Camless engines...

#1

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Chattanooga, TN

Posts: 497

Likes: 0

Received 0 Likes

on

0 Posts

This crossed my mind this morning and a quick wiki says it's considered the "holy grail". My question for you advanced techies, what prevents a completely new system from being employed like this now? We certainly have the computing power in super small packages (nexus 7 anyone?). Potentially eliminating timing chains, leaving only the crank pulley. Our car computers already fire a spark and fuel for an individual cylinder, why not also some sort of actuator to control the valves directly?

Potential for it is great MPG putting around, and max power at WOT without having to change cams to find a happy middle ground or extreme to either side.. or for those that like big cams, re-tune the PC for larger duration/life all of the time! Less rotating mass all around on top of that. I know there is some limiting factor or someone like mercedes would have already mastered this.. but what is that factor?

Potential for it is great MPG putting around, and max power at WOT without having to change cams to find a happy middle ground or extreme to either side.. or for those that like big cams, re-tune the PC for larger duration/life all of the time! Less rotating mass all around on top of that. I know there is some limiting factor or someone like mercedes would have already mastered this.. but what is that factor?

#3

I've seen a few prototype designs but don't know if they got anywhere...they were using 48 volt systems.

I would think your main limiting factor would be the crank/ rods with holding a super high piston speed....as fee as cooling for the solenoid cooling is think keeping them in a flowing oil bath would do the trick, but not sure.

I've always liked the ideas of this, or even this combined with a rotory valve

I would think your main limiting factor would be the crank/ rods with holding a super high piston speed....as fee as cooling for the solenoid cooling is think keeping them in a flowing oil bath would do the trick, but not sure.

I've always liked the ideas of this, or even this combined with a rotory valve

#5

So has Fiat and I think Volvo...on a side note...if your old Koenigsegg isn't fast enough just trade up for the new camless model! Lol. I love those cars and have drooled over them and the Grumpert since first seeing them on Top Gear UK

#6

Teching In

Join Date: May 2008

Location: Stockholm-Sweden

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

A cam less engine with computer controlled valves would be a fantastic engine.

MANY have tried to get it to work. The problem is the speed, force and precision that is needed.

MANY have tried to get it to work. The problem is the speed, force and precision that is needed.

#7

From what I understand in in formula one racing the system they use is under a lot of pressure and leaks down pressure pretty quick...so I would guess either a GREAT long lasting better seals would be needed or some kind of high pressure pump run off the motor would be needed.

Trending Topics

#8

TECH Enthusiast

iTrader: (6)

Join Date: Jan 2012

Location: Alexandria, Ky

Posts: 541

Likes: 0

Received 0 Likes

on

0 Posts

There has been lots of R&D done in the past 10 yrs in this area by Formula 1 engineers. The only thing that limits them currently to make more power is the valvetrain. They developed a system of solenoids to fire the valves (as 89ROC-Z mentioned above). I've read they were able to rev these prototypes engines north of 30,000 rpms. Pretty crazy stuff to come in the future I'd say, it always trickles down eventually.

#10

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Chattanooga, TN

Posts: 497

Likes: 0

Received 0 Likes

on

0 Posts

lot's of interesting points here, I'm going to have to look into some more stuff on this. I think it's an interesting idea, and most certainly as others have pointed out, ridiculous high stability in the valve-train is another HUGE advantage.. 30K RPMS in F1!? O_O. Racing is certainly where we will see it first, but my thought is the potential for an economical and still high powered engine. It's taking VVT to a whole new level, as well as eliminating a lot of wear components from an engine!

#12

TECH Regular

Basically, from what I've researched, there are two predominate valve actuation systems for camless engines; pneumatic and electromagnetic. F1 uses pneumatic valves in their engines. I believe Del West manufactures those parts. It's a very complex design. I don't even want to know how long r&d took. Electromagnetic valves are the most interesting to me. It's too very complex and least developed out of the two. A huge barrier is controlling the magnetic residual effect of turning on and off the electromagnet. If we see camless engines on the roads in the future, I believe it will use the electromagnetic technology.

#13

12 Second Club

iTrader: (49)

also, think of all the problems the DOD/AFM motors are having. I assume it would operate on the same pricipal of computer activated solenoids, and without some serious money sunk into R&D, I dont see this being much of something we will see in the near future.

Plus the DI craze will hold consumers over for the time being.

#14

TECH Enthusiast

iTrader: (3)

It's been researched a lot... One thing a lot of people don't take into account is exactly HOW profound of a difference this would make. Will fully variable lift and duration events, there would no longer be trade-offs between mid and high RPM power based on cam selection. You could program the optimal lift and duration for the entire RPM range. You could also do things like reduce lift and duration at part throttle to increase gas milage, ect. No more crappy street manner because of a large cam, either

Just think for a second what the torque curve would look like

This style valvetrain in a high compression DI motor, you'd be looking at retarded amounts of power with great street manners, and even better gas mileage than we get out of 6 speed LS cars.

