68 Camaro Build with a Gen V Swap

#81

I then welded up the notch similar to how I did the other side. You can see how much more I cut out near the motor mount stand and a little more near the upper a-arm. I couldnt cut out too much near the motor mount stand due to the nut access, I could have welded the nut to the frame but I thought of that too late. Access to these nuts are fun. Got it painted the next day.

#82

The reason I was trying to make so much room for the suction and discharge was my original plan to use a Motech manifold here. They are the only people I have found that make a Gen V compressor manifold but its big and exits towards the a-arm and I would have to put some kind of tight 90 degree ac fitting on there to make it work.

I was worried about making the Motech manifold fit so I reached out to Hawks Motorsports. Hawks makes an LS3 manifold (photo below) that has a 90 degree exit and should work out perfect for me. I spoke to them and they said they are beginning to get more involved with the Gen V swap stuff and had plans to make this manifold for the LT1 compressor in the next few months. Hawks Motorsports was kind enough to try to work with me on making a manifold for my truck compressor. I sent my compressor off and we will wait and see if they can make it happen, fingers crossed! If all works out I'm sure they will offer this in their lineup for anyone needing one.

The other option is have is to use the stock ac lines but I'd need to source them if the manifold does not work out.

I was worried about making the Motech manifold fit so I reached out to Hawks Motorsports. Hawks makes an LS3 manifold (photo below) that has a 90 degree exit and should work out perfect for me. I spoke to them and they said they are beginning to get more involved with the Gen V swap stuff and had plans to make this manifold for the LT1 compressor in the next few months. Hawks Motorsports was kind enough to try to work with me on making a manifold for my truck compressor. I sent my compressor off and we will wait and see if they can make it happen, fingers crossed! If all works out I'm sure they will offer this in their lineup for anyone needing one.

The other option is have is to use the stock ac lines but I'd need to source them if the manifold does not work out.

#83

Now that I have stuck the motor in and out I figure it will be the last time I stick it in so I decided to test the fitment of the trans inside the raised tunnel. Of course, as I finished sticking it in I remembered wanting to shave down the power steering box a little to clear the headers as mentioned when test fitting them. I might be able to keep the motor in there while I do it we'll see.

Here are some pics of me sticking it in there trying not to dent the firewall. Speaking of firewall, I took off the cowl vent and hammered out the remaining dents and put a little filler and smoothed it out some. Came out nice, not perfect but easy on the eyes haha.

Trans has plenty of room in the tunnel and the ground clearance is good. I have not seen the trans pan on the car version of this 10 speed but the truck version's pan is not deep in my opinion. The trans is currently sitting on the stock crossmember and a 2x4. The crossmember was moved a few inches back by the previous owner to run the 700r4. I planed on using the same corssmember in the original position with a little cutting and welding to get it where I need it to be.

Here are some pics of me sticking it in there trying not to dent the firewall. Speaking of firewall, I took off the cowl vent and hammered out the remaining dents and put a little filler and smoothed it out some. Came out nice, not perfect but easy on the eyes haha.

Trans has plenty of room in the tunnel and the ground clearance is good. I have not seen the trans pan on the car version of this 10 speed but the truck version's pan is not deep in my opinion. The trans is currently sitting on the stock crossmember and a 2x4. The crossmember was moved a few inches back by the previous owner to run the 700r4. I planed on using the same corssmember in the original position with a little cutting and welding to get it where I need it to be.

#85

I'm going to get the ICTbillet PS bracket pretty soon and see if it fits. I was originally going with a T56 so I got the rear with a 3:70 gear. I'll see how that goes and swap to something more appropriate if needed.

#88

I ended up hacking up my stock crossmember (saw someone else do the same) and offset it a few inches back to accept the new trans. The height was not changed, only the rearward position. I had some 1/8" plate laying around and this is what the stock crossmember is made from. It crossmember is very solid but the weight of the trans worries me a little for some reason. I think I'm going to stiffen it up a bit and clean up some of the tall edges that kiss the floor a little. I placed a spacer between the crossmember and mount so I could drop it a little if needed to get the angle corrected once the car is together. I also have quite a bit of room to raise the trans if needed too.

#90

I've got a little done since I last posted but I've been busy with life. I decided to clean off all the old Dynamat and coat the floor just to make sure no rust comes back. I planned on not using Dynamat anymore due to it possibly being the reason the pans rusted? Might not be the reason but the car had leaks and the mat held some water in the trunk. This stuff sucks taking it off and the only way was with a heat gun then a wire wheel along with elbow grease.

I also finally opened up my fuel tank box and put a coat of paint on the fuel tank. Its installed now but not fully buttoned down.

I also finally opened up my fuel tank box and put a coat of paint on the fuel tank. Its installed now but not fully buttoned down.

