Hydraulic Plumbing (as in lowriders)

#1

I'm trying to post up some PM's so it may be a tad confusing. All the bold stuff is from caliswangin916. I'm the one usually asking the questions.

This all concerns this thread:

Hydraulic Coilover Thread

from caliswangin916

This all concerns this thread:

Hydraulic Coilover Thread

from caliswangin916

sup Jason, just caught your thread about hydraulics for an f body. i'm into lowriders and was going to juice my ss over a year ago. i tried thinkin out a few ways to get it done but bottom line is there is not a way that i've found to make hydraulics work and be good for the ss. it is possible but you would not have a shock which is ok. you can use accumulators which will act as shocks and springs but when the car is laid out, the accumulators will not be active thus you are on springs only(if you incorporate them) or you'd be on metal. there's a lot more to it but too much to type. if you need dimensions to parts and more info on lowrider hydraulics, i could catch you up to speed. i've bought a lot of stuff to accomplish this but none that would satisfy me by keeping my ss's perforfance from being substantially affected negatively. and to be honest with you, it seems unsafe due to the ls1's power.

camaro's are rear wheel drive which is a plus but the front end suspension is set up like a front wheel drive. fwd cars can be safely lifted but the camaro strut mount setup is not like that of a honda. f bods have a shitty front setup for hydraulics. PERIOD.

**** i would love to have the ss juiced properly but i haven't come up with a safe and feasible way.

come up with a few ideas and i will tell you what is wrong with them. i know of plenty of ways of how a setup won't work but haven't found a way to make it work. i will give you $100 if you can come up with a way to do this that won't make the car unsafe and not hurt performance much.i'm willing to lose .5 off the quarter mile if i could do this. i'd make it up with nitrous.

2 pumps, 4 dumps, 4 accumulators, 4-16 switches, 4 batts at 24 volts. streetcharger. powerball front and back.

types of cylinders available- regualr, reverse flow, sideports.

i'm not a fan of prohopper but did buy some 6" cylinders for the front. technically you wouldn't need more than a 4" cylinder but those would have to be custome made and more money. not necessary.

my hydraulic stuff is mainly from black magic. i can get you more info on the gear once you can setup the front. that is 10000 times more inportant to make this work.

i'm very serious about doing this. and have gotten very pissed that i can't find a way.

i know of two ways that will work to lift and lay but not worthy in an ls1 that gets stomped on.

sorry, i'm rambling because this has made me crazy and i put it off for a long time now but i was thinking about gettin back to it.

hit me back up and claim that $100. hahha.

Brian

camaro's are rear wheel drive which is a plus but the front end suspension is set up like a front wheel drive. fwd cars can be safely lifted but the camaro strut mount setup is not like that of a honda. f bods have a shitty front setup for hydraulics. PERIOD.

**** i would love to have the ss juiced properly but i haven't come up with a safe and feasible way.

come up with a few ideas and i will tell you what is wrong with them. i know of plenty of ways of how a setup won't work but haven't found a way to make it work. i will give you $100 if you can come up with a way to do this that won't make the car unsafe and not hurt performance much.i'm willing to lose .5 off the quarter mile if i could do this. i'd make it up with nitrous.

2 pumps, 4 dumps, 4 accumulators, 4-16 switches, 4 batts at 24 volts. streetcharger. powerball front and back.

types of cylinders available- regualr, reverse flow, sideports.

i'm not a fan of prohopper but did buy some 6" cylinders for the front. technically you wouldn't need more than a 4" cylinder but those would have to be custome made and more money. not necessary.

my hydraulic stuff is mainly from black magic. i can get you more info on the gear once you can setup the front. that is 10000 times more inportant to make this work.

i'm very serious about doing this. and have gotten very pissed that i can't find a way.

i know of two ways that will work to lift and lay but not worthy in an ls1 that gets stomped on.

sorry, i'm rambling because this has made me crazy and i put it off for a long time now but i was thinking about gettin back to it.

hit me back up and claim that $100. hahha.

Brian

Last edited by JasonWW; 12-04-2007 at 11:24 PM.

#2

from caliswangin916

here is a thread i started on layitlow.com. it is the the lowrider of lowrider websites. but they don't f with camaros or anything newer style(euros, ect). don't expect to get help there.

by the way i do have a 91 camaro with hydraulics. they know nothing over there about camaros. hahaha.

i only know of 1 camaro that does have hydraulics but i don't feel that it is safe. i also know of another way to do it but again, not safe in my view. both will work but how long and will i be alive still is the question.

it does have a pic of one of my ideas. again, not safe.

http://www.layitlow.com/forums/index...pic=248503&hl=

by the way i do have a 91 camaro with hydraulics. they know nothing over there about camaros. hahaha.

i only know of 1 camaro that does have hydraulics but i don't feel that it is safe. i also know of another way to do it but again, not safe in my view. both will work but how long and will i be alive still is the question.

it does have a pic of one of my ideas. again, not safe.

http://www.layitlow.com/forums/index...pic=248503&hl=

#3

I don't think you read my thread very closely. I'm not going to make a traditional lowrider. I'm not going to have it hop or anything like that. It will move up and down more slowly. The car will actually be riding on coilovers. This is going to have great cornering and ride quality. The only function the hydraulics have will be to move the coilovers up and down. By doing that, I can lay it on the ground (after tubbing the wheel wells), raise it to ride height and also be able to raise it way up for steep driveways. It will also be computer controlled to drop when parked and lift to ride height when cranked up.

Then again, you may not have seen my main thread. Is this the one you saw?

https://ls1tech.com/forums/showth...=1#post8233686

Let me know what you think.

Then again, you may not have seen my main thread. Is this the one you saw?

https://ls1tech.com/forums/showth...=1#post8233686

Let me know what you think.

