I have an Idea to reduce turbo lag!!!!

#1

On The Tree

Thread Starter

Join Date: May 2005

Location: GA

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

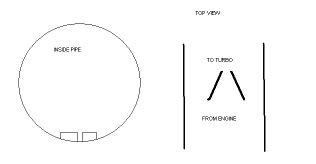

I used to work on f-18's in the navy and they have a a thing called a vortex generator in the intake to pre swirl the incoming air. Its really small and looks like a piece angle iron sticking up about 1". now what if you welded a 1/2" one in your exhuast pipe about 6 inches before the turbo. My theory is it would preswirl the air to get the wheel spinning quicker. This could also be applied to the intake pipe.

Has anyone tried this and what are your thoughts?

Has anyone tried this and what are your thoughts?

#4

TECH Enthusiast

iTrader: (5)

Join Date: Feb 2004

Location: Detroit area, MI

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

I would think that on a jet it is static air the the turbine is pushing against at 1000mph, getting it to start moving in the same direction as the turbine would increase efficiency where in a turbo the exhuast is being plumbed to the turbo in a tube. I would guess that in the exhaust pipe the exhaust starts to swirl a bit before it gets to the turbo due to the vortex that the wheel is causing itself by spinning. maybe I am wrong. It would be like that Tornado thing they sell for intakes, it is just a restriction in the end, anything the air hits will slow it down even small crimps in a bent pipe.

#5

TECH Addict

iTrader: (6)

It wouldn't work on the exhaust side because the turbines aren't axial flow. Stator vanes are used in a lot of jet engines, but you couldn't just put them on an off the shelf turbo because the air would hit the impeller at the wrong angle. The impeller would have to be designed for it, and even then it wouldn't be an advantage.

There is such a thing as variable turbine vanes that they've used on turbochargers for a while. http://www.motorage.com/motorage/dat...08/article.pdf

There is such a thing as variable turbine vanes that they've used on turbochargers for a while. http://www.motorage.com/motorage/dat...08/article.pdf

#6

TECH Fanatic

iTrader: (9)

Doesnt work.. They already have something similar for the Diesels now called a TAG (Turbo Air Guide). Some people swear by it, but all dyno tests shows about an average loss of 10-15 hp in diesels.. And now that i think of it, there is one for gassers- called the Tornado, you've all heard of that piece of ****.. The only reason it works on jets is because the air is practically being forced into the turbine at high speeds. I wouldnt think it is used to help speed up the turbine, but rather to direct the air slope to match the turbine fin slope so you dont have restriction.

#7

On The Tree

Thread Starter

Join Date: May 2005

Location: GA

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

Ok first the TORNANDO is junk!! it says it swirls the air. Why in the **** would you need to swirl the air on recipicating ENGINE?? Second, What i'm talking about iS not even shaped like a tornando or stator vanes on a jet engine. Yes it works on a jet engine because air is being forced in at a high rate of speed. I think it would be the same consept of air bieng forced into the turbine housing from a turbo motor.

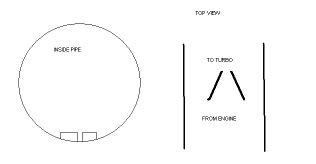

A vortex generator is nothing more than a small piece of metal. airplanes use everywhere to swirl air to gain stability and reduce turbulance. Now if you scaled the f-18 vortex generator down to the size of the exhaust pipe it would prolly sit about 1/8 up from the bottom of the inside of the pipe. An o'2 sensor is prolly more resrictive than this would.

A vortex generator is nothing more than a small piece of metal. airplanes use everywhere to swirl air to gain stability and reduce turbulance. Now if you scaled the f-18 vortex generator down to the size of the exhaust pipe it would prolly sit about 1/8 up from the bottom of the inside of the pipe. An o'2 sensor is prolly more resrictive than this would.

Last edited by lt1fbody355; 10-15-2005 at 07:58 PM.

Trending Topics

#8

Launching!

Join Date: Dec 2001

Location: Wallingford, CT

Posts: 289

Likes: 0

Received 0 Likes

on

0 Posts

I have a feeling that device in the intake plays a minor part in equalizing the pressure across the face of the engine inlet. Probably something to do with the fact that the air has to make an S curve in that aircraft. It might even help to decelerate the inlet airspeed to below the speed of sound.

Whatever its for, I can assure you that there is no such device between the combustion chamber and the turbine inlet of those engines. That would be comparable to the pre-turbo turbine area. The jet inlet would be comparable to something between the air filter and the compressor wheel.

In either case, its not something I would do.

Whatever its for, I can assure you that there is no such device between the combustion chamber and the turbine inlet of those engines. That would be comparable to the pre-turbo turbine area. The jet inlet would be comparable to something between the air filter and the compressor wheel.

In either case, its not something I would do.

#9

Lt1,

Impeller (compressor wheel) inlet pre-swirl does work better on Axial compressors then Centrifugal. The main reason behind inlet pre-swirl is to improve low speed pressure ratio, but it does come with a hit (increased inlet losses). Also I have not looked at a FA-18 engine but can say with some certainty that IGV (inlet guide vane(s)) are adjustable. A jet plane can overcome these inlet losses because inlet is generally not static (plane is usually in motion and at a good clip). In addition axial compressor are very sensitive to inlet pressure distortion and require IGV anyway so why not make them adjustable.

