Is a 9.05 dcr too high to run 93?

#1

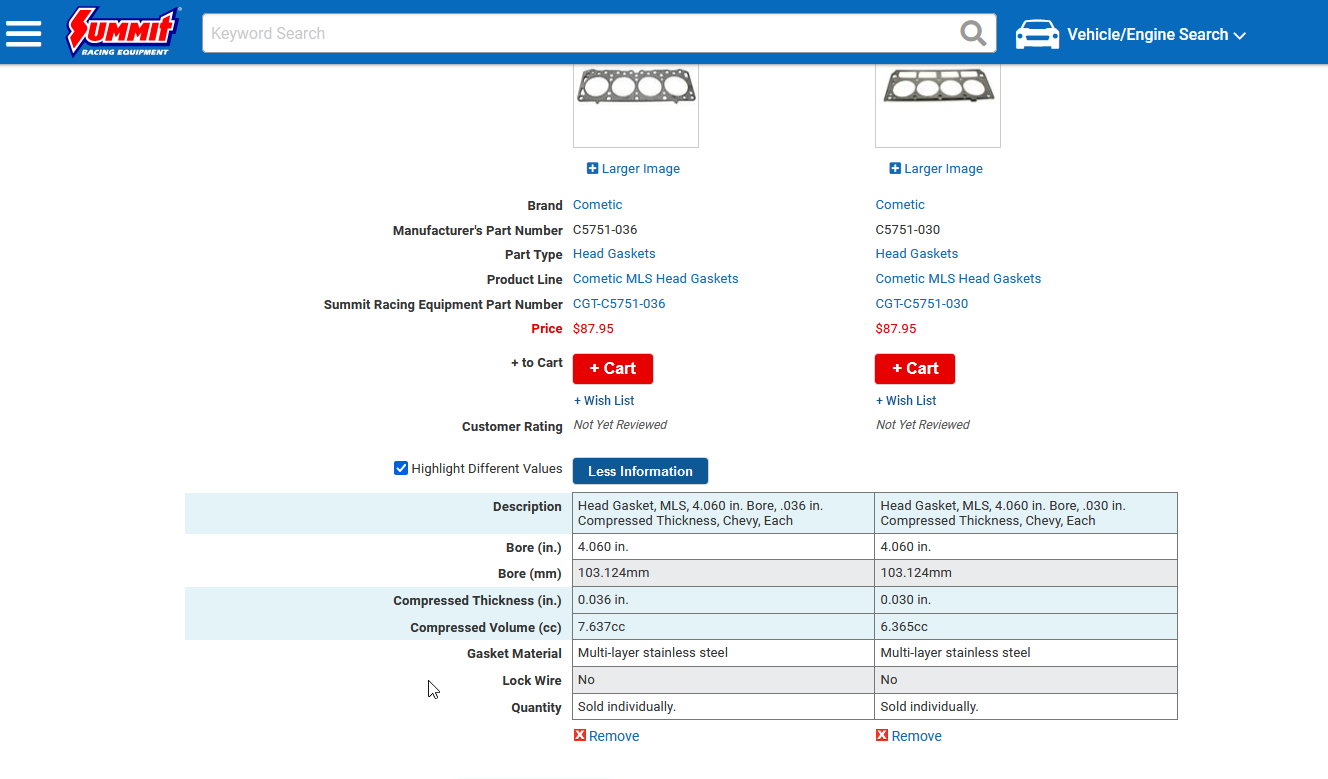

Currently getting ready to drop the heads onto my LQ4 408 and am trying to figure out what headgaskets I need to make my quench and dynamic compression end up where I want, currently calculating the dynamic compression ratio at 9.05:1 with a 0.040" thickness headgasket, is that too high to safely run 93? With a 0.051" headgasket it drops to 8.8:1 but a headgasket that thick would make my quench nearly 0.057" and I feel that is too much for a NA engine. I am not opposed to switching to solely running e85 if I have to.

#3

I would have to retard the cam a minimum of six degrees to bring my dcr down to 8.6:1 but I feel like that’s a bit excessive.

#4

Are you calculating using the IVC @ .006" lift?

#5

no I am using IVC @.050 my cam card doesn’t give IVC @.006

After calculating my IVC @.006 it should be somewhere around 77.5, using the Wallace racing dcr calculator it would put my dcr around 8.01:1, but compared against the go fast math calculator using IVC @0.050" which results in a dcr of 9:1. that large of a difference just doesn't just seem right to me.

Here are the cam spec if someone would like to check my work, all these specs are from cam motion @ .050"

244/250 111.5+3.5 108 ICL

intake exhaust

IVO - 15.1 BTDC EVC - 9.1 ATDC

IVC - 49.1 ABDC EVO - 60.9 BBDC

244.2 @ .050" 250.1 @ .050"

After calculating my IVC @.006 it should be somewhere around 77.5, using the Wallace racing dcr calculator it would put my dcr around 8.01:1, but compared against the go fast math calculator using IVC @0.050" which results in a dcr of 9:1. that large of a difference just doesn't just seem right to me.

Here are the cam spec if someone would like to check my work, all these specs are from cam motion @ .050"

244/250 111.5+3.5 108 ICL

intake exhaust

IVO - 15.1 BTDC EVC - 9.1 ATDC

IVC - 49.1 ABDC EVO - 60.9 BBDC

244.2 @ .050" 250.1 @ .050"

Last edited by Fireballmatt15; 07-07-2024 at 12:05 PM.

#6

Cammotion typically has 55* more duration @ .006". So adding half of that to your IVC @ .006" should be close to your new calculation. A point difference is not surprising.

Trending Topics

#8

TECH Senior Member

The following users liked this post:

68Formula (07-07-2024)

#9

I also have people telling me that the cam is way too big for the engine and I will have constant issues with the valve train like eating lifters, breaking valve springs, wearing out cam bearings and cracking rockers and that I need to swap to a smaller camshaft. I don’t think the cam is