#4

from caliswangin916

the goal is to get a spring and a shock in somewhere with the hydraulic cylinder in place. there is very little clearance to get anything besides the basic strut setup in there. so a the best i can come up with is getting a mini spring in but no strut which is ok if you are riding on accumulators but when the car is fully dropped, there is no hydraulic pressure to help the suspension ride good. you could set it up where the cylinder at its lowest point when fully dropped still has say about a 2" extension thus allowing the accumulator to work, but if pressure is lost such as through a hose leak or break, you would be chitoutofluck and ridin like chit if your spring setup is not set up correctly. being stuck 100's of miles away from home could mean deep chit.

it has been done where a mount is welded onto the body of the car, but since this is a unibody, i don't like the idea but you would have the hydraulic cylinder totally independent of the strut assembly. hbiggest problem here is that where the mount is welded to the car could collapses and EFFF up the car. also a hurdle is where to mount the pivot point of the cylinder onto the lower a arm. again room is very little.

your post #3 with the drawn pic does not even seem feasible. there is very little room to get a shock in there.

the pic with the side of the bird is way over the top but the biggest problem is clearance under the hood for all that stuff. and you have to remember that the top of the coilover is used as a mount to hold the upper a arm in place.

the pic of the front of the bird---1 problem is the flow of the cylinder, the fitting will be towards the ground, once the car is lowered, it will hit the ground when you ride lowered. i know because i originally did that with my 91 camaro, i could not ride with the car lowered because the fitting would hit the ground. even if you could get 2" of clearance from the fitting to the ground, it is very dangerous. there is also still mounting issues with the top a arm and a spot for the cylinder to sit. both mounts could be fabbed but you have very little room.

fab it up and let me know. i really want this done.

it has been done where a mount is welded onto the body of the car, but since this is a unibody, i don't like the idea but you would have the hydraulic cylinder totally independent of the strut assembly. hbiggest problem here is that where the mount is welded to the car could collapses and EFFF up the car. also a hurdle is where to mount the pivot point of the cylinder onto the lower a arm. again room is very little.

your post #3 with the drawn pic does not even seem feasible. there is very little room to get a shock in there.

the pic with the side of the bird is way over the top but the biggest problem is clearance under the hood for all that stuff. and you have to remember that the top of the coilover is used as a mount to hold the upper a arm in place.

the pic of the front of the bird---1 problem is the flow of the cylinder, the fitting will be towards the ground, once the car is lowered, it will hit the ground when you ride lowered. i know because i originally did that with my 91 camaro, i could not ride with the car lowered because the fitting would hit the ground. even if you could get 2" of clearance from the fitting to the ground, it is very dangerous. there is also still mounting issues with the top a arm and a spot for the cylinder to sit. both mounts could be fabbed but you have very little room.

fab it up and let me know. i really want this done.

#5

Maybe we can help each other. I'd like to know a few things about hydraulics that' skind of firsthand info and I might be able to figure out a way to mount the components that you want.

First, tell me what yar vehicle we're dealing with. Is it your LS1 camaro in the sif pic?

What do you want it to do?

I just want to adjust my ride height electronically and don't mind if it takes a few seconds to go up or down.

Do you want yours to be slow like that or fast?

Do you want electronic control or just manual switches?

Do you want it to hop or dance around?

Smooth ride and good handling or stiff lowrider like ride?

Have you already ruled out an air system?

Some of the questions I had were:

If you use 4 cylinders and a single pump running on 12v how fast or slow would it take to lift the whole car say 4"? Are we talking 3-4 seconds or 10-15 seconds?

How much voltage can those motors take?

Think it would be worth it to add a second battery and run the pump 24v?

I doubt I would run the pump with the engine off, but I might every now and then just to lift the car up once.

Doubling the motor voltage doesn't double the speed does it? Maybe just speeds it up a little? Or does it increase the pressure? Both?

How much does a single motor/pump assembly weigh? About 30lbs?

Would all 3/8 lines be fine for my setup?

I was also considering a mini pump, any experience with those? They are like $150. Or should I stick with a fullsized pump assembly?

Have you ever seen double action pumps or cylinders that can lift a wheel?

First, tell me what yar vehicle we're dealing with. Is it your LS1 camaro in the sif pic?

What do you want it to do?

I just want to adjust my ride height electronically and don't mind if it takes a few seconds to go up or down.

Do you want yours to be slow like that or fast?

Do you want electronic control or just manual switches?

Do you want it to hop or dance around?

Smooth ride and good handling or stiff lowrider like ride?

Have you already ruled out an air system?

Some of the questions I had were:

If you use 4 cylinders and a single pump running on 12v how fast or slow would it take to lift the whole car say 4"? Are we talking 3-4 seconds or 10-15 seconds?

How much voltage can those motors take?

Think it would be worth it to add a second battery and run the pump 24v?

I doubt I would run the pump with the engine off, but I might every now and then just to lift the car up once.

Doubling the motor voltage doesn't double the speed does it? Maybe just speeds it up a little? Or does it increase the pressure? Both?

How much does a single motor/pump assembly weigh? About 30lbs?

Would all 3/8 lines be fine for my setup?

I was also considering a mini pump, any experience with those? They are like $150. Or should I stick with a fullsized pump assembly?

Have you ever seen double action pumps or cylinders that can lift a wheel?

#6

from Jasonww

From caliswangin916

i understand that the front is a shock, but it is very close to a strut due to the coil around it. it is a very different suspension setup. i refer to it as a strut because it is locked in place by a nut.

a stock strut assembly is roughly 22-24" IIRC. that is fully extended on the vehicle. i lowered my front quite a bit and now my strut assembly is about 19" when fully extended. pretty much that koni setup will have about 19" fully extended when thus only giving you about a 3-4" of length that you can make up with a cylinder. a 4" cylinder will be at least 6" in total length when fully collapsed. add a fitting to the end and now you're at 7-8" of length that you have to cram in. and i definitely don't see how you could mount a cylinder on top of the koni.

accumulators are at the pump so there is no issue with there use. they make the ride much better. plenty of euro(non tradtional lowriders, ie f bods, civics, pretty much anything newer) can use accumulators to take the place of a shocks work.

First, tell me what year vehicle we're dealing with. Is it your LS1 camaro in the sig pic?

00 SS in my sig. that ride height is pretty low already. it isn't speed bump friendly. i can drop down maybe 1 more inch once i can lift the car up with switches.

What do you want it to do?

the basics man. i'm not into hopping. i want to lift and lower over speed bumps and make the car look mean.

I just want to adjust my ride height electronically and don't mind if it takes a few seconds to go up or down.

