kst8engineer - '71 Chevelle LS1/T56 build thread

#121

TECH Resident

iTrader: (3)

Join Date: Sep 2005

Location: Edmond, Oklahoma

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

You still have 4-wheel drums? I remember my old 4 wheel non power assist drums. They could be downright scary once you got them hot. I am surprised it runs so well with the wrong cam. You know its really gonna wake up once you swap in the new one. My first drive was somewhat tortuous because I was also breaking in a new motor. Keeping her under 3000 rpms(for the most part) for a 1000 miles was tough.

P.S. Shouldn't you be engineering a tractor not looking around on LS1tech?

P.S. Shouldn't you be engineering a tractor not looking around on LS1tech?

#122

Teching In

Join Date: Jun 2006

Location: Amarillo, Texas

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Really cool project! That first drive is the best.

Glad to see you got your spark back.

I see after reading post #107 here in your build thread, I didn't tell you anything you didn't already know...

Get those brakes fixed/upgraded! Way too nice of a car to get crunched!

Glad to see you got your spark back.

I see after reading post #107 here in your build thread, I didn't tell you anything you didn't already know...

Get those brakes fixed/upgraded! Way too nice of a car to get crunched!

#123

On The Tree

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: Kansas

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

You still have 4-wheel drums? I remember my old 4 wheel non power assist drums. They could be downright scary once you got them hot. I am surprised it runs so well with the wrong cam. You know its really gonna wake up once you swap in the new one. My first drive was somewhat tortuous because I was also breaking in a new motor. Keeping her under 3000 rpms(for the most part) for a 1000 miles was tough.

P.S. Shouldn't you be engineering a tractor not looking around on LS1tech?

P.S. Shouldn't you be engineering a tractor not looking around on LS1tech?

Tractor engineering requires some occaisonal encouragement from LS1tech!

Really cool project! That first drive is the best.

Glad to see you got your spark back.

I see after reading post #107 here in your build thread, I didn't tell you anything you didn't already know...

Get those brakes fixed/upgraded! Way too nice of a car to get crunched!

Glad to see you got your spark back.

I see after reading post #107 here in your build thread, I didn't tell you anything you didn't already know...

Get those brakes fixed/upgraded! Way too nice of a car to get crunched!

#126

On The Tree

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: Kansas

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

I made a mockup/template of my fuel pump cover this evening.

And here's the flat pattern I'll cut the sheetmetal from:

When I tried to bleed the brakes this evening, I noticed that I'm losing fluid out of the rear master cylinder reservoir, and it's leaking out the joint between the master cylinder and the brake booster. I'm guessing this means there's a seal of some sort on the cylinder piston that's worn out. Sooooo, I can spend money on the old drum/drum master, or I can start working toward the disc/disc swap. Does anyone know of a good source for the brackets to adapt the front F-body disc brakes to the Chevelle drum spindles? I'll hunt through my info and find the guys I've run across before, but I'm up for suggestions as well!

And here's the flat pattern I'll cut the sheetmetal from:

When I tried to bleed the brakes this evening, I noticed that I'm losing fluid out of the rear master cylinder reservoir, and it's leaking out the joint between the master cylinder and the brake booster. I'm guessing this means there's a seal of some sort on the cylinder piston that's worn out. Sooooo, I can spend money on the old drum/drum master, or I can start working toward the disc/disc swap. Does anyone know of a good source for the brackets to adapt the front F-body disc brakes to the Chevelle drum spindles? I'll hunt through my info and find the guys I've run across before, but I'm up for suggestions as well!

#127

TECH Resident

iTrader: (3)

Join Date: Sep 2005

Location: Edmond, Oklahoma

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

That little cover should look pretty sharp. I like you you blended it into the hump over the axle. As far as brake caliper brackets you might try Kore3. I know they do alot of C5 conversion stuff and I have heard their customer service is top notch.

#130

TECH Senior Member

iTrader: (12)

BRP markets brackets for the 4th Gen F-Body brakes.. I was looking at it also.. Don't know if you saw my last post.. I picked up a 2002 Z28 to for parts.. I am going to start parting it out and selling off the parts I don't need or want. but Brakes is one thing I want to convert over to my 71 nova along with the LS1 and 4L60e...

I am sure that there are other vendors that markets the brackets too. the thing that they say is that they have a bracket for the Drum Brake spindle also !

