does anyone sell a 4inch IC core?

#1

10 Second Club

Thread Starter

iTrader: (22)

Join Date: Mar 2006

Location: Northwest side of Chicago

Posts: 3,677

Likes: 0

Received 2 Likes

on

2 Posts

Im looking for a 4inch thick core, 27ish long and 12inch high. I have a cheap Ebay one now with a 5psi drop at 20lbs. The way everything is built on my car it would be alot easier if i could just replace the core and not the end tanks and mess with the cold side piping

#5

10 Second Club

Thread Starter

iTrader: (22)

Join Date: Mar 2006

Location: Northwest side of Chicago

Posts: 3,677

Likes: 0

Received 2 Likes

on

2 Posts

Well maybe ill just wait untill I can afford to redo the cold side and probably a bunch of other stuff to make a vertical work. I have a decent pressure drop but my bp is not bad. About 1.8:1 ratio. Would it be accurate if I tested ic loss by tapping into a one off the comp cover to the boost controller? Now that im thinking about it that line would have a boost bleed off and would show lower psi.

#6

7 Second Club

iTrader: (7)

Huh? Pressure drop is directly associated with area and volume and how good the core actually is. Sure a vertical design will be more efficient in terms of how much of the core it uses but using a good core with lots of area will help dramatically. Hell the treadstone 4.5" intercoolers that are a straight across design work wonderfully especially for the price.

#7

with your 370 you will me moving ~670cfm at 7k rpm

with the typical 16 row, 3" thick horizontal pass cores out there the flow area is in the area of 11 square inches

with they typical 16row, 4" thick horzonal pass cores out there the flow area isn in the area of 15 square inches

dum

now compare that to a vertical pass core that has roughly the same overall dimensions..... such as the treadstone trv259

that has a flow area of ~28 square inches.... and is still only 3.5" thick

to say the vertical pass will not cool like a horizontal because the flow tubes are much shorter is total BS.dum dumyes the tube runs are much shorter....... BUT the air speed is also much slower through the core because of the much greater flow area of the vertical pass

Look at the flow area of a2w setups...dum a plain small *** 4.5x4.5x12 a2w core has the flow area of ~30 square inches.... nearly triple and double that of the horizontal 3 and 4" cores everyone runs

yeah the horizontal cores work great on small displacement motors, but looks at the flow rate of those motors compared to the v8 spinning nicely

small displacement motors dont fight for flow area..... they are fighting outrageous compressor discharge temps and benefit from the excellent efficiency of the nicer cores such as bell/garrett

