New steam lines with AN hose and Fittings

#1

TECH Enthusiast

Thread Starter

Join Date: Jun 2005

Location: Wichita, KS

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

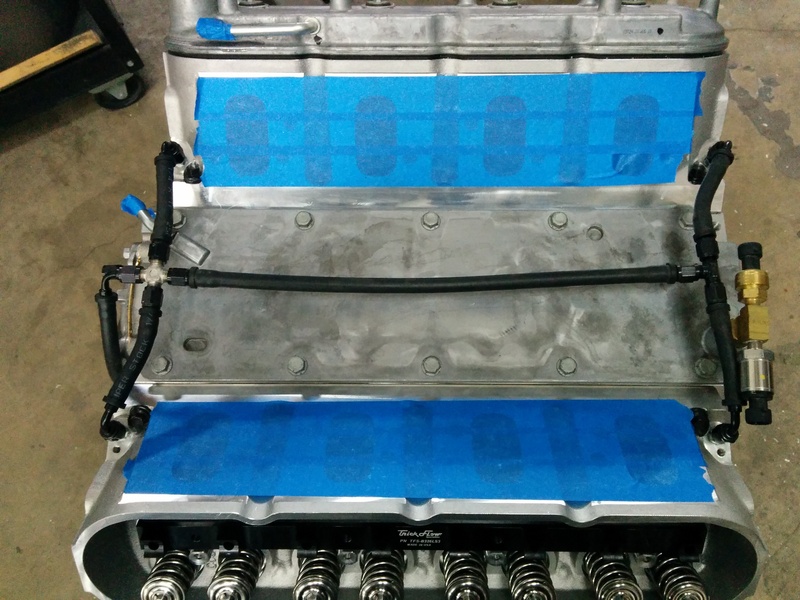

A few weeks ago I was driving home and noticed my car was driving strange, so I looked down to check the gauges and DAMN! My coolant temp was over 235 degrees! I limped the car home and popped the hood to find out I blew a hole in the steam line running to the radiator... After the stress I went through that night, I decided to make a bomb proof system.

Earl's -4AN Steam Vent Adapters

10" -4AN brake hose with crimped on ends

-4AN Female to -6AN Male adapter

-6AN 90 degree Fitting

-6AN Hose (Just barely fits on the radiator nipple)

Passenger side--

DSCF6269 by Josh Belisle, on Flickr

DSCF6269 by Josh Belisle, on Flickr

Driver Side--

DSCF6270 by Josh Belisle, on Flickr

DSCF6270 by Josh Belisle, on Flickr

Complete to radiator--

DSCF6271 by Josh Belisle, on Flickr

DSCF6271 by Josh Belisle, on Flickr

Radiator attachment--

DSCF6268 by Josh Belisle, on Flickr

DSCF6268 by Josh Belisle, on Flickr

I'm mostly posting this to share another option for someone that wants to run AN hose. And no, this isn't a 4 corner setup, but I can expand it to one the day I choose to remove my intake. Also, haven't seen anyone else run these Earl's fittings, so I wanted to share what I did!

Earl's -4AN Steam Vent Adapters

10" -4AN brake hose with crimped on ends

-4AN Female to -6AN Male adapter

-6AN 90 degree Fitting

-6AN Hose (Just barely fits on the radiator nipple)

Passenger side--

DSCF6269 by Josh Belisle, on Flickr

DSCF6269 by Josh Belisle, on FlickrDriver Side--

DSCF6270 by Josh Belisle, on Flickr

DSCF6270 by Josh Belisle, on FlickrComplete to radiator--

DSCF6271 by Josh Belisle, on Flickr

DSCF6271 by Josh Belisle, on FlickrRadiator attachment--

DSCF6268 by Josh Belisle, on Flickr

DSCF6268 by Josh Belisle, on FlickrI'm mostly posting this to share another option for someone that wants to run AN hose. And no, this isn't a 4 corner setup, but I can expand it to one the day I choose to remove my intake. Also, haven't seen anyone else run these Earl's fittings, so I wanted to share what I did!

#3

TECH Enthusiast

Thread Starter

Join Date: Jun 2005

Location: Wichita, KS

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

Thanks! I bought 10 feet of -6 hose, so hopefully it's enough to do the catch can hose, as well. Thinking about moving the catch can in the engine bay where everyone else has it ....

