Oil drain and wastegate questions

#1

OIL DRAIN

I got some -10 AN plates for the oil drains on my twin BW S300, now obviously the drain outlet has a square hole and my plate has a round hole. The plates I bought has a recess for an o ring which is provided in the packaging, but so is a standard oil drain composite gasket with a square hole. Are the composite gasket and O-ring both used here? Or just one or the other? It seems that because the drain outlet is square, and the o ring is circular, that that wont work....but maybe I'm wrong.

WASTE GATES

I ordered some Vibrant wastegate gaskets (my Tial 38 has flanges not vbands). They have a bulged/beveled side and the opposite side of the gasket is indented, which side goes where? Does the inlet and outlet of the gate both need a gasket?

I also used two gate flanges to make a disconnectable section on the gate tubing, about halfway from the up pipe to the gate itself. Should I use a gasket between these flanges as well, or just some RTV?

Thanks

I got some -10 AN plates for the oil drains on my twin BW S300, now obviously the drain outlet has a square hole and my plate has a round hole. The plates I bought has a recess for an o ring which is provided in the packaging, but so is a standard oil drain composite gasket with a square hole. Are the composite gasket and O-ring both used here? Or just one or the other? It seems that because the drain outlet is square, and the o ring is circular, that that wont work....but maybe I'm wrong.

WASTE GATES

I ordered some Vibrant wastegate gaskets (my Tial 38 has flanges not vbands). They have a bulged/beveled side and the opposite side of the gasket is indented, which side goes where? Does the inlet and outlet of the gate both need a gasket?

I also used two gate flanges to make a disconnectable section on the gate tubing, about halfway from the up pipe to the gate itself. Should I use a gasket between these flanges as well, or just some RTV?

Thanks

#2

I wouldn't use the o-ring and the gasket. Probably just the gasket.

For the gates I would put the raised portion toward whichever surface has a rougher finish. It probably wont matter much though. You can use a gasket on the outlet also if you have them but copper spray would probably be fine since there is little to no pressure there as long as the surfaces are flat. You can find the stainless gaskets online for about a dollar each.

Just saw it looks like you have a flange between the hotside and gate under pressure. This might require a gasket but if the surfaces are truly machine flat you can get away with just a sealant.

For the gates I would put the raised portion toward whichever surface has a rougher finish. It probably wont matter much though. You can use a gasket on the outlet also if you have them but copper spray would probably be fine since there is little to no pressure there as long as the surfaces are flat. You can find the stainless gaskets online for about a dollar each.

Just saw it looks like you have a flange between the hotside and gate under pressure. This might require a gasket but if the surfaces are truly machine flat you can get away with just a sealant.

#3

PIC of drain setup?

Lots of center sections are square shaped, lots of drain flanges are round. composite gaskets that are either round, or square are commonly used. The ROUND flange, is usually to accommodate the round shape of the drain fitting(in your case a -10 AN fitting). If they sent you an O ring, it sounds like it is threaded for 10AN ORB(o ring boss) and not pipe thread(more common).

If it is a -10 ORB..you will need to put the o ring around the 10 an threads that thread into your oil drain flange..... and still would need the composite gasket, to go between your plate, and the turbo center section. I may have misunderstood your question but, I think that is what you are asking. Pics would help since I still read pop out books.

WG

As long as the wastegate is flat on both sides of the flange...(38mm 2 bolts are I think)..you could use your gasket flip flopped either way.

People either use these style gaskets, or RTV...whichever you feel more comfortable using, should work no problem.

Lots of center sections are square shaped, lots of drain flanges are round. composite gaskets that are either round, or square are commonly used. The ROUND flange, is usually to accommodate the round shape of the drain fitting(in your case a -10 AN fitting). If they sent you an O ring, it sounds like it is threaded for 10AN ORB(o ring boss) and not pipe thread(more common).

If it is a -10 ORB..you will need to put the o ring around the 10 an threads that thread into your oil drain flange..... and still would need the composite gasket, to go between your plate, and the turbo center section. I may have misunderstood your question but, I think that is what you are asking. Pics would help since I still read pop out books.

