Post your best welds!

#84

TECH Enthusiast

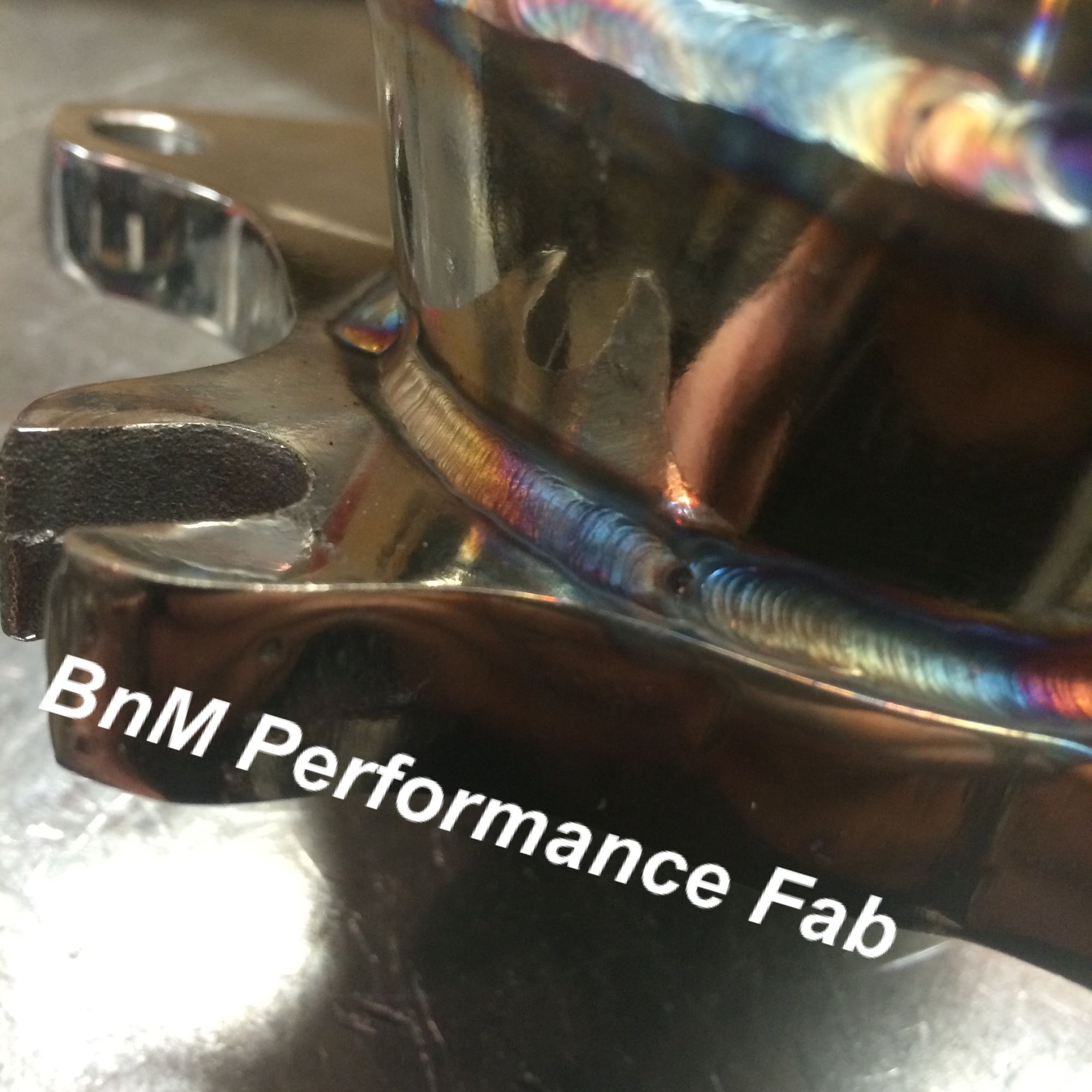

beauty isn't the most important factor in welds, though it can go hand in hand with really good weld quality. Things like proper penetration without burn through or thin spots & needed filler thickness for strength can be more important, especially with projects like most of mine that you need the weld to disappear after grind, sand & polish.

Course on something like a stainless pipe that you won't grind & will be seen, hard to beat a really awesome row of dimes look.

Course on something like a stainless pipe that you won't grind & will be seen, hard to beat a really awesome row of dimes look.