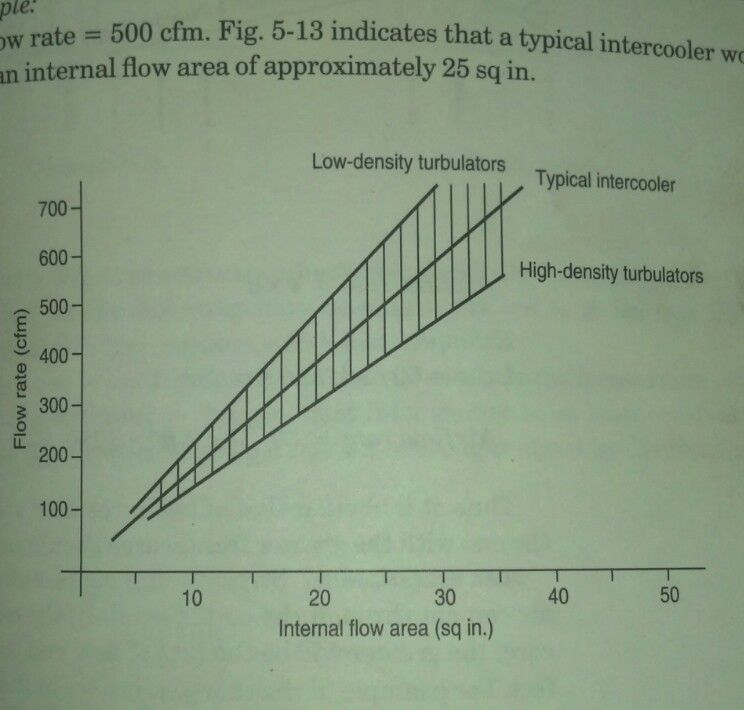

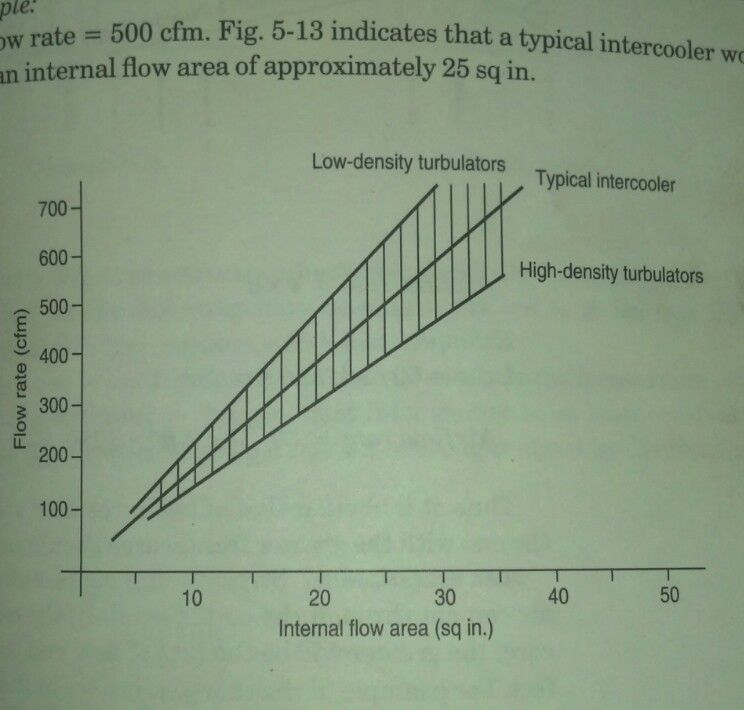

Here is a guide line from corky bell. Match up your 670 to that

with the typical 16 row, 3" thick horizontal pass cores out there the flow area is in the area of 11 square inches

with they typical 16row, 4" thick horzonal pass cores out there the flow area isn in the area of 15 square inches

dum

now compare that to a vertical pass core that has roughly the same overall dimensions..... such as the treadstone trv259

that has a flow area of ~28 square inches.... and is still only 3.5" thick

to say the vertical pass will not cool like a horizontal because the flow tubes are much shorter is total BS.dum dumyes the tube runs are much shorter....... BUT the air speed is also much slower through the core because of the much greater flow area of the vertical pass

Look at the flow area of a2w setups...dum a plain small *** 4.5x4.5x12 a2w core has the flow area of ~30 square inches.... nearly triple and double that of the horizontal 3 and 4" cores everyone runs

yeah the horizontal cores work great on small displacement motors, but looks at the flow rate of those motors compared to the v8 spinning nicely

small displacement motors dont fight for flow area..... they are fighting outrageous compressor discharge temps and benefit from the excellent efficiency of the nicer cores such as bell/garrett

Here is a guide line from corky bell. Match up your 670 to that

Trending Topics

#8

Huh? Pressure drop is directly associated with area and volume and how good the core actually is. Sure a vertical design will be more efficient in terms of how much of the core it uses but using a good core with lots of area will help dramatically. Hell the treadstone 4.5" intercoolers that are a straight across design work wonderfully especially for the price.

#9

To the OP. So you know

I had a 3" thick CX racing a2a. I had decent pressure drop at only 15psi of boost. And the thermal efficiency was meh. (turbulator density very not dense at all)

So I bought a big tread stone 1245, nice big end tanks and flow diverters.

It acted the exact same way as my old CX on the blower. Just slightly better

Tried and tried to make a big vertical flow fit but it wasn't going to happen. So I ended up going to a small a2w

Can make fun of my vid here but it doesn't lie. The blower is moving perhaps half or a little more of what our 370s do

That is my old CX core. Wide open hardly any turbulator density... vs small a2w

30sq inches for the a2w.. 11 for the a2a

.

I had a 3" thick CX racing a2a. I had decent pressure drop at only 15psi of boost. And the thermal efficiency was meh. (turbulator density very not dense at all)

So I bought a big tread stone 1245, nice big end tanks and flow diverters.

It acted the exact same way as my old CX on the blower. Just slightly better

Tried and tried to make a big vertical flow fit but it wasn't going to happen. So I ended up going to a small a2w

Can make fun of my vid here but it doesn't lie. The blower is moving perhaps half or a little more of what our 370s do

That is my old CX core. Wide open hardly any turbulator density... vs small a2w

30sq inches for the a2w.. 11 for the a2a

.

