1986 gmc c-1500 (c10), lq4, t56

#81

Launching!

Thread Starter

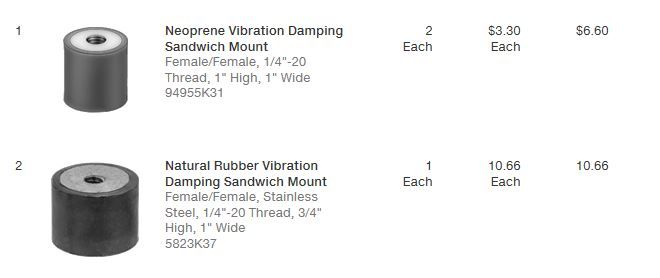

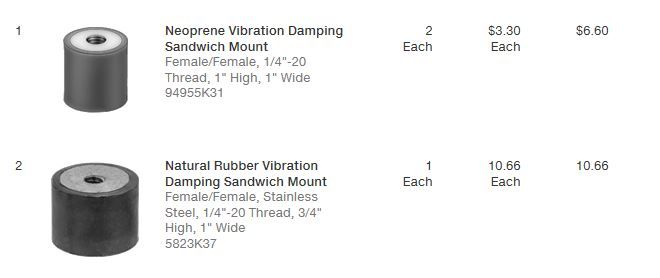

Very nice!! I'm in the middle of an LS1/4l80e swap. Really wanted to mount my pcm inside, but my PSI harness isn't long enough and I can't find room under the dash. Where did you get the rubber pieces for under the pcm mount??