#91

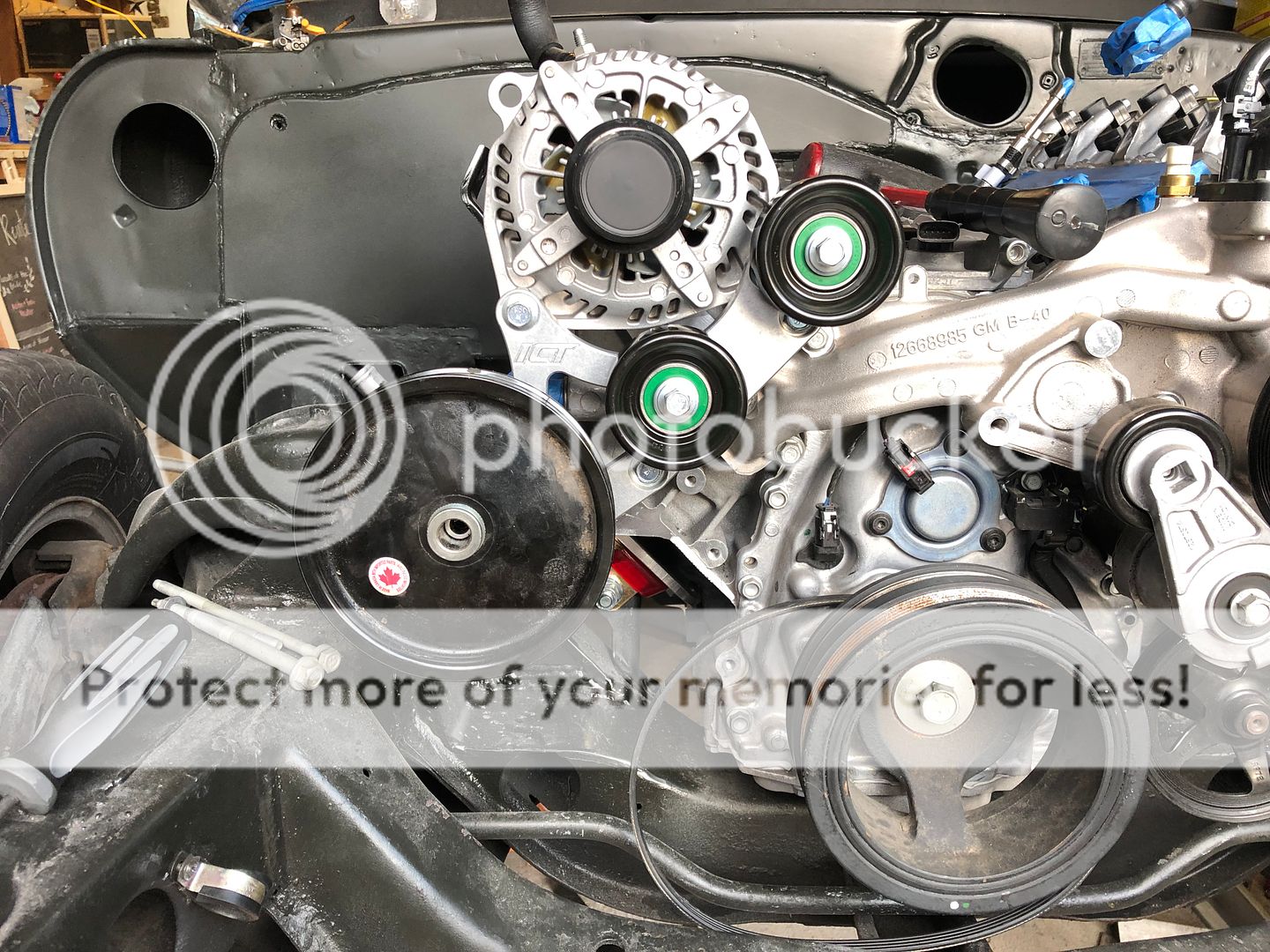

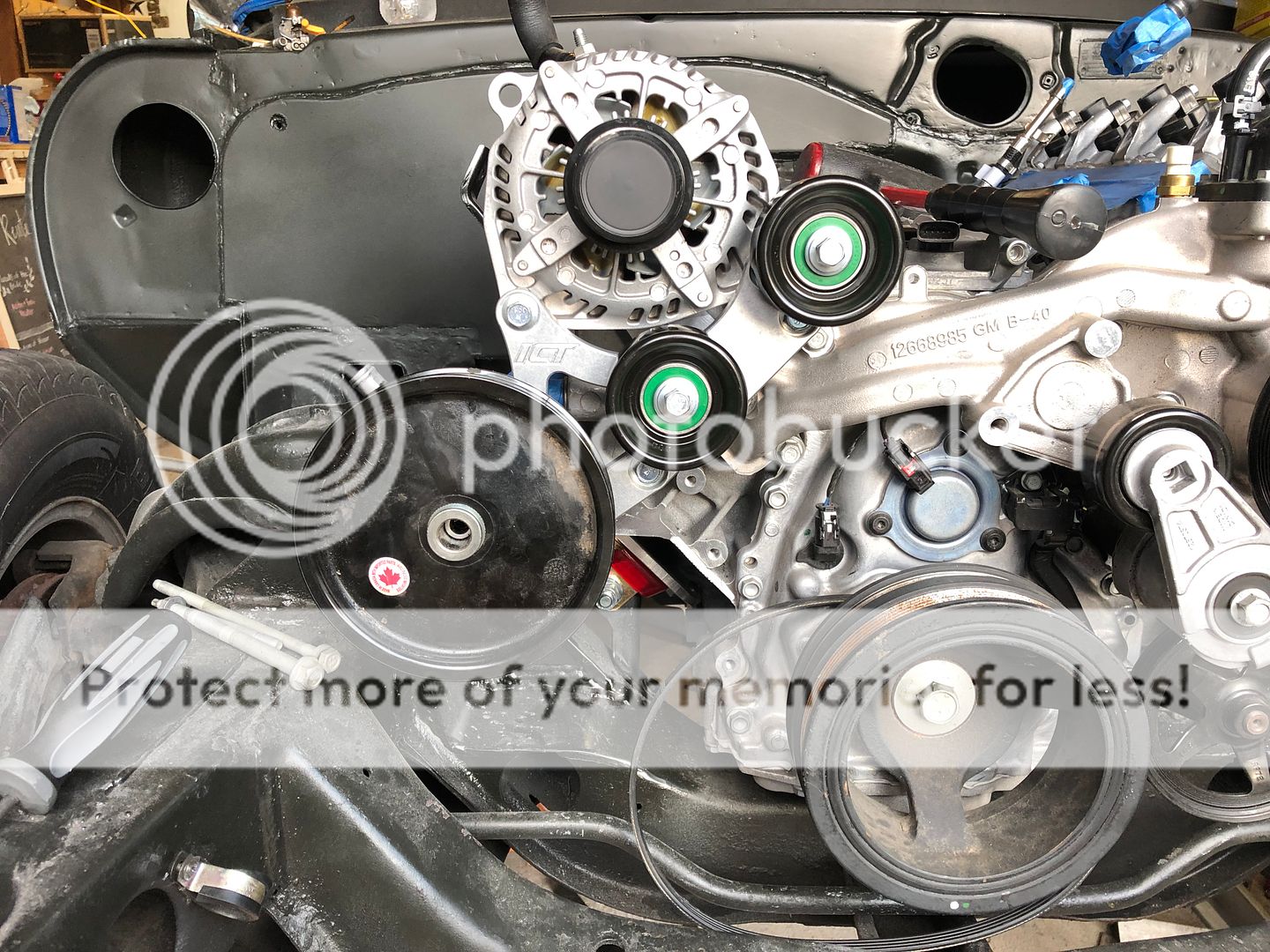

I also received my ICTBillet power steering pump bracket and installed it. Due to my position of the motor this bracket hits my a-arm and will not work for me. Like most things with this car plans have now changed. I'll be returning the PS bracket and going another direction with my setup. I have found a replacement accessory drive from Drive Junky that is pretty nice, it keeps the water pump so thats cool but I cannot use my factory compressor or vacuum pump. I should get the new drive installed in the next couple of weeks.

#92

Got my headers installed! I ended up needing to massage the steering box and one of the tubes slightly to get them to fit due to the motors position in the car. These headers fit tight against the motor as advertised, this presents a small issue with the new Holley trans crossmember I'm installing. The PS header does not line up with the exhaust relief cutouts on the crossmember. Easy fix, just need to rout the exhaust over a bit, I post some photos of this later on. Another issue was the DS header flange had an issue sitting flush on the head, it seemed to be bulged out a hair in the center, hopefully the gasket and bolt torque will account for the misalignment issue. If you hold a straight edge across the header flange its off by a few thousandths in the center. PS header also clears the factory starter heat shield so thats kind of cool.