Do you want yours to be slow like that or fast?

slow. 12 volts will not work even if you have 3-4 batteries in parallel. i'm planning 4 batteries, 2 to make 12 volts and then series them to the other pair to get 24 volts. this allows a decent lift speed yet still allow a good amount of play time. 36 volts is too fast for me. 48 volts will get the front to hop a little which is too violent for me.

Do you want electronic control or just manual switches?

manual, electronics can fail. if something happens and the switch is set to raise the car, you will be fucked because the pump will keep going til the batteries die or you have a fire. hahaha. i also will be using pressure relief valves to not over pressurize the hydraulic system if a failure were to occur thus giving me time to disconnect my quick disconnect(ground release).

for lowering(dumping), electronics are fairly safe. you could just use an auxillary from an alarm system.

Do you want it to hop or dance around?

not at all. i want to lift and lower and still somewhat keep my car's performance. i've talked to a well known hopper/dancer who did dance a 93-94 camaro but it was a throw away car. he said he'd break the hatch. camaros don't have frame which sucks. i know these cars can take abuse such as wheelies whn drag racing, but hopping/dancing is much more abusive. because it is constant.

Smooth ride and good handling or stiff lowrider like ride?

my car rides like **** right now on stock cut springs and low profile tires. i want the accumulators in my setup to help the ride. they are adjustable which is a plus.

Have you already ruled out an air system?

i definitely would not do air. i'm a hydraulic person. i very much hate air. worst part about air in an f bod is that when laid, you will be riding on the bag's rubber. i don't like that. i'm going to end up spending much more on hydraulics but i love hydraulics. i might be able to talk to black magic(hydraulic company) and see if he could fab me up a custom cylinder to make the lower mount easier, i've already made a plate to mount the top. but even so, there will be a problem still with a getting a spring in there that will be compressed all the time. their shop is in vegas and i might make a trip out there sometime early 08. CCE has some good suspension parts but i would not buy any of their hydraulic parts.

Some of the questions I had were:

If you use 4 cylinders and a single pump running on 12v how fast or slow would it take to lift the whole car say 4"? Are we talking 3-4 seconds or 10-15 seconds?Think it would be worth it to add a second battery and run the pump 24v?

slow. very slow, it may not even be able to fully raise the front end. that was the case on my 91 camaro where i ran 3 batteries in parallel it would not raise me and my 300lb friend. hahha. 24 volts is the minimum. 36 volts is too fast for me but it is actually considered slow for many people. that stuff you can deal with later. changing battery setup is easy.

How much voltage can those motors take?

they can easily take 72 volts and last hoppers very long. they are often pushed to 96 volts. i have saco brand motors which are much better than no name chinese ones. i also will use gel cells which have a lower cca than what street hoppers will use. it is possible to make an f bod hop. i wouldn't do it to mine. i know how, but not willing to try that suspension setup.

I doubt I would run the pump with the engine off, but I might every now and then just to lift the car up once.

you're batteries will not be in line with the engine's battery. you will have to charge them with a separate charger or buy a streetcharger which will use the car's alternator while the engine is running to charge your batts for the hydraulics. it will not charge as much as a home charger but will keep you going a bit longer. but this is also dependent on how much you hit the switches. also buy carling brand switches. chinese ones will **** up.

Doubling the motor voltage doesn't double the speed does it? Maybe just speeds it up a little? Or does it increase the pressure? Both?

How much does a single motor/pump assembly weigh? About 30lbs?

my pumps are about 30-40lbs each. i have 2. batteries are about 30-35 each for gel cells. you have to have a pump/battery rack. a bunch of other little things. i figure i will be about 3-400lbs heavier when done. which will kill my 1/4 mile time a bit but i'll make it back up with some spray. more weight in the back may actually not be too bad.

Would all 3/8 lines be fine for my setup?

yes. 3/8 will be faster than 1/2. gear selection for the pump will also affect speed.

I was also considering a mini pump, any experience with those? They are like $150. Or should I stick with a fullsized pump assembly?

no do not go mini. many problems too it. get a 2 pump 4 dump setup. no manifold bs. it's not worth it. i'm spending quite a bit on my pumps to get what i want the first time around. camaros are not light cars. do not go single pump.

Have you ever seen double action pumps or cylinders that can lift a wheel?

yeah i have, not going to work. they are quite expensive, and setup with those will be much harder due to clearance and a bunch of other factors. look into it, maybe i'm wrong.

If I understand the basics of a lowrider hydraulic system, to raise the car you hit a switch which turns on the motor. The motor builds pressure and pushes the fluid through the check valve. Then when you release the switch, the motor turns off and the check valve keeps the fluid from returning to the motor and keeps the car up in the air, right?

switch will open solenoids that will give power to the pump. check valve is to stop pressure from going back into the pumps tank.

Then you hit the switch the other direction and it activates the dump valve which lets the fluid go back to the tank.

yes, dump to release pressure into the pumps tank via a second route.

If you were to remove the check valve, would the weight of the car on the cylinder push the fluid back through the gears? I imagine the pressure is fairly high so maybe it would even manually turn the gears and motor backward letting the pressure return. Does that sound right? Would it hurt anything?

correct. it will hurt your gear and you will not have achieved lifting and hold the vehicle up.

I think if a lowrider wanted his car to be able to push down a single wheel, he would install a 4 pump system, right? One for each wheel.

technically there are many ways to go about lifting and lowering. you could go single pump, 8 dump manifold or traditional 8 dump to achieve independent lift and lowering. but this will give you much headaches. the least is a 2 pump 4 dump setup. this will work fine. you could go 2 pump 6 or 8 dumps. or go all independent with 4 pumps. 4pumps and not enough batteries is a flaw. keep it simple 2 pump, 4 dump first, then try new setups later. going the cheap route will cost more in the end. spending too much than necessary in a 4 pump is a waste. you also will have more trouble fitting the pumps in the car. too many flaws to this.

Man, I think your wrong on a lot of points.

First, if you swap over to the shorter Koni 8216 coilover there is plenty of room between the coilover top to the hood.

You can buy 4" stroke cylinders and that short sucker may fit above the stock shock.

The upper A-arm mount can be easily bolted into place while leaving the entire center area free.