My access plate is some what like yours in design. but what I did was make a frame out of 1"X metal for the underside of the trunk floor, drilled and used U-nut on it.. used double sided tape and fasten to the under side of the trunk. Both the Truck Floor and the cover has matching holes.. I then used rounded hex headed bolt. I also have a matching frame on top. I also make a rubber gasket to seal it.

On taking the panel off, the under frame stays in place and putting the cover back on..I just drop the cover and top frame it in place and screw it tight. The two frames help strength the area of the floor.. maybe overkill.. but don't we all love to go over board on making and fab up things !

I am sure that there are other vendors that markets the brackets too. the thing that they say is that they have a bracket for the Drum Brake spindle also !

My access plate is some what like yours in design. but what I did was make a frame out of 1"X metal for the underside of the trunk floor, drilled and used U-nut on it.. used double sided tape and fasten to the under side of the trunk. Both the Truck Floor and the cover has matching holes.. I then used rounded hex headed bolt. I also have a matching frame on top. I also make a rubber gasket to seal it.

On taking the panel off, the under frame stays in place and putting the cover back on..I just drop the cover and top frame it in place and screw it tight. The two frames help strength the area of the floor.. maybe overkill.. but don't we all love to go over board on making and fab up things !

#132

On The Tree

Great build! My son and I are building a 1966 GTO and did four wheel disks on the cheap. We put rear disks on the 12 bolt rear end (was a chevy rear). To do this we used a spacer from BRP and bought rear disks from a 2002 Chevy blazer. It bolted up with minimal effort. On the front we used 2000 Camaro disk brakes and again used a BRP bracket (and reused the front drum spindles), this set up bolted up with absolutely no problem. We used the 2000 camaro master cylinder, cut the brackets from the old GTO power booster and then mounted the brackets to a booster from a 1985 Monte Carlo booster. We cut the end from the booster, and treaded it and reattached the GTO end (that bolts to the brake petal). The whole set up cost less than $450! See entry 17 and 20 (we later changed out the fat Man “tall” spindles for the old drum spindles) at my build tread: http://www.hotrodders.com/forum/jour...07&action=view

#134

On The Tree

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: Kansas

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

I ordered a set of brackets to mount the F-body front brakes to the Chevelle drum spindles from Rich Hoag yesterday. $50 for the pair seemed like a good deal with shipping included. From what I understand, I'll have to grind or machine one area on the hub to get the bracket to sit level, and I'll have to turn down the OD of the hub slightly as well to fit into the "hat" area of the F-body rotor.

Have any of you guys run across a detailed "how-to" on swapping the F-body brakes onto an A-body? I'll need to install longer wheel studs into the Chevelle hubs, so I need to figure out what p/n studs to buy. I also need to figure out what adapters I need to buy for the brake lines, or possibly run all new lines.

I went ahead and picked up a new power drum/drum master cylinder for the Chevelle and installed it this evening. The brakes are considerably better than they were before, but still far from good. I'm anxious to get the 4-wheel discs on.

