Started on my twin turbo build. Pics inside.

#21

Update

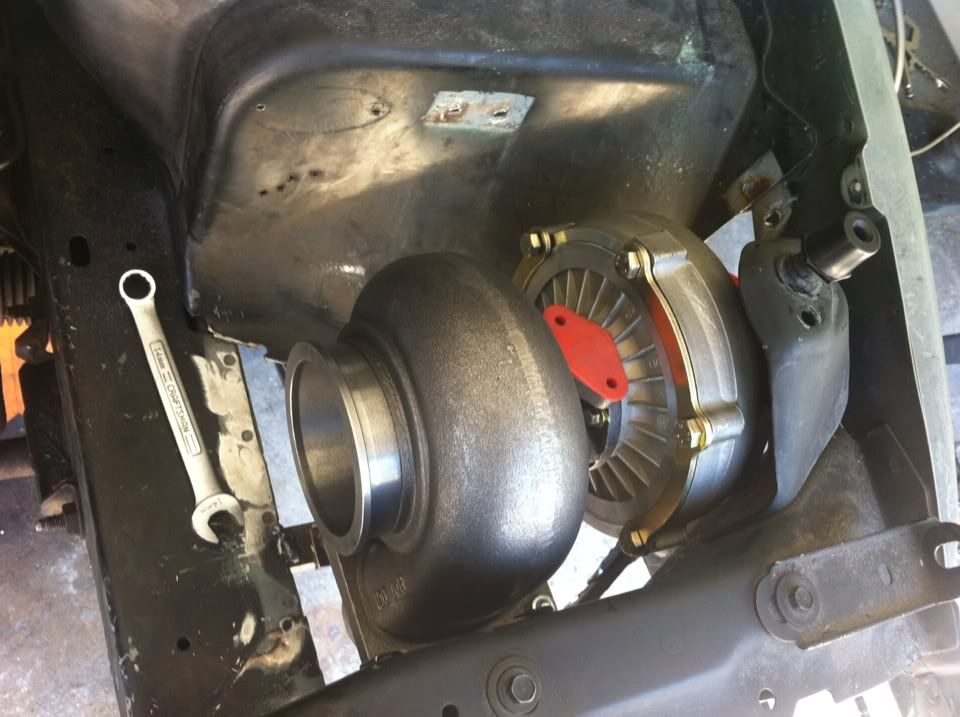

Unfortunately I wasn't able to get nearly as much done as I wanted this wknd. Out of this whole wknd I was only able to work on it yesterday. Anyhow, I finished up the driver side section. I forgot to take the final pics but here's a few I took along the way.

I'll post up some more pics this wk.

Unfortunately I wasn't able to get nearly as much done as I wanted this wknd. Out of this whole wknd I was only able to work on it yesterday. Anyhow, I finished up the driver side section. I forgot to take the final pics but here's a few I took along the way.

I'll post up some more pics this wk.

#23

TECH Regular

iTrader: (15)

Join Date: Jun 2004

Location: Shawnee KS

Posts: 498

Likes: 0

Received 0 Likes

on

0 Posts

I'm going to highly recomend solid mounts. Now that you have flex couplers the twisting of the motor is going to try and rip the couplers apart over a short period of time. With solid mounting you could have also ditched the flex couplers as they won't be needed.

#26

As for the fuse boxes...I'll be relocating them into the cockpit. I might be deleting the ABS. Not sure yet. If I don't I'll relocate that as well. I just need to find out if the ABS block needs to be at a certain level compared to the master cylinder.

Last edited by Danny; 05-30-2012 at 10:24 AM.

#28

TECH Regular

iTrader: (15)

Join Date: Jun 2004

Location: Shawnee KS

Posts: 498

Likes: 0

Received 0 Likes

on

0 Posts

Pollys will help. Just keep an eye on the flex couplers. Ive also had to replace polly mounts even with the kit wrapped very well in those areas. If its just the manifold its not too bad on it, with a downpipe in there as well it deforms them.