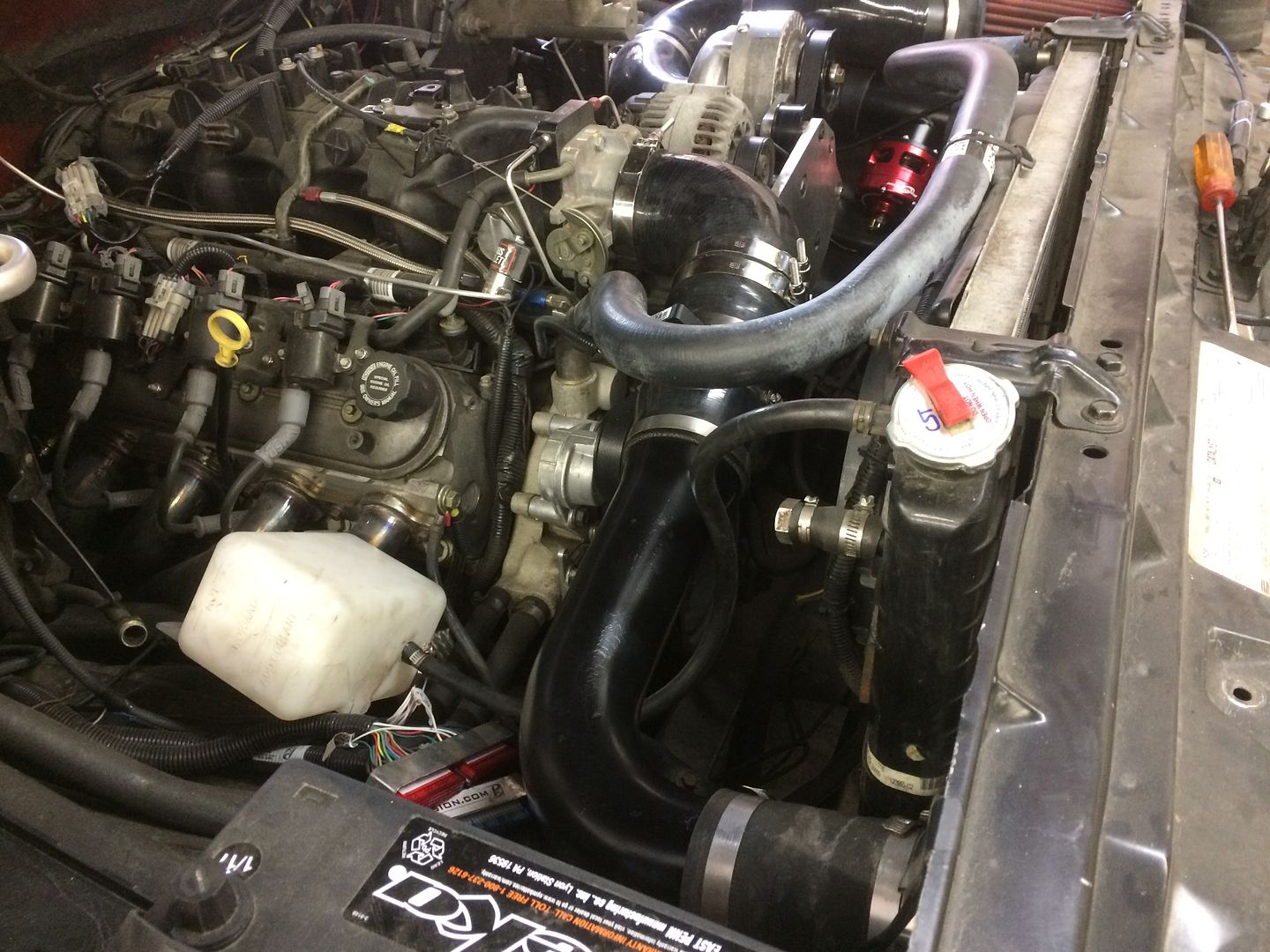

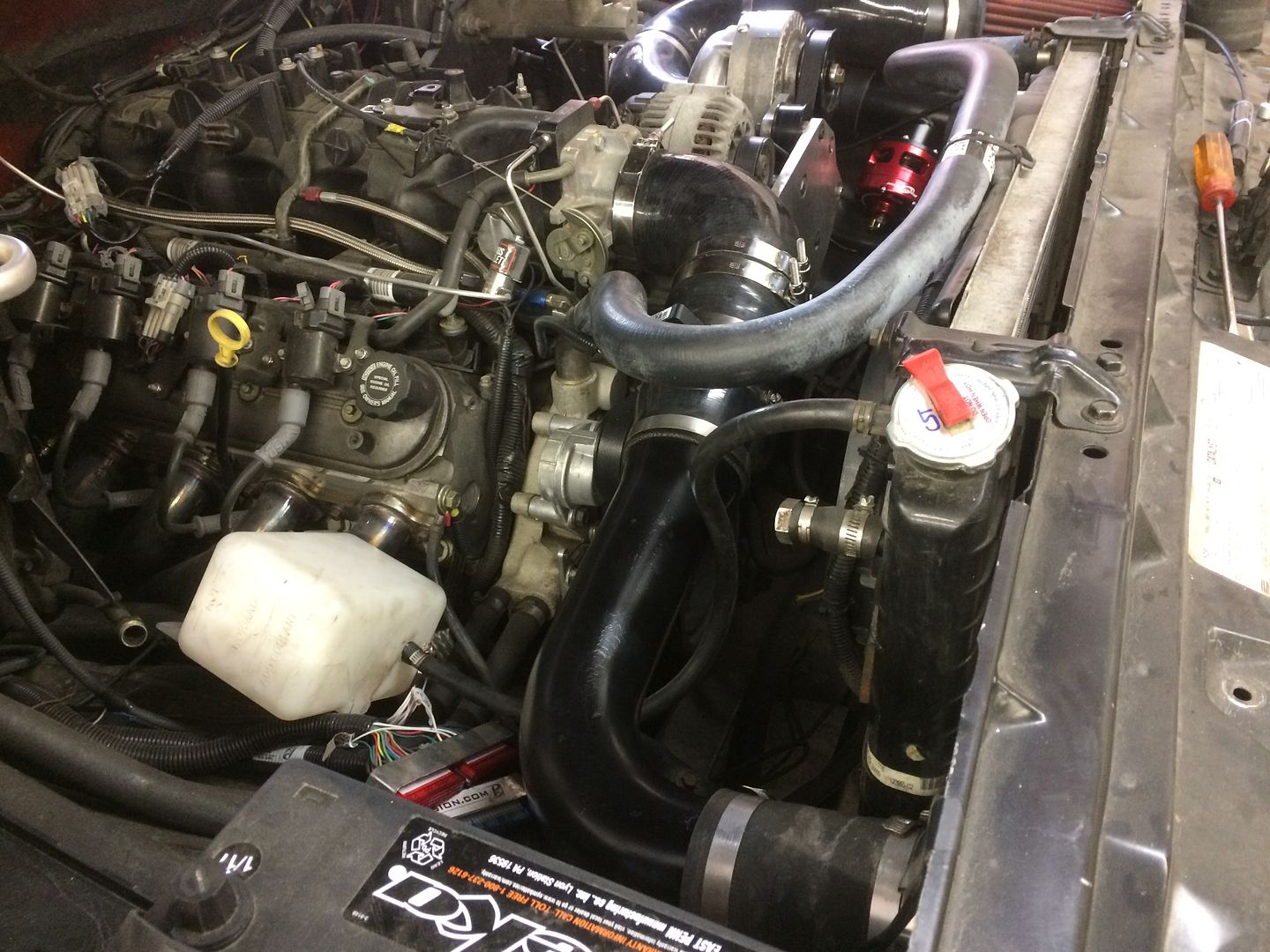

I am using an LS3 camaro water pump, with the upper radiator hose Gates part # 23080. Same lower radiator hose as the 99+ trucks. The 2010+ Camaro pump uses the same belt spacing as the truck accessories if you decide you want something different in the future.

I am using an LS3 camaro water pump, with the upper radiator hose Gates part # 23080. Same lower radiator hose as the 99+ trucks. The 2010+ Camaro pump uses the same belt spacing as the truck accessories if you decide you want something different in the future.

This is what I used specifically, but plenty of different sizes available.

#82

Launching!

Thread Starter

Installed my Intellitronix LED dash. P/N DP6004 in red. I really like it. I probably prefer the factory gauges, but any electronic-to-mechanical speedometer solution is expensive, and I still didn't have a tach. This was a cheaper solution that gave me working gauges and I think it looks OK in the truck.

My fuel gauge still doesn't work though (didn't work with the factory gauge either). I'm using an '87 R10 sending unit which should be the same 0-90ohm signal, so not sure what I'm missing. It's always pegged at full. Thoughts?

My fuel gauge still doesn't work though (didn't work with the factory gauge either). I'm using an '87 R10 sending unit which should be the same 0-90ohm signal, so not sure what I'm missing. It's always pegged at full. Thoughts?