Just think for a second what the torque curve would look like

This style valvetrain in a high compression DI motor, you'd be looking at retarded amounts of power with great street manners, and even better gas mileage than we get out of 6 speed LS cars.

#15

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Chattanooga, TN

Posts: 497

Likes: 0

Received 0 Likes

on

0 Posts

Ronin you hit it on the head as to what sparked it in my mind. I even mentioned that somewhat initially :-)

As for di motors.. they still have some kinks to be worked out. Sludge buildup being a huge one...

Electromagnetic actuators for valves.. there's a wild idea! I knew about the pneumatic but that's the first ive heard of the other. I'm going to have to look into that. I would imagine its similar to the mag Lev trains and rollercoaster tech that's out there. Some serious power and potential in that kind of electromagnetic design. Activation and de-activation is slightly delayed though isn't it maybe that's why we don't have that available haha.

As for di motors.. they still have some kinks to be worked out. Sludge buildup being a huge one...

Electromagnetic actuators for valves.. there's a wild idea! I knew about the pneumatic but that's the first ive heard of the other. I'm going to have to look into that. I would imagine its similar to the mag Lev trains and rollercoaster tech that's out there. Some serious power and potential in that kind of electromagnetic design. Activation and de-activation is slightly delayed though isn't it maybe that's why we don't have that available haha.

#16

TECH Regular

Ronin you hit it on the head as to what sparked it in my mind. I even mentioned that somewhat initially :-)

As for di motors.. they still have some kinks to be worked out. Sludge buildup being a huge one...

Electromagnetic actuators for valves.. there's a wild idea! I knew about the pneumatic but that's the first ive heard of the other. I'm going to have to look into that. I would imagine its similar to the mag Lev trains and rollercoaster tech that's out there. Some serious power and potential in that kind of electromagnetic design. Activation and de-activation is slightly delayed though isn't it maybe that's why we don't have that available haha.

As for di motors.. they still have some kinks to be worked out. Sludge buildup being a huge one...

Electromagnetic actuators for valves.. there's a wild idea! I knew about the pneumatic but that's the first ive heard of the other. I'm going to have to look into that. I would imagine its similar to the mag Lev trains and rollercoaster tech that's out there. Some serious power and potential in that kind of electromagnetic design. Activation and de-activation is slightly delayed though isn't it maybe that's why we don't have that available haha.

#17

TECH Addict

iTrader: (33)

Have you seen the electromagnetic valves that are merely spinning ***** with holes through them? That is the extremely efficient setup.

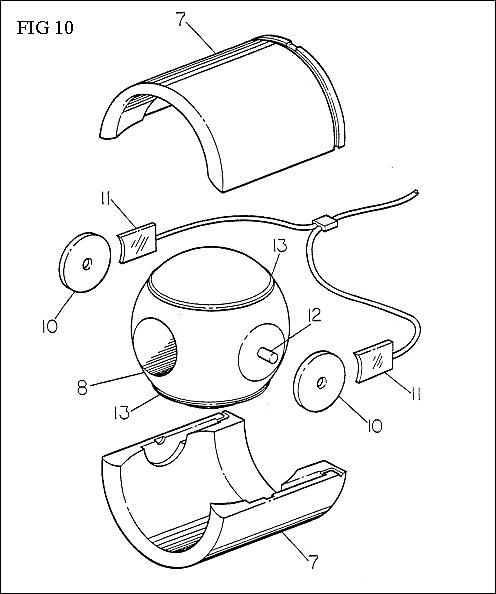

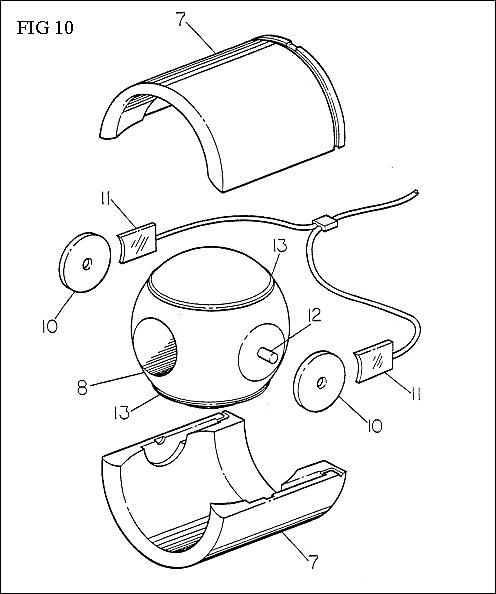

2. Electromechanical Ball Valves

An alternative to the conventional poppet valve for use in camless valve trains is a ball valve. This type of electromechanical valve system consists of a ball through which a passage passes. If the ball is rotated such that the passage lines up with other openings in the valve assembly, gas can pass through it. (Exactly like the ball valves many of us use to control our boost.) Opening and closing the valve is accomplished by electromagnets positioned around its exterior.