Also got the intake manifold installed and purchased the engine covers. I'm missing the studs to mount them but one of the guys on Corvetteforum was nice enough to send me his old studs for free as long as I covered the shipping.

Also got the intake manifold installed and purchased the engine covers. I'm missing the studs to mount them but one of the guys on Corvetteforum was nice enough to send me his old studs for free as long as I covered the shipping.

#95

I ended up changing my mind about my hackjob crossmember I made and figured I would purchase a Holley crossmember and hack it up instead. I found a post on ls1tech where a guy used a T56 crossmember to install his 6l90 so I figure this would be a good starting point.

Sorry for the lack of photos, I away from the car but I'll get photos of the crossmember installed later on.

Here are a few pics of what needed to be done on order to make it fit. I had to cut out some of the diagonal gussets to clear the pan and then I had to lift the mounting position roughly 2" high and 3/4" forward to bold up to my trans witht he trans sitting at 3 degrees. Also reinstalled the diagonal gusset plate off to the side to maybe help keep strength.

It ended up working out great and is way stronger than my hackjob crossmember. I did not want to risk hitting a big bump and the stock crossmember bend and screw things up so this should help that not happen.

In order to lift the mounting point and move it forward I just used some leftover Ridtech axle tube tabs from my 4-link kit and the plate with the mounting holes came with the crossmember, I guess it might be a spacer?

Sorry for the lack of photos, I away from the car but I'll get photos of the crossmember installed later on.

Here are a few pics of what needed to be done on order to make it fit. I had to cut out some of the diagonal gussets to clear the pan and then I had to lift the mounting position roughly 2" high and 3/4" forward to bold up to my trans witht he trans sitting at 3 degrees. Also reinstalled the diagonal gusset plate off to the side to maybe help keep strength.

It ended up working out great and is way stronger than my hackjob crossmember. I did not want to risk hitting a big bump and the stock crossmember bend and screw things up so this should help that not happen.

In order to lift the mounting point and move it forward I just used some leftover Ridtech axle tube tabs from my 4-link kit and the plate with the mounting holes came with the crossmember, I guess it might be a spacer?