#83

TECH Enthusiast

iTrader: (5)

Join Date: Aug 2008

Location: nh

Posts: 656

Likes: 0

Received 0 Likes

on

0 Posts

Has to be a short to ground somewhere in the circuit for the fuel gauge...

Nice work! I like using Performance Dyno. My friend Derek rents his dyno to do all his tuning as well. Great guys.

Nice work! I like using Performance Dyno. My friend Derek rents his dyno to do all his tuning as well. Great guys.

#84

Launching!

Thread Starter

I can't say enough about Josh and Pete. I often think how lucky I am to have them right in my own backyard.

#86

Launching!

Thread Starter

Haven't posted in awhile, but got the photobucket thing straightened out. I did the $29 a year plan. I thought that was worth it to get all the photos back into my 2 build threads.

Anyway, this past winter I lowered the truck 3" front and rear, new wheels and tires, chevy grill (with late-model GMC emblem), and did 4.11s in the rear. The 4.11s with the T56 are SO nice. Obviously much quicker, but highway cruising is also MUCH better. I could barely use 6th before because of the 3.42s, tall tires, and .56 6th......it was too tall. Now 75mph is around 2200 rpm.....perfect.

At the track, the Nitto 555 G2s hooked surprisingly well. The 4.11s were almost perfect. Truck felt awesome in 4th gear with the nitrous.....pulled really hard as evidenced by the 114mph trap speed. I think this baby is a bit of a sleeper.