Referring to Figure 10, the valve housing (7) is shown in two pieces. Ball valve (8) has two rigidly attached pivots (12). The disc (10) is permanently attached and indexed to the ball valve and contains permanent magnets around its perimeter. The electromagnets (11) are situated on both sides of the ball valve (8) and they are fixed to the valve housing.

The electromagnets are controlled through the ECU. A crank trigger sensor on the crankshaft provides information about the position of the pistons relative to top dead centre. Thus, at top dead centre of the power stroke, the ECM could be used to fix the polarity of both electromagnets so that they are of opposite polarity to the magnets in the ball valve, rotating the ball valve to the closed position.

The substitution of a simple, efficient ball valve and valve housing arrangement in a a four stroke reciprocation piston engine eliminates all the independent moving parts in the valve train. This may even be an improvement over the poppet valve camless system - the ball valve needs only to rotate on its axis to achieve the desired flow conditions, rather than be accelerated up and down in a linear fashion. A partially open ball valve state may also be able to be used to create more turbulence.

Electromechanical valve train implementation would not be possible with a normal 12V electrical system. As has been covered previously in AutoSpeed ("Goodbye 12 volts... hello 42 volts!"), the automotive industry has chosen a 42V electrical system as the next automotive standard. Consequently, the energy demand of EMVT can be optimally matched by a crankshaft-mounted starter-generator (KSG - in Siemens speak) operating at 42V; it is integrated in the flywheel and designed for the starting process as well as generator operation.

2. Electromechanical Ball Valves

An alternative to the conventional poppet valve for use in camless valve trains is a ball valve. This type of electromechanical valve system consists of a ball through which a passage passes. If the ball is rotated such that the passage lines up with other openings in the valve assembly, gas can pass through it. (Exactly like the ball valves many of us use to control our boost.) Opening and closing the valve is accomplished by electromagnets positioned around its exterior.

Referring to Figure 10, the valve housing (7) is shown in two pieces. Ball valve (8) has two rigidly attached pivots (12). The disc (10) is permanently attached and indexed to the ball valve and contains permanent magnets around its perimeter. The electromagnets (11) are situated on both sides of the ball valve (8) and they are fixed to the valve housing.

The electromagnets are controlled through the ECU. A crank trigger sensor on the crankshaft provides information about the position of the pistons relative to top dead centre. Thus, at top dead centre of the power stroke, the ECM could be used to fix the polarity of both electromagnets so that they are of opposite polarity to the magnets in the ball valve, rotating the ball valve to the closed position.

The substitution of a simple, efficient ball valve and valve housing arrangement in a a four stroke reciprocation piston engine eliminates all the independent moving parts in the valve train. This may even be an improvement over the poppet valve camless system - the ball valve needs only to rotate on its axis to achieve the desired flow conditions, rather than be accelerated up and down in a linear fashion. A partially open ball valve state may also be able to be used to create more turbulence.

Electromechanical valve train implementation would not be possible with a normal 12V electrical system. As has been covered previously in AutoSpeed ("Goodbye 12 volts... hello 42 volts!"), the automotive industry has chosen a 42V electrical system as the next automotive standard. Consequently, the energy demand of EMVT can be optimally matched by a crankshaft-mounted starter-generator (KSG - in Siemens speak) operating at 42V; it is integrated in the flywheel and designed for the starting process as well as generator operation.

#19

www.sturmaninduistries.com

Their digitally activated valve engine: http://www.sturmanindustries.com/mai...eActuation.htm

Their digitally activated valve engine: http://www.sturmanindustries.com/mai...eActuation.htm

#20

FormerVendor

Join Date: Nov 2012

Location: Sacramento, CA

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

This is true. F1 teams also have a spare air tank when the systems fail, they try to delay an air leak by re-pressurizing the system during a pit stop. These systems are a great design because it eliminates a valve spring, but is very unreliable.

Williams F1/Renault have been working on the camless design for years. Still, a major hill to climb is interference from the F1 engine and the solenoids. Here's a wonderful article on pneumatic and electronic solenoid designs, a simple breakdown. http://scarbsf1.com/valves.html

I'm hoping to see koenigsegg's creation come to life here in the future. It would be a major step in development. I would love to get my hands on one and try to understand the programming of it.

Williams F1/Renault have been working on the camless design for years. Still, a major hill to climb is interference from the F1 engine and the solenoids. Here's a wonderful article on pneumatic and electronic solenoid designs, a simple breakdown. http://scarbsf1.com/valves.html

I'm hoping to see koenigsegg's creation come to life here in the future. It would be a major step in development. I would love to get my hands on one and try to understand the programming of it.