#97

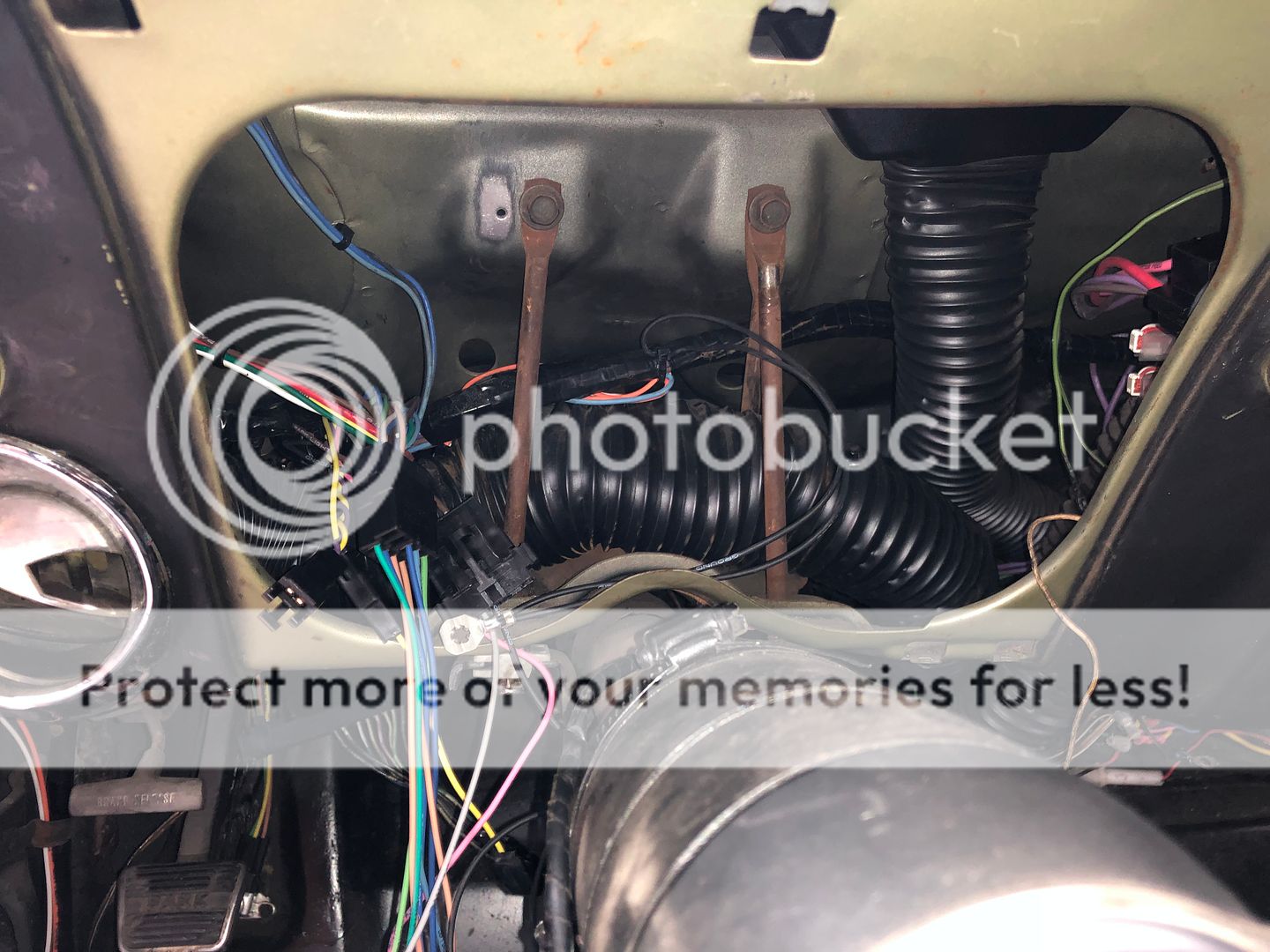

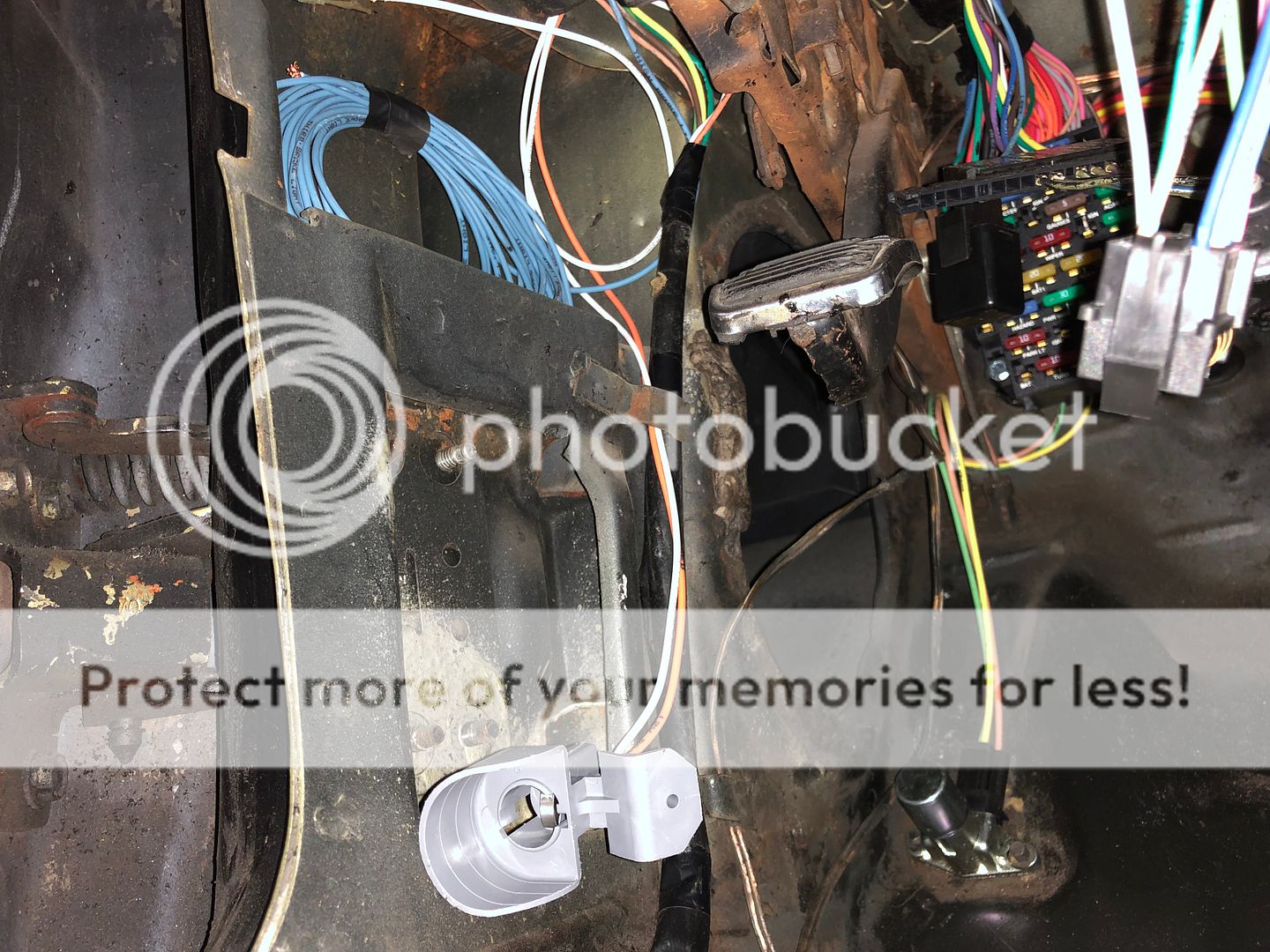

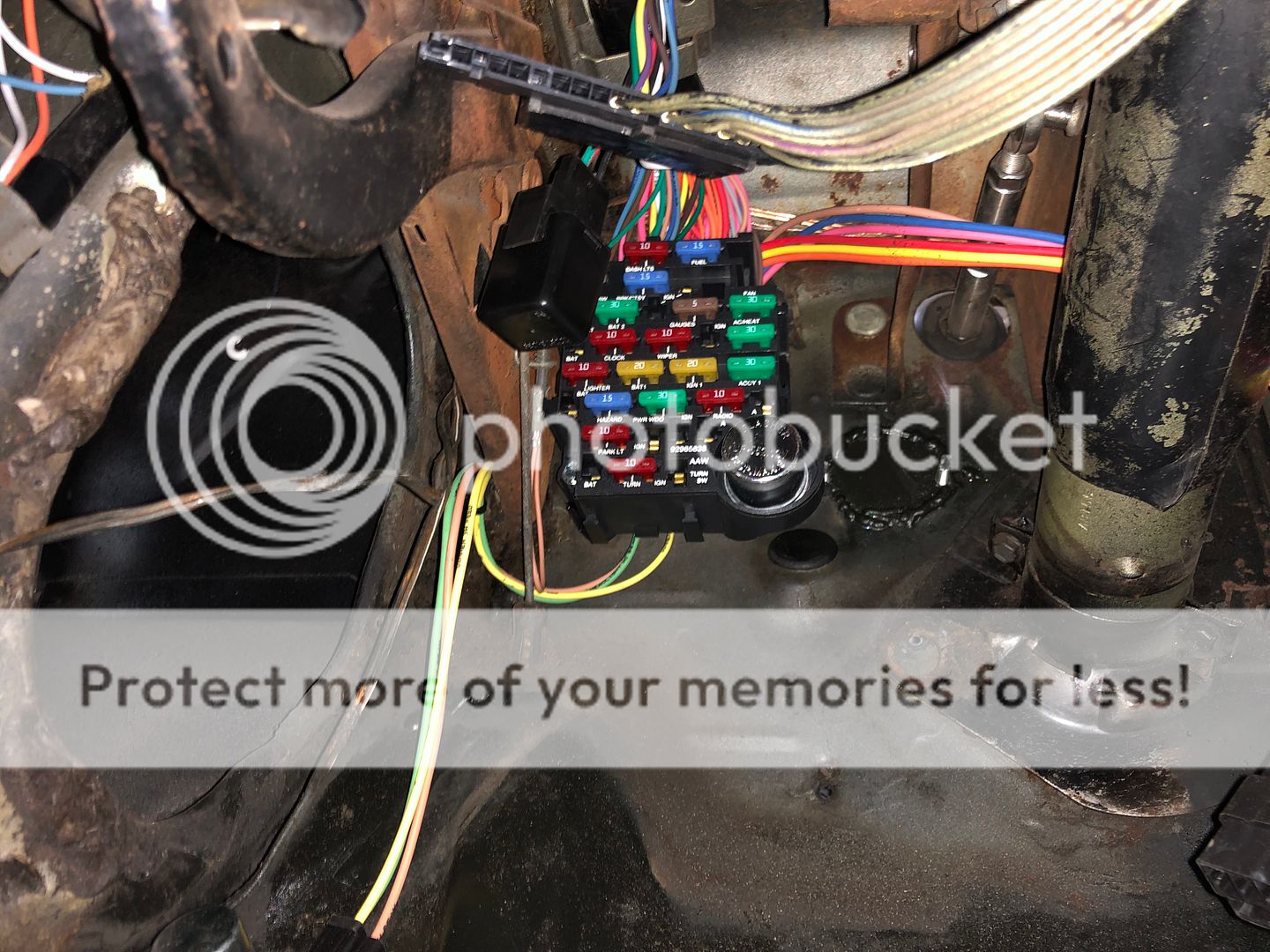

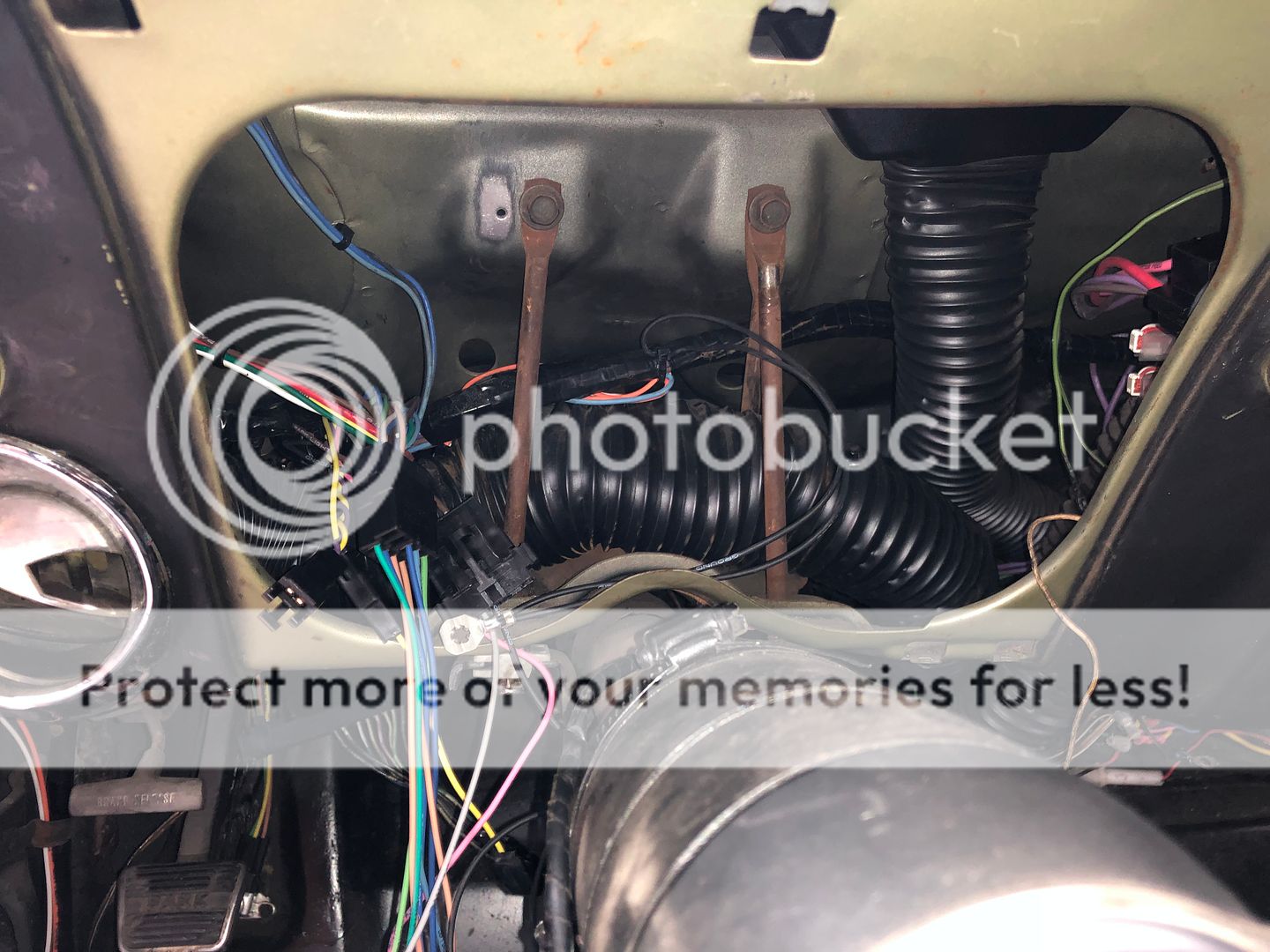

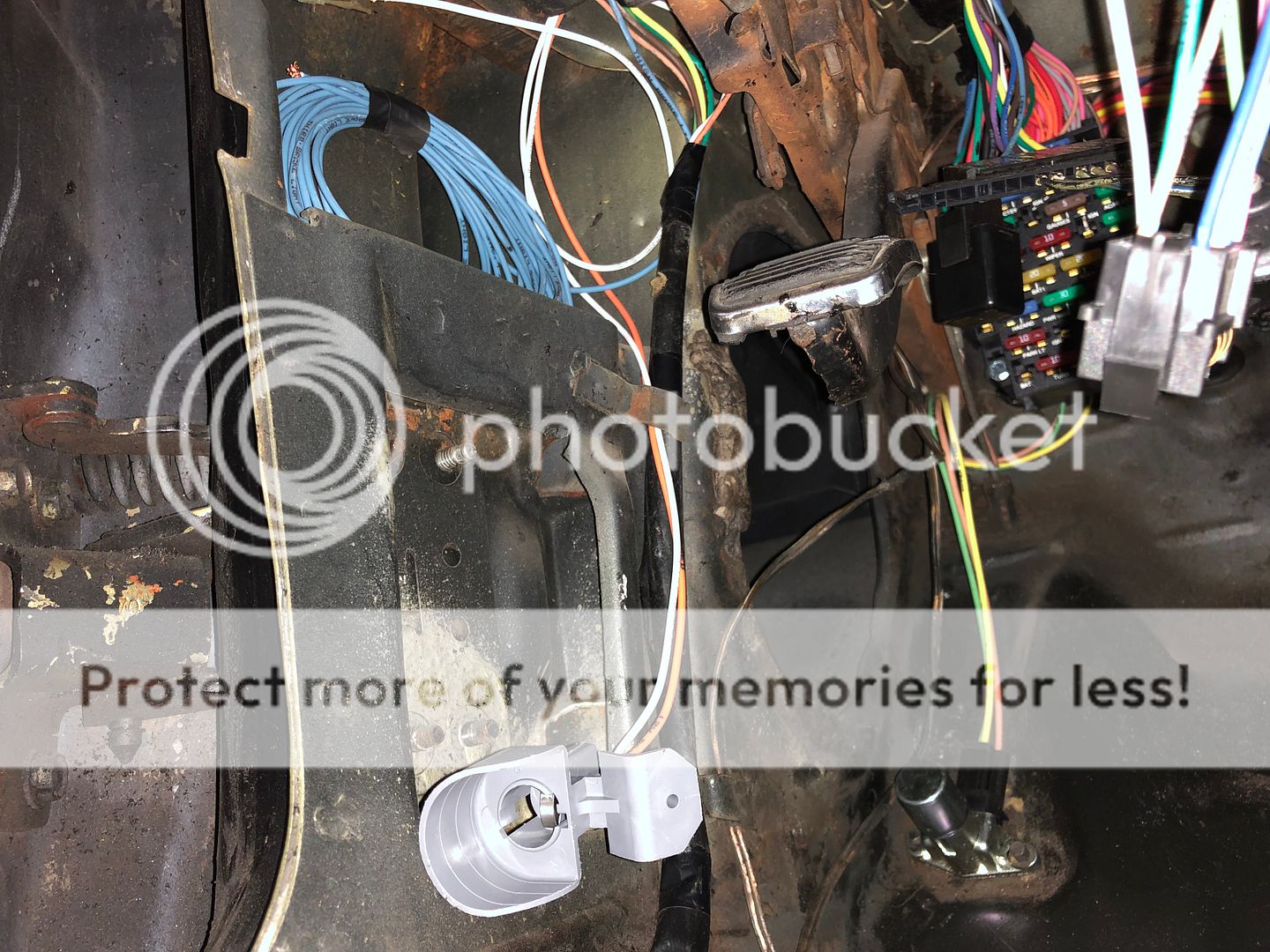

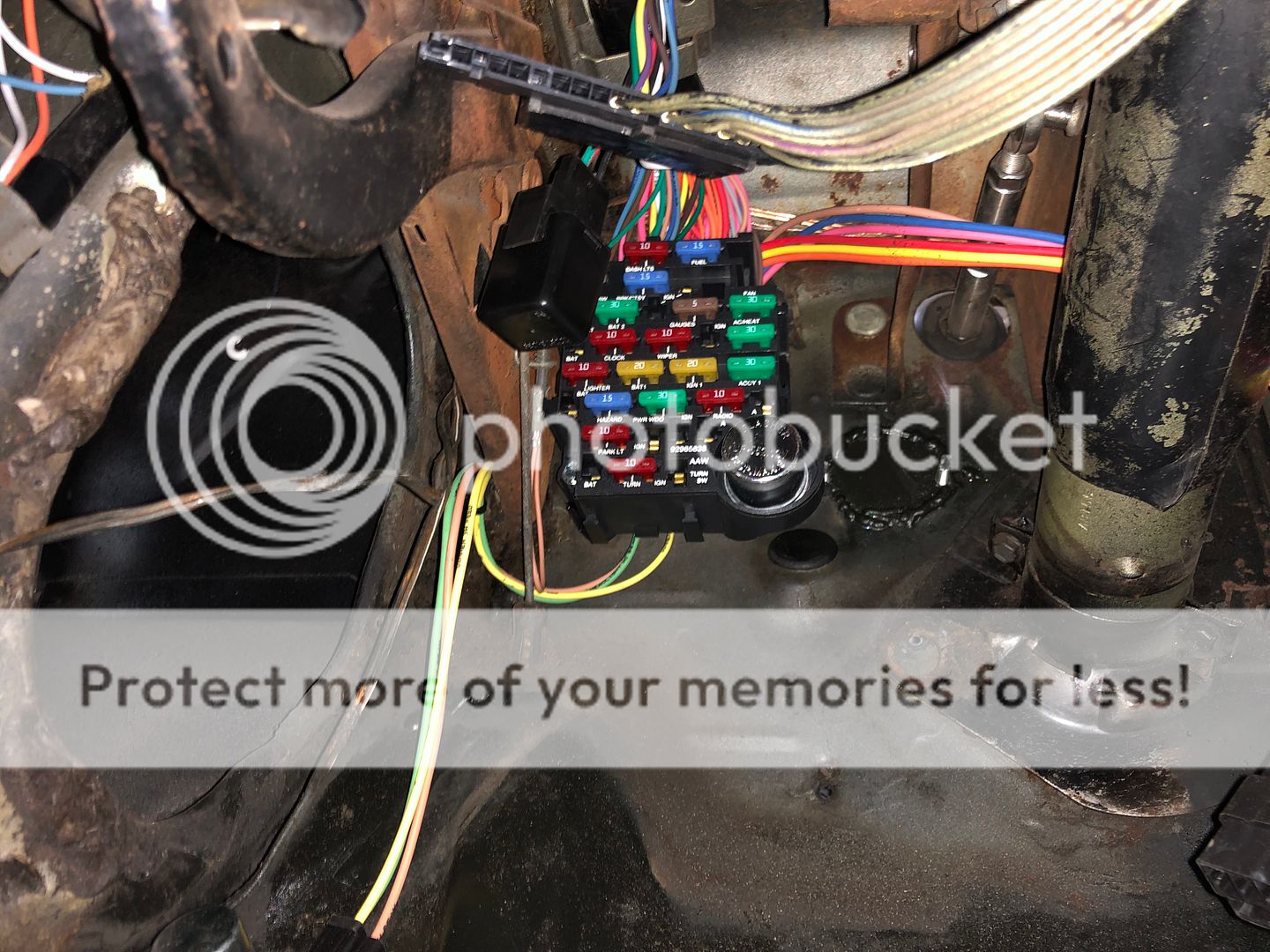

I decided to redo all the wiring and chose the American Auto Wire Classic Update kit. This thing is very cool and user friendly, the guys at AAW have great customer service, I called an asked a few questions and they were very knowledgeable and helped me out.

I started with the dash area and then worked to the back of the car. I did not finish wiring up the neutral safety switch, backup lights or the vintage air system yet. My engine harness will come with an extra module that should control the reverse lights and it is also equipped with a neutral safety output that I'll wire in later once I get my engine harness.