Next upgrade is U-joints. I can't believe what wimpy U-joints are used in these 12-bolts.....1310s....how lame. I've broke one already. I'll be upgrading to 1350s this winter if not sooner. Unfortunately it's an expensive project. Between both yokes and a new driveshaft I'm looking at around $700-800. Worth it for reliability I guess. It's either that or I drive the truck easier......and that's certainly not an option.

Anyway, this past winter I lowered the truck 3" front and rear, new wheels and tires, chevy grill (with late-model GMC emblem), and did 4.11s in the rear. The 4.11s with the T56 are SO nice. Obviously much quicker, but highway cruising is also MUCH better. I could barely use 6th before because of the 3.42s, tall tires, and .56 6th......it was too tall. Now 75mph is around 2200 rpm.....perfect.

At the track, the Nitto 555 G2s hooked surprisingly well. The 4.11s were almost perfect. Truck felt awesome in 4th gear with the nitrous.....pulled really hard as evidenced by the 114mph trap speed. I think this baby is a bit of a sleeper.

Next upgrade is U-joints. I can't believe what wimpy U-joints are used in these 12-bolts.....1310s....how lame. I've broke one already. I'll be upgrading to 1350s this winter if not sooner. Unfortunately it's an expensive project. Between both yokes and a new driveshaft I'm looking at around $700-800. Worth it for reliability I guess. It's either that or I drive the truck easier......and that's certainly not an option.

Last edited by 67 goat; 06-22-2018 at 08:45 AM.

#87

On The Tree

Hey bud, first off, thank you for this build thread. Iíve learned a lot just reading what you did. Iím in the middle of an ls1 - t56 swap in my 86 Sierra. I have a question for ya. What did you do for the drive shaft? Did it fit right up or did you have to build one?

also, do you have any pics on how you did the clutch pedal and hydraulic mounting?

also, do you have any pics on how you did the clutch pedal and hydraulic mounting?

Last edited by bmorrow8; 08-04-2018 at 04:06 PM.

#88

Launching!

Thread Starter

Hey bud, first off, thank you for this build thread. Iíve learned a lot just reading what you did. Iím in the middle of an ls1 - t56 swap in my 86 Sierra. I have a question for ya. What did you do for the drive shaft? Did it fit right up or did you have to build one?

also, do you have any pics on how you did the clutch pedal and hydraulic mounting?

also, do you have any pics on how you did the clutch pedal and hydraulic mounting?

I got really lucky with my driveshaft because the length was perfect as-is. TH350s share the same 27 spline output shaft as T56s so your slip-yoke will work, so it's just the length you need to worry about, which will be determined by where you put the motor front to rear . I have my motor pushed as far back as I could. I think my passenger side valve cover is about 3/4" off the firewall. It's funny you mention the driveshaft though, because I'm upgrading mine either this week or next. I keep breaking the wimpy, factory 1310 u-joints when I use the nitrous, especially if I get a little wheel-hop, so I'm having a driveshaft made with 1350 u-joints. Of course, this requires a new slip-yoke and pinion yoke.

As for the clutch pedal and hydraulics, I don't have a pic at the moment, but it was super easy. I'm using factory pedals and a factory master cylinder. If you're truck was an auto, you'll have to drill holes for the master cylinder, but it's cake because GM dimpled the firewall where the holes are supposed to be! Thanks GM! Then I used the factory T56 hydraulic lines to go from the C10 master cylinder to the late-model GTO T56. It only required one adapter at the master cylinder to step down the size. I forget that adapter size, but google will tell you. Or just take the master cylinder and the hydraulic line to any auto parts store and they'll be able to figure out what adapter. If you have trouble though, let me know.

#89

On The Tree

Awesome. Thanks for the insight and help. Iím sure Iíll be messaging you later on lol. Did you stick with the speed engineering headers? I read they donít work with the t56? Is that true? What did you have to do to get them to fit?

#90

Launching!

Thread Starter

Message away! I'm happy to help. If you need any additional pics, let me know. The truck will be on the lift soon for a driveshaft upgrade anyway.

#91

Launching!

