LSA return fuel line

#1

Hi guys.

Been searching without much luck on what options I have for a fuel return line on a LSA.

This is a crate motor into a circuit chassis so none of the standard tank or pump bits in this case.

The only aftermarket option I've found is $800 base alone and I've read some bad things about the bypass regs not having stable pressure.

(I will be running roughly 800hp in the future and fuel system is 40L cell, surge, 3 external pumps, -8 feed (possibly twin) and -6 return)

I'm open to brazing fittings onto the standard rail but last I looked I think the blower hat blocks the rear points of the rails where I'd ideally tap into.

I'm also weary about starving one bank if I were to tap into the side.

Also reading but haven't found definitive info on whether the ecu regulates fuel pump voltage (my wiring kit does require signal wire from fuel pump in factory form, whether that relates to this or not though. Doubt it'd work with aftermarket pumps anyway) and also that the feed inlet into the rail has some form of ventilation so isn't great to be used as the return line.

It's the last step to finishing off my build so all help is greatly appreciated.

Thanks, Ryan.

Been searching without much luck on what options I have for a fuel return line on a LSA.

This is a crate motor into a circuit chassis so none of the standard tank or pump bits in this case.

The only aftermarket option I've found is $800 base alone and I've read some bad things about the bypass regs not having stable pressure.

(I will be running roughly 800hp in the future and fuel system is 40L cell, surge, 3 external pumps, -8 feed (possibly twin) and -6 return)

I'm open to brazing fittings onto the standard rail but last I looked I think the blower hat blocks the rear points of the rails where I'd ideally tap into.

I'm also weary about starving one bank if I were to tap into the side.

Also reading but haven't found definitive info on whether the ecu regulates fuel pump voltage (my wiring kit does require signal wire from fuel pump in factory form, whether that relates to this or not though. Doubt it'd work with aftermarket pumps anyway) and also that the feed inlet into the rail has some form of ventilation so isn't great to be used as the return line.

It's the last step to finishing off my build so all help is greatly appreciated.

Thanks, Ryan.

#2

TECH Apprentice

iTrader: (8)

I would think any return style set up for fuel injection would work. I have an LSA with gmpp harness and its programmed to have a set pressure. Not variable like the camaro. I decided to run a return less setup tho using the caddy pump. It's a twin pump good up to 7-800. Look up Vaporworx, Carl there builds PWM setups to control the pumps, works flawless on mine. Good luck with the build

#4

TECH Apprentice

iTrader: (8)