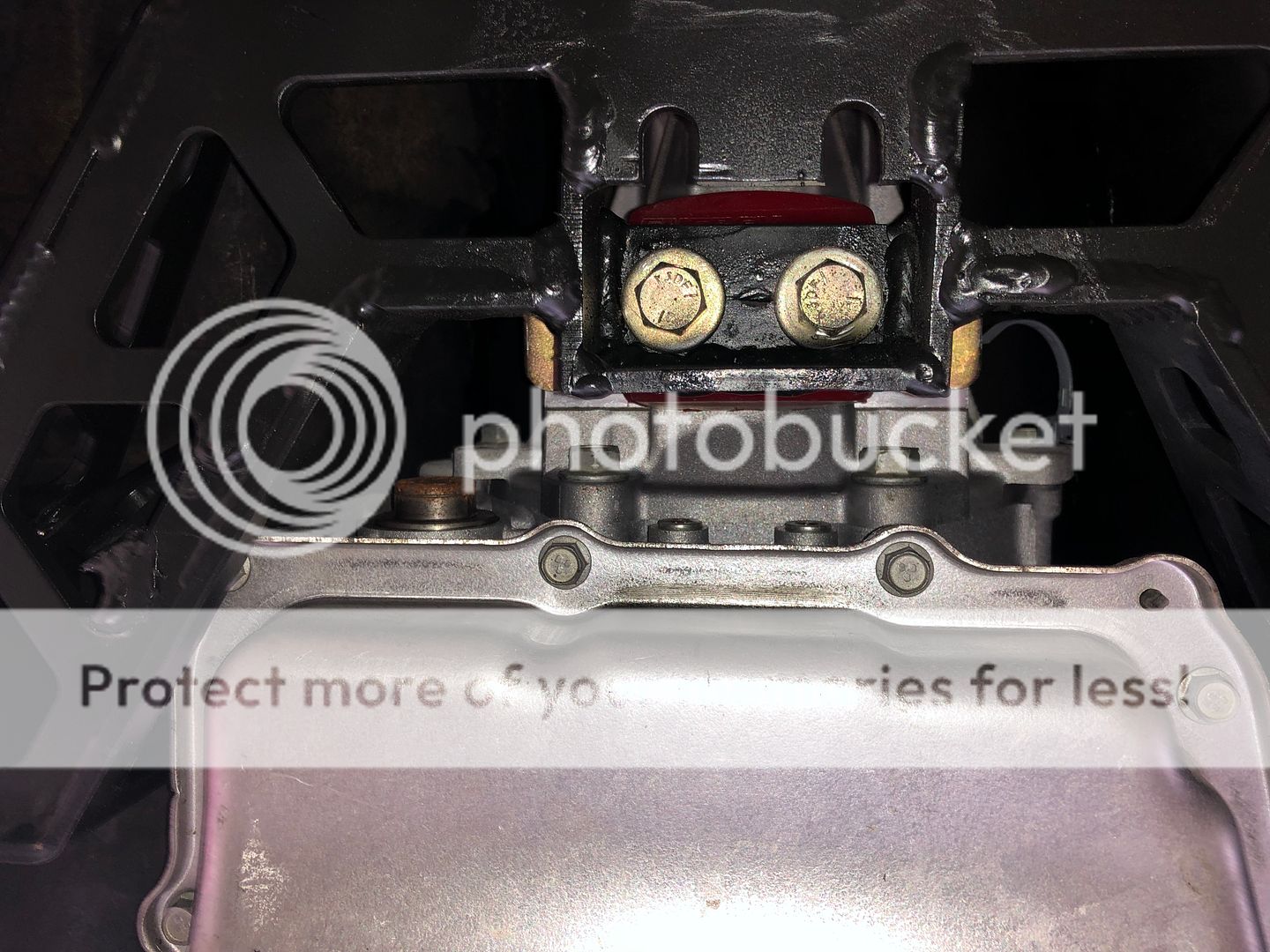

I then went to the engine bay and started on the engine harness and front lights. Turns out with a newer motor you dont really use many of the engine related wires or at least I did not. The kit is cool though, it comes wires prewired for an ECM mounted in the engine bay so you can just wire this right up to your swap harness and roll with it. I have installed my main power junction stud directly below the break booster to keep it kind of hided. This stud will supply power to most of the car. After I got the stud installed I slapped the front fenders back on for the front wire fitment.

I started with the dash area and then worked to the back of the car. I did not finish wiring up the neutral safety switch, backup lights or the vintage air system yet. My engine harness will come with an extra module that should control the reverse lights and it is also equipped with a neutral safety output that I'll wire in later once I get my engine harness.

I then went to the engine bay and started on the engine harness and front lights. Turns out with a newer motor you dont really use many of the engine related wires or at least I did not. The kit is cool though, it comes wires prewired for an ECM mounted in the engine bay so you can just wire this right up to your swap harness and roll with it. I have installed my main power junction stud directly below the break booster to keep it kind of hided. This stud will supply power to most of the car. After I got the stud installed I slapped the front fenders back on for the front wire fitment.