#85

TECH Enthusiast

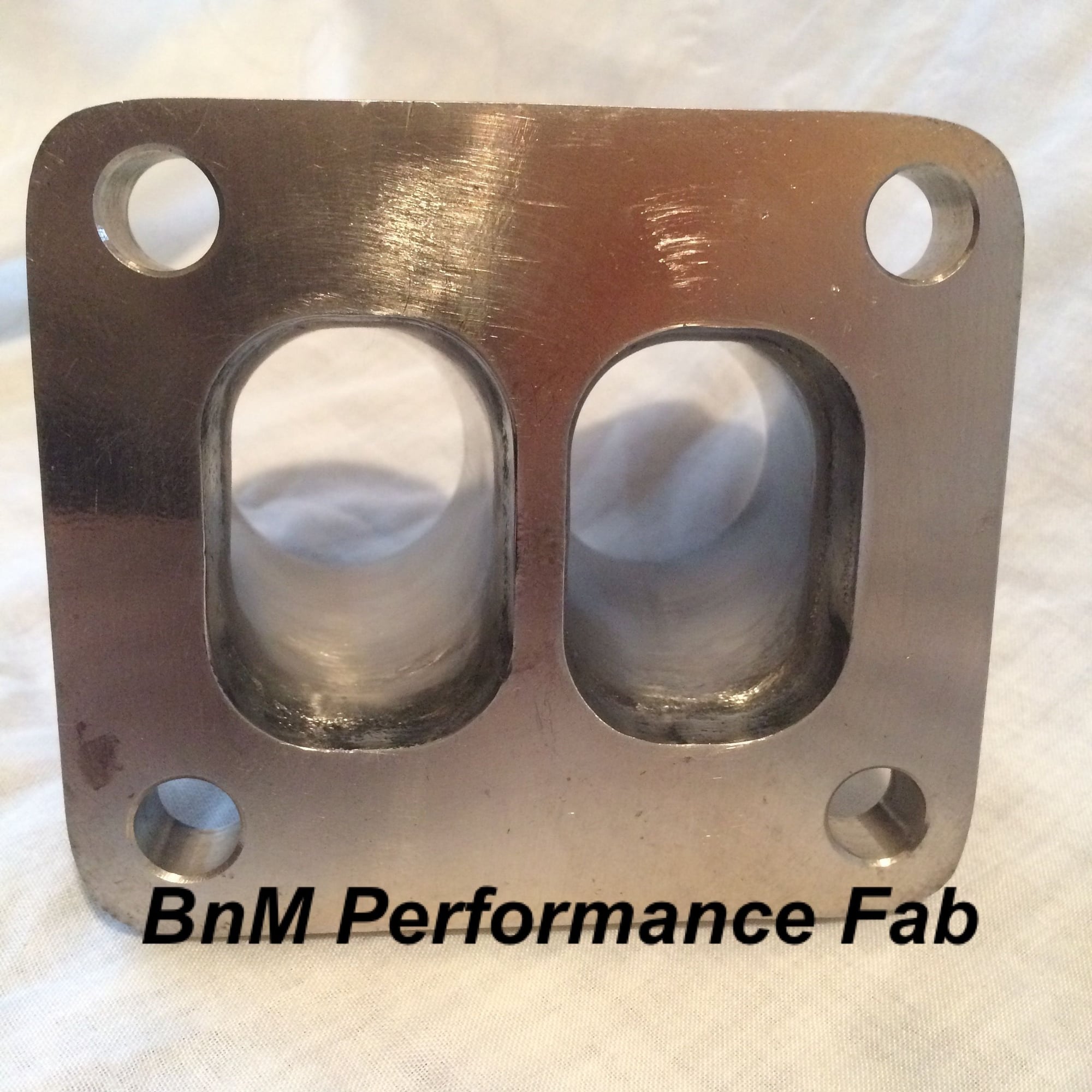

A few of my welds after sanding & partial polishing. Got a few low spots I may fill in & re sand & polish.

One little tip I learned before & forgot was you can use aluminum on the backside of stainless during welding, which will help shield the air without additional backside purging & neaten up the backside weld where you didn't have a tight fit. The bends pictured here were made by removing pie cuts with a hand grinder & a 6" quickie disc, so they weren't all perfect fit. I didn't remember about putting aluminum on the backside till the last few joints. eh

One little tip I learned before & forgot was you can use aluminum on the backside of stainless during welding, which will help shield the air without additional backside purging & neaten up the backside weld where you didn't have a tight fit. The bends pictured here were made by removing pie cuts with a hand grinder & a 6" quickie disc, so they weren't all perfect fit. I didn't remember about putting aluminum on the backside till the last few joints. eh

#87

On The Tree

Join Date: Oct 2008

Location: Surprise, AZ

Posts: 128

Likes: 0

Received 0 Likes

on

0 Posts

i have to make an intercooler this week, i'll post up some of my aluminum welds when its done. i'm a little rusty, so we'll see how this goes

#91

TECH Fanatic

iTrader: (8)

I'm 39 and all I've ever done is weld/fab work. Been a union Boilermaker for nearly 14 years. I'll post a link to some stainless tube welding I posted on a welding forum a few years ago. This is what I do pretty much day in day out.http://www.millerwelds.com/resources...t-I-do-at-work

#92

11 Second Club

iTrader: (14)

Join Date: Mar 2008

Location: Houston

Posts: 1,434

Likes: 0

Received 0 Likes

on

0 Posts

Man some of you guys are freaking incredible! I just started playing with the TIG process a couple weeks ago and I'm hooked (buying an HTP221 in a couple weeks)

I only have about 3 solid hours of actual welding but I'm getting the feel for it pretty quickly. Here's a few pics of some today, any advice on improvements is greatly appreciated.

