is there any gain in headers vs manifolds in the 600-700hp range

#1

Teching In

Thread Starter

iTrader: (1)

Join Date: Sep 2017

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

I'm looking to do a 6L in a truck and have another thread on that with my current plan etc. I was planning on running the stock manifolds facing forward with a 2.25 y to a t4 flange. It has been recommended to use the stock manifold on drivers side and a log style header/turbo inlet on pass side to mount turbo on. However I keep liking the two sides being more similar than diff. I know its not about balanced flow its about velocity/heat/drive pressure..... Anyways I was thinking of buying a set of jba shorty headers and making my hot side from there. Is there any benefit in any of the three diff choices? I own a 6.5 diesel and the crossover manifold is the hold up for the hot side so I just Dont like the idea, I know diff world all together but you know... Thanks for any input and experiences, def learning how big a diff between turbo gas and diesel are!!! First turbo gas here!

#3

You'll find many people who are using the factory style manifolds with good luck. The factory style LS manifolds are much improved over the manifolds on the SBCs. The SBC manifolds were likely cast iron and were a hassle to weld, heavy and flowed poorly. The LS manifolds are still on the heavy side but they weld super easy and flow probably somewhere close to a set of shorty headers.

Headers are just fine too. It all depends on how much money you want to spend. Personally I would just use the manifolds. They are abundant and cheap, or free. Also, you should never have issues with fitment or sealing like headers sometimes cause. 600+ RWHP could easily be done with factory style manifolds. Repurposing factory parts is the creative process that I feel like hot rodding is all about. Anyone can buy things from a catalog....