#30

Well, I really didn't get much done this wknd because I needed another 2.5" U bent to finish the charge pipes. I'll be picking some up today and finishing up the hotside this wk.

I'm also going to be starting on the down-pipes and I wanted some opinions. I'm going to be using 3.5" 16 gauge for the exhaust. Here are two choices...

Should I have each down pipe merge into a X-pipe in front of the motor, then reduce it to 3" and after the X-pipe and follow that all the way back???

OR

Should I just run each DP individually with no merging, reduce it to 3" and follow it all the way back???

What do you guys think?

I'm also going to be starting on the down-pipes and I wanted some opinions. I'm going to be using 3.5" 16 gauge for the exhaust. Here are two choices...

Should I have each down pipe merge into a X-pipe in front of the motor, then reduce it to 3" and after the X-pipe and follow that all the way back???

OR

Should I just run each DP individually with no merging, reduce it to 3" and follow it all the way back???

What do you guys think?

#33

So you're saying that dual 3" outlets will be enough? I was told that you always want at least the same size as the turbo outlet itself to help with spool and boost. On these turbos the outlets check in at 3.5". So if I put in 3" down pipes I would be going backwards, don't you think? This is just what I think. Mind you, it's my first turbo setup so I'm kinda new.

As for the X-pipe. I think it'll sound better than without it. Also, I think it will help with scavenging.

As for the X-pipe. I think it'll sound better than without it. Also, I think it will help with scavenging.

#34

UPDATE

I haven't been able to put much time into my car as I would like. Trying to juggle my girls bday party, my kids bday party, baby shower for my "soon to be baby boy" and working OT at work has left me drained and almost no time to spare.

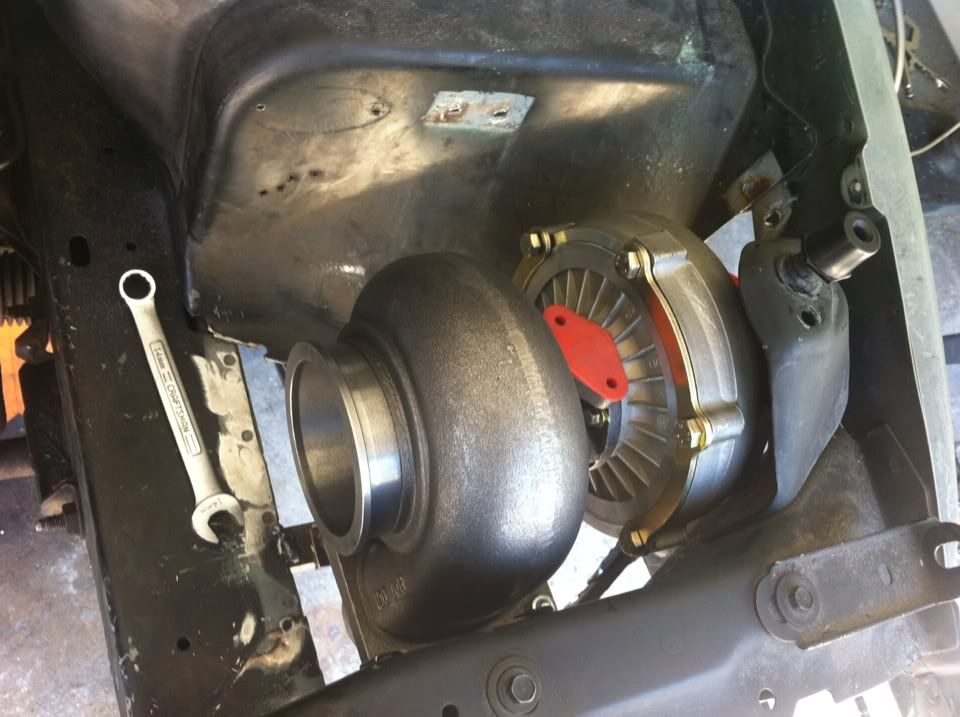

HOWEVER, that did not stop me from sneaking in a few hrs here and there. So far I have both down-pipes welded up and installed. Turbos are mounted. Oil feed has been tapped and return fittings have been welded to the timing cover. Last night I finished cutting and shaping the flanges for the oil feed/return and cutting the fitting to get ready to weld everything up.

