Oil Pressure or lack there of. (Dry Sump)

#1

Teching In

Thread Starter

Join Date: Mar 2007

Location: Louisville, KY

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

Let me just get right to the point.

Problem:

Only 20-25psi of oil pressure.

Oil Pressure does not increase with RPM.

Oil System:

This is an LS1 and dry sump system out of an ASA Roundie-Round car.

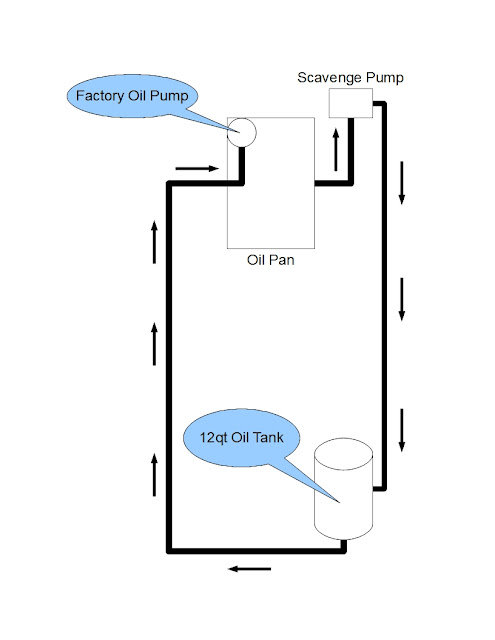

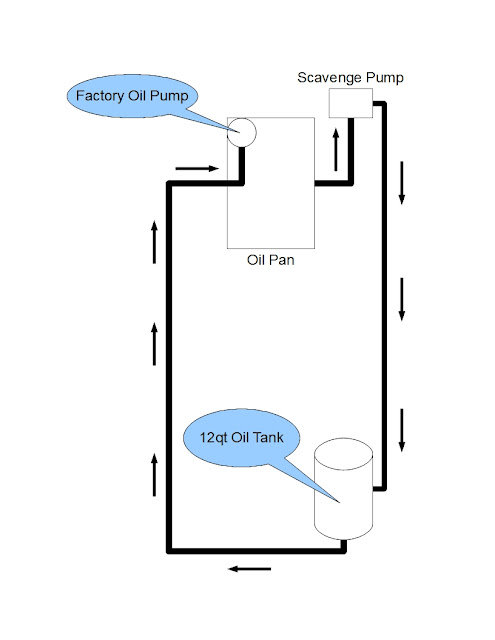

Basically, there is two separate oil systems.

1. The external single stage scavenge pump just sucks the oil from the pan and sends it back to the oil tank in the rear.

2. The factory pump is used with the only difference being that the pick up is connected directly to the bottom of the oil tank instead of sucking oil out of the pan.

History:

Engine:

Oil pressure gauge:

What I've done so far:

Modification from when this system was in the ASA car:

There are more pictures of before and after the modifications here: OIL PAN MODS

Moving forward:

New oil pump? Possible the oil pump is on the way out and not able to build pressure.

What would prevent pressure from increasing when the RPM increases?

Plug next to oil pump. Possible I knocked it out? I don't really know what I am looking for and I can't find any pictures.

Anything else you would suggest that I check?

Any and all help is greatly appreciated.

Problem:

Only 20-25psi of oil pressure.

Oil Pressure does not increase with RPM.

Oil System:

This is an LS1 and dry sump system out of an ASA Roundie-Round car.

Basically, there is two separate oil systems.

1. The external single stage scavenge pump just sucks the oil from the pan and sends it back to the oil tank in the rear.

2. The factory pump is used with the only difference being that the pick up is connected directly to the bottom of the oil tank instead of sucking oil out of the pan.

History:

Engine:

- Engine has been sitting for several years.

- The engine has next to no run time. It was freshened up by Lingenfelter right before the car was wrecked. (Rear end locked up and put the car into the wall, no damage to engine)

- Oil pressure while in the ASA car was 75-80psi cold, 40-45psi hot.

