~85 psi at the Fuel Rail??

#1

Whats up everyone I have done a fair amount of research on this issue, but have yet to find a similar scenario to my current problem. To give some background I have a 2006 Mazda RX8 that I put a LS1/T56 into from a 2004 Pontiac GTO donor. The car runs great, however I have been fighting this intermittent hard start issue. Sometimes you hop in it fires right up and your good to go, other times it take a few times and extended crank time to get it up and running. Once it starts though it idles fine, and drives without any noticeable issues. Hasn't thrown any codes either.

I went through and checked the basics, plugs, wires, coils, cam sensor, crank sensor, and still the same issue. So just to humor myself I decided to check my fuel pressure, and something is obviously jacked up. When I turn the key you can hear the pump turn on and prime, and when it does this the fuel pressure gauge (measured at the rail) charges to ~80 psi then settles quickly back to around ~50 psi and then stays there. However, once I crank it over and it starts up the fuel pressure immediately jumps back to ~85 psi and stays there. Turn the car off and the fuel pressure drops back to ~50 psi. It doesn't stay at 50 psi though. It drops at about ~1psi a min. I waited ~45 mins and when I returned it was ~ 10 psi at the rail.

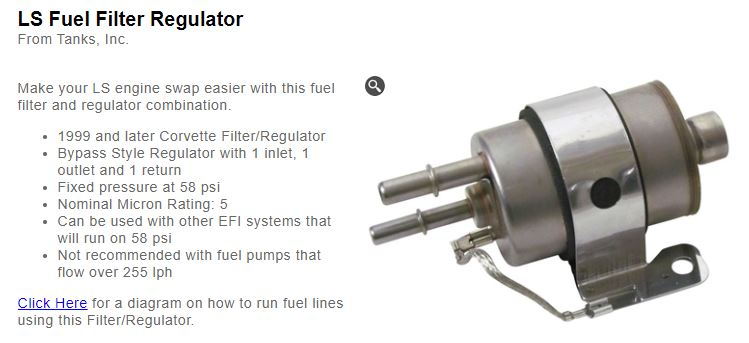

I have a walbro in tank fuel pump, plumbed to a corvette style fuel filter/regulator, to the stock ls1 fuel rail. My initial guess from everything I have researched would be that the regulator is shot? Its brand new at least it was at the time of install (less than a year ago), also if it failed I would expect to see low fuel pressure not high. Also the fuel pressure dropping has to either be injectors leaking by or the check valve in the pump is dead. If the check valve in the pump is the problem i assume i can add an inline check valve to remedy that problem, but that wouldn't help the crazy high fuel pressure. Any thoughts or ideas? Any help would be greatly appreciated, been fighting this for about a month now, and I finally think I'm on the right direction.....hopefully.

I went through and checked the basics, plugs, wires, coils, cam sensor, crank sensor, and still the same issue. So just to humor myself I decided to check my fuel pressure, and something is obviously jacked up. When I turn the key you can hear the pump turn on and prime, and when it does this the fuel pressure gauge (measured at the rail) charges to ~80 psi then settles quickly back to around ~50 psi and then stays there. However, once I crank it over and it starts up the fuel pressure immediately jumps back to ~85 psi and stays there. Turn the car off and the fuel pressure drops back to ~50 psi. It doesn't stay at 50 psi though. It drops at about ~1psi a min. I waited ~45 mins and when I returned it was ~ 10 psi at the rail.

I have a walbro in tank fuel pump, plumbed to a corvette style fuel filter/regulator, to the stock ls1 fuel rail. My initial guess from everything I have researched would be that the regulator is shot? Its brand new at least it was at the time of install (less than a year ago), also if it failed I would expect to see low fuel pressure not high. Also the fuel pressure dropping has to either be injectors leaking by or the check valve in the pump is dead. If the check valve in the pump is the problem i assume i can add an inline check valve to remedy that problem, but that wouldn't help the crazy high fuel pressure. Any thoughts or ideas? Any help would be greatly appreciated, been fighting this for about a month now, and I finally think I'm on the right direction.....hopefully.

#2

ModSquad

iTrader: (6)

I had a similar issue with my Chevelle. I had a Walbro 255 with a corvette filter/reg. Worked great. 58 lbs at idle. Yay. This was feeding an LS2 with LS3 topend 500 hp engine. Built the 434 and while car was apart, I threw a Walbro 450 in the tank. Started car and had tuning issues as to be expected, but got them under control somewhat and checked fuel pressure. It read 78-80 if I remember right...maybe more? Been a couple years. Anyway, I ended up going with an aftermarket regulator to get the pressure right. Apparently the corvette regulator couldn’t handle the extra flow from the 450? No idea what pump your running, just sharing how my experience went.