#99

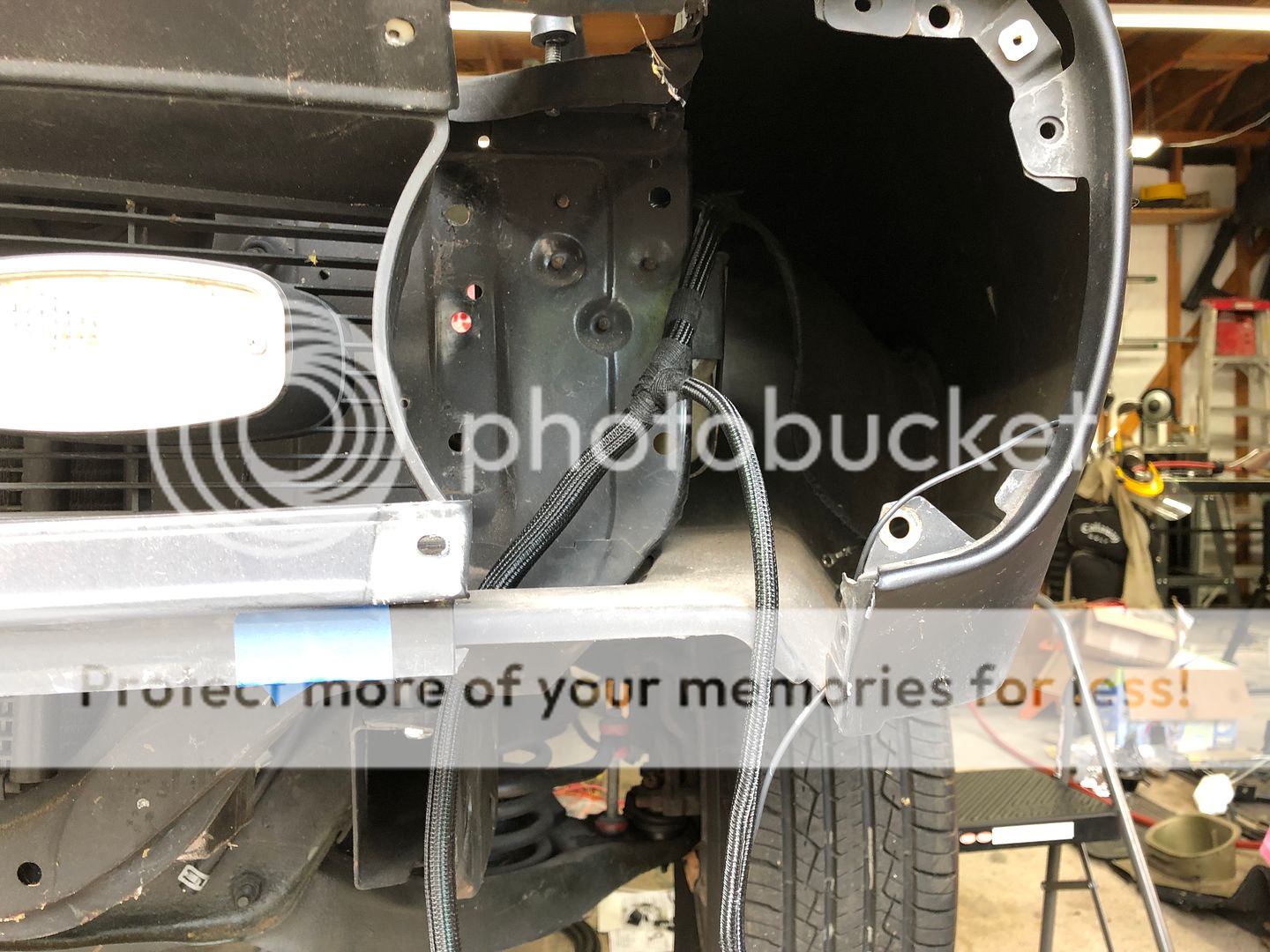

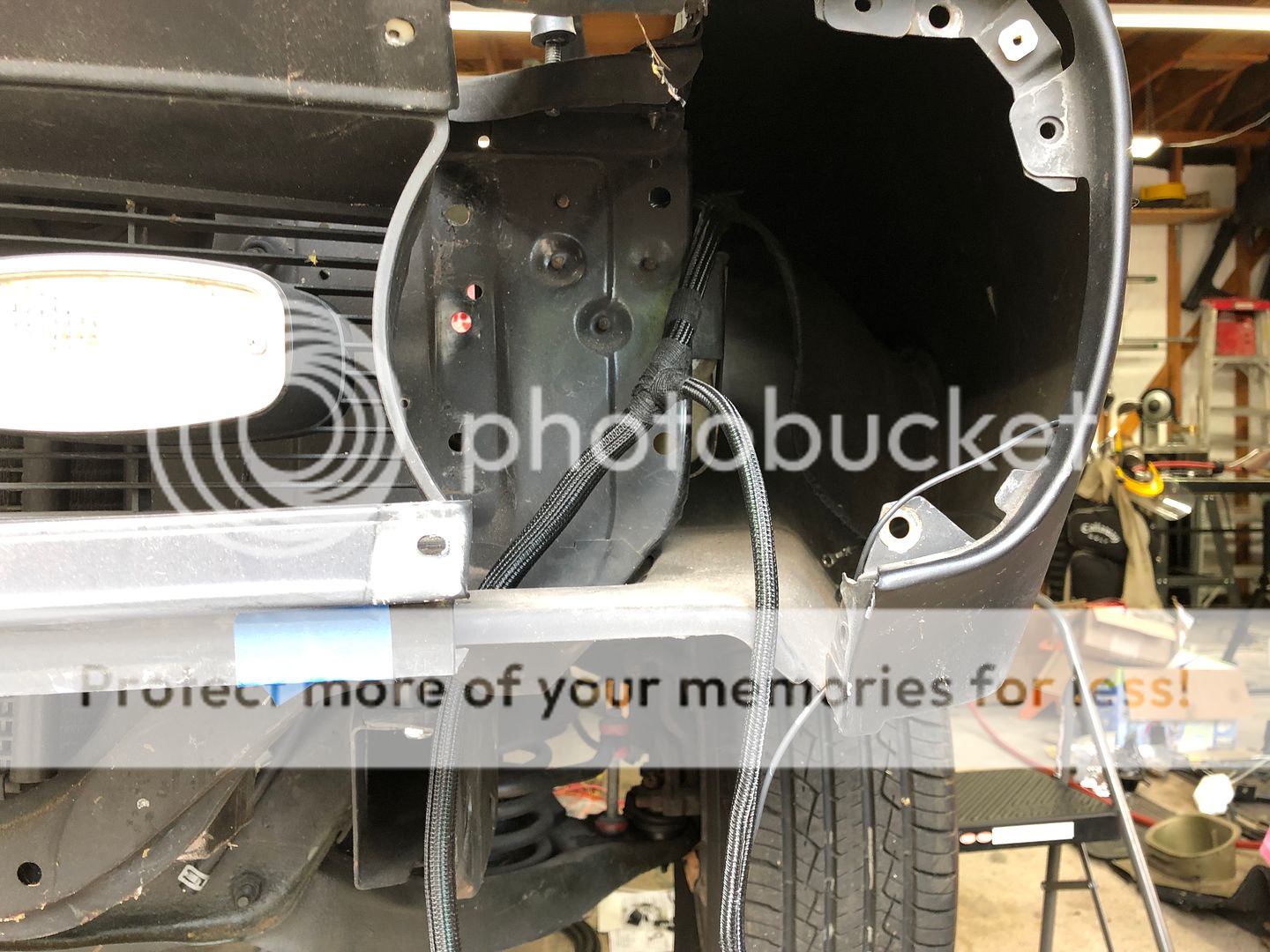

Heres a few photos of the front lighting and wiper motor wiring. I also ran the AAW ECM wiring similar to the front lights, everything is located behind the fender out of the way or under the core support, ended up looking pretty cool.

I also hooked up my power wire from my alternator to the main junction stud and back to the battery to charge it. I ran a remote solenoid like others do as a safety feature with the main power wire, its only hot when its cranked. Heres some photos of the trunk mounted battery and how I ran the wire to the starter. The charge wire and solenoid wire are ran down the DS of the car. This setup is pretty common and is similar to Mad Electrical's and the sticky on pro-touring.

I also hooked up my power wire from my alternator to the main junction stud and back to the battery to charge it. I ran a remote solenoid like others do as a safety feature with the main power wire, its only hot when its cranked. Heres some photos of the trunk mounted battery and how I ran the wire to the starter. The charge wire and solenoid wire are ran down the DS of the car. This setup is pretty common and is similar to Mad Electrical's and the sticky on pro-touring.