Post your best welds!

#141

Race your car!

iTrader: (50)

Wish it was more impressive. I've taken a bunch to an actual weld inspector that does military inspections and he cross sectioned some of my joints and they are sound, just suck appearance wise to what's in here.

I doctor asked what I was doing and when I told him headers he laughed and said yeah for that it's fine... Apparently I could mig them with 308 wire and they would b fine just nowhere near the appearance I find acceptable

I doctor asked what I was doing and when I told him headers he laughed and said yeah for that it's fine... Apparently I could mig them with 308 wire and they would b fine just nowhere near the appearance I find acceptable

#142

8 Second Truck Club

iTrader: (32)

I'm a 100% self taught tig welder. I purchased a Miller Dynasty 200 back around 2008 and have only tig welded since then. I haven't fired up my Miller mig machine once. It is not too difficult to get a weld that will "work", but I agree with you JL, making the welds perfect looking a pretty is a whole different game and can be very frustrating for me at times. I've never done the social media thing, but my brother recently talked me into getting an instagram account. There are some amazing things being posted on there in the tig world. Some of the **** I have to wonder if it is even real. Pisses me off for sure.

#144

Race your car!

iTrader: (50)

I was actually looking at the alpha tig that Amazon has. I know it's not a miller/Lincoln but every review I have read said good things, and for 800 bucks it is cheap enough so I could buy 2 before I'm at one miller or Lincoln machine.... And I know for a fact Miller and Lincoln machines do break too.

It is supposed to use the same consumables as the Miller/Lincoln, and I understand once you're used to their foot pedal, there's really no operating difference. And it has all the settings to play with you would ever want.

It is supposed to use the same consumables as the Miller/Lincoln, and I understand once you're used to their foot pedal, there's really no operating difference. And it has all the settings to play with you would ever want.

#145

8 Second Truck Club

iTrader: (32)

lol, you aint getting into a miller dynasty for 2 times 800. Everyone thought I was crazy when I bought a dynasty having never held a tig torch, but it was my freakin money.

I do see good reviews all the time on cheaper machines. I would like to see someone like Marcella weld up an intake with a 800 dollar machine and see what it looks like compared to his monsterous $$$ Dynasty 350 set up with Helium/Argon gas mixers and all that ****. I bet he has close to 10 grand in his rig with all the add on ****, but his welds look like a machine did them. Does not look humanly possible to do what that man does.

I'd be willing to bet, he could lay it down pretty close to just as good with a cheaper machine. A nice looking weld is probably 85% person, 15% machine.

I do see good reviews all the time on cheaper machines. I would like to see someone like Marcella weld up an intake with a 800 dollar machine and see what it looks like compared to his monsterous $$$ Dynasty 350 set up with Helium/Argon gas mixers and all that ****. I bet he has close to 10 grand in his rig with all the add on ****, but his welds look like a machine did them. Does not look humanly possible to do what that man does.

I'd be willing to bet, he could lay it down pretty close to just as good with a cheaper machine. A nice looking weld is probably 85% person, 15% machine.

#146

Race your car!

iTrader: (50)

That's my thought. My error, I am borrowing a diversion 165, and have seen a used one locally for 1200 bucks, not sure what they go for new but I considered buying one but the alpha tig from what everyone says, is stable and good/solid.

I have not tried anything with mixing gasses, etc. and I never will. Tig gets argon mig gets 75/25 argon/c02. I may try strait argon with 308 wire in the mig, but that's a maybe.

I have not tried anything with mixing gasses, etc. and I never will. Tig gets argon mig gets 75/25 argon/c02. I may try strait argon with 308 wire in the mig, but that's a maybe.