Here's a pic of the flanges and fitting ready to be welded.

Here's a pic of the timing cover with the return fittings welded.

The oil flanges should be welded and installed by tonight. The Treadstone intercooler, wastegates and a few misc things should be here tomorrow.

I haven't been able to put much time into my car as I would like. Trying to juggle my girls bday party, my kids bday party, baby shower for my "soon to be baby boy" and working OT at work has left me drained and almost no time to spare.

HOWEVER, that did not stop me from sneaking in a few hrs here and there. So far I have both down-pipes welded up and installed. Turbos are mounted. Oil feed has been tapped and return fittings have been welded to the timing cover. Last night I finished cutting and shaping the flanges for the oil feed/return and cutting the fitting to get ready to weld everything up.

Here's a pic of the flanges and fitting ready to be welded.

Here's a pic of the timing cover with the return fittings welded.

The oil flanges should be welded and installed by tonight. The Treadstone intercooler, wastegates and a few misc things should be here tomorrow.

#36

I will be sure and take pics today and post some up. I've been really busy lately and haven't really had time to work on it. This wknd I actually had a whole Saturday to myself but I was dead in the water. Treadstone send me the wrong intercooler so I wasn't able to do much. My goal is to have the complete system working in the next 2 weeks tops.

#39

On The Tree

iTrader: (14)

Subbed! Good work so far, excited for the rest.

Turbo noob here as well, so correct me if i'm wrong, but on the exhaust topic, i would think you should run tubes that are the same size at the turbo outlet, and run those all the way back, no reducing. I wouldn't imagine that integrating an x-pipe versus separate pipes would make a difference in power, though i could see it helping with backpressure. I don't honestly know. I bet it would sound nasty though

Turbo noob here as well, so correct me if i'm wrong, but on the exhaust topic, i would think you should run tubes that are the same size at the turbo outlet, and run those all the way back, no reducing. I wouldn't imagine that integrating an x-pipe versus separate pipes would make a difference in power, though i could see it helping with backpressure. I don't honestly know. I bet it would sound nasty though

#40

UPDATE

Here's a few updated pics. I haven't gotten much work done lately since I needed the intercooler and a few other parts.

My -10 oil return lines welded to the timing cover. I also rec'd a ASP 25% UD pulley so that should give me even more clearance between the lines and the pulley....

My intercooler finally showed up yesterday after receiving the wrong one the first time...

The outlet on the intercooler is a little on the small side @ 3" OD. That makes it around 2.8" +/- ID. I ordered a 3.5" OD lip to weld onto the intercooler. This should work a lot better IMO. Here's a pic of the lip...

And compared to the 3" lip on the intercooler...

Hopefully this wknd I'll have a chance to cut the core support to mount the Griffin radiator and install the intercooler.

Here's a few updated pics. I haven't gotten much work done lately since I needed the intercooler and a few other parts.

My -10 oil return lines welded to the timing cover. I also rec'd a ASP 25% UD pulley so that should give me even more clearance between the lines and the pulley....

My intercooler finally showed up yesterday after receiving the wrong one the first time...

The outlet on the intercooler is a little on the small side @ 3" OD. That makes it around 2.8" +/- ID. I ordered a 3.5" OD lip to weld onto the intercooler. This should work a lot better IMO. Here's a pic of the lip...

And compared to the 3" lip on the intercooler...

Hopefully this wknd I'll have a chance to cut the core support to mount the Griffin radiator and install the intercooler.

Last edited by Danny; 07-03-2012 at 11:07 AM.