Started to learn tig welding today.

#1

Staging Lane

Thread Starter

Join Date: Nov 2010

Location: Las Vegas, NV

Posts: 85

Likes: 0

Received 0 Likes

on

0 Posts

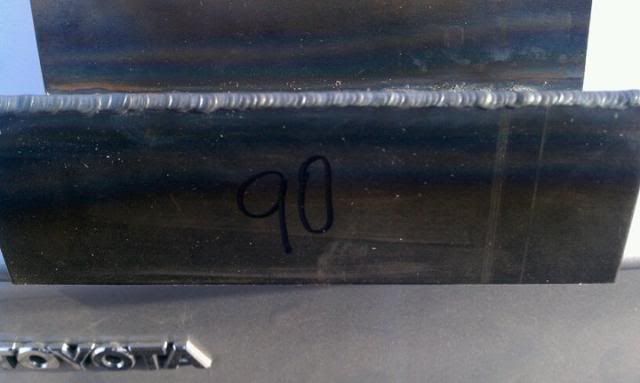

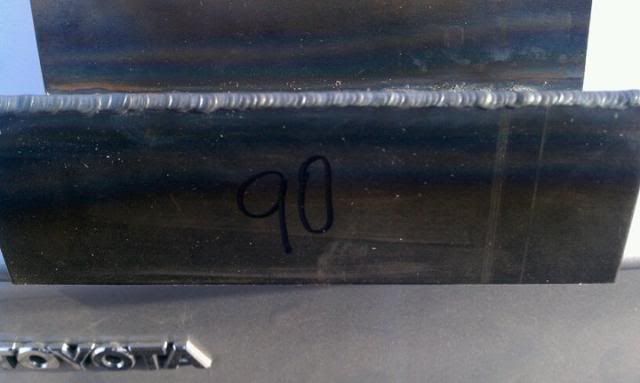

Still need work but I am pretty happy with the results. Scored a 90% on it in class. Hopefully I'll start fabricating up my own custom parts in the near future.

Weld bead (sideways)

Graded by the instructor

Vertical

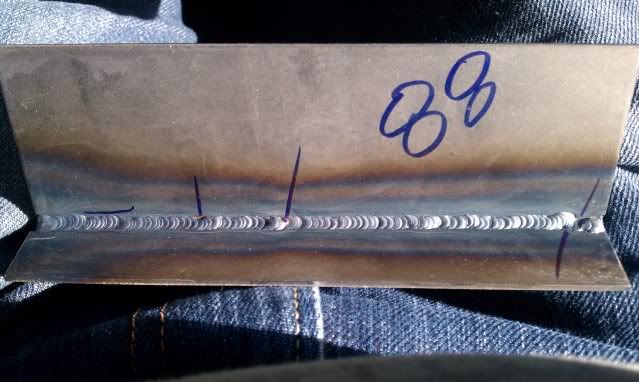

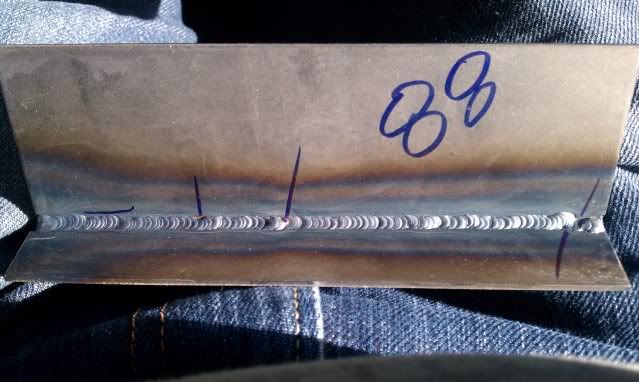

Penetration (backside)

Up close (vertical view)

********UPDATE 2/27/11*******

T joint

Weld bead (sideways)

Graded by the instructor

Vertical

Penetration (backside)

Up close (vertical view)

********UPDATE 2/27/11*******

T joint

Last edited by Mr.Nguyen; 02-27-2011 at 05:29 PM.

#4

So I'm curious what was the reason for the 10% off?

Looks pretty decent, heat control could be a little better (not that I'm saying I can do better myself, I seem to be able to do things with a MIG most can't but I'm slow to learn with my TIG, I keep thinking a formal class might help...)

Looks pretty decent, heat control could be a little better (not that I'm saying I can do better myself, I seem to be able to do things with a MIG most can't but I'm slow to learn with my TIG, I keep thinking a formal class might help...)

#5

Staging Lane

Thread Starter

Join Date: Nov 2010

Location: Las Vegas, NV

Posts: 85

Likes: 0

Received 0 Likes

on

0 Posts

-10% was where the penetration got a little thin. Lol. The teacher is actually a welding inspector for the state of nv. So he is pretty critical. But any criticism will be taken as constructive criticism. Thoughts, comments, and tips will be greatly appreciated.