Thread Starter

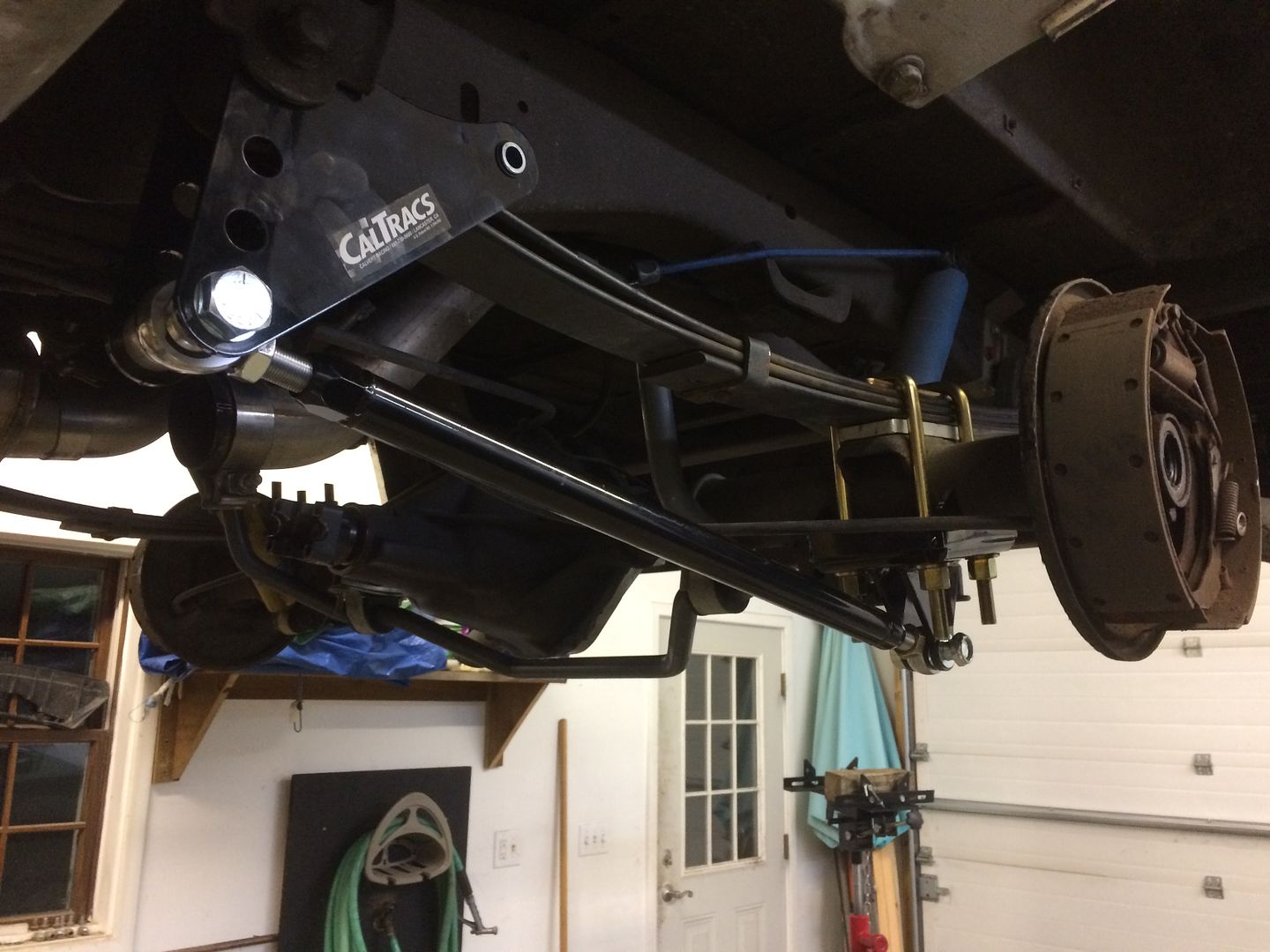

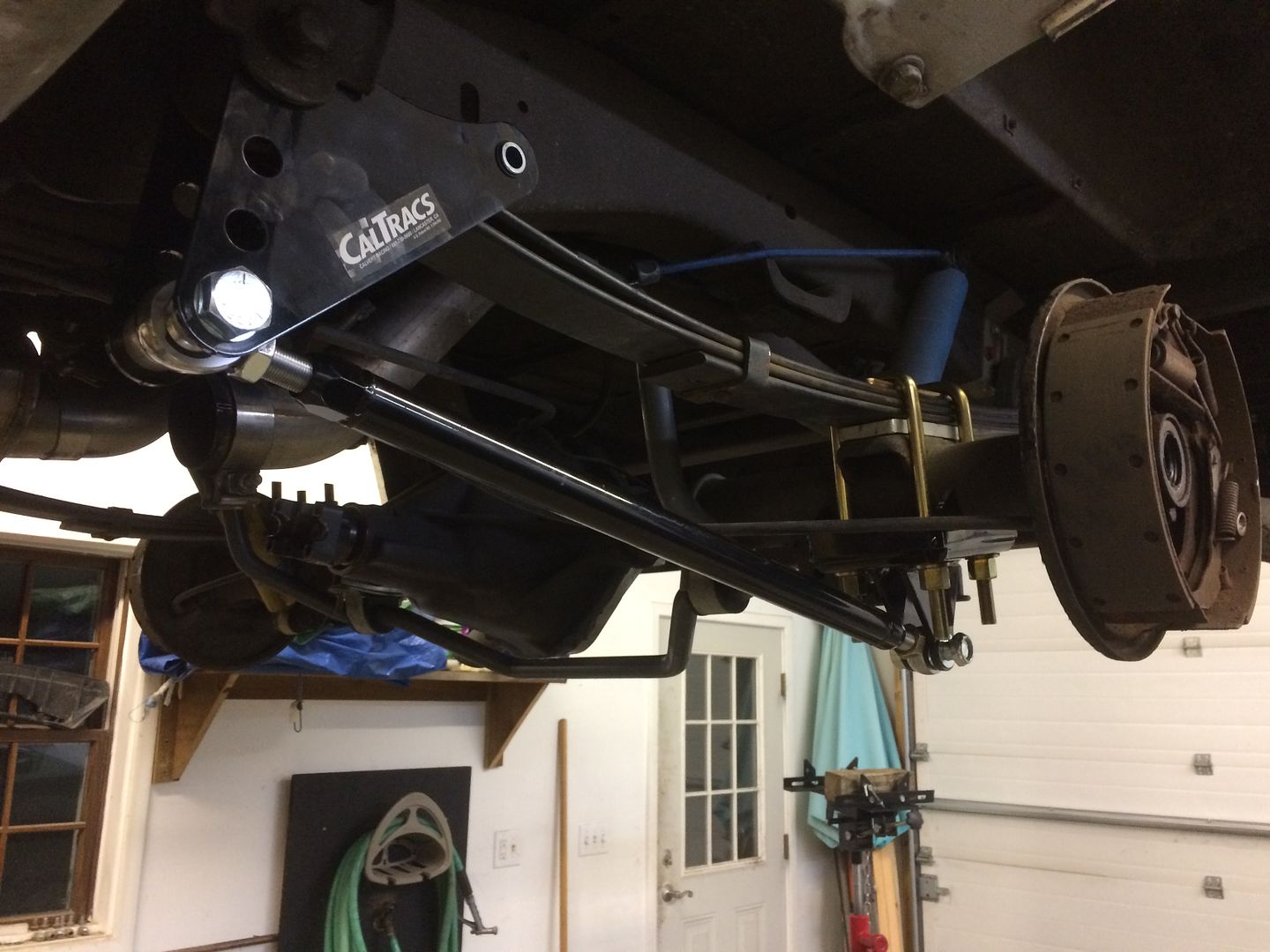

Added a procharger P1SC this Spring. I bought it used and got a super good deal on it. I also added Caltracs, and a T56 magnum, and a 4" driveshaft.

Truck made 480 RWHP (SAE corrected). I only took a photo of actual HP, hence the 500.