That upper shock sheetmetal is very strong as it is designed to support the weight of the car.

These cars do not use struts.

My design requires the hydraulics to be very rigid so accumulators can not be used.

The cylinder is no where near the lower A-arm and it's fitting is on the top. I modded the picture to show that.

First, if you swap over to the shorter Koni 8216 coilover there is plenty of room between the coilover top to the hood.

You can buy 4" stroke cylinders and that short sucker may fit above the stock shock.

The upper A-arm mount can be easily bolted into place while leaving the entire center area free.

That upper shock sheetmetal is very strong as it is designed to support the weight of the car.

These cars do not use struts.

My design requires the hydraulics to be very rigid so accumulators can not be used.

The cylinder is no where near the lower A-arm and it's fitting is on the top. I modded the picture to show that.

i understand that the front is a shock, but it is very close to a strut due to the coil around it. it is a very different suspension setup. i refer to it as a strut because it is locked in place by a nut.

a stock strut assembly is roughly 22-24" IIRC. that is fully extended on the vehicle. i lowered my front quite a bit and now my strut assembly is about 19" when fully extended. pretty much that koni setup will have about 19" fully extended when thus only giving you about a 3-4" of length that you can make up with a cylinder. a 4" cylinder will be at least 6" in total length when fully collapsed. add a fitting to the end and now you're at 7-8" of length that you have to cram in. and i definitely don't see how you could mount a cylinder on top of the koni.

accumulators are at the pump so there is no issue with there use. they make the ride much better. plenty of euro(non tradtional lowriders, ie f bods, civics, pretty much anything newer) can use accumulators to take the place of a shocks work.

First, tell me what year vehicle we're dealing with. Is it your LS1 camaro in the sig pic?

00 SS in my sig. that ride height is pretty low already. it isn't speed bump friendly. i can drop down maybe 1 more inch once i can lift the car up with switches.

What do you want it to do?

the basics man. i'm not into hopping. i want to lift and lower over speed bumps and make the car look mean.

I just want to adjust my ride height electronically and don't mind if it takes a few seconds to go up or down.

Do you want yours to be slow like that or fast?

slow. 12 volts will not work even if you have 3-4 batteries in parallel. i'm planning 4 batteries, 2 to make 12 volts and then series them to the other pair to get 24 volts. this allows a decent lift speed yet still allow a good amount of play time. 36 volts is too fast for me. 48 volts will get the front to hop a little which is too violent for me.

Do you want electronic control or just manual switches?

manual, electronics can fail. if something happens and the switch is set to raise the car, you will be fucked because the pump will keep going til the batteries die or you have a fire. hahaha. i also will be using pressure relief valves to not over pressurize the hydraulic system if a failure were to occur thus giving me time to disconnect my quick disconnect(ground release).

for lowering(dumping), electronics are fairly safe. you could just use an auxillary from an alarm system.

Do you want it to hop or dance around?

not at all. i want to lift and lower and still somewhat keep my car's performance. i've talked to a well known hopper/dancer who did dance a 93-94 camaro but it was a throw away car. he said he'd break the hatch. camaros don't have frame which sucks. i know these cars can take abuse such as wheelies whn drag racing, but hopping/dancing is much more abusive. because it is constant.

Smooth ride and good handling or stiff lowrider like ride?

my car rides like **** right now on stock cut springs and low profile tires. i want the accumulators in my setup to help the ride. they are adjustable which is a plus.

Have you already ruled out an air system?

i definitely would not do air. i'm a hydraulic person. i very much hate air. worst part about air in an f bod is that when laid, you will be riding on the bag's rubber. i don't like that. i'm going to end up spending much more on hydraulics but i love hydraulics. i might be able to talk to black magic(hydraulic company) and see if he could fab me up a custom cylinder to make the lower mount easier, i've already made a plate to mount the top. but even so, there will be a problem still with a getting a spring in there that will be compressed all the time. their shop is in vegas and i might make a trip out there sometime early 08. CCE has some good suspension parts but i would not buy any of their hydraulic parts.

Some of the questions I had were:

If you use 4 cylinders and a single pump running on 12v how fast or slow would it take to lift the whole car say 4"? Are we talking 3-4 seconds or 10-15 seconds?Think it would be worth it to add a second battery and run the pump 24v?

slow. very slow, it may not even be able to fully raise the front end. that was the case on my 91 camaro where i ran 3 batteries in parallel it would not raise me and my 300lb friend. hahha. 24 volts is the minimum. 36 volts is too fast for me but it is actually considered slow for many people. that stuff you can deal with later. changing battery setup is easy.

How much voltage can those motors take?

they can easily take 72 volts and last hoppers very long. they are often pushed to 96 volts. i have saco brand motors which are much better than no name chinese ones. i also will use gel cells which have a lower cca than what street hoppers will use. it is possible to make an f bod hop. i wouldn't do it to mine. i know how, but not willing to try that suspension setup.

I doubt I would run the pump with the engine off, but I might every now and then just to lift the car up once.

you're batteries will not be in line with the engine's battery. you will have to charge them with a separate charger or buy a streetcharger which will use the car's alternator while the engine is running to charge your batts for the hydraulics. it will not charge as much as a home charger but will keep you going a bit longer. but this is also dependent on how much you hit the switches. also buy carling brand switches. chinese ones will **** up.

Doubling the motor voltage doesn't double the speed does it? Maybe just speeds it up a little? Or does it increase the pressure? Both?

How much does a single motor/pump assembly weigh? About 30lbs?

my pumps are about 30-40lbs each. i have 2. batteries are about 30-35 each for gel cells. you have to have a pump/battery rack. a bunch of other little things. i figure i will be about 3-400lbs heavier when done. which will kill my 1/4 mile time a bit but i'll make it back up with some spray. more weight in the back may actually not be too bad.

Would all 3/8 lines be fine for my setup?

yes. 3/8 will be faster than 1/2. gear selection for the pump will also affect speed.

I was also considering a mini pump, any experience with those? They are like $150. Or should I stick with a fullsized pump assembly?

no do not go mini. many problems too it. get a 2 pump 4 dump setup. no manifold bs. it's not worth it. i'm spending quite a bit on my pumps to get what i want the first time around. camaros are not light cars. do not go single pump.

