Fix for this?

#3

TECH Junkie

iTrader: (4)

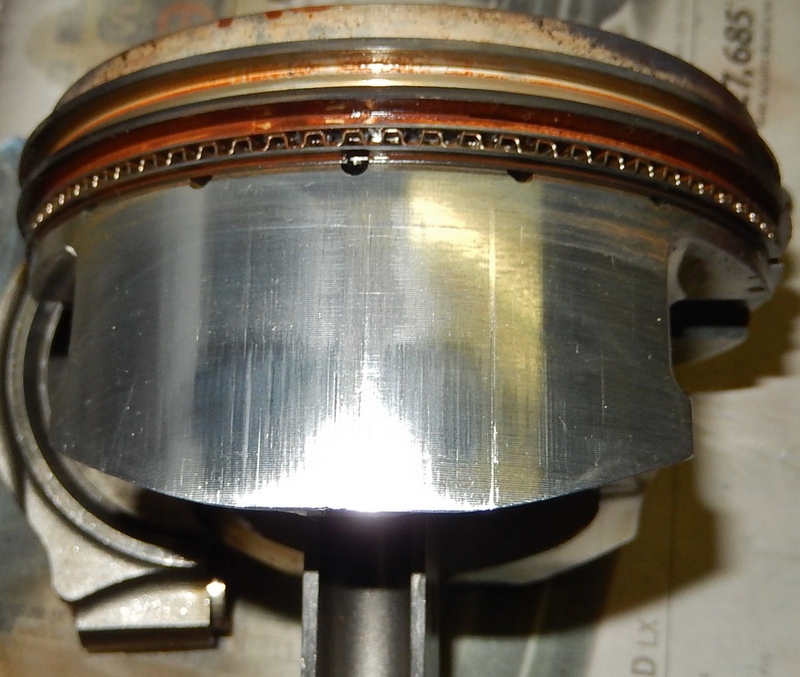

I guess I could try to give you more answers. Many stroke/bore combinations actually pull the piston slightly out of the bore add that to the fact that pistons are clearanced for the crankshaft and or short skirt can leave a lot to be desired when in comes to keeping the piston from rocking in the bore= causing accelerated piston skirt/bore wear. Pistons to wall clearance can also cause this but due to thermal expansion of the piston there is only so much you can do.

#4

TECH Addict

Thread Starter

iTrader: (6)

Join Date: Jun 2005

Location: Winnipeg, Canada

Posts: 2,210

Likes: 0

Received 0 Likes

on

0 Posts

I guess I could try to give you more answers. Many stroke/bore combinations actually pull the piston slightly out of the bore add that to the fact that pistons are clearanced for the crankshaft and or short skirt can leave a lot to be desired when in comes to keeping the piston from rocking in the bore= causing accelerated piston skirt/bore wear. Pistons to wall clearance can also cause this but due to thermal expansion of the piston there is only so much you can do.

#5

TECH Addict

Thread Starter

iTrader: (6)

Join Date: Jun 2005

Location: Winnipeg, Canada

Posts: 2,210

Likes: 0

Received 0 Likes

on

0 Posts

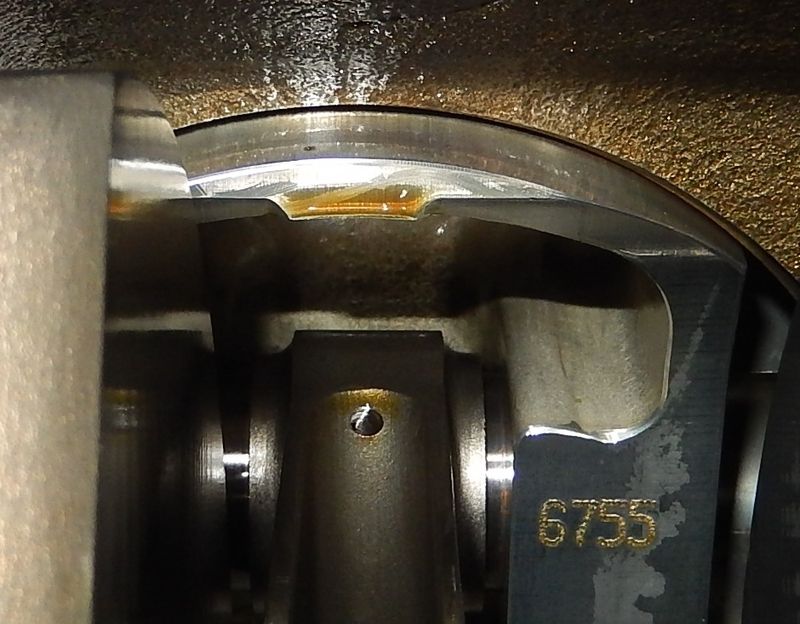

After cleaning up a few piston tops, it looks like detonation has been occurring. Is this the typical skirt pattern seen from detonation? Possible lubrication or clearance issue? Cooling issue?

Last edited by DrX; 07-28-2015 at 04:30 PM.

Trending Topics

#8

TECH Addict

Thread Starter

iTrader: (6)

Join Date: Jun 2005

Location: Winnipeg, Canada

Posts: 2,210

Likes: 0

Received 0 Likes

on

0 Posts

Cylinders measure pretty round and straight at 4.1275 +/- .0005 with the +/- being at the bottoms. Measured in 4 directions at 3 depths.

Piston skirts all measure 4.125 at widest dimensions. Land diameter is 4.084.

So I get .00125 for PB clearance?? (4.1275 - 4.125) / 2

Or is it just calculated as bore diameter - piston diameter? In that case it would be .0025

Piston skirts all measure 4.125 at widest dimensions. Land diameter is 4.084.

So I get .00125 for PB clearance?? (4.1275 - 4.125) / 2

Or is it just calculated as bore diameter - piston diameter? In that case it would be .0025

Last edited by DrX; 07-29-2015 at 10:12 PM.

#9

Moderator

iTrader: (20)

Cylinders measure pretty round and straight at 4.1275 +/- .0005 with the +/- being at the bottoms. Measured in 4 directions at 3 depths.

Piston skirts all measure 4.125 at widest dimensions. Land diameter is 4.084.

So I get .00125 for PB clearance?? (4.1275 - 4.125) / 2

Or is it just calculated as bore diameter - piston diameter? In that case it would be .0025

Piston skirts all measure 4.125 at widest dimensions. Land diameter is 4.084.

So I get .00125 for PB clearance?? (4.1275 - 4.125) / 2

Or is it just calculated as bore diameter - piston diameter? In that case it would be .0025

With a torque plate bolted on, the taper in the cylinders might go away.

#15

TECH Addict

Thread Starter

iTrader: (6)

Join Date: Jun 2005

Location: Winnipeg, Canada

Posts: 2,210

Likes: 0

Received 0 Likes

on

0 Posts

I think it is probably correct at .005 PB, but I was reading the bore gauge(.0005) wrong. What threw me off was I used a dial caliper at the top of the bore as a sanity check and it was telling me it was under 4.130. Now it looks like that caliper reads around .002 under actual.