#147

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 81 Likes

on

72 Posts

Pretty welds are like a karate trophy from elementary school. Sure its a prize to be proud of and a nice accomplishment but doesnt guarantee.....well anything. I made a living as a welder for a while. I learned to weld with my welds being destructive tested just like most others who went to welding school. The prettiest welds didnt always pass once they were bent 180 degrees. I guess when its all about function you start putting looks on the back burner for real world application. At a place I welded there was a rotary table that was hand built. It was an old lathe chuck (big one) hooked to a table to could vary its angle and a gear and motor attached to the back of it like a starter and flywheel. It was foot pedal controlled and varied in speed as to how fast it rotated. Prop up, chuck a piece of pipe or a flange in there, and once you did it a few times you could create welds with machine like accuracy. The tig welds I turned out of there were amazing. In the end though, they werent necessarily any better then ones someone did on a flat table, just prettier.

#151

Race your car!

iTrader: (50)

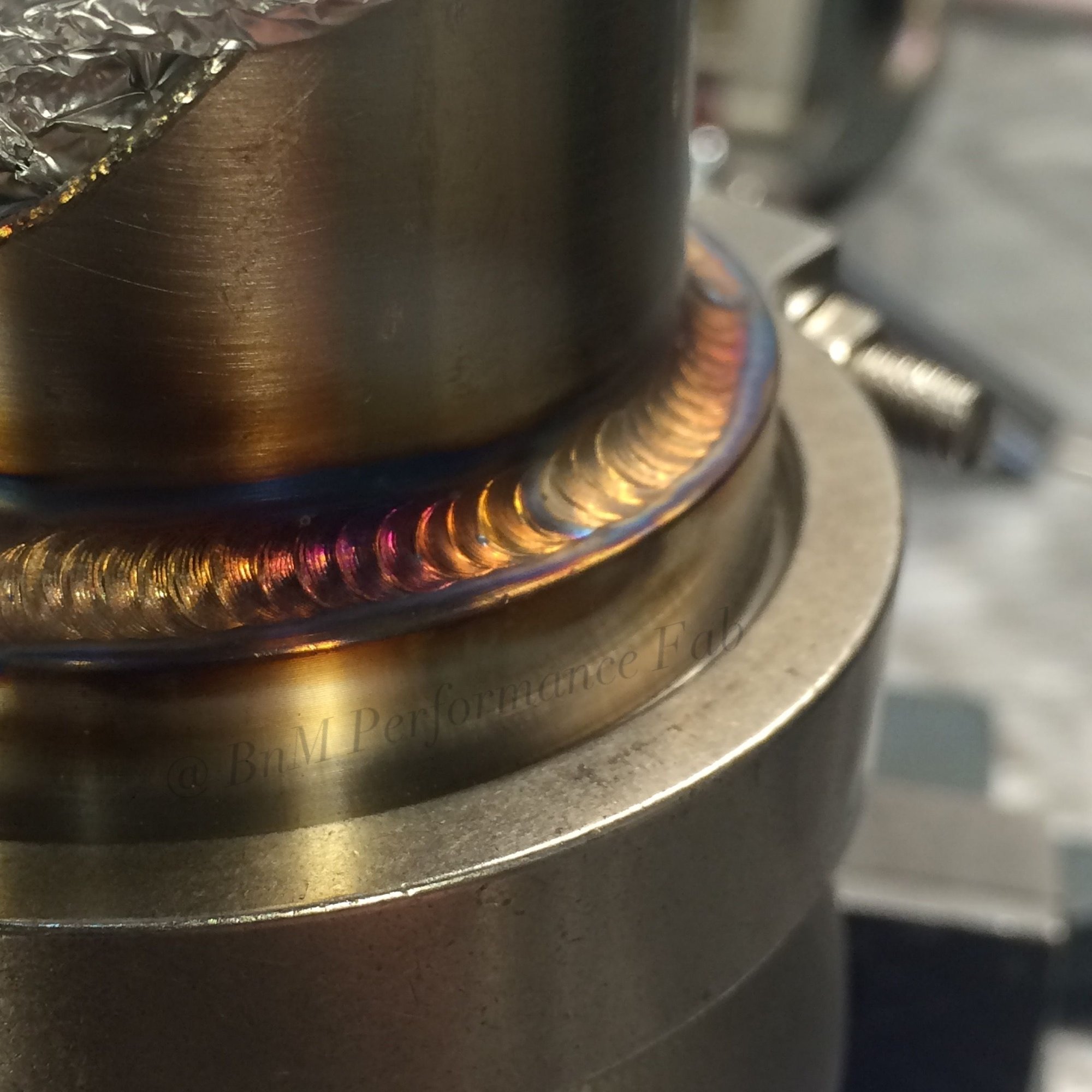

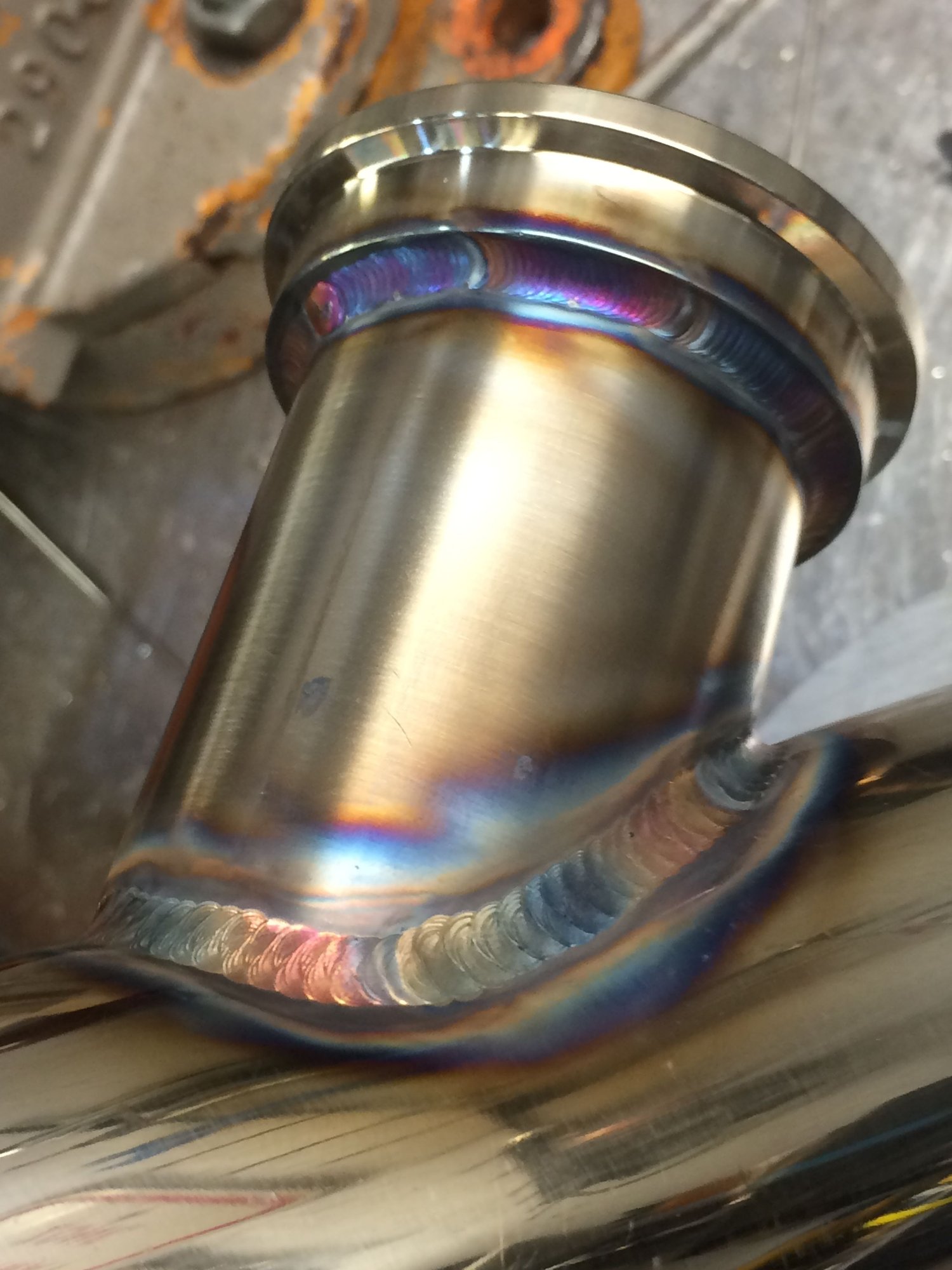

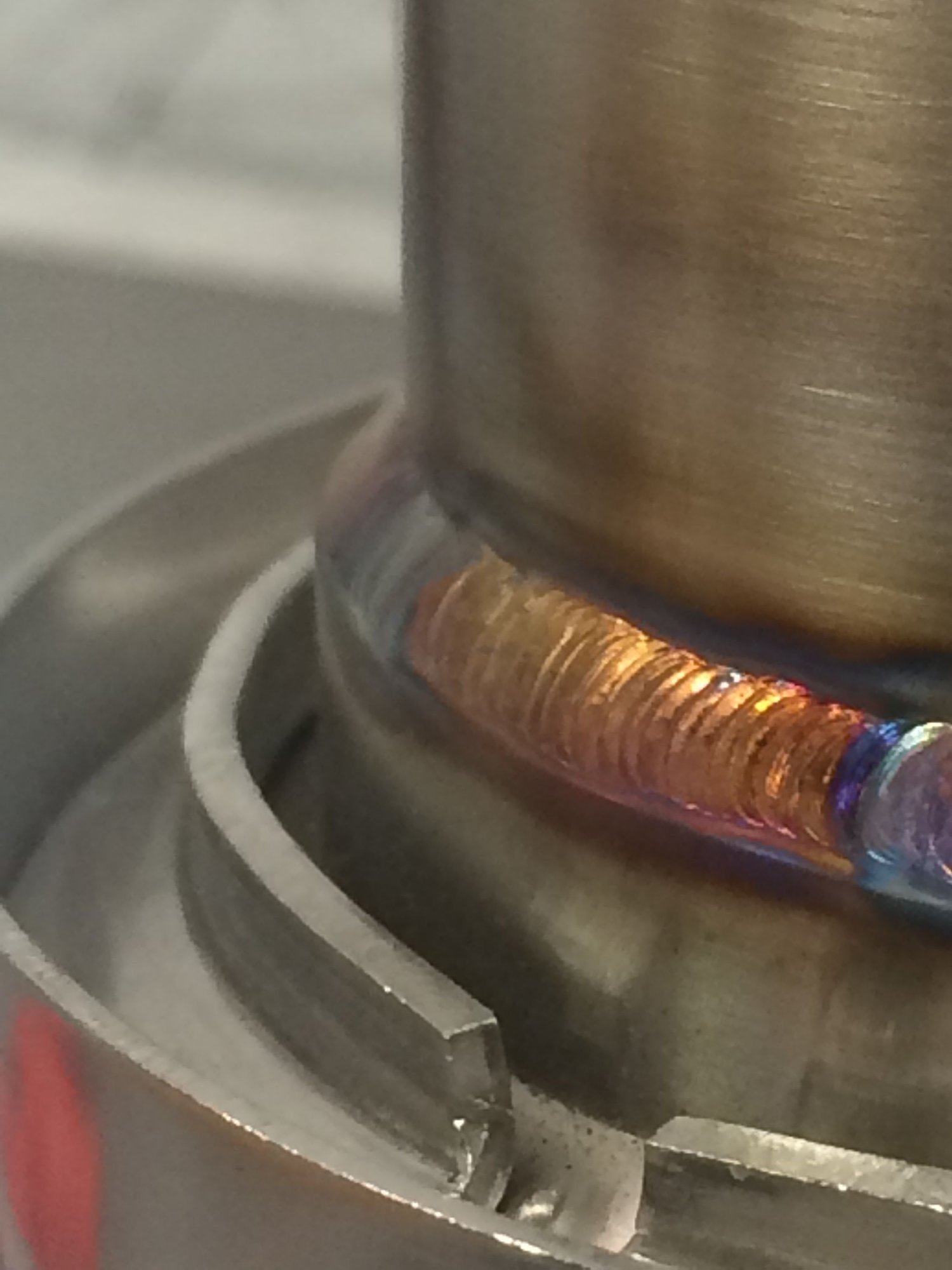

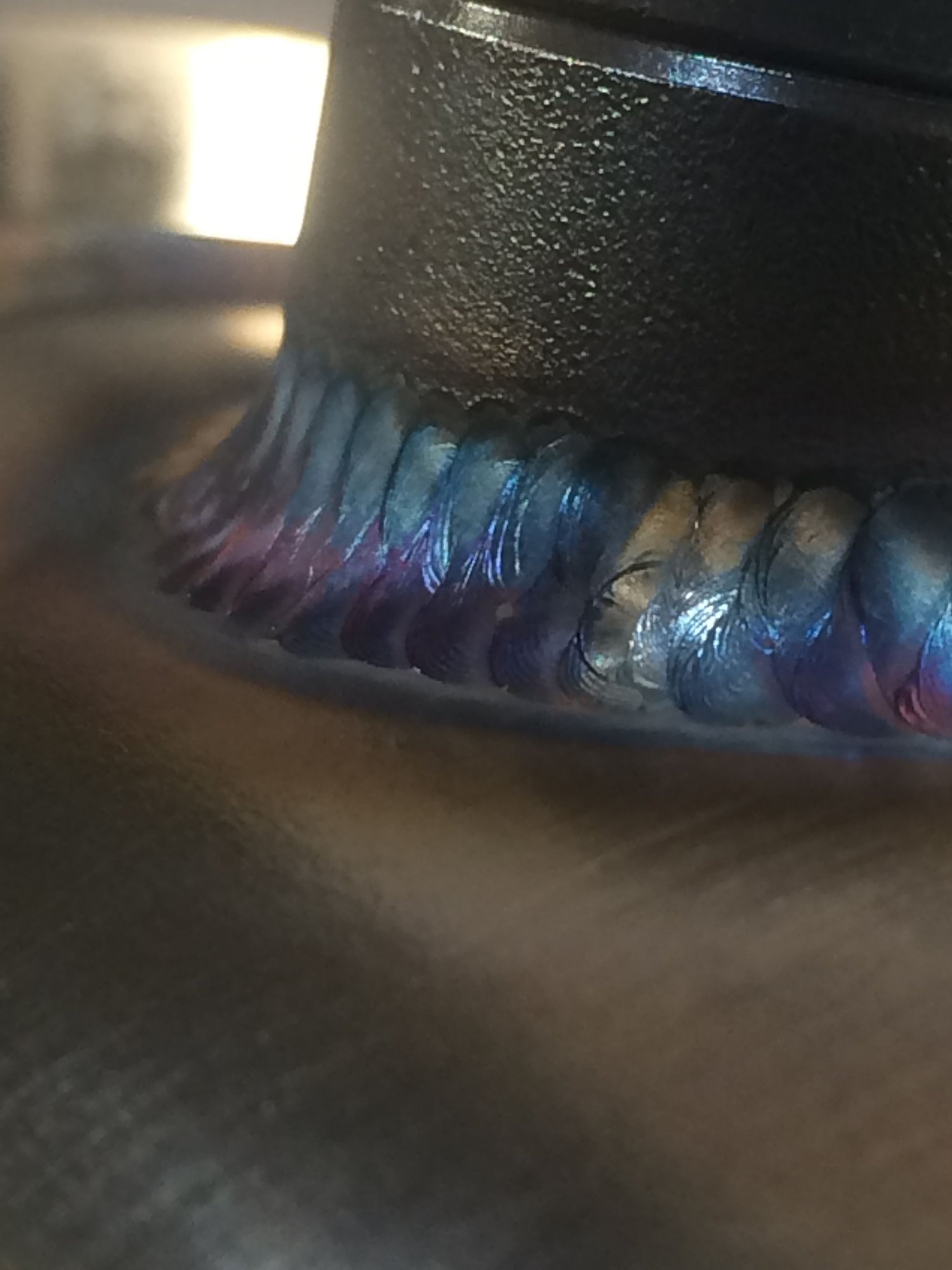

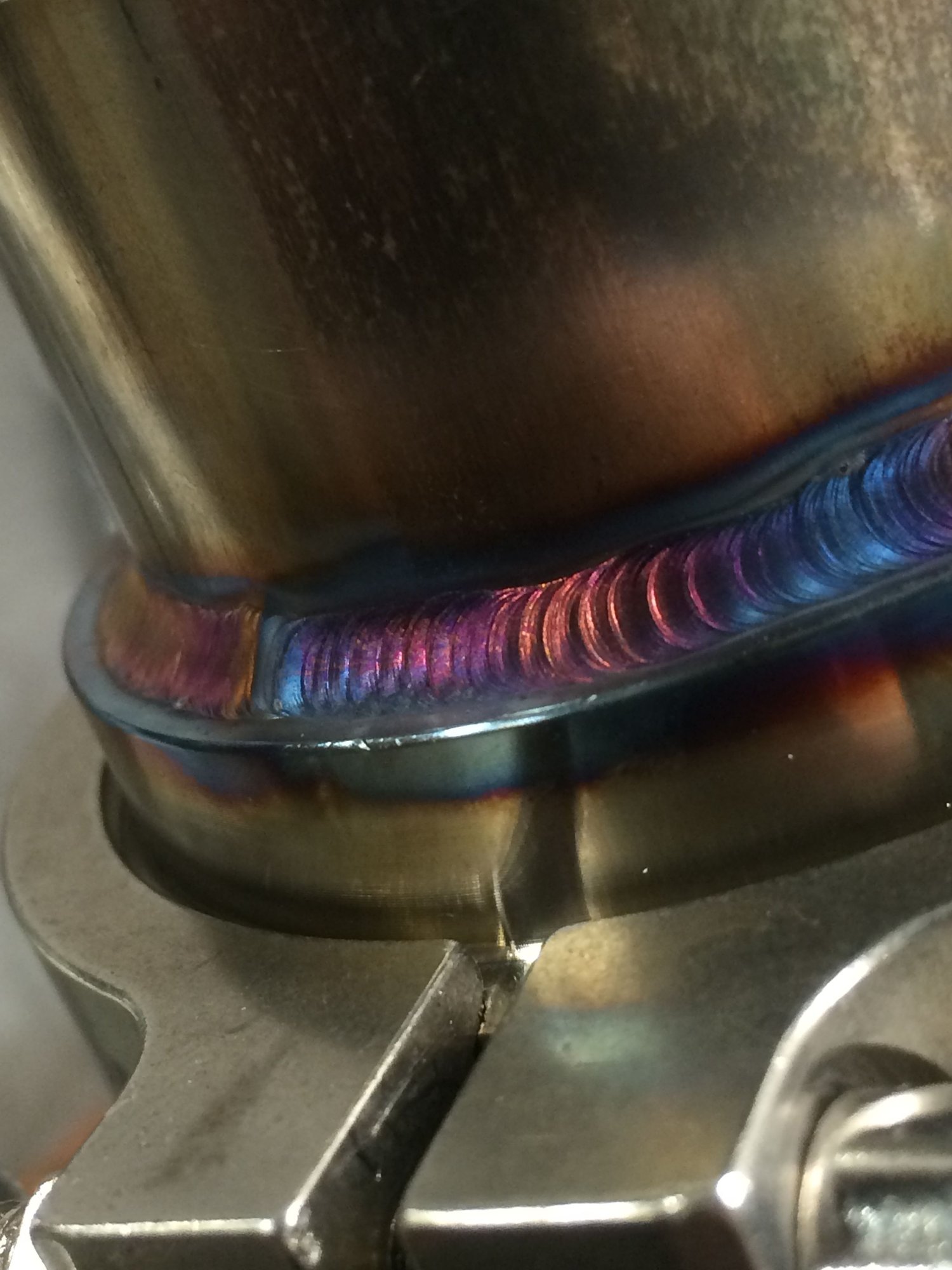

I have no clue how you get that color in a stainless weld, the stacks of dimes I can understand and have successfully done but everything I do comes out looking grey in color, I know I'm getting penetration as I've had welds tested and they held no problems but that coloration... Are you using strait argon gas? How much gas are you flowing out the tip, curious as I have yet to get anything that's been any color other than grey.