I only have about 3 solid hours of actual welding but I'm getting the feel for it pretty quickly. Here's a few pics of some today, any advice on improvements is greatly appreciated.

#93

11 Second Club

iTrader: (3)

Join Date: Jan 2008

Location: Aiken, SC

Posts: 623

Likes: 0

Received 0 Likes

on

0 Posts

I'm no welder but one that I work with (petrochem plant) showed me how easy it is to practice the hand motion for "walking the cup" like you see in most of the stainless pipe welds in this thread. Hold a AA battery between your thumb and middle finger with your index finger resting over the end. Press it down on a piece of paper on roughly a 45° angle and practice walking the lines it makes in a zigzag just as those welds look. You can easily see the trace the sharp edge leaves on the paper. I thought it was a pretty cool trick and some of you hobbyist welders might be able to use it when you are bored at work.

#94

11 Second Club

iTrader: (14)

Join Date: Mar 2008

Location: Houston

Posts: 1,434

Likes: 0

Received 0 Likes

on

0 Posts

I'm no welder but one that I work with (petrochem plant) showed me how easy it is to practice the hand motion for "walking the cup" like you see in most of the stainless pipe welds in this thread. Hold a AA battery between your thumb and middle finger with your index finger resting over the end. Press it down on a piece of paper on roughly a 45° angle and practice walking the lines it makes in a zigzag just as those welds look. You can easily see the trace the sharp edge leaves on the paper. I thought it was a pretty cool trick and some of you hobbyist welders might be able to use it when you are bored at work.

For some strange reason I have better results freehanding than walking the cup. I'm sure it's a lack of practice but still doesn't make sense to me. When you guys walk the cup, do you still use the same filler placement (at the center/base) or do you use a stitch pattern?

#95

11 Second Club

iTrader: (3)

Join Date: Jan 2008

Location: Aiken, SC

Posts: 623

Likes: 0

Received 0 Likes

on

0 Posts

Your explanation of hand placement doesn't make a lot of sense with a real torch (index finger placement)

For some strange reason I have better results freehanding than walking the cup. I'm sure it's a lack of practice but still doesn't make sense to me. When you guys walk the cup, do you still use the same filler placement (at the center/base) or do you use a stitch pattern?

For some strange reason I have better results freehanding than walking the cup. I'm sure it's a lack of practice but still doesn't make sense to me. When you guys walk the cup, do you still use the same filler placement (at the center/base) or do you use a stitch pattern?

#96

11 Second Club

iTrader: (14)

Join Date: Mar 2008

Location: Houston

Posts: 1,434

Likes: 0

Received 0 Likes

on

0 Posts

Oh I see. I don't know, I'm the last person to be giving advice. It's probably me but I don't think the battery reference is good practice. There's no way I could hold my torch anywhere close to that position due to heat (I'd have to hold right behind the cup) that being the case, wrist motion would be completely different.

I'm not trying to be rude, just referencing the technique to my experience (which is extremely limited)

I'm not trying to be rude, just referencing the technique to my experience (which is extremely limited)

#97

FormerVendor

iTrader: (15)

I need to try this, sounds like it would work.

I have been wanting to take my "G" welding tests, but not sure how many I can get through. I am guessing the first 3 for sure..

They finally have a test facility in Dallas!! Wooohoo! Calling them now.

I have been wanting to take my "G" welding tests, but not sure how many I can get through. I am guessing the first 3 for sure..

They finally have a test facility in Dallas!! Wooohoo! Calling them now.

Last edited by SNLPerformance; 02-02-2015 at 10:07 AM.

#98

TECH Enthusiast

Yea the battery is just an excuse to practice wrist motion. Could also do this with a pencil.

Practice is useful. The one season I took agriculture class in high school, they taught gas & arc welding. Since I had contacts & no useable glasses at the time, I couldn't arc weld. So I sat there for the whole hour for a couple of weeks inside playing with an arc weld simulator, which tracked your distancing & hand motion skills. I was bad *** on the simulator next to everybody else waiting a turn for a minute of real arc welding.

Still never used a real arc welder, but those hours of simulator practice came in handy on the gas welding, which came in handy for learning tig welding.

practice is practice, Wax on , wax off, kick ***.

Practice is useful. The one season I took agriculture class in high school, they taught gas & arc welding. Since I had contacts & no useable glasses at the time, I couldn't arc weld. So I sat there for the whole hour for a couple of weeks inside playing with an arc weld simulator, which tracked your distancing & hand motion skills. I was bad *** on the simulator next to everybody else waiting a turn for a minute of real arc welding.

Still never used a real arc welder, but those hours of simulator practice came in handy on the gas welding, which came in handy for learning tig welding.

practice is practice, Wax on , wax off, kick ***.