#10

7 Second Club

iTrader: (7)

LOL seeing as how the typical large 4"+ core horizontal flow intercoolers have been efficient at 1000 hp with only a couple psi drop what I said is true. I'm not debating that a vertical flow intercooler isn't better, I'm saying that with a good core a horizontal flow works just fine for the power level the OP is asking for based on what he is running into with a cheap ebay one. Go ahead and argue with yourself though you are good at it.

#11

perhaps I don't want any pressure drop associated to flow restriction

Can I see some data logs to back your statement? We are talking v8 here not not some 3 liter at 1khp moving 400cfm

You don't get it do you. The eBay core he has has zero tubulator density as it is. So where is his pressure drop coming from? Enlighten me

Yes it has **** for thermal efficiency but the "shitty core" won't be causing the pressure drop

Can I see some data logs to back your statement? We are talking v8 here not not some 3 liter at 1khp moving 400cfm

You don't get it do you. The eBay core he has has zero tubulator density as it is. So where is his pressure drop coming from? Enlighten me

Yes it has **** for thermal efficiency but the "shitty core" won't be causing the pressure drop

#13

To be completely honest, I'm completely confused by every argument you've given in this thread, mainly because I'm confused as to how you two are actually disagreeing. He's agreeing with you in every way, but saying that an efficient horizontal will still get the job done.

The problem is that increasing the flow area of the intercooler beyond the flow requirements of the actual engine isn't going to increase efficiency. If you can get enough flow area from a horizontal to meet your CFM requirements, switching to a vertical with twice the area isn't going to increase efficiency any, so it won't matter.

If core thickness is equal, the flow increase across the core between a vertical and horizontal is going to be directly proportional to the lengths. A 24 x 12 inch vertical flow will flow exactly twice as much a horizontal with the same dimensions. A 36 x 12 inch vertical flow will flow 3 times as much as a horizontal with the same dimensions. Don't forget that the inlet/outlet piping sizes on the intercooler must be large enough to support the extra flow of the vertical intercooler otherwise you may gain some cooling efficiency but it won't do much for actual flow.

The problem is that increasing the flow area of the intercooler beyond the flow requirements of the actual engine isn't going to increase efficiency. If you can get enough flow area from a horizontal to meet your CFM requirements, switching to a vertical with twice the area isn't going to increase efficiency any, so it won't matter.

If core thickness is equal, the flow increase across the core between a vertical and horizontal is going to be directly proportional to the lengths. A 24 x 12 inch vertical flow will flow exactly twice as much a horizontal with the same dimensions. A 36 x 12 inch vertical flow will flow 3 times as much as a horizontal with the same dimensions. Don't forget that the inlet/outlet piping sizes on the intercooler must be large enough to support the extra flow of the vertical intercooler otherwise you may gain some cooling efficiency but it won't do much for actual flow.

Last edited by HexenLord; 05-03-2013 at 08:39 PM.

#15

9 Second Club

It just all boils down to having adequate size and design to allow both airflow and offer enough cooling.

Your video with the air blower, I assume the A2W is a quality piece, and the A2A is just a cheap ebay piece ? If so, hardly a fair comparison. It just shows what everyone knows, that the ebay stuff are relatively poor.

There are also cheap chinese A2W cores available too, which I'm sure do not perform very well.

#16

No that is a cheap frozenboost cooler.

It is all about the turbulator density. That is what I think is not being followed here

A CX core of identical size to a quality core will have less pressure drop. There is hardly any tubulator density.... it is a straight open shot through the charge tubes

It will have horrible thermal properties because of this but not pressure drop compared to a good core of equal size

I am speaking for CX cores, there are a lot of tube n fin eBay junk out there that will pose horrible pressure drop.

Corkys table is black and white about what I am talking. Do you understand what that table says?

On a 4" thick 12" tall horizontal core you will never be much if any more than 15 square inches of flow area. Don't care if it is Garrett core or china special.

Is that suitable for a v8? I don't, leaving free power on the table

.