If you are good with some complex math then purchase “Centrifugal Compressor Design and Performance” by David Japikse. It is very well written and dedicates a part to pre-swirl.

The big problem with centrifugal pre-swirl is low inlet mach number versus axial. As an example axial compressors typically require a Mn (mach number) of 0.6 or greater and centrifugals like turbo work in 0.15-0.25. With larger inlet numbers (Mn) guide vanes become smaller and more efficient.

Another problem is you will loose some efficiency, do to inlet blockage.

If you have more questions let me know.

Mike

Impeller (compressor wheel) inlet pre-swirl does work better on Axial compressors then Centrifugal. The main reason behind inlet pre-swirl is to improve low speed pressure ratio, but it does come with a hit (increased inlet losses). Also I have not looked at a FA-18 engine but can say with some certainty that IGV (inlet guide vane(s)) are adjustable. A jet plane can overcome these inlet losses because inlet is generally not static (plane is usually in motion and at a good clip). In addition axial compressor are very sensitive to inlet pressure distortion and require IGV anyway so why not make them adjustable.

If you are good with some complex math then purchase “Centrifugal Compressor Design and Performance” by David Japikse. It is very well written and dedicates a part to pre-swirl.

The big problem with centrifugal pre-swirl is low inlet mach number versus axial. As an example axial compressors typically require a Mn (mach number) of 0.6 or greater and centrifugals like turbo work in 0.15-0.25. With larger inlet numbers (Mn) guide vanes become smaller and more efficient.

Another problem is you will loose some efficiency, do to inlet blockage.

If you have more questions let me know.

Mike

Last edited by Skunkworks; 10-15-2005 at 10:38 PM.

#12

TECH Fanatic

iTrader: (9)

You also have to remember that no matter how much your swirl your air before the turbine, that swirl will still be interupted by the "snail" path it has to take to get to the turbine wheel. Trust me, some egghead engineer has already tried it.. The only way you can better a turbo is by variable geometry, which is already a reality..

#14

NKAWTG...N

iTrader: (3)

Join Date: Nov 2003

Location: Wichita, KS

Posts: 4,760

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by aboadnan

What if we inject water before the turbo?

I know that it is not a good idea but will it work?

I was told that they do it to jet engines to get more thrust.

I know that it is not a good idea but will it work?

I was told that they do it to jet engines to get more thrust.

As for jet engines, they can't really be directly compared to a turbo. Jet engines have a series of compressor vanes, not exactly the same as a turbo. And with a jet, the water-injection is used to cool the air in the combustion chamber. The injection of coolant into the combustion chamber inlet increases the mass flow rate through the turbine. The pressure and temperature drop across the turbine results in an increase in pressure in the jet pipe, giving additional thrust. Also, the consequent reduction in turbine inlet temperature allows the fuel system to increase the fuel flow to a valve giving an increase in rotational speed of the engine.

But water can also be sprayed into the compressor air inlet. When the water/coolant is sprayed into the compressor inlet, the temperature of the air is reduced, increasing the density of the compressor inlet air,\ and the thrust is increased.

#15

TECH Apprentice

iTrader: (6)

Join Date: Jul 2003

Location: Decatur, Indiana

Posts: 344

Likes: 0

Received 0 Likes

on

0 Posts

Would a bit of extra fuel injected at the right time at the right spot in front of the turbo increase exhaust pressure. Do this just enough to help spool the turbo.

Just a thought I am no expert and do not know if this would help or hurt.

Just a thought I am no expert and do not know if this would help or hurt.

#16

TECH Fanatic

iTrader: (10)

Join Date: Dec 2003

Location: omaha, NE

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

i wouldnt say you want to swirl the sir but if you could some how direct it better. for example when you used to wash your bike and you hit your pedal at just the right spot it used to spin really fast. well if you hit those vanes of the turbo just right you would think it would help it spin faster rather than needing lots of exhaust velocity. thats my idea

#18

Originally Posted by Technoman64

Would a bit of extra fuel injected at the right time at the right spot in front of the turbo increase exhaust pressure. Do this just enough to help spool the turbo.

Just a thought I am no expert and do not know if this would help or hurt.

Just a thought I am no expert and do not know if this would help or hurt.

#19

TECH Fanatic

iTrader: (9)

Sure, you can shoot fuel into your exhaust if you want to spit out your turbine wheel and go down in a hail of firery death..

Nitrous is used to to create more energy in the combustion chamber, which creates more exhaust in turn.

Water injection before the turbine would worsen the lag because you are cooling the exhaust expansion that is used to spin the turbine.

The only idea that I can see working to help sppol a turbo faster is to cool the exhaust directly after the turbo at a rapid rate- this would help the scavenging effect and expansion of gases pre-turbo

Nitrous is used to to create more energy in the combustion chamber, which creates more exhaust in turn.

Water injection before the turbine would worsen the lag because you are cooling the exhaust expansion that is used to spin the turbine.

The only idea that I can see working to help sppol a turbo faster is to cool the exhaust directly after the turbo at a rapid rate- this would help the scavenging effect and expansion of gases pre-turbo

, BUT not easy solutions.

, BUT not easy solutions.