Have you ever seen double action pumps or cylinders that can lift a wheel?

yeah i have, not going to work. they are quite expensive, and setup with those will be much harder due to clearance and a bunch of other factors. look into it, maybe i'm wrong.

If I understand the basics of a lowrider hydraulic system, to raise the car you hit a switch which turns on the motor. The motor builds pressure and pushes the fluid through the check valve. Then when you release the switch, the motor turns off and the check valve keeps the fluid from returning to the motor and keeps the car up in the air, right?

switch will open solenoids that will give power to the pump. check valve is to stop pressure from going back into the pumps tank.

Then you hit the switch the other direction and it activates the dump valve which lets the fluid go back to the tank.

yes, dump to release pressure into the pumps tank via a second route.

If you were to remove the check valve, would the weight of the car on the cylinder push the fluid back through the gears? I imagine the pressure is fairly high so maybe it would even manually turn the gears and motor backward letting the pressure return. Does that sound right? Would it hurt anything?

correct. it will hurt your gear and you will not have achieved lifting and hold the vehicle up.

I think if a lowrider wanted his car to be able to push down a single wheel, he would install a 4 pump system, right? One for each wheel.

technically there are many ways to go about lifting and lowering. you could go single pump, 8 dump manifold or traditional 8 dump to achieve independent lift and lowering. but this will give you much headaches. the least is a 2 pump 4 dump setup. this will work fine. you could go 2 pump 6 or 8 dumps. or go all independent with 4 pumps. 4pumps and not enough batteries is a flaw. keep it simple 2 pump, 4 dump first, then try new setups later. going the cheap route will cost more in the end. spending too much than necessary in a 4 pump is a waste. you also will have more trouble fitting the pumps in the car. too many flaws to this.

#7

With the setup I have planned the hydraulics have to be very rigid. If you add accumulators it will move. It needs to be rigid to allow the shocks to work properly.

As far as the room on top of the Koni 1139 shocks, You have to measure from the tophat area which is where the rod end will be attached all the way to the hood. The threaded shaft will be gone, the rubber mount above it will be gone and you'll have a hole to let the cylinder through the sheetmetal.

Here is the stock koni tophat:

This is what it would be replaced with:

This unit just screws on in it's place. You may be right though. Once you figure the the cylinder will also have to be extended some in order to allow the suspension to drop a little more plus there is the 90* fitting on top. Also keep in mind I will be running 2" drop spindles. It's just really hard to say whether it would fit with the 1139 Konis. I may have to swap to the shorter 8216's. Then there would be plenty of room for sure.

Considering the amount of money you want to spend, plus you need better shocks anyway, why not try what I'm doing? Replace the front shocks with good Koni 8216 SA's and some 500lb springs. They will ride much better and handle much better. Then run a 4" or 6" cylinder on top of it. As long as the cylinder is super stiff like a steel mount, it will allow the springs and shocks to work properly.

Now the other area you have to look out for is the front tire contacting the sheetmetal. I see you have tall tires like me, so you will be limited as far as how low you can drop it. I think you have maybe 2" of travel left up front. If you did my setup your shocks would have a good 2"-2.5" of travel, but your tire would rub if you hit a bump of any kind. To actually drive the car at a lower height you'd need to tub the front and rear wheels. OR switch over to shorter tires, like a lot of lowrider guys do. I plan to tub my car front and rear so I can lower the ride height and still have a good 2.5" of travel on the compression side.

I'll get back to you on some of the other points. Just remember, you have to throw out all that typical lowrider thinking and see this as a coilover suspended car and only the upper shock mount will move up and down hydraulically.

As far as the room on top of the Koni 1139 shocks, You have to measure from the tophat area which is where the rod end will be attached all the way to the hood. The threaded shaft will be gone, the rubber mount above it will be gone and you'll have a hole to let the cylinder through the sheetmetal.

Here is the stock koni tophat:

This is what it would be replaced with:

This unit just screws on in it's place. You may be right though. Once you figure the the cylinder will also have to be extended some in order to allow the suspension to drop a little more plus there is the 90* fitting on top. Also keep in mind I will be running 2" drop spindles. It's just really hard to say whether it would fit with the 1139 Konis. I may have to swap to the shorter 8216's. Then there would be plenty of room for sure.

Considering the amount of money you want to spend, plus you need better shocks anyway, why not try what I'm doing? Replace the front shocks with good Koni 8216 SA's and some 500lb springs. They will ride much better and handle much better. Then run a 4" or 6" cylinder on top of it. As long as the cylinder is super stiff like a steel mount, it will allow the springs and shocks to work properly.

Now the other area you have to look out for is the front tire contacting the sheetmetal. I see you have tall tires like me, so you will be limited as far as how low you can drop it. I think you have maybe 2" of travel left up front. If you did my setup your shocks would have a good 2"-2.5" of travel, but your tire would rub if you hit a bump of any kind. To actually drive the car at a lower height you'd need to tub the front and rear wheels. OR switch over to shorter tires, like a lot of lowrider guys do. I plan to tub my car front and rear so I can lower the ride height and still have a good 2.5" of travel on the compression side.

I'll get back to you on some of the other points. Just remember, you have to throw out all that typical lowrider thinking and see this as a coilover suspended car and only the upper shock mount will move up and down hydraulically.

Trending Topics

#8

Do you know if any dump valves can handle high pressure in both directions? I was thinking they all had a high pressure side and a low pressure side with the plunger in between. I need a design that can handle high pressure from either side.

from caliswangin916

best hopping/dancing dump out there is an adex(its a replica of the oldschool plane's adex). hoppers trust this no matter what. there is a virtual lifetime warranty on them. they run about 375-425 for the basic regualr non polished. you will not need these for your application. a basic italian dump from a good company will last fine and hold pressure fine. many hop on these to high inches say 40-60 inches before going to adex. they run about 60-70 bucks.

i've got somewhere around 15-1800 on my parts right now and i don't even have the strut setup yet. concentrate on that first and i can get you all the pump/dump info that will make things last and low maintenance.

from caliswangin916

best hopping/dancing dump out there is an adex(its a replica of the oldschool plane's adex). hoppers trust this no matter what. there is a virtual lifetime warranty on them. they run about 375-425 for the basic regualr non polished. you will not need these for your application. a basic italian dump from a good company will last fine and hold pressure fine. many hop on these to high inches say 40-60 inches before going to adex. they run about 60-70 bucks.

i've got somewhere around 15-1800 on my parts right now and i don't even have the strut setup yet. concentrate on that first and i can get you all the pump/dump info that will make things last and low maintenance.