Oil pressure gauge:

- Originally was a mechanical gauge mounted to the factory OP location. Reading at that location was 10-15psi.

- Moved the gauge to a port on the remote oil filter and the pressure was 15-20psi.

- Bought an electrical gauge and readings were the same on both.

What I've done so far:

- Manually primed the system to ensure flow from the scavenge pump to the tank, even though this should not effect the engine oil pressure.

- Rerouted the oil lines in the car making it so all the oil lines are lower than the port at the base of the oil tank. Doing this netted me an additional 5psi of pressure, but still did not increase with RPM.

- When I filled the tank, I took line off that connects to the factory pump until it was full of oil, then reconnected it.

Modification from when this system was in the ASA car:

- Modified front of the pan to clear steering rack.

- Relocated pickup points and AN fitting locations to fit my car.

- Truck pick-up tube was used and new RED o-ring was installed. Fit is good.

There are more pictures of before and after the modifications here: OIL PAN MODS

Moving forward:

New oil pump? Possible the oil pump is on the way out and not able to build pressure.

What would prevent pressure from increasing when the RPM increases?

Plug next to oil pump. Possible I knocked it out? I don't really know what I am looking for and I can't find any pictures.

Anything else you would suggest that I check?

Any and all help is greatly appreciated.

#3

LS1Tech Sponsor

If it is the pump the likely culprit is the pressure control valve in the pump. If you had any debris that got into the pickup and went into the pressure control valve it could now be stuck in the open condition. If the pressure control valve is stuck the easiest thing to do is just get a new pump. For an ASA engine I would just get an OEM GM LS1/LS6/LS2 pump or the standard volume Melling pump.

Any chance anything is restricting the inlet to the pump from the sump tank (debris in the screen, collapsed screen, collapsed oil line liner, etc.)?

I don't have a picture of the plastic plug but I will try to get one at work next week.

Did you change the timing gear to a double row chain type gear? If you used a double roller timing chain it is easy to put the oil pump spacers on the wrong way and block oil from from the pump. [BTW - no reason to change to a double chain, it just adds more mass.]

Any chance anything is restricting the inlet to the pump from the sump tank (debris in the screen, collapsed screen, collapsed oil line liner, etc.)?

I don't have a picture of the plastic plug but I will try to get one at work next week.

Did you change the timing gear to a double row chain type gear? If you used a double roller timing chain it is easy to put the oil pump spacers on the wrong way and block oil from from the pump. [BTW - no reason to change to a double chain, it just adds more mass.]

#5

Teching In

Thread Starter

Join Date: Mar 2007

Location: Louisville, KY

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

If it is the pump the likely culprit is the pressure control valve in the pump. If you had any debris that got into the pickup and went into the pressure control valve it could now be stuck in the open condition. If the pressure control valve is stuck the easiest thing to do is just get a new pump. For an ASA engine I would just get an OEM GM LS1/LS6/LS2 pump or the standard volume Melling pump.

Any chance anything is restricting the inlet to the pump from the sump tank (debris in the screen, collapsed screen, collapsed oil line liner, etc.)?

I don't have a picture of the plastic plug but I will try to get one at work next week.

Did you change the timing gear to a double row chain type gear? If you used a double roller timing chain it is easy to put the oil pump spacers on the wrong way and block oil from from the pump. [BTW - no reason to change to a double chain, it just adds more mass.]

Any chance anything is restricting the inlet to the pump from the sump tank (debris in the screen, collapsed screen, collapsed oil line liner, etc.)?

I don't have a picture of the plastic plug but I will try to get one at work next week.

Did you change the timing gear to a double row chain type gear? If you used a double roller timing chain it is easy to put the oil pump spacers on the wrong way and block oil from from the pump. [BTW - no reason to change to a double chain, it just adds more mass.]

Thanks for the response. I will check the oil line one more time, but I don't think there are any restrictions. I have plenty of oil on the floor of my garage from checking.

I never went into the engine, or changed out the timing chain, so I'm pretty confident in saying that the spacers are correct.

I'm going to order an oil pump today and give it a shot.

Stock volume pump, Check!

Shim to increase pressure or leave it alone?

Thanks again!

Shawn

#6

LS1Tech Sponsor

Stock oil pump is fine. No shim needed. The shim doesn't increase the flow of the pump - just the pressure so at low RPM the shim does nothing. It only increases the pressure once the pump can produce enough flow to create more pressure than the spring setting.

FYI - all of the ASA engines had stock GM LS1/LS6 oil pumps.

FYI - all of the ASA engines had stock GM LS1/LS6 oil pumps.

Jason,

Thanks for the response. I will check the oil line one more time, but I don't think there are any restrictions. I have plenty of oil on the floor of my garage from checking.

I never went into the engine, or changed out the timing chain, so I'm pretty confident in saying that the spacers are correct.

I'm going to order an oil pump today and give it a shot.

Stock volume pump, Check!

Shim to increase pressure or leave it alone?

Thanks again!

Shawn

Thanks for the response. I will check the oil line one more time, but I don't think there are any restrictions. I have plenty of oil on the floor of my garage from checking.

I never went into the engine, or changed out the timing chain, so I'm pretty confident in saying that the spacers are correct.

I'm going to order an oil pump today and give it a shot.

Stock volume pump, Check!

Shim to increase pressure or leave it alone?

Thanks again!

Shawn

#7

LS1Tech Sponsor

On a wet sump engine with a pickup tube that can be an issue.

In this case the engine is a dry sump engine with a dry sump system based on the ASA engine configueration. In that pan (a fabricated Moroso pan) the pickup for the scavenge pump is built into the side of the fabricated pan so it can't move (not without it being fairly obvious after you wrecked your car or something like that). The pickup for the pressure pump is actually at the bottom of the dry sump tank and that oil is then fed to the pump via a line and fitting that goes into the pan. So again no pickup tube moving too close to the bottom of the pan to be a possible issue.

In this case the engine is a dry sump engine with a dry sump system based on the ASA engine configueration. In that pan (a fabricated Moroso pan) the pickup for the scavenge pump is built into the side of the fabricated pan so it can't move (not without it being fairly obvious after you wrecked your car or something like that). The pickup for the pressure pump is actually at the bottom of the dry sump tank and that oil is then fed to the pump via a line and fitting that goes into the pan. So again no pickup tube moving too close to the bottom of the pan to be a possible issue.

Trending Topics

#9

Teching In

Thread Starter

Join Date: Mar 2007

Location: Louisville, KY

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

Pulled the oil pump last night and was hoping to find some visible flaw. I did not find anything, but then again, that was the first time that I have dissected a LS oil pump so a flaw could be in plain sight and I would miss it.

I also check for restrictions or issues in all components leading to the oil pump. Oil pan plumbing is clean and clear. The line from the tank to the oil pan is clean and clear. I also pulled the oil tank and disassembled it to make sure there were no issues, and everything looked good.

I found the infamous plug next to the oil pump and that is physically there. I didn't pull it out, but being that the small freeze plug was in place, I assume the plug is behind it.

Now I'm just waiting on a new oil pump. Being the cheap *** that I am, I found the cheapest dealer online and ordered up a pump. For my case, gmpartsdirect was the winner. What I didn't look at was shipping terms. I ordered the pump Monday and as of today, it still hasn't shipped. I guess I should have just sucked it up and bought one from the local dealer. That way I would have an answer to whether the problem is resolved this weekend. Right now, I'm looking at sometime next week.

I also check for restrictions or issues in all components leading to the oil pump. Oil pan plumbing is clean and clear. The line from the tank to the oil pan is clean and clear. I also pulled the oil tank and disassembled it to make sure there were no issues, and everything looked good.

I found the infamous plug next to the oil pump and that is physically there. I didn't pull it out, but being that the small freeze plug was in place, I assume the plug is behind it.

Now I'm just waiting on a new oil pump. Being the cheap *** that I am, I found the cheapest dealer online and ordered up a pump. For my case, gmpartsdirect was the winner. What I didn't look at was shipping terms. I ordered the pump Monday and as of today, it still hasn't shipped. I guess I should have just sucked it up and bought one from the local dealer. That way I would have an answer to whether the problem is resolved this weekend. Right now, I'm looking at sometime next week.