WG

As long as the wastegate is flat on both sides of the flange...(38mm 2 bolts are I think)..you could use your gasket flip flopped either way.

People either use these style gaskets, or RTV...whichever you feel more comfortable using, should work no problem.

#4

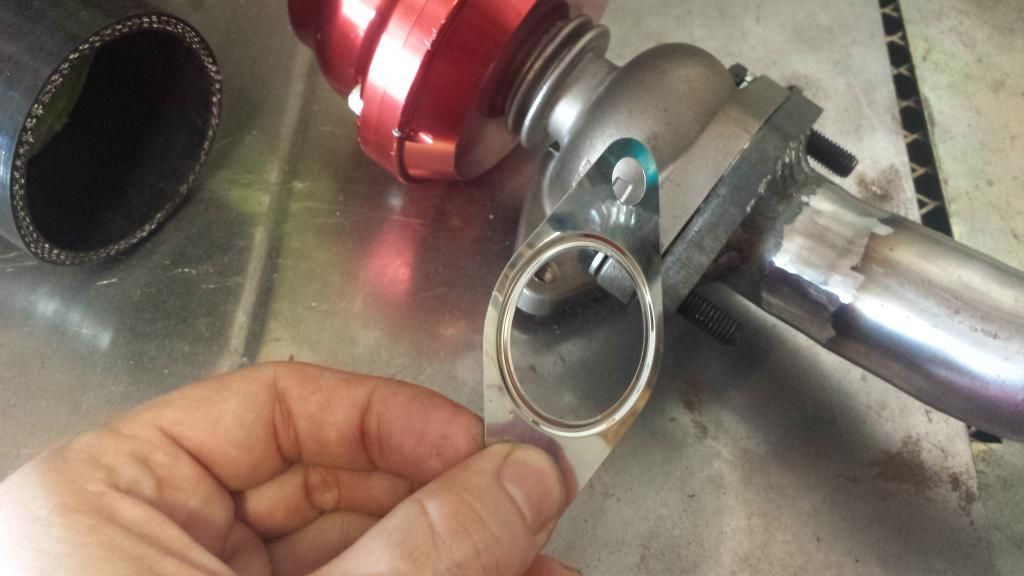

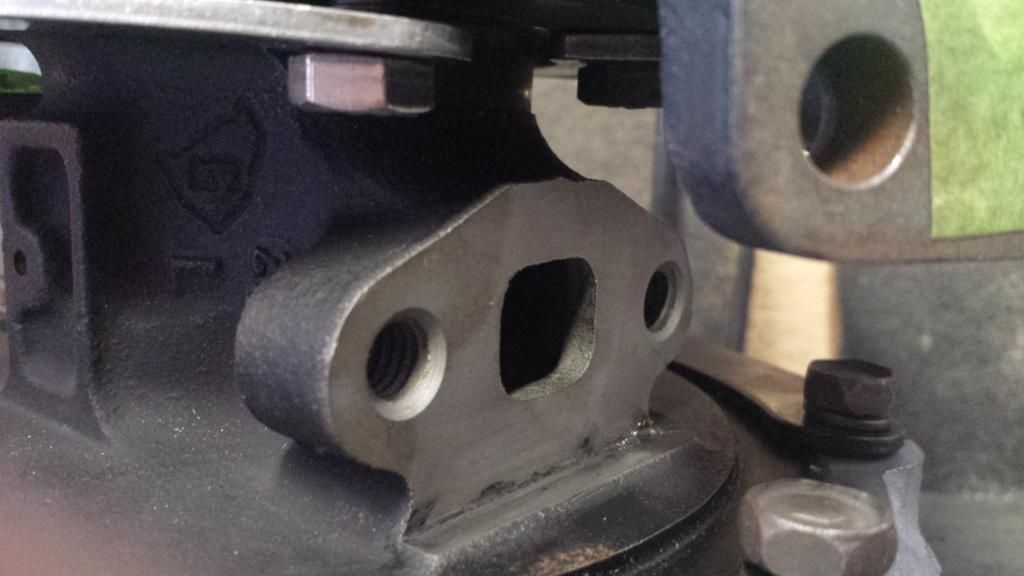