#9

For my setup I need to raise and lower each wheel indepently. Lowering is no problem as each wheel will have a dump valve, but lifting will be a problem since I do not want to run a pump for each wheel. What I was hoping was to run a dump in place of the check valves with a single pump. Then wire it up that a lift signal on one of the wheels would open that wheels dump valve and turn the motor on. Since the other 3 dump valves would be shut, the pressure would only go to that one wheel that has the valve open.

In order for this setup to work, the dump valve would need to be able to withstand the pressure from both the pump and the cylinder. I don't know if it can handle pressure from both sides.

It would also have to allow the fluid to run back through the gears instead of having a seperate return line. Do you think it would damage anything?

If so, then I may have to figure out another way to control everything.

Did you see that video I posted? How do you think they got that little tiny pump to lift the car on 12volts? Maybe a special motor optimized for that voltage? Like say a 6v motor and then run it at 12v-13v?

In order for this setup to work, the dump valve would need to be able to withstand the pressure from both the pump and the cylinder. I don't know if it can handle pressure from both sides.

It would also have to allow the fluid to run back through the gears instead of having a seperate return line. Do you think it would damage anything?

If so, then I may have to figure out another way to control everything.

Did you see that video I posted? How do you think they got that little tiny pump to lift the car on 12volts? Maybe a special motor optimized for that voltage? Like say a 6v motor and then run it at 12v-13v?

#10

from caliswangin916

4 pumps is overkill. you can make a setup act like a 4 pump with 6 or eight dumps which i think is overkill as well. there is no need to individually lift each corner. you would make it harder to get an even lift. the equiptment to lift/lower is easy. don't worry about that for now. get a safe front suspension setup idea going and i'll try it myself to see if it works. i still don't understand how/where the hydraulic cylinder would sit to be secure when lifting and lowering. i don't think you will need lowered spindles to do this. my car is very low and sits on 215/35/18's or 215/40/18's(depending on my mood). there is no need for dropped spindles to align the front as it sits.

yeah i know there are plenty of other points in your messages. do what you think will work or show me completely what you intend. i've only skimmed your thread. i need sometime to sit and think about it, but i still don't know about sitting a cylinder on top of the koni assembly. good luck because i really want you to get this done so i can get mine done. you just have to do it, get down and dirty and see if there are problems that you didn't think of. i had a bunch of design theories but when i actually took everything apart, i was not able to come up with a solution that was safe.

yeah i know there are plenty of other points in your messages. do what you think will work or show me completely what you intend. i've only skimmed your thread. i need sometime to sit and think about it, but i still don't know about sitting a cylinder on top of the koni assembly. good luck because i really want you to get this done so i can get mine done. you just have to do it, get down and dirty and see if there are problems that you didn't think of. i had a bunch of design theories but when i actually took everything apart, i was not able to come up with a solution that was safe.

#11

I'm trying to make the whole setup light weight and as cheap as I can. Seeing as how no one seems interested in this I may just forget trying to make it easy for others to install, and just focus on a one-off setup where weight and cost are not that big a deal.

As far as batteries, I plan to have the one under the hood and I was planning to have a second in the back, mainly for the stereo system and I would run dual alternators to keep them charged up. I believe I could wire the pump motor up so both batteries would give it 24v for lifting them and then go back to being seperated. I don't think that would hurt anything except maybe add some static to the stereo when the car lifts up, maybe. I don't need any play time with it. Most of the time it will lift only when the car is running. So that may fix the battery situation.

Something else to consider if you don't plan to run electronics is how you'll know when you are at ride height. Playing with it manually is fun and all, but when your ready to hit the freeway you want the ride height to be where you have the alignment set. That way you don't wear out your tires or make the car handle dangerously. With air setups you can just note the air pressure and return the car to that, but with hydraulics, you need something similar. I plan to spend $800 on that Dakota Digital setup with the ride height sensors, but if you don't want to spend that, then you can probably buy just the sensors and rig them to show you the voltage at your ride height. Then you just lift or lower the car manually until they show the right voltage and you'll be set.

As far as batteries, I plan to have the one under the hood and I was planning to have a second in the back, mainly for the stereo system and I would run dual alternators to keep them charged up. I believe I could wire the pump motor up so both batteries would give it 24v for lifting them and then go back to being seperated. I don't think that would hurt anything except maybe add some static to the stereo when the car lifts up, maybe. I don't need any play time with it. Most of the time it will lift only when the car is running. So that may fix the battery situation.

Something else to consider if you don't plan to run electronics is how you'll know when you are at ride height. Playing with it manually is fun and all, but when your ready to hit the freeway you want the ride height to be where you have the alignment set. That way you don't wear out your tires or make the car handle dangerously. With air setups you can just note the air pressure and return the car to that, but with hydraulics, you need something similar. I plan to spend $800 on that Dakota Digital setup with the ride height sensors, but if you don't want to spend that, then you can probably buy just the sensors and rig them to show you the voltage at your ride height. Then you just lift or lower the car manually until they show the right voltage and you'll be set.

#12

there is no need to individually lift each corner.

This doesn't make sense?

The donut would need to be welded to the cylinder at about the halfway point. Or I could add a sleeve between the cylinder cap about 2"? long and weld it on. If I remember right, there is about 4" from the sheetmetal to the hood, so figure 3" of cylinder and the last inch for the fitting. I'm assuming the cylinders can be welded on. If not, I'll have to space it and just tack the donut on it so it doesn;t drop down and then make the donut bolt onto the car.

I'll try and do a close up drawing of how the cylinder will mount through the metal.

Last edited by JasonWW; 12-05-2007 at 12:39 AM.