#7

Bryan,

When you say "final connection there" are you talking about as opposed to terminating at the radiator bung? If so I am really interested in where on pump you tapped? Any pics of the pump area after being tapped? Thank!

When you say "final connection there" are you talking about as opposed to terminating at the radiator bung? If so I am really interested in where on pump you tapped? Any pics of the pump area after being tapped? Thank!

Trending Topics

#8

Launching!

iTrader: (8)

Correct, I do not run back to the radiator. I just ran through all of my pictures, and I could not find a great shot, but maybe these will help. The front facing hose is short and does a 90 into the top/back of the pump. You can just barely see it at the top-left of the pump in the second shot.

If you click on a picture, it should take you to my photobucket album. You are welcome to poke around all 38 pages, but I don't think you'll find a better shot of it than these.

If you click on a picture, it should take you to my photobucket album. You are welcome to poke around all 38 pages, but I don't think you'll find a better shot of it than these.

#9

TECH Enthusiast

Thread Starter

Join Date: Jun 2005

Location: Wichita, KS

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

That looks nice! But that would never fit under the FAST intakes. You high-rise guys have it easy!

I wanted to drill and tap my water pump, but I was lazy and didn't want to take it off...

I wanted to drill and tap my water pump, but I was lazy and didn't want to take it off...

#10

Correct, I do not run back to the radiator. I just ran through all of my pictures, and I could not find a great shot, but maybe these will help. The front facing hose is short and does a 90 into the top/back of the pump. You can just barely see it at the top-left of the pump in the second shot.

If you click on a picture, it should take you to my photobucket album. You are welcome to poke around all 38 pages, but I don't think you'll find a better shot of it than these.

If you click on a picture, it should take you to my photobucket album. You are welcome to poke around all 38 pages, but I don't think you'll find a better shot of it than these.

I re-read your message and downloaded/blew up the pic and I can now see where you tapped in to. Really appreciate this info, I am going to duplicate your set up, thanks again!

Ron

#11

TECH Resident

iTrader: (13)

I like this setup. The LS cooling systems kind of confuse me the more and more of these variations I see....On my LS1 S10, I came off the factory steam vent and plumbed it into the heatcore line, which made it difficult to bleed.

Where is/are the appropriate location(s) to plumb the steam ports? On my 300zx, I have an overflow tank as the highest point in the system, and a hose going to a radiator cap welded off the top of the waterpump, whihc is the 2nd highest point in the system (just above top of heads).

The steam vent line, is this suppose to go to the high pressure system, or to the vented low pressure system (AKA between cap and overflow). The first one makes more sense because coolant in heads are under pressure. Sorry for long post and thread jack.

Where is/are the appropriate location(s) to plumb the steam ports? On my 300zx, I have an overflow tank as the highest point in the system, and a hose going to a radiator cap welded off the top of the waterpump, whihc is the 2nd highest point in the system (just above top of heads).

The steam vent line, is this suppose to go to the high pressure system, or to the vented low pressure system (AKA between cap and overflow). The first one makes more sense because coolant in heads are under pressure. Sorry for long post and thread jack.

#18

That's MISTER MODERATOR

iTrader: (9)

Aeroquip makes a nylon braided hose?? I'm not seeing it: http://aeroquipperformance.com/p-24060-hoses.html

I don't see any problem with using StartLite with convoluted wire loom. Many OEM's do it and I think it adds a nice finishing touch.

I added pics to this thread to show an alternative way to do the steam vents. There's many ways to do it. We all have our own way of doing things.

I don't see any problem with using StartLite with convoluted wire loom. Many OEM's do it and I think it adds a nice finishing touch.

I added pics to this thread to show an alternative way to do the steam vents. There's many ways to do it. We all have our own way of doing things.

#19

TECH Addict

iTrader: (66)

Aeroquip makes a nylon braided hose?? I'm not seeing it: http://aeroquipperformance.com/p-24060-hoses.html

I don't see any problem with using StartLite with convoluted wire loom. Many OEM's do it and I think it adds a nice finishing touch.

I added pics to this thread to show an alternative way to do the steam vents. There's many ways to do it. We all have our own way of doing things.

I don't see any problem with using StartLite with convoluted wire loom. Many OEM's do it and I think it adds a nice finishing touch.

I added pics to this thread to show an alternative way to do the steam vents. There's many ways to do it. We all have our own way of doing things.