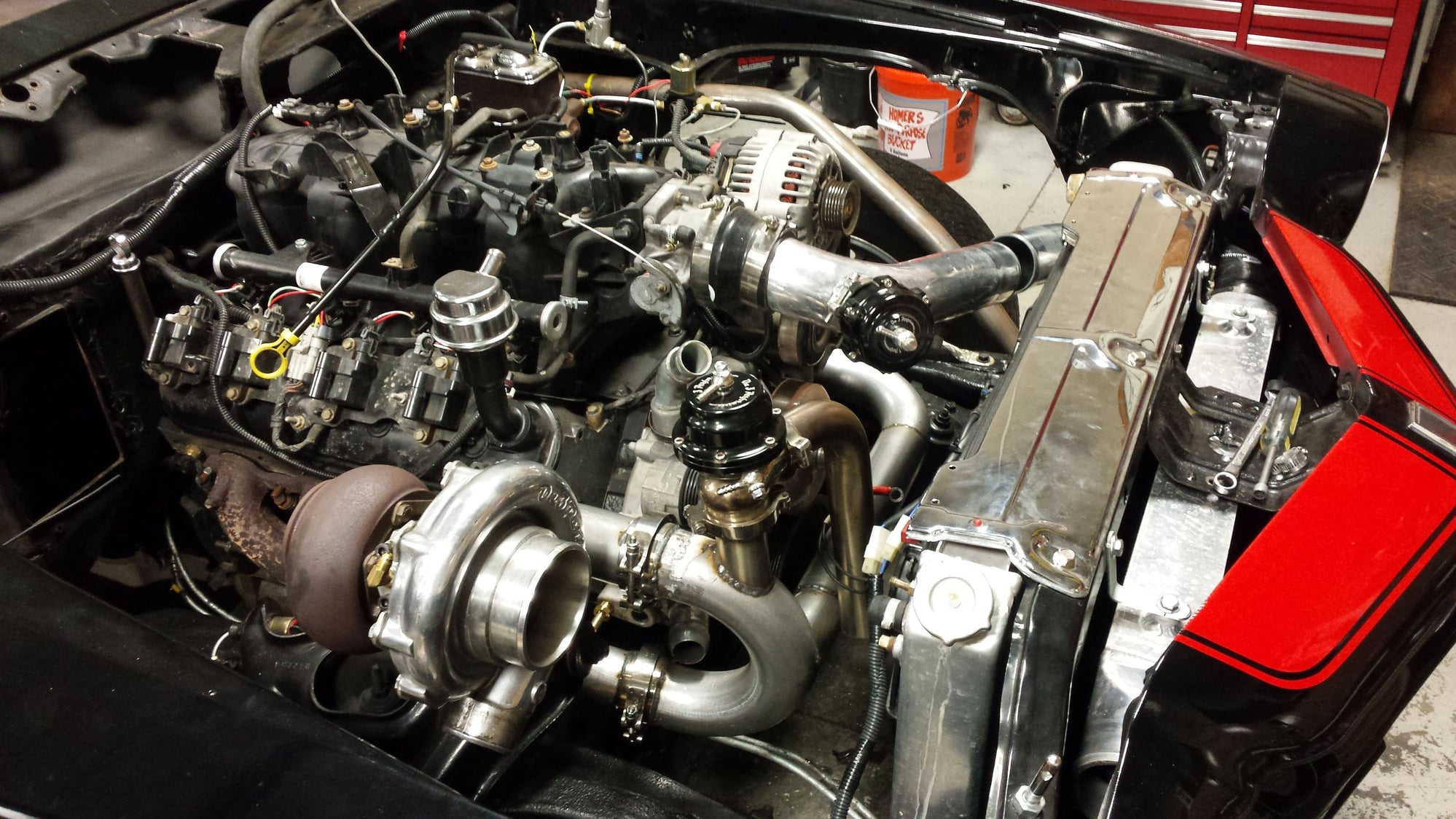

Here's my setup, truck manifolds flipped upside down into a true divided scroll using 2.5" pipe. I ground all of the casting numbers, heat shield mounts etc off of these. I even cut off the EGR mounting pad off and stitched the massive holes back up with a MIG so after grinding it down, they looked real nice and smooth.

Headers are just fine too. It all depends on how much money you want to spend. Personally I would just use the manifolds. They are abundant and cheap, or free. Also, you should never have issues with fitment or sealing like headers sometimes cause. 600+ RWHP could easily be done with factory style manifolds. Repurposing factory parts is the creative process that I feel like hot rodding is all about. Anyone can buy things from a catalog....

Here's my setup, truck manifolds flipped upside down into a true divided scroll using 2.5" pipe. I ground all of the casting numbers, heat shield mounts etc off of these. I even cut off the EGR mounting pad off and stitched the massive holes back up with a MIG so after grinding it down, they looked real nice and smooth.

#4

TECH Addict

iTrader: (1)

Look up a kb racing manifold. That is what you need to do. That's what we did it's super easy and super clean. I guarantee the shorty truck headers will crack and fall apart in the first 3k miles. The log we made glows red hot during a pull and it's 3/16" thick I think if it were a header it would crack the welds in no time.

Last edited by MY_2K_Z; 09-21-2017 at 12:43 AM.

#5

Why do you think that?

There are two stickies at the top of this forum pertaining to building a hotside utilizing truck manifolds. Seems to be a lot of people doing it that way.

I don't see how they could crack, they're pretty thick anyways. I'm expecting my share of problems with my recently finished turbo build, but I'm honestly not expecting the manifolds to be one of them. I believe you are the first person I've read about mentioning the manifolds cracking.... Maybe from the turbo hanging on the pipework? Or maybe you had set of manifolds that had casting defects and metallurgy problems not outwardly visible with the naked eye?

RonSSNova on here has gone 9.09@151 in his Nova, and I believe he has been running his flipped truck manifolds on his 5.3 for just over 3 years.

There are two stickies at the top of this forum pertaining to building a hotside utilizing truck manifolds. Seems to be a lot of people doing it that way.

I don't see how they could crack, they're pretty thick anyways. I'm expecting my share of problems with my recently finished turbo build, but I'm honestly not expecting the manifolds to be one of them. I believe you are the first person I've read about mentioning the manifolds cracking.... Maybe from the turbo hanging on the pipework? Or maybe you had set of manifolds that had casting defects and metallurgy problems not outwardly visible with the naked eye?

RonSSNova on here has gone 9.09@151 in his Nova, and I believe he has been running his flipped truck manifolds on his 5.3 for just over 3 years.

Trending Topics

#10

#11

Teching In

Thread Starter

iTrader: (1)

Join Date: Sep 2017

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

I actually did a ton of research today on the topic of hot side sizing, intercooler sizing etc. There is actually some in depth math equations for all of it. Basically the velocity remaining the same speed from the valve to the scroll is the perfect scenario. 1 5/8 primary headers and 2.25 merge piping is good to like 1000hp!!! Funny how most on the shelf turbo headers are 1.75 and 1.875 to a 3" collector!!! That is way huge for almost everyone. One equation I hate to agree with is the engine cfm requirement formula.... Again I'm from the turbo diesel world and it is similar but volume and pressures are diff with a diesel, high boost on a diesel is over 100psi, lol. Low compression is 17:1

#12

My understanding - and I don't claim to be any kind of expert! - is that sure, a properly-sized pair of headers will give a decent power boost over a typical set of cast-iron manifolds. My guess is that on a turbo LS engine, they'd probably be good for a solid 32-40 horsepower at peak (since IIRC long tube headers are good for 20-25 hp on a N/A engine).