#13

I admit, in my main hydraulic thread I glossed over a few things that I already had worked out in my head. My setup is going to be pretty sophisticated, while you want a more bare bones setup. You should be able to do your setup just like this:

First I'll show you how to mount the upper A-arms while leaving a lot of room in the center for the cylinder to mount.

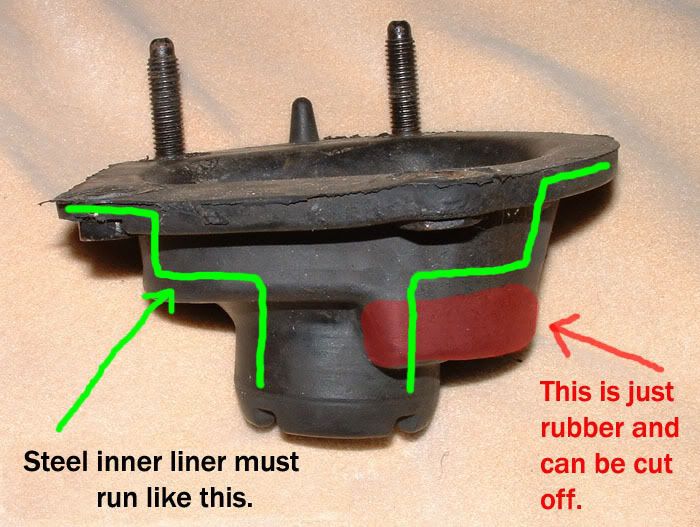

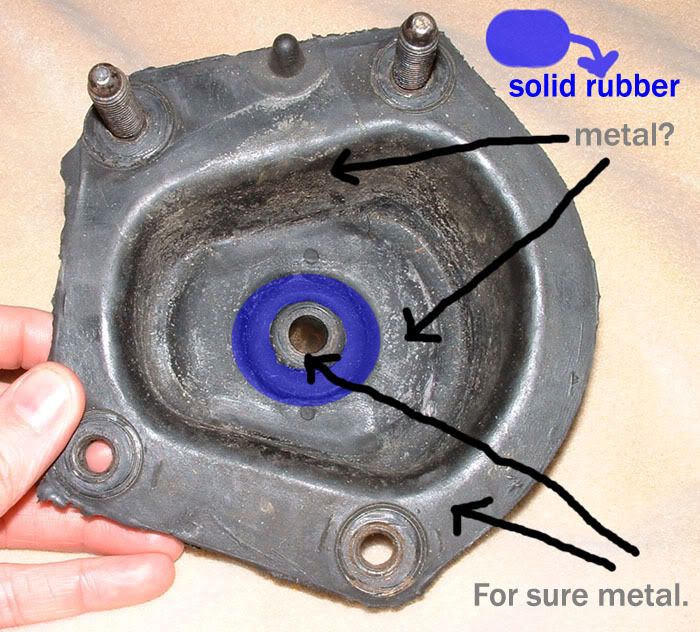

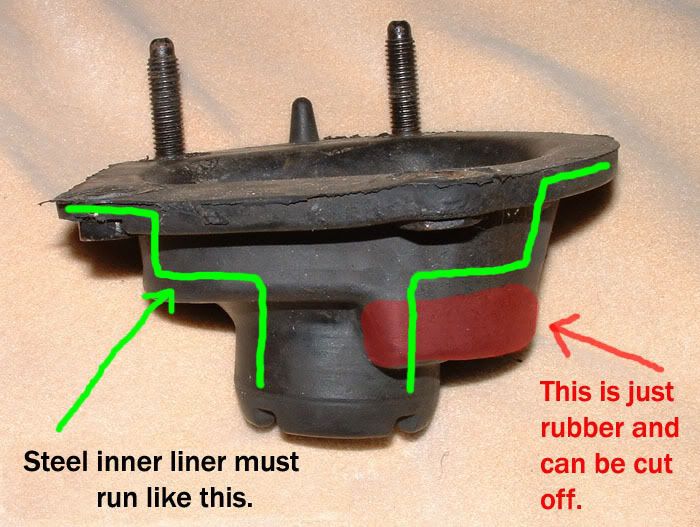

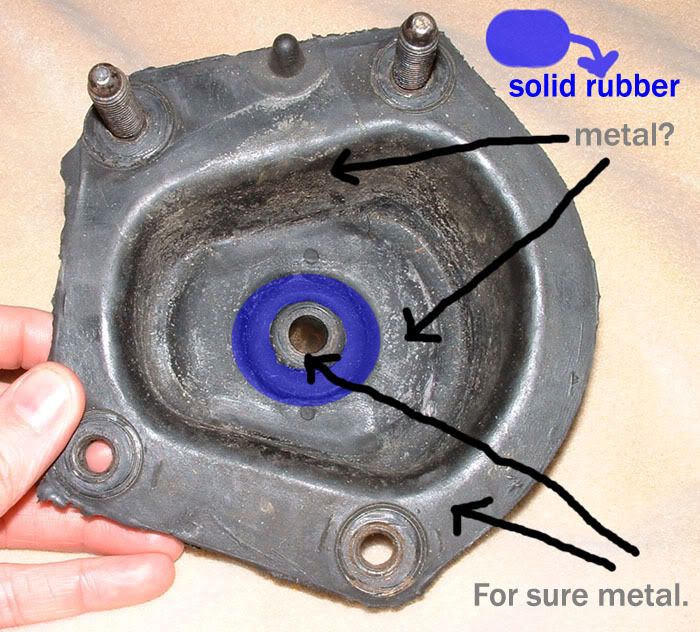

Here is the upper shock mount (ignore the picture wording):

Take this and cut the center out of it leaving only the ring that has the bolts and nuts on it. This ring can be bolted on to hold the A-arm in place.

The top of the coilover will have a rod end like this:

But instead of welding 2 tabs, we cut out that lowered center piece. With this and the rubber center section both cut out, you can look under the car straight up and see the reinforced fender sheetmetal. This is what will give us the room to mount the cylinder to the fender sheetmetal. The exact spacing as far as how low the cylinder will need to drop below the metal is still to be determined, but I'm thinking about half the cylinder on top and half on bottom. So the donut would be around the middle of the cylinder. Then you just fab up a a 2 sided tab and bolt it to the cylinder shaft. The shocks rodend will then bolt to the tab similar to the 3rd pic above.