#4

When my cheap knock-off Corvette regulator failed it pegged my fuel pressure gauge. Replaced with a quality WIX/NAPA Gold version and it's been fine since. The cheap versions aren't worth the cardboard boxes they come in.

The following users liked this post:

1964SS (02-12-2020)

#5

I had a similar issue with my Chevelle. I had a Walbro 255 with a corvette filter/reg. Worked great. 58 lbs at idle. Yay. This was feeding an LS2 with LS3 topend 500 hp engine. Built the 434 and while car was apart, I threw a Walbro 450 in the tank. Started car and had tuning issues as to be expected, but got them under control somewhat and checked fuel pressure. It read 78-80 if I remember right...maybe more? Been a couple years. Anyway, I ended up going with an aftermarket regulator to get the pressure right. Apparently the corvette regulator couldnít handle the extra flow from the 450? No idea what pump your running, just sharing how my experience went.

Ya this is my guess as well, just wanting to get some other insights/opinions.

#6

TECH Fanatic

iTrader: (7)

Id like to interject my thought and process for checking a regulator. Inside the vette regulator and others is a spring (adjustable or preset) and some sort of disk or ball pressing on a seat. Most fuel pumps can supply at least 125 psi of fuel pressure and have a one way back-flow preventing valve to maintain pressure when the pump is not running. It obviously bleads down over time. This maintains pressure in the lines after the engine is shut down for fast restarts. So if you connect a pressure gage on the pump outlet and run the pump, it would read about 125psi. Then reconnect the pump to the regulator and measure the outlet pressure. if the vette regulator is reading correctly, it should read about 58psi with the pump running. This is because the pump pressurizes the outlet port and connected lines and injectors. The pump pressure is set by the spring pressure on the ball/disk. Any pressure over the spring setting and the fuel applies more pressure than the spring pressure and opens the ball/seat to return the fuel back to the tank through the return line. This is how it regulates the pressure. If the engine is using enough fuel to lower the rail pressure below the spring set point, the ball/disk closes and raises the rail pressure back up to the preset pressure. Thats the theory behind how the system works.

So, the easiest way I have found to test a regulator is to remove it from the system and drain out any fuel. Then using a standard air compressor, apply 125 pisi of air the the inlet port, monitored with an air gage. The gage will read the regulated pressure. If the ball/disk leaks, the readings will be less than the set pressure. If the gage reads much higher, like 85 psi, in this case, then the regulator ball/disk is either sticking closed or the return portion of the system is restricted.

I do realize there are flow dynamics that are different between fuel and air but this is a safe, quick and easy way of testing the regulator. Remember you have mechanical issue that is showing its effects as a significant pressure increase. So dont guess, think, wonder or throw money at the issue. Test, measure and eval you results.

Just my thoughts and process.

So, the easiest way I have found to test a regulator is to remove it from the system and drain out any fuel. Then using a standard air compressor, apply 125 pisi of air the the inlet port, monitored with an air gage. The gage will read the regulated pressure. If the ball/disk leaks, the readings will be less than the set pressure. If the gage reads much higher, like 85 psi, in this case, then the regulator ball/disk is either sticking closed or the return portion of the system is restricted.

I do realize there are flow dynamics that are different between fuel and air but this is a safe, quick and easy way of testing the regulator. Remember you have mechanical issue that is showing its effects as a significant pressure increase. So dont guess, think, wonder or throw money at the issue. Test, measure and eval you results.

Just my thoughts and process.

Last edited by aknovaman; 02-13-2020 at 10:19 AM.

#7

Id like to interject my thought and process for checking a regulator. Inside the vette regulator and others is a spring (adjustable or preset) and some sort of disk or ball pressing on a seat. Most fuel pumps can supply at least 125 psi of fuel pressure and have a one way back-flow preventing valve to maintain pressure when the pump is not running. It obviously bleads down over time. This maintains pressure in the lines after the engine is shut down for fast restarts. So if you connect a pressure gage on the pump outlet and run the pump, it would read about 125psi. Then reconnect the pump to the regulator and measure the outlet pressure. if the vette regulator is reading correctly, it should read about 58psi with the pump running. This is because the pump pressurizes the outlet port and connected lines and injectors. The pump pressure is set by the spring pressure on the ball/disk. Any pressure over the spring setting and the fuel applies more pressure than the spring pressure and opens the ball/seat to return the fuel back to the tank through the return line. This is how it regulates the pressure. If the engine is using enough fuel to lower the rail pressure below the spring set point, the ball/disk closes and raises the rail pressure back up to the preset pressure. Thats the theory behind how the system works.