#154

Race your car!

iTrader: (50)

Any less and I get nothing for a puddle to feed the filler into... So how I'm going to get filler melted in without the heat I have no idea.

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

#155

Yep, ideally you want them straw color, but reds, blues and purples are ok, grey is a sign of too much heat, I'd suggest moving a bit faster. I'm in school for welding, set to take tig and advanced tig next semester. I'll be learning under a fella who works in the aerospace field welding thin, and exotic metals. Magnesium, cobalt, inconel, titanium, things like that. Only reason I chose the school I'm at.

#156

8 Second Truck Club

iTrader: (32)

Any less and I get nothing for a puddle to feed the filler into... So how I'm going to get filler melted in without the heat I have no idea.

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

This may sound crazy, but maybe you need to turn the heat up (amperage), but move faster. That will give you a puddle to work with.

Give me some examples of material, material thickness, tungsten size and amp settings you are using.

#157

Any less and I get nothing for a puddle to feed the filler into... So how I'm going to get filler melted in without the heat I have no idea.

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

Sound welds, and pretty I guess don't always go together. Haven't had anything fatigue crack yet so too much heat may just be stopping appearance, doesn't appear to be affecting strength...

I have been using these

http://www.dogfab.com/FURICK_CUPS.php

Excellent coverage and being able to see through is sweet especially out of position.

#158

Race your car!

iTrader: (50)

I'm using a number 7 cup that came with the Miller diversion 165 I'm borrowing. Setting wise I've been using the gas flow at 15 cfh on the flow gauge, tungsten is the one he welded came with, got to ha about .100 in diameter I haven't measured it but I know it's the one it came with as the machine was never used, 302 18 ga ss with 308 filler, did the mufflers which was 409 ss and a 302ss bracket, used 309 filler. Amperage I have been trying it all over but if I go any higher than 45 I burn holes in shot so I've been keeping he dial down at what I think is 40, (rotary dial and it's a little under the 45 amp mark).

I don't have any good pictures on the phone, most of the scraps I tested on after fabbing the headers I chucked, I have this one of the 409 muffler/302 bracket:

I don't have any good pictures on the phone, most of the scraps I tested on after fabbing the headers I chucked, I have this one of the 409 muffler/302 bracket:

#159

I'm using a number 7 cup that came with the Miller diversion 165 I'm borrowing. Setting wise I've been using the gas flow at 15 cfh on the flow gauge, tungsten is the one he welded came with, got to ha about .100 in diameter I haven't measured it but I know it's the one it came with as the machine was never used, 302 18 ga ss with 308 filler, did the mufflers which was 409 ss and a 302ss bracket, used 309 filler. Amperage I have been trying it all over but if I go any higher than 45 I burn holes in shot so I've been keeping he dial down at what I think is 40, (rotary dial and it's a little under the 45 amp mark).

I don't have any good pictures on the phone, most of the scraps I tested on after fabbing the headers I chucked, I have this one of the 409 muffler/302 bracket:

I don't have any good pictures on the phone, most of the scraps I tested on after fabbing the headers I chucked, I have this one of the 409 muffler/302 bracket:

#160

Race your car!

iTrader: (50)

Yes that's exactly what they look like. I have tried a red, blue and green tungsten fwiw, and none of them made any real difference. Only thing I've seen matter is how fine a point I get the tip to. Seems a really fine tip doesn't last long, but it's easier t keep the heat focused in one small spot with it, played with that a bunch but didn't see any dramatic differences.