#6

Staging Lane

Thread Starter

Join Date: Nov 2010

Location: Las Vegas, NV

Posts: 85

Likes: 0

Received 0 Likes

on

0 Posts

On picture number 4 where the white mark is on the back side of the work piece. That is where I got points taken off for penetration not meeting his standards. It did get a little thin.

Trending Topics

#8

TECH Addict

iTrader: (8)

if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

#9

TECH Addict

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

It was still 100% penetration. I used to TIG weld vessels as a ASME section 5 welder for 9 years.. Made stuff for Cali (earthquake code) to hold 10,000psi of natural gas.....very strict standards, x-ray tests...etc..... 100% is 100%....lol. If he marked me down for that saying it was "thin" I would have told him to go to hell and called him an idiot.  if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

if you would have made it all thin like that it would have been 100... he probably just marked it because you varied from one spot to the other. It looks like the amount of weld surface excedes the material thickness by 200% .... its more than good.

#10

I mostly agree with pwrtrip75, except that I could see if you got marked off for varying your penetration, but that's still awfully fussy to call on someone just getting started.

My $.02 from what I'm seeing in the pictures is that in a perfect world all of your weld would look like the spot marked. You have full penetration there, but didn't put any more heat into the weld then you needed to get that full penetration. No big deal for mild steel but it could make a difference for some aluminum, stainless and some alloys that could get brittle and even damaged with excessive heat input.

My $.02 from what I'm seeing in the pictures is that in a perfect world all of your weld would look like the spot marked. You have full penetration there, but didn't put any more heat into the weld then you needed to get that full penetration. No big deal for mild steel but it could make a difference for some aluminum, stainless and some alloys that could get brittle and even damaged with excessive heat input.

#11

Staging Lane

Thread Starter

Join Date: Nov 2010

Location: Las Vegas, NV

Posts: 85

Likes: 0

Received 0 Likes

on

0 Posts

In 2 weeks we are starting on stainless steel. After that I finally get to start on aluminum.

Silverback, what do you mean brittle? Aluminum and stainless would require less penetration or more?

Silverback, what do you mean brittle? Aluminum and stainless would require less penetration or more?

#12

TECH Addict

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

penetration is penetration. period. it's either there or it isn't.

aluminum and SS don't require any different amounts necessarily, but you have to be more in control of your heat input. Keep in mind, heat input is a function of travel speed too, not just volts/amps. stainless is a little less forgiving than mild steel, and alumuinum is even less forgiving. for example, say you're welding 1/8" steel plate together, you might set your TIG to 160 amps (for example) and hit the pedal wide open and go. With aluminum, you'll be better off setting it upwards of 200 amps and you'll be feathering the pedal the whole way. you'll learn this in your class quite quickly i'm sure.

aluminum and SS don't require any different amounts necessarily, but you have to be more in control of your heat input. Keep in mind, heat input is a function of travel speed too, not just volts/amps. stainless is a little less forgiving than mild steel, and alumuinum is even less forgiving. for example, say you're welding 1/8" steel plate together, you might set your TIG to 160 amps (for example) and hit the pedal wide open and go. With aluminum, you'll be better off setting it upwards of 200 amps and you'll be feathering the pedal the whole way. you'll learn this in your class quite quickly i'm sure.

#14

TECH Addict

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

that's basically all there is to it. but the way aluminum dissipates heat is much different that ferrous metals. i'm not trying to scare you, it isn't that hard, it's just different. i love welding aluminum, but i don't get to do it that often any more

#16

Staging Lane

Thread Starter

Join Date: Nov 2010

Location: Las Vegas, NV

Posts: 85

Likes: 0

Received 0 Likes

on

0 Posts

#17

TECH Addict

iTrader: (4)

Join Date: Apr 2010

Location: Longview,TX & Tricitys,WA

Posts: 2,200

Likes: 0

Received 1 Like

on

1 Post

That looks pretty good for starting, tig is awesome because you can get damn near perfect welds everytime. Once you get better at it the bead will be perfect all the way down and penetration will be better on that backside. I hate taking my car into an exhaust shop or stuff where i see other peoples welds cause honestly most will suffice but look like ****.

#18

TECH Apprentice

iTrader: (11)

Join Date: Jul 2005

Location: NWburbs of Chicago

Posts: 395

Likes: 0

Received 0 Likes

on

0 Posts

Lookin good man. Keep it up. Im pretty much just starting out myself, graduating last semester. All I do is practice every chance I get. Keep us updated on your progress.

#19

TECH Resident

iTrader: (7)

Join Date: Sep 2005

Location: DFW, Texas

Posts: 883

Likes: 0

Received 0 Likes

on

0 Posts

Those look good! Im I-CAR certified in MIG but TIG is another ball game. I work with a guy who was a fabricator for a porsche club racing team and can only dream to TIG as well as he can one day.