But since the discussion specifically mentions "the 600-700hp range", I would be forced to ask if the added cost & concerns with cracking would be worth it. Turbocharged LS engines can make 600-700hp easily, it's not like the OP is looking for every little smidgen of power that the engine can generate.

My own answer to that question is that no, at that power level, there's no compelling reason to run headers. Bolt on the manifolds & forget about it!

But since the discussion specifically mentions "the 600-700hp range", I would be forced to ask if the added cost & concerns with cracking would be worth it. Turbocharged LS engines can make 600-700hp easily, it's not like the OP is looking for every little smidgen of power that the engine can generate.

My own answer to that question is that no, at that power level, there's no compelling reason to run headers. Bolt on the manifolds & forget about it!

#13

TECH Junkie

iTrader: (28)

A few people on here have tested crossover piping diameter and 2.25" is said to be able to support 1400-1600hp before it becomes a real issue and needing 2.5" diameter.

From 8 years ago:

https://ls1tech.com/forums/forced-in...manifolds.html

From 8 years ago:

https://ls1tech.com/forums/forced-in...manifolds.html

#14

Yes I agree, most people tend to oversize their exhaust pipe. I have had several people ask me why I built my crossover pipe out of 2.5" instead of 3". In all reality, 2.5" is WAY more than enough until you start getting into some really insane power.

IMO, whatever additional power you could get from headers is outweighed by the fact that you will likely have more fights with leaks, cracks etc. from the headers as opposed to a huge chunk of beefy cast steel that is the manifolds. And, if you want more power? More boost.......

I don't have any pics of the manifolds after I completely smoothed them out but you can see where I removed basically everything and it looked real nice when it was done. I also had to change the kickup of the angle for the collector for one manifold to clear everything else. No big deal, cut, weld grind. Super easy.

IMO, whatever additional power you could get from headers is outweighed by the fact that you will likely have more fights with leaks, cracks etc. from the headers as opposed to a huge chunk of beefy cast steel that is the manifolds. And, if you want more power? More boost.......

I don't have any pics of the manifolds after I completely smoothed them out but you can see where I removed basically everything and it looked real nice when it was done. I also had to change the kickup of the angle for the collector for one manifold to clear everything else. No big deal, cut, weld grind. Super easy.

#16

So I did the math. Turns out that manifolds collectors aren't a restriction on a t4 or t6 turbo. The reality is a long tube design is definitely going to flow better than a stock manifold. So yes it has the potential to make more power. Can you turn up the boost and force it to make more power? Sure. On a 700hp car you won't need headers to make that power. On a super high hp car you'd probably be better off with headers, but manifolds seem to do alright.

#19

A pic of my long tube up and forward turbo headers from stainless works. Plug wires are custom made and I love them. I always make my own wires it looks nicer. The plugs can be difficult at times but it is doable with these headers.

#20

Looks real good man.

I'd also like to add that I had acquired several sets of manifolds when I was planning my hotside.

I ended up with 2 or 3 sets of truck manifolds, one set off of a 5.3, another from a 6.0, and another yet from a 6.2.... They all were very similar in terms of dimensions of the primary tubes and the collectors, only differences were the EGR bosses etc..

I also had some manifolds from a LS2 and another set from an LS1....... The LS1 had the smallest collector diameter, the LS2s were close in size to the trucks but IIRC the truck manifolds all had the biggest collector size.

I'd also like to add that I had acquired several sets of manifolds when I was planning my hotside.

I ended up with 2 or 3 sets of truck manifolds, one set off of a 5.3, another from a 6.0, and another yet from a 6.2.... They all were very similar in terms of dimensions of the primary tubes and the collectors, only differences were the EGR bosses etc..

I also had some manifolds from a LS2 and another set from an LS1....... The LS1 had the smallest collector diameter, the LS2s were close in size to the trucks but IIRC the truck manifolds all had the biggest collector size.