The youtube link to the dyno pull only works in Google Chrome for some reason....well, not Internet Explorer anyway.....haven't tried others.

Truck made 480 RWHP (SAE corrected). I only took a photo of actual HP, hence the 500.

The youtube link to the dyno pull only works in Google Chrome for some reason....well, not Internet Explorer anyway.....haven't tried others.

#95

Launching!

Thread Starter

I took a video of the pinion angle while on the dyno this time, and even with the Catracs it moved more than I expected, so I was very hesitant to add more power. I'm going to drive it as-is for this season, then likely to a 4-link next winter, THEN add boost.

Last edited by 67 goat; 05-14-2019 at 03:25 PM. Reason: Add video

#96

I did the mid-shift conversion. I thought I had a picture, but I'll take one tonight of where it comes thru the floor. I'm guessing it's very close to where a factory 4 speed shifter would come thru. I think it's perfect. I'll likely make my own shifter, but might buy one from Hurst if I can find one with the right length and bends.

This is the mid-shift conversion kit I used. They call it a front shift.

https://shiftsst.com/store/shifters/...shift-kit.html

No linkage. I'm running a concentric slave hydraulic setup. I'm running a factory C10 master cylinder to the factory GTO (LS) slave and using the GTO hydraulic lines which have really sweet quick disconnects throughout. The only adapter you need is at the master cylinder to go from 1/4" to 3/16" I think.

You should definitely do the 6 speed manual!!!

This is the mid-shift conversion kit I used. They call it a front shift.

https://shiftsst.com/store/shifters/...shift-kit.html

No linkage. I'm running a concentric slave hydraulic setup. I'm running a factory C10 master cylinder to the factory GTO (LS) slave and using the GTO hydraulic lines which have really sweet quick disconnects throughout. The only adapter you need is at the master cylinder to go from 1/4" to 3/16" I think.

You should definitely do the 6 speed manual!!!

#97

Launching!

Thread Starter

My setup is:

Factory C10 pedals (make sure you get vacuum brake/hydraulic clutch pedals). You can find them on eBay all day.

Factory C10 master cylinder

LS car slave cylinder

LS car hydraulic lines

1 adapter (reducer) to go from the C10 master outlet to the LS car hydraulic line. I don't remember exactly, but roughly the metric equivalent of 1/4 to 3/16. Maybe M6 to M5? Once you have the parts in hand just go to a parts store and you can figure it out.

#98

I used a factory C10 master cylinder and I love it. In my opinion, it's the only way to go. It's a factory part and you know it'll fit perfect, especially if you're running factory pedals (which I would also recommend if you don't already have them). It mounts next the brake booster, towards the outside of the truck, with plenty of clearance.

My setup is:

Factory C10 pedals (make sure you get vacuum brake/hydraulic clutch pedals). You can find them on eBay all day.

Factory C10 master cylinder

LS car slave cylinder

LS car hydraulic lines

1 adapter (reducer) to go from the C10 master outlet to the LS car hydraulic line. I don't remember exactly, but roughly the metric equivalent of 1/4 to 3/16. Maybe M6 to M5? Once you have the parts in hand just go to a parts store and you can figure it out.

My setup is:

Factory C10 pedals (make sure you get vacuum brake/hydraulic clutch pedals). You can find them on eBay all day.

Factory C10 master cylinder

LS car slave cylinder

LS car hydraulic lines

1 adapter (reducer) to go from the C10 master outlet to the LS car hydraulic line. I don't remember exactly, but roughly the metric equivalent of 1/4 to 3/16. Maybe M6 to M5? Once you have the parts in hand just go to a parts store and you can figure it out.

#99

Launching!

Thread Starter

Worth every penny to me. I love factory stuff because you know it fits perfect. It's always a gamble with aftermarket stuff.

Yes, the slave cylinder you speak of is a concentric slave. Standard issue for T56 cars. I'm assuming you're running a T56?

Yes, the slave cylinder you speak of is a concentric slave. Standard issue for T56 cars. I'm assuming you're running a T56?