So, the easiest way I have found to test a regulator is to remove it from the system and drain out any fuel. Then using a standard air compressor, apply 125 pisi of air the the inlet port, monitored with an air gage. The gage will read the regulated pressure. If the ball/disk leaks, the readings will be less than the set pressure. If the gage reads much higher, like 85 psi, in this case, then the regulator ball/disk is either sticking closed or the return portion of the system is restricted.

I do realize there are flow dynamics that are different between fuel and air but this is a safe, quick and easy way of testing the regulator. Remember you have mechanical issue that is showing its effects as a significant pressure increase. So dont guess, think, wonder or throw money at the issue. Test, measure and eval you results.

Just my thoughts and process.

So, the easiest way I have found to test a regulator is to remove it from the system and drain out any fuel. Then using a standard air compressor, apply 125 pisi of air the the inlet port, monitored with an air gage. The gage will read the regulated pressure. If the ball/disk leaks, the readings will be less than the set pressure. If the gage reads much higher, like 85 psi, in this case, then the regulator ball/disk is either sticking closed or the return portion of the system is restricted.

I do realize there are flow dynamics that are different between fuel and air but this is a safe, quick and easy way of testing the regulator. Remember you have mechanical issue that is showing its effects as a significant pressure increase. So dont guess, think, wonder or throw money at the issue. Test, measure and eval you results.

Just my thoughts and process.

Great write up, thank you for taking the time to post. I am following and completely agree with your opinion.

That being said when I got home today (and before I read this) I pulled the rail with the injectors still attached and primed the system to verify that none of the injectors were leaking by. Good news is, none of them were.

However, I still am loosing about a ~psi a minute of pressure. That being said that loss can only come from one place since itís not coming from the rail, lines, or injectors.

The pump check valve. What Iím curious about though is, is that rate of pressure loss normal? Or should it hold pressure after the pump shuts off for longer than a 1 psi a min drop (I.e. in an hour the gauge is reading close to 0 psi). If that drop in pressure of about 1psi a min is normal, then I agree (and now can test) that the only issue is the FPR. If that drop in pressure is not normal then I suspect the check valve in the pump is bad, AND the FPR is bad (causing the 85psi when idle).

Trending Topics

#9

That being said, anyone out there run a corvette style FPR with a pump that flows more than 255LPH? If so do you experience any issues killing this style FPR? Like I stated in an earlier post some sites that sell it state its not recommended with use of a pump that flows > 255LPH. I don't want to keep having to replace this FPR, so im trying to decide while its dead do I go with the corvette FPR that just failed or replace it with an adjustable Aeromotive one and dial it in to 58 psi.

#11

TECH Fanatic

iTrader: (23)

It's likely the return flow to your tank is insufficient for the volume of the pump, so pressure at the rail goes high when engine is consuming small amounts of fuel. Easy test, go run the engine hard and watch the fuel pressure come down.

On the flip side, testing by Lngenfelter showed that the fuel filter becomes a restriction at 270 lph (same as f body). What that means is the rail pressure will go below set point when your engine demands more than that. Basically you've got a tuning nightmare on your hands with both high and low pressure swings. The high pressure swings are the much harder part to deal with because it won't be consistent enough to tune around.

On the flip side, testing by Lngenfelter showed that the fuel filter becomes a restriction at 270 lph (same as f body). What that means is the rail pressure will go below set point when your engine demands more than that. Basically you've got a tuning nightmare on your hands with both high and low pressure swings. The high pressure swings are the much harder part to deal with because it won't be consistent enough to tune around.

#12

It's likely the return flow to your tank is insufficient for the volume of the pump, so pressure at the rail goes high when engine is consuming small amounts of fuel. Easy test, go run the engine hard and watch the fuel pressure come down.

On the flip side, testing by Lngenfelter showed that the fuel filter becomes a restriction at 270 lph (same as f body). What that means is the rail pressure will go below set point when your engine demands more than that. Basically you've got a tuning nightmare on your hands with both high and low pressure swings. The high pressure swings are the much harder part to deal with because it won't be consistent enough to tune around.

