Corvette Build v2.0

#1

[link to original build - https://ls1tech.com/forums/forced-in...hp-815wtq.html ]

Earlier this season I was making some test hits on the car and noticed a drop in oil pressure. It dropped off in a big chunk at first, but was still making 'driveable' pressure. Then it slowly started dropping further and further till it got down around 12psi hot idle and would sit at 0psi on start up till it built some pressure. I changed the oil, cut the filter, didn't see any metal, but something was wrong for the oil pressure to keep getting worse and worse.

I'd turned the boost up this year and was making close to 1,000whp on a stock crank and Eagle H-beam rods, so I decided that I would investigate and possibly upgrade at the same time.

Everything coming apart:

Root cause: broken Melling oil pump pressure spring. I'd never ever heard of one of these breaking, and while I'd thought about possible pump/bypass problems, the symptoms didn't seem right w/ the pressure fluctuating. $5 part started thousands and thousands of dollars of rebuild/upgrades.

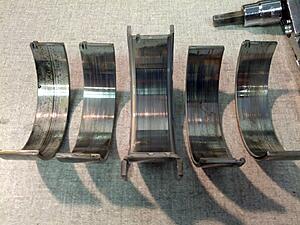

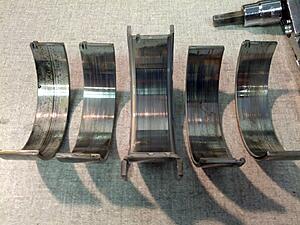

Bearings looked ok, little wear from the lack of oil pressure:

I decided to rebuild the motor while it was out using a new Lunati Signture Series crankshaft and Callies Ultra-H rods. I reused the same Wiseco pistons and kept compression ~10:1. I also reused the lightly ported LSA heads, but upgraded to a CCP Stg. 3 'Jam' cam. I swapped to a 10-rib belt setup using an ATI 8.190" balancer and the blower pulley will be a 3.85" from Dallas Performance. Just got word from Siebert Performance here in KS that the motor is all done:

While everything has been apart I've been talking to the guys across town at ProCharger about some possible upgrades to make use of this new motor. I picked up one of their first race series intercoolers that should handle all the boost the new blower is going to make (more on that to come later )

)

My old motor held up great and other than the oil pump spring it looks like it could have kept on going at the ~950whp level for a while longer. With this new setup though I'm hoping for ~25psi and ~1,100whp.

Earlier this season I was making some test hits on the car and noticed a drop in oil pressure. It dropped off in a big chunk at first, but was still making 'driveable' pressure. Then it slowly started dropping further and further till it got down around 12psi hot idle and would sit at 0psi on start up till it built some pressure. I changed the oil, cut the filter, didn't see any metal, but something was wrong for the oil pressure to keep getting worse and worse.

I'd turned the boost up this year and was making close to 1,000whp on a stock crank and Eagle H-beam rods, so I decided that I would investigate and possibly upgrade at the same time.

Everything coming apart:

Root cause: broken Melling oil pump pressure spring. I'd never ever heard of one of these breaking, and while I'd thought about possible pump/bypass problems, the symptoms didn't seem right w/ the pressure fluctuating. $5 part started thousands and thousands of dollars of rebuild/upgrades.

Bearings looked ok, little wear from the lack of oil pressure:

I decided to rebuild the motor while it was out using a new Lunati Signture Series crankshaft and Callies Ultra-H rods. I reused the same Wiseco pistons and kept compression ~10:1. I also reused the lightly ported LSA heads, but upgraded to a CCP Stg. 3 'Jam' cam. I swapped to a 10-rib belt setup using an ATI 8.190" balancer and the blower pulley will be a 3.85" from Dallas Performance. Just got word from Siebert Performance here in KS that the motor is all done:

While everything has been apart I've been talking to the guys across town at ProCharger about some possible upgrades to make use of this new motor. I picked up one of their first race series intercoolers that should handle all the boost the new blower is going to make (more on that to come later

)

)

My old motor held up great and other than the oil pump spring it looks like it could have kept on going at the ~950whp level for a while longer. With this new setup though I'm hoping for ~25psi and ~1,100whp.

#6

Trending Topics

#10

picked the motor up from the builder on sunday... it's back home on the stand, should drop it in soon.

It seems like I'm on a streak for breaking parts that shouldn't break though....

First that melling oil pump spring, then when the heads were going on, one of the ARP studs snapped. Thankfully the break was so jagged it just unscrewed with some downward pressure.

Anyone ever broken one of these before?

It seems like I'm on a streak for breaking parts that shouldn't break though....

First that melling oil pump spring, then when the heads were going on, one of the ARP studs snapped. Thankfully the break was so jagged it just unscrewed with some downward pressure.

Anyone ever broken one of these before?

#14

More parts... now that I have my flywheel I can lock it and torque the balancer bolt, then drop it in this weekend

Racetronix goodies including a walbro '450' in tank pump:

Centerforce DYAD clutch with dfx discs:

Picked up the fittings I needed for the tight firewall fitment on c6 vettes:

Local guy helped weld my Tial 50mm flange to the new intercooler:

Racetronix goodies including a walbro '450' in tank pump:

Centerforce DYAD clutch with dfx discs:

Picked up the fittings I needed for the tight firewall fitment on c6 vettes:

Local guy helped weld my Tial 50mm flange to the new intercooler:

Last edited by turbotuner20v; 08-01-2014 at 09:09 AM.

#18

The DFX is basically a standard DYAD, but instead of using organic discs like the base DYAD it upgrads to the ceramic DFX disks. Holding capacity is rated at 1340 torque.

#20

Didn't get much done this weekend... had to swap my front leaf spring because my bolts were seized and the car was slammed way too low with the blower and iron block. On the motor side I mocked everything up and checked alignment and fitment, but forgot I didn't have a socket for the balancer bolt and the stores were closed. The flywheel is installed and locked, so I'll drop the motor in after I torque the bolt (feels like I've said that too many times :/ )

I had to use the Edelbrock 8896 water pump to fit the wider 10-rib belt (I have no idea how guys get the ls3/ls7 water pumps to work without massive belt overhang):

For the belt to fit I had to grind down the '8896' casting on the front of the pump:

The coolant port is also in a different spot than the ls3/7 pumps and has a large casting chunk that interferes with the procharger bracket. I had to grind the corner down:

I don't know what I'd do without my laser alignment tool, it took a few shims behind the blower pulley to get it lined up with the crank pulley:

I had to use the Edelbrock 8896 water pump to fit the wider 10-rib belt (I have no idea how guys get the ls3/ls7 water pumps to work without massive belt overhang):

For the belt to fit I had to grind down the '8896' casting on the front of the pump:

The coolant port is also in a different spot than the ls3/7 pumps and has a large casting chunk that interferes with the procharger bracket. I had to grind the corner down:

I don't know what I'd do without my laser alignment tool, it took a few shims behind the blower pulley to get it lined up with the crank pulley:

what unit blower unit will you tun?

what unit blower unit will you tun?