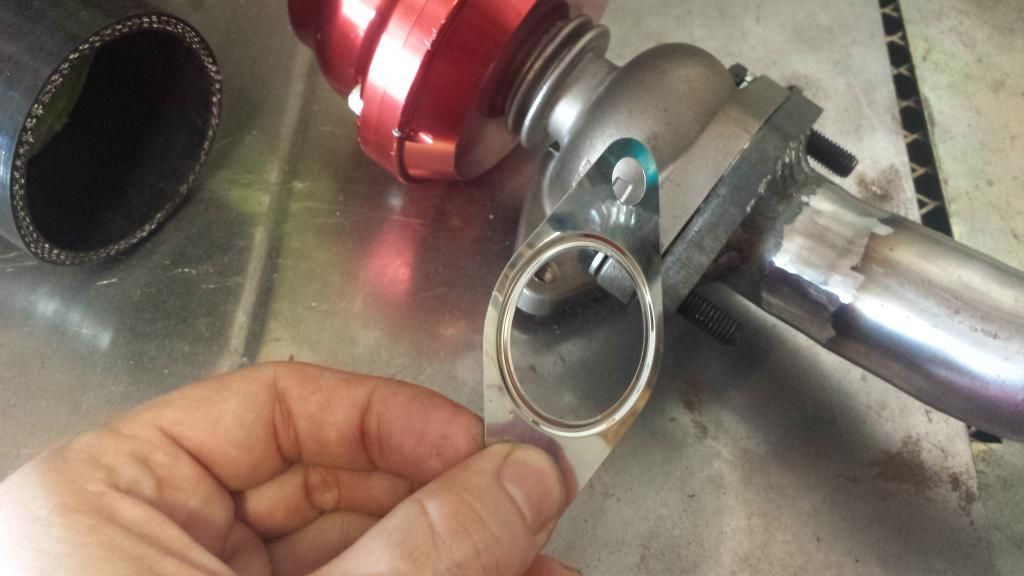

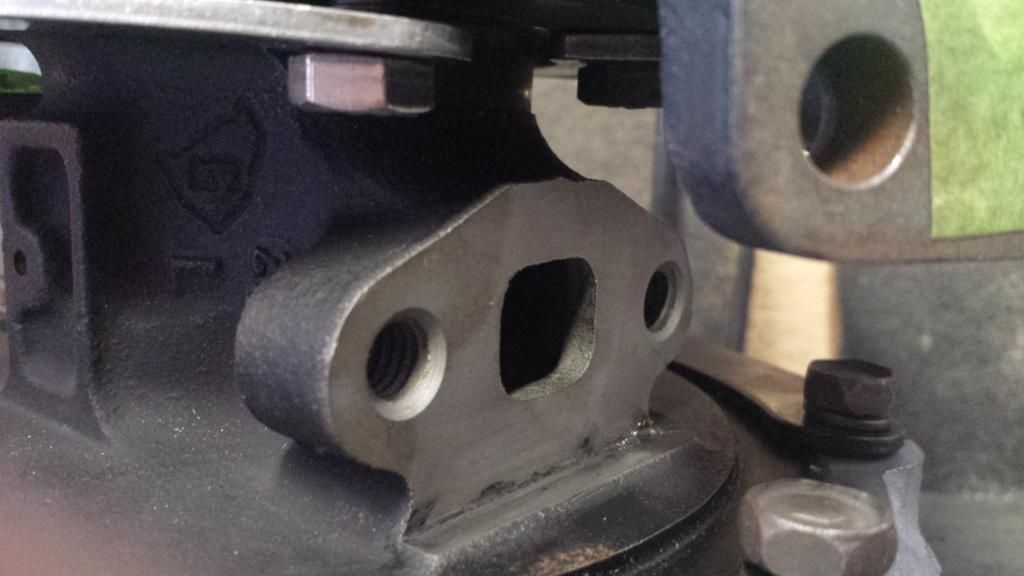

Here are some pictures. As you can see the wastegate gaskets have the beveled edge on one side. I assumed it had something to do with getting a good seal around the fire ring on the gate inlet, so I thought it needed to face a specific way.

