mount as pictured to provide a mount for the hydraulic cylinder.

#37

Some of these cars have enough grip they will lift an inside wheel while cornering. If the cylinder isn't held firmly in one spot, the shocks can't do their job. Ride quality will suffer and so will the grip.

I'm guessing you don't care much about cornering, but I want to keep all my cornering grip and not have it suffer with the new setup.

I'm guessing you don't care much about cornering, but I want to keep all my cornering grip and not have it suffer with the new setup.

#38

That shaft should be a lot stronger than that. It obviously handles side loads pretty well considering they use them to hop the cars. While driving it will only be extanded about half way. It will only be extended fully when I'm driving real slow over a steep driveway. The cylinder will be fixed at it's angle. No way the shaft would bend or the cylinder would bend. Those parts can't be as weak as your saying.

#39

Keep in mind I'm not building a lowrider. I'm just using their parts.

I may have to find new ways of using these basic parts.

I may have to find new ways of using these basic parts. There's no way I want to run 4 extra batteries. If I HAD to, I'd switch over to an air system to save weight. Not only would the extra weight reduce acceleration, but also hurt cornering and stopping distances. 4 big batteries plus another pump will add a lot of weight. Then you have the situation of trying to charge the batteries. That's not at all what I want. I have to adapt these parts to serve my purposes.

That entire Cozytech setup fit under the hood. I don't think it had extra batteries either. It was a tad slow, but I wouldn't mind so much considering it's size.

#40

Some of these cars have enough grip they will lift an inside wheel while cornering. If the cylinder isn't held firmly in one spot, the shocks can't do their job. Ride quality will suffer and so will the grip.

I'm guessing you don't care much about cornering, but I want to keep all my cornering grip and not have it suffer with the new setup.

I'm guessing you don't care much about cornering, but I want to keep all my cornering grip and not have it suffer with the new setup.

i want the car to look cool, get over speed bumps, ride better than stock suspension with cut springs, handle in turns, and straightaway racing in a car that can run low 12's-high 11's.

i have my front sway bar off for dragging and you will too if you want to do side to side moves. sam strano is totally against this in another thread. many say it is unsafe but my driving habits have not changed with it off. but then again i know i'm not setup as it is to try to corner with a z06.