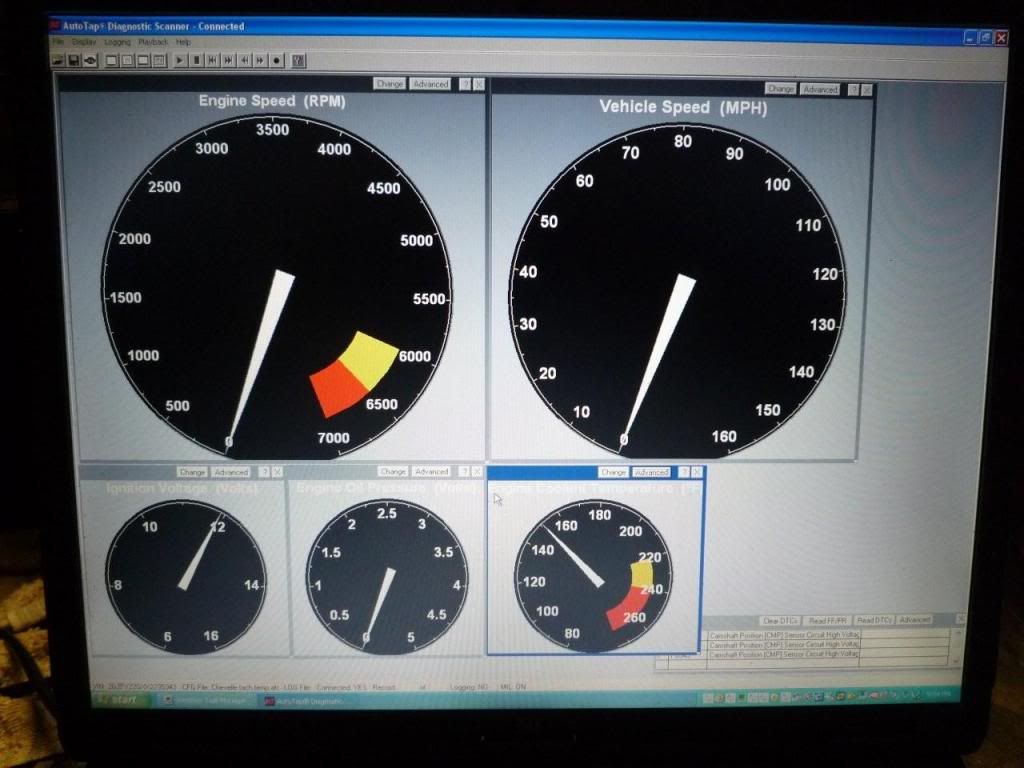

I played with the AutoTAP configuration a little more tonight as well, and I now have full gauges working on the AutoTAP, with the exception of oil pressure. For some reason, oil pressure displays correctly on the Trans Am gauges, but it doesn't display on the AutoTAP. Any ideas why? I'll see if I can post a picture of the AutoTAP screen later.

Have any of you guys run across a detailed "how-to" on swapping the F-body brakes onto an A-body? I'll need to install longer wheel studs into the Chevelle hubs, so I need to figure out what p/n studs to buy. I also need to figure out what adapters I need to buy for the brake lines, or possibly run all new lines.

I went ahead and picked up a new power drum/drum master cylinder for the Chevelle and installed it this evening. The brakes are considerably better than they were before, but still far from good. I'm anxious to get the 4-wheel discs on.

I played with the AutoTAP configuration a little more tonight as well, and I now have full gauges working on the AutoTAP, with the exception of oil pressure. For some reason, oil pressure displays correctly on the Trans Am gauges, but it doesn't display on the AutoTAP. Any ideas why? I'll see if I can post a picture of the AutoTAP screen later.

#136

TECH Senior Member

iTrader: (12)

Post up your findings on the Brake brackes... I will most likely convert my Nova to the Camaro brakes also. Like to know what you think of them as compared to the BRP ones ?.

From what I under stand.. it is one spot on the face/front of the Spindle.. the top threaded boss for the upper anchor pin... (?)..

From what I under stand.. it is one spot on the face/front of the Spindle.. the top threaded boss for the upper anchor pin... (?)..

#137

On The Tree

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: Kansas

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

I agree, Bczee. I think it's just one spot (one of the threaded hole bosses) on the spindle that needs to be ground down, and then I think you also have to turn the OD of the hub down slightly to fit in the "hat" region of the rotor.

#139

On The Tree

The conversion to Camaro brakes was really easy on the 66 GTO (and should be even easier on your Chevy). On the 1966 A Body "Drum" spindles, no grinding was necessary. The Brackets bolted right up. If you have a "Disk" spindle, you will have to grind away a portion of the top bolt area. You are correct that a part of the "hub" has to be turned down to clear the hat of the disk brake rotor, but I had a friend who chucked it up in a lathe and the whole process took just a few minutes per hub (he took about 1/8 off the diameter, if I remember correctly). I probably could have done it with a grinder, but he was close by. As to the hub studs, NAPA stores carry the Dorman line of wheel studs. Just take one of your old ones, and they can match it up to the correct number, then you can order same type, just longer. Finally, I used the flex lines from the Camaro donor car for the front. I also purchased the Metric Bubble flare line from NAPA (that type end is needed to screw into the flex line at the brake caliper), then after the line was bent to fit up to the front junction block, I cut the bubble flare off the junction block end and did a standard double flare. It was very easy and it works great, and any replaceable parts are standard GM. Good luck on your project!

#140

Teching In

iTrader: (2)

Join Date: Mar 2007

Location: Arkansas

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

which brackets did you use RicOtt? I have an 02 Trans Am that im about to part out and if i can get those brakes working on my chevelle i could save money for now and put towards the fuel system and other parts.

Last edited by cypher; 07-20-2009 at 12:29 PM.