For the drain questions here are some pictures. you can see there's a cut o ring groove in the back of the plate. By the way I think it is 10 AN not ORB but I'll double check. You can see the gasket that came with it as well. I just don't see how the o ring could be used since the turbo oil drain port is square?

For the drain questions here are some pictures. you can see there's a cut o ring groove in the back of the plate. By the way I think it is 10 AN not ORB but I'll double check. You can see the gasket that came with it as well. I just don't see how the o ring could be used since the turbo oil drain port is square?

#5

Honestly, I have never seen a drain flange like that. I don't have any insight for that..only a guess or two. Not gonna "guess" on something dealing with oil.

Treadstone give any insight?

Treadstone give any insight?

#6

Yeah actually I finally got through to them. Turns out some turbo drain flanges are machined with provisions to use an o ring. Since mine is not, they said just to use the standard gasket, no o ring.

Still questioning the correct position of the gate gaskets.

Still questioning the correct position of the gate gaskets.

#7

cool.

If both gate flanges are flat...no receiver groove to match the design of that gasket, they could go either way. Tial 2 bolt 38mm flanges, should be flat on inlet and outlet so you should be able to mount gasket either way ...

If both gate flanges are flat...no receiver groove to match the design of that gasket, they could go either way. Tial 2 bolt 38mm flanges, should be flat on inlet and outlet so you should be able to mount gasket either way ...

Trending Topics

#8

Your drain adapters were designed to use an o-ring I would recommend to use them, no gasket.

The gate gasket shouldn't matter, it will crush down when torqued. But I normally recommend putting the raised area towards the heat source, it depends on location.

The gate gasket shouldn't matter, it will crush down when torqued. But I normally recommend putting the raised area towards the heat source, it depends on location.

#9

Only use the o-ring if the o-ring itself will actually sit against solid metal. O-ring looks fairly small diameter though compared to the centre section oil hole ?

As for the metal gaskets, I'd put the raised bit towards the flange that is least likely to be flat.

BUT....

If my flanges were not flat, I'd make them flat and use no gaskets at all. Maybe a little bit of copper based RTV on the surfaces

As for the metal gaskets, I'd put the raised bit towards the flange that is least likely to be flat.

BUT....

If my flanges were not flat, I'd make them flat and use no gaskets at all. Maybe a little bit of copper based RTV on the surfaces

#13

Yeah the o ring is a smaller diameter than the BW oil outlet so Im not going to use it. Ill just use the gasket on there.

Stevie, is that copper RTV the same stuff most people use on their turbo flanges? Why don't most people use a gasket?

Stevie, is that copper RTV the same stuff most people use on their turbo flanges? Why don't most people use a gasket?

#14

Maybe this is a dumb question, but the Wastegate has the fire ring/valve seat on the inlet which prevents the two flanges from mating up to each other. You can see this in one of my pictures. Is that normal?

#15

As said, if the flanges are flat, two machined surfaces...no gasket or sealer is required.

if they are not flat, make them flat.

Gaskets or sealers are there to account for any imperfections or if things are not flat.

So really...both should not be needed. But the sealer mentioned or the type of gasket you have should be quite fine to use either way.

But in a perfect world, they arent needed.

I was quite lucky welding all my stuff up, amazingly nothing warped and everything is sealing perfectly with no gaskets or sealer at all.

The valve seat will push against the valve when you tighten up the two flanges. Just push it hard, the valve moves. It just means the seat itself is replaceable as it can wear over time. A long time though I'd think.

if they are not flat, make them flat.

Gaskets or sealers are there to account for any imperfections or if things are not flat.

So really...both should not be needed. But the sealer mentioned or the type of gasket you have should be quite fine to use either way.

But in a perfect world, they arent needed.

I was quite lucky welding all my stuff up, amazingly nothing warped and everything is sealing perfectly with no gaskets or sealer at all.

The valve seat will push against the valve when you tighten up the two flanges. Just push it hard, the valve moves. It just means the seat itself is replaceable as it can wear over time. A long time though I'd think.

#16