Does that make sense? Tommorrow I'll dig up some better pictures and show the position of the cylinder through the sheetmetal.

First I'll show you how to mount the upper A-arms while leaving a lot of room in the center for the cylinder to mount.

Here is the upper shock mount (ignore the picture wording):

Take this and cut the center out of it leaving only the ring that has the bolts and nuts on it. This ring can be bolted on to hold the A-arm in place.

The top of the coilover will have a rod end like this:

But instead of welding 2 tabs, we cut out that lowered center piece. With this and the rubber center section both cut out, you can look under the car straight up and see the reinforced fender sheetmetal. This is what will give us the room to mount the cylinder to the fender sheetmetal. The exact spacing as far as how low the cylinder will need to drop below the metal is still to be determined, but I'm thinking about half the cylinder on top and half on bottom. So the donut would be around the middle of the cylinder. Then you just fab up a a 2 sided tab and bolt it to the cylinder shaft. The shocks rodend will then bolt to the tab similar to the 3rd pic above.

Does that make sense? Tommorrow I'll dig up some better pictures and show the position of the cylinder through the sheetmetal.

Last edited by JasonWW; 12-05-2007 at 01:09 AM.

#14

I know this isn't exactly what you're looking for but when I was into large import sedans (lexus & infinity) there was a relatively new product that sounds like its designed for exactly what you want to do. Its made by a company in japan called Bold World, known for slammed sedans that function on coilovers. There's an upper hat on the coilover that is also an air cylinder to allow the height to be raised when required. They don't have it listed on their website but you can buy just the upper cup/air cylinder and then all you need is some air lines and a small compressor/tank combo.

Here's an image to give you an idea.

Link to manufacturer

Here's an image to give you an idea.

Link to manufacturer

#15

I know this isn't exactly what you're looking for but when I was into large import sedans (lexus & infinity) there was a relatively new product that sounds like its designed for exactly what you want to do. Its made by a company in japan called Bold World, known for slammed sedans that function on coilovers. There's an upper hat on the coilover that is also an air cylinder to allow the height to be raised when required. They don't have it listed on their website but you can buy just the upper cup/air cylinder and then all you need is some air lines and a small compressor/tank combo.

Here's an image to give you an idea.

Link to manufacturer

Here's an image to give you an idea.

Link to manufacturer

That's for the link, though. I have not seen this particular brand.

Any idea what the pricing is? I can't read anything.

Ah, it looks like a rebadged Roberuta Cup design. That's the one I've seen in the past so it probably costs the same.

#16

I found a similar design sold in the US from Umbrella Auto Design. They say it's better than the Roberuta Cup. It's still $3000 and I think you can only have ride height or higher. So it's not something I would consider. They do say it gives 5" of lift, but looking at the picture of the cups, I doubt it.

Video here:

http://www.umbrellaautodesign.com/co...t_pending.html

And here:

http://www.noticias.info/video/video...Id=ys6zCuSJIYQ

Video here:

http://www.umbrellaautodesign.com/co...t_pending.html

And here:

http://www.noticias.info/video/video...Id=ys6zCuSJIYQ

#17

Bold World is the parent company for Roberuta. I'm sure pricing is similar to what you've seen in the past. Just drive around super slammed all the time and raise it if/when you need to, that's true baller style, LOL.

#18

For my setup I need to raise and lower each wheel indepently. Lowering is no problem as each wheel will have a dump valve, but lifting will be a problem since I do not want to run a pump for each wheel. What I was hoping was to run a dump in place of the check valves with a single pump. Then wire it up that a lift signal on one of the wheels would open that wheels dump valve and turn the motor on. Since the other 3 dump valves would be shut, the pressure would only go to that one wheel that has the valve open.

2 PUMPS 8 DUMPS

In order for this setup to work, the dump valve would need to be able to withstand the pressure from both the pump and the cylinder. I don't know if it can handle pressure from both sides.

ITALIAN DUMPS WILL WORK FINE. NO NEED TO SPEND HIGH DOLLARS ON ADEXES. it will hold pressure fine and keep the the fluid from returning to the pump. there are also open dumps until you hit a switch which cause them to close. running an 8 dump setup has the disadvantage that there are now 4 more dumps that can fail.

It would also have to allow the fluid to run back through the gears instead of having a seperate return line. Do you think it would damage anything?

If so, then I may have to figure out another way to control everything.

Did you see that video I posted? How do you think they got that little tiny pump to lift the car on 12volts? Maybe a special motor optimized for that voltage? Like say a 6v motor and then run it at 12v-13v?

12 volts will not work. neither will 12 volts up front and one additional battery in the back. there is a possibility that the pump motor would try to draw a lot of amps causing electrical pronblems to the rest of the car if you used the front battery.

2 PUMPS 8 DUMPS

In order for this setup to work, the dump valve would need to be able to withstand the pressure from both the pump and the cylinder. I don't know if it can handle pressure from both sides.

ITALIAN DUMPS WILL WORK FINE. NO NEED TO SPEND HIGH DOLLARS ON ADEXES. it will hold pressure fine and keep the the fluid from returning to the pump. there are also open dumps until you hit a switch which cause them to close. running an 8 dump setup has the disadvantage that there are now 4 more dumps that can fail.

It would also have to allow the fluid to run back through the gears instead of having a seperate return line. Do you think it would damage anything?

If so, then I may have to figure out another way to control everything.

Did you see that video I posted? How do you think they got that little tiny pump to lift the car on 12volts? Maybe a special motor optimized for that voltage? Like say a 6v motor and then run it at 12v-13v?

12 volts will not work. neither will 12 volts up front and one additional battery in the back. there is a possibility that the pump motor would try to draw a lot of amps causing electrical pronblems to the rest of the car if you used the front battery.

#20

What ever happened to that air bag idea you had a while back, I quite liked those universal air strut type sleeves for the front and if you wanted to get super fancy with it you could always run linear potentiometers to measure your wheel travel and adjust air in each corner accordingly, could even have it setup to dump air pressure in the outer side of the car in a turn to help out the sway bars. Hydraulics just seem... heavy.