On the flip side, testing by Lngenfelter showed that the fuel filter becomes a restriction at 270 lph (same as f body). What that means is the rail pressure will go below set point when your engine demands more than that. Basically you've got a tuning nightmare on your hands with both high and low pressure swings. The high pressure swings are the much harder part to deal with because it won't be consistent enough to tune around.

That being said I had this car tuned ~3 months ago, and paid $700 for the tune work, and it showed to maintain a nice AFR the entire time. I am wondering though if we just got lucky that day or what. My fear is that now that I know the fuel pressure is a problem, once I fix it, I may be running super lean. Thats assuming at the time of the tune the tuner was leaning out the mixture to get a good AFR (but not knowing my fuel pressure was at 80PSI). I dont know if it is that impactful since the tune to my understanding is based on the injector pulses/control/flow rate, and I dont know how much the ~22psi difference would make. If I get it back to 58 PSI in theory I should still "get" the same amount of fuel, but if I dont I likely will need to get it re-tuned which really pisses me off haha.

#15

I have HPtuners and actually did this the other day. It confirmed what we all assumed itís the FPR that has failed causing the high fuel rail pressure. Plan is to replace it with an Aeromotive 13109, and re-plumb the system to eliminate the corvette FPR all together. Then dial it in to ~58psi, and be good to go!

#17

Bad news is, car still has the intermittent hard start issue. This is really starting to wear.

Problem remains the same after replacing/swapping the FPR, crank sensor, cam sensor, plugs, wires, and coils.

My only thought i keep coming back to is my injectors. I have done the test to verify they are not leaking, and I can here the ďclick clickĒ when the car is running on all of them, but I just donít know what else could cause this intermittent hard start, I really thought finding the pressure so out of whack was it, but even with it perfect it still does it.

The engine sat for many years in my garage before it was swapped in, thatís the only thing that makes me think even though I havenít been able to catch it or prove it that maybe something is going on with the injectors causing the intermittent hard starts. Because I have fuel pressure and spark. I donít know....any input or help is greatly appreciated.

#18

Figured I would come back to update this, in case someone else has a similar issue. Good news is, I got and installed the new FPR and now I consistently get ~58psi at all conditions.

Bad news is, car still has the intermittent hard start issue. This is really starting to wear.

Problem remains the same after replacing/swapping the FPR, crank sensor, cam sensor, plugs, wires, and coils.

My only thought i keep coming back to is my injectors. I have done the test to verify they are not leaking, and I can here the ďclick clickĒ when the car is running on all of them, but I just donít know what else could cause this intermittent hard start, I really thought finding the pressure so out of whack was it, but even with it perfect it still does it.

The engine sat for many years in my garage before it was swapped in, thatís the only thing that makes me think even though I havenít been able to catch it or prove it that maybe something is going on with the injectors causing the intermittent hard starts. Because I have fuel pressure and spark. I donít know....any input or help is greatly appreciated.

Bad news is, car still has the intermittent hard start issue. This is really starting to wear.

Problem remains the same after replacing/swapping the FPR, crank sensor, cam sensor, plugs, wires, and coils.

My only thought i keep coming back to is my injectors. I have done the test to verify they are not leaking, and I can here the ďclick clickĒ when the car is running on all of them, but I just donít know what else could cause this intermittent hard start, I really thought finding the pressure so out of whack was it, but even with it perfect it still does it.

The engine sat for many years in my garage before it was swapped in, thatís the only thing that makes me think even though I havenít been able to catch it or prove it that maybe something is going on with the injectors causing the intermittent hard starts. Because I have fuel pressure and spark. I donít know....any input or help is greatly appreciated.

#19

you really think that will solve the hard start? Just a tuning issue now....because the hard start was doing the exact same thing before and after the tune.

#20

TECH Addict

iTrader: (1)

Since you have HPtuners you can monitor the fuel trims and see if the computer is compensating for a tune that was mapped for higher fuel pressure. It's possible the car was tuned with normal fuel pressure so I would just check trims first to see where things are at. If it's clear the trims are high (i.e. double digit percentages) that would be a good indication the tune was done for higher pressures.

Are you confident you are getting good voltage for the ECM during cranking? Perhaps the way you are wired and grounded is occasionally not giving enough juice for the ECM to fire the injectors and coils during high amp crank draw.

Are you confident you are getting good voltage for the ECM during cranking? Perhaps the way you are wired and grounded is occasionally not giving enough juice for the ECM to fire the injectors and coils during high amp crank draw.