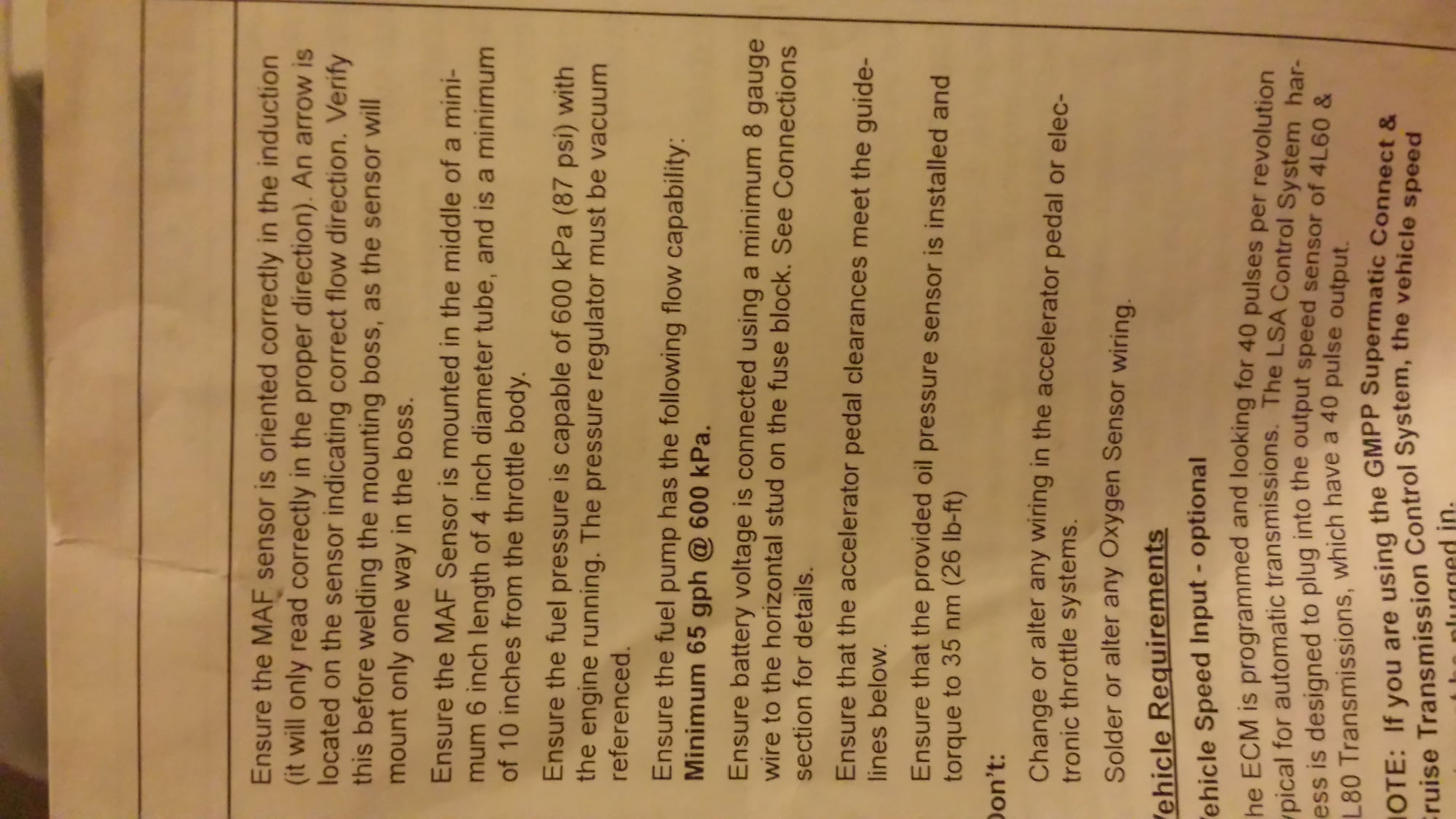

Yeah same thing GM Performance Parts (GMPP). In the paperwork that comes with it, it says it 87 PSI while running with a vacuum referenced regulator and the pump must handle 65 GPH @ 600 kPa. I think I set mine to 87 and have the Vaporworx controlling the pump.

Last edited by lowerthanyou00; 08-04-2015 at 05:18 PM.

Trending Topics

#8

On The Tree

iTrader: (9)

GM recently updated the fueling instructions for the LSA since the previous requirements were incorrect. The 87psi is what is needed for the LS9 engine. Want to guess who has been questioning this with GM for quite some time?

Check the GM Performance website for new instructions.

Check the GM Performance website for new instructions.

#10

TECH Addict

iTrader: (22)

The ears on the rear of the blower arent required to run the blower. Cut them off and weld ports on as needed

Alternatively you can run a standard AFPR as a retunless system with whatever pump you want. That way you can keep the stock rails and not have to worry about a OEM regulator controlling pressure under high power situations

Alternatively you can run a standard AFPR as a retunless system with whatever pump you want. That way you can keep the stock rails and not have to worry about a OEM regulator controlling pressure under high power situations

#11

On The Tree

A single line system has no temperature control and any air in it has to exit via the injectors.

A return system circulates fuel and if the rail is between the pump & regulator air bubbles will get purged through the regulator.

A return system circulates fuel and if the rail is between the pump & regulator air bubbles will get purged through the regulator.