It is all about the turbulator density. That is what I think is not being followed here

A CX core of identical size to a quality core will have less pressure drop. There is hardly any tubulator density.... it is a straight open shot through the charge tubes

It will have horrible thermal properties because of this but not pressure drop compared to a good core of equal size

I am speaking for CX cores, there are a lot of tube n fin eBay junk out there that will pose horrible pressure drop.

Corkys table is black and white about what I am talking. Do you understand what that table says?

On a 4" thick 12" tall horizontal core you will never be much if any more than 15 square inches of flow area. Don't care if it is Garrett core or china special.

Is that suitable for a v8? I don't, leaving free power on the table

.

#17

7 Second Club

iTrader: (7)

Funny you mention it because I do have some actual data, back to back testing a cheap 3" ebay core and that exact treadstone 4.5" core that you talked about. Now keep in mind this isn't as scientific as your leaf blower test. LOL

GTO with a 6.0L and tiny 2871r twins that like to blow lots of hot air at 16 psi and makes right around 800 horsepower. With the included cheap 3" "ebay" core intercooler I would see ~4 psi drop across the core and intake air temperatures would skyrocket up 56 degrees F over a 7 second dyno pull.

Now with the only change being that treadstone horizontal flow 4.5" core intercooler I did the same exact test. I saw right around a 1 psi drop across the core which was a 4x improvement and temperatures only went up 19 degrees over the 7 second pull which was almost a 3x improvement from before with the shitty 3" core. I've seen way more turbo and supercharger setups that I can count and that is among some of the best results I've seen even comparing to my Camaro's PT900 a/w core.

GTO with a 6.0L and tiny 2871r twins that like to blow lots of hot air at 16 psi and makes right around 800 horsepower. With the included cheap 3" "ebay" core intercooler I would see ~4 psi drop across the core and intake air temperatures would skyrocket up 56 degrees F over a 7 second dyno pull.

Now with the only change being that treadstone horizontal flow 4.5" core intercooler I did the same exact test. I saw right around a 1 psi drop across the core which was a 4x improvement and temperatures only went up 19 degrees over the 7 second pull which was almost a 3x improvement from before with the shitty 3" core. I've seen way more turbo and supercharger setups that I can count and that is among some of the best results I've seen even comparing to my Camaro's PT900 a/w core.

#18

It is all about the turbulator density. That is what I think is not being followed here

A CX core of identical size to a quality core will have less pressure drop. There is hardly any tubulator density.... it is a straight open shot through the charge tubes

Corkys table is black and white about what I am talking. Do you understand what that table says?

A CX core of identical size to a quality core will have less pressure drop. There is hardly any tubulator density.... it is a straight open shot through the charge tubes

Corkys table is black and white about what I am talking. Do you understand what that table says?

I noticed you mentioned Bell intercoolers in an earlier post, and this is straight out of their FAQ.

Originally Posted by Bell Intercoolers

What factors affect the pressure or flow loss?

The internal flow area is the major controlling factor. Tube length is the second biggest consideration, as a tube twice as long as another will have nearly twice the drag at the same air velocity. Tube entry and turbulator density play small roles and can be considered insignificant. When configuring the orientation of the core in a given space, always position the core to offer the shortest length tube and the most number of tubes. Clearly, this optimizes the internal flow area.

The internal flow area is the major controlling factor. Tube length is the second biggest consideration, as a tube twice as long as another will have nearly twice the drag at the same air velocity. Tube entry and turbulator density play small roles and can be considered insignificant. When configuring the orientation of the core in a given space, always position the core to offer the shortest length tube and the most number of tubes. Clearly, this optimizes the internal flow area.

#20

Turbulator density isn't really an issue. It only becomes an issue if the core itself is at its flow limit with your setup, then the turbulators interfere further. They are only one part of the equation along with core flow area, inlet/outlet flow area, and turbulator density. If the core flow area and the inlet/outlet flow area are large enough to outflow your needs, the turbulators probably aren't going to be an issue, regardless of density. They aren't going to make a good core cause pressure drops. All they do is effectively reduce the core flow area, but the amount they reduce it by isn't substantial enough to worry about.

I noticed you mentioned Bell intercoolers in an earlier post, and this is straight out of their FAQ.

I noticed you mentioned Bell intercoolers in an earlier post, and this is straight out of their FAQ.

Answer my question, you just said if the core is at the flow limit of the setup...

So you feel a 15square inch flow area core is not at the flow limit of a 370 cube engine??? Answer that