#10

Teching In

Thread Starter

Join Date: Mar 2007

Location: Louisville, KY

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

After seeing the oil pump condition and having a gut feeling that the OP was not my issue, I kept digging into this issue for a logical answer.

I'm pretty sure I found the problem. My lines running to my remote oil filter were backwards. I was backfeeding the oil filter, which means I was sending very very little if any oil to the engine.

I'm going to put everything back together in the next day or so and see if I truly did find my missing OP.

I hope I haven't hurt anything. I never put a load on the engine and never rev'd it past 3k or so, but I did let it run for quite a while (20min total).

Do you think I've done any damage?

I'm pretty sure I found the problem. My lines running to my remote oil filter were backwards. I was backfeeding the oil filter, which means I was sending very very little if any oil to the engine.

I'm going to put everything back together in the next day or so and see if I truly did find my missing OP.

I hope I haven't hurt anything. I never put a load on the engine and never rev'd it past 3k or so, but I did let it run for quite a while (20min total).

Do you think I've done any damage?

#11

LS1Tech Sponsor

If you didn't run it under load it is very likely that everything is ok. Minimum required idle oil pressure on the LS type engines is fairly low - something like 6 or 8 psi.

One thing to check would be to section the oil filter and see if you have any bearing material in the filter. If you are racing this vehicle and plan to do your own service/upkeep a filter sectioning tool is a good thing to have.

One thing to check would be to section the oil filter and see if you have any bearing material in the filter. If you are racing this vehicle and plan to do your own service/upkeep a filter sectioning tool is a good thing to have.

After seeing the oil pump condition and having a gut feeling that the OP was not my issue, I kept digging into this issue for a logical answer.

I'm pretty sure I found the problem. My lines running to my remote oil filter were backwards. I was backfeeding the oil filter, which means I was sending very very little if any oil to the engine.

I'm going to put everything back together in the next day or so and see if I truly did find my missing OP.

I hope I haven't hurt anything. I never put a load on the engine and never rev'd it past 3k or so, but I did let it run for quite a while (20min total).

Do you think I've done any damage?

I'm pretty sure I found the problem. My lines running to my remote oil filter were backwards. I was backfeeding the oil filter, which means I was sending very very little if any oil to the engine.

I'm going to put everything back together in the next day or so and see if I truly did find my missing OP.

I hope I haven't hurt anything. I never put a load on the engine and never rev'd it past 3k or so, but I did let it run for quite a while (20min total).

Do you think I've done any damage?

#12

Teching In

Thread Starter

Join Date: Mar 2007

Location: Louisville, KY

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

I put most everything back together last night, but before doing so, I did a thorough inspection of the motor. As of last night, I still had oil dripping off the cam. Pulled the valve covers and there were no visible issues there. Cylinder bores still had prominent cross hatching. Pulled a main cap and didn't find any scoring or visible wear at all.

I think I'm good to go. Obviously the OP wasn't optimum, but it looks like I always had some sort of OP.

During re-assembly I found that the AN line that is inside my oil pan may have been crimped a little. Just to be safe I lengthened and rerouted that line to ensure there is no kinking moving forward.

I haven't sectioned the filter yet, but will do so today. I did stop by the parts store on the way home and picked up a new filter.

I still have a little bit of work to do today before I get to a point where I can see if I truly did find my problem. Hopefully I'll have a positive update tonight.

I think I'm good to go. Obviously the OP wasn't optimum, but it looks like I always had some sort of OP.

During re-assembly I found that the AN line that is inside my oil pan may have been crimped a little. Just to be safe I lengthened and rerouted that line to ensure there is no kinking moving forward.

I haven't sectioned the filter yet, but will do so today. I did stop by the parts store on the way home and picked up a new filter.

I still have a little bit of work to do today before I get to a point where I can see if I truly did find my problem. Hopefully I'll have a positive update tonight.