Bad Valve causing ticking?

#1

Lately, I've been noticing more noise coming from the engine. More than the normal LSX sounds. Today, it just seemed like it got worse. Mainly noticeable around 2,000-2,400 rpm. Drove home with the rpms no higher than 1,500.

Here are my engine specs: 2004 LS6 block, Mahle forged pistons, 4" SCAT forged crankshaft, SCAT h-beams rods, EPS cam - 226 intake duration, 0.598 lift; 234 exhaust duration, 0.601" lift 113 centerline, 7.35" pushrods, LS6 heads, decked 0.20", stock rocker arms, Patriot Gold valve springs, factory LS6 intake, pacesetter headers. About 40,000 miles since I built it.

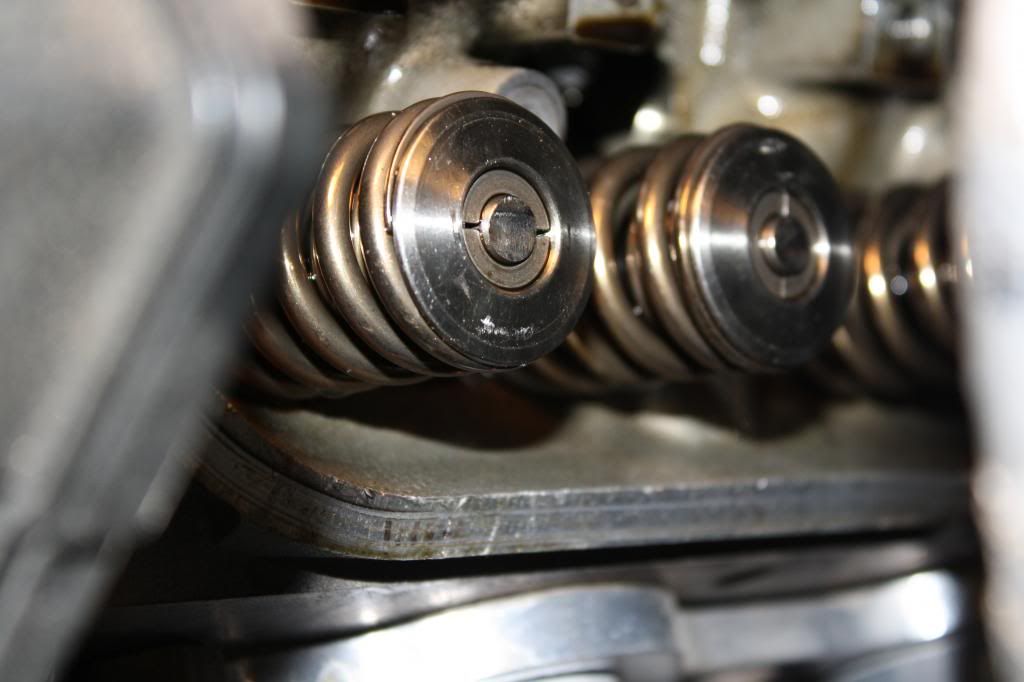

Got home today and pulled the driver's side valve cover. This is the only thing that looked out of place:

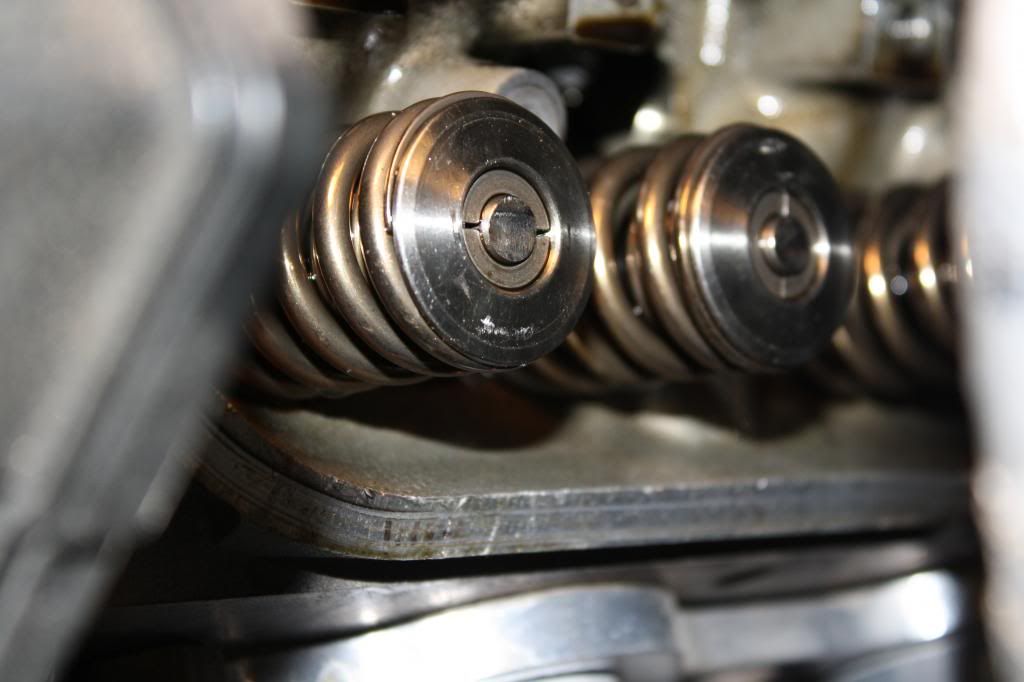

Corresponding rocker arm:

So, does this look significant enough to cause some ticking? What could be the cause of the damage to the valve stem? This is the only valve that has this degradation. Thoughts?

Here are my engine specs: 2004 LS6 block, Mahle forged pistons, 4" SCAT forged crankshaft, SCAT h-beams rods, EPS cam - 226 intake duration, 0.598 lift; 234 exhaust duration, 0.601" lift 113 centerline, 7.35" pushrods, LS6 heads, decked 0.20", stock rocker arms, Patriot Gold valve springs, factory LS6 intake, pacesetter headers. About 40,000 miles since I built it.

Got home today and pulled the driver's side valve cover. This is the only thing that looked out of place:

Corresponding rocker arm:

So, does this look significant enough to cause some ticking? What could be the cause of the damage to the valve stem? This is the only valve that has this degradation. Thoughts?

#3

TECH Fanatic

iTrader: (11)

Maybe the lift has caused the stems and rockers to wear a bit. I'd imagine this would throw your preload off.

Now that there is visible wear and tear I'd imagine the hardness of the metals surface has been compromised accelerating wear.

40k is a lot for .60+" lift. Long term benefit to roller rockers maybe?

Now that there is visible wear and tear I'd imagine the hardness of the metals surface has been compromised accelerating wear.

40k is a lot for .60+" lift. Long term benefit to roller rockers maybe?

#4

FormerVendor

iTrader: (13)

That type of wear will cause noise.

Valve tip wear like this is common on .650ish lift cams with springs that are 450lbs open pressure. It's fairly rare for it to happen with .600ish lift and 360 lbs open pressure.

An aftermarket valve with a soft tip could be the culprit. I noticed the valve next to it is also in distress. The tip should be flat and smooth, not dimpled or trenched.

Good oil with ZDDP additives helps prevent this issue.

Valve tip wear like this is common on .650ish lift cams with springs that are 450lbs open pressure. It's fairly rare for it to happen with .600ish lift and 360 lbs open pressure.

An aftermarket valve with a soft tip could be the culprit. I noticed the valve next to it is also in distress. The tip should be flat and smooth, not dimpled or trenched.

Good oil with ZDDP additives helps prevent this issue.

#6

FormerVendor

iTrader: (13)

Shimming the rockers for a more narrow wipe pattern only increases the amount of time that the rocker is dragging itself across the valve tip and will exacerbate valve tip wear.

#7

Guys,

This stems back to a problem we had back in 2008-2009 or so.

We warrantied alot of product back then and will stand behind it now as well.

Our valve supplier had an intermittent problem with the machine that hardens the tips of the valves. Unfortunately for us we found out after some heads had already shipped and were out in the field. The percentage failures were was low which I why it passed the QC for a bit at the manufacturer, but to be super safe, we invested in a dedicated machine to to a 100% inspection on all the valve we had in inventory and all the valves we received.

Anyway....OP, shoot me a phone call and we can arrange getting the product back here to get that handled. All the freight will be on our dime as well and we will send you new gaskets for the install.

My direct line is (661)705-8508

-Tony

This stems back to a problem we had back in 2008-2009 or so.

We warrantied alot of product back then and will stand behind it now as well.

Our valve supplier had an intermittent problem with the machine that hardens the tips of the valves. Unfortunately for us we found out after some heads had already shipped and were out in the field. The percentage failures were was low which I why it passed the QC for a bit at the manufacturer, but to be super safe, we invested in a dedicated machine to to a 100% inspection on all the valve we had in inventory and all the valves we received.

Anyway....OP, shoot me a phone call and we can arrange getting the product back here to get that handled. All the freight will be on our dime as well and we will send you new gaskets for the install.

My direct line is (661)705-8508

-Tony

Trending Topics

#9

Thanks for the reply, Tony. I'd love to have these warrantied out, however, I can't in good conscience! They are just stock LS6 heads, milled 0.20" with factory valves.

Still looking at my options (replace the valves and springs; get new heads with valves and springs; sell the f'ing thing!!!)

#10

Guys, the OP had also PM'ed me and I just assumed he was inquiring about an issue with an AFR head, especially after I saw pics of the failure.

It was very reminiscent of what we saw from a few sets of AFR heads back in 08'

Brian Tooley and I just hung up the phone and had a good laugh over it!

OP....I don't recommend lots of lift and lots of spring pressure with stock rockers if your truly putting the miles you are on the combination.

Some guys are lucky to see 3000 miles a year with their hot rod.

Replace the defective valves and strongly consider a good aftermarket roller rocker....Im very partial to the YT Ultralites

PM me if you need some additional help or advice

Cheers,

Tony

#11

Moderator

iTrader: (20)

The wipe pattern on stock rockers is very wide because they "rock" on the valve tip like a rocking chair rocks on the floor until higher lifts when they start dragging themselves across the top of the valve tip. The wipe pattern is set by the stock valve tip height and rocker rail height and should not be changed for a vehicle where durability is required.

Shimming the rockers for a more narrow wipe pattern only increases the amount of time that the rocker is dragging itself across the valve tip and will exacerbate valve tip wear.

Shimming the rockers for a more narrow wipe pattern only increases the amount of time that the rocker is dragging itself across the valve tip and will exacerbate valve tip wear.

#12

After doing a lot of research and figuring out the best option versus cost, I believe that I'm going to send my heads to TEA for their Stage 2 porting job. This will give me new valves and springs and added performance that my 383 has probably needed (stock 243 heads were unported). If I can swing a little more $$, I might upgrade the valves to turn-downed LS3 valves for better weight reduction.

Secondly, I am considering sending my rockers out for an upgrade to the CHE precision rocker trunnion modification. I've read a lot about the CHE upgrade and I really like everything I've read.

Lastly, I will upgrade the pushrods to 11/32 or 3/8 Manton's after checking the pre-load once again.

Secondly, I am considering sending my rockers out for an upgrade to the CHE precision rocker trunnion modification. I've read a lot about the CHE upgrade and I really like everything I've read.

Lastly, I will upgrade the pushrods to 11/32 or 3/8 Manton's after checking the pre-load once again.

#13

Update: Heads are at TEA currently. Will go with turned-down LS3 intake valves and check the cc on the chambers.

Rockers with the CHE trunnion upgrade are done at West Coast Cylinder Heads and were shipped out yesterday.

Waiting for the heads to come back before ordering pushrods. Need to double, triple, quadruple check the length.

Lastly, I decided I'm going to order the Brian Tooley SLR lifters and some LS2 trays.

Rockers with the CHE trunnion upgrade are done at West Coast Cylinder Heads and were shipped out yesterday.

Waiting for the heads to come back before ordering pushrods. Need to double, triple, quadruple check the length.

Lastly, I decided I'm going to order the Brian Tooley SLR lifters and some LS2 trays.

#14

12 Second Club

iTrader: (4)

My car ate a valve up like this along with a noise that came and went if the engine reved above 2000 rpm. Let engine idle and it would stop. I found this first. Had the valves replaced and changed lifters only to have the same noise. It took a long time to figure it out because at that point I was just throwing parts at it. I was almost ready to pull the engine when I found the oil pump oring had shrinked and cracked in half and it showed no signs of a pressure problem in the guage. Changed the oring along with a new tick performance ported ls6 pump. Problem solved.

Just my experience.

Im almost willing to bet it was a valve toward the front of the enigine. If your oring is bad its sucking air and oil. The lifters in the front are last in line to get oil. Needless to say if the oring is cracked their is not enough oil for the last lifters in line and the start making noise after running for a minute above 2k rpms. Above 2k the go dry. No oil for the lifter means none makes it to the top of the enigine for the valve and rocker.

Again this is what happened to me. Just something to consider.

Just my experience.

Im almost willing to bet it was a valve toward the front of the enigine. If your oring is bad its sucking air and oil. The lifters in the front are last in line to get oil. Needless to say if the oring is cracked their is not enough oil for the last lifters in line and the start making noise after running for a minute above 2k rpms. Above 2k the go dry. No oil for the lifter means none makes it to the top of the enigine for the valve and rocker.

Again this is what happened to me. Just something to consider.

Last edited by BKsNHRA; 08-27-2013 at 01:58 PM.

Just busting your *****, I know what's going to happen the next time I slip up!

Just busting your *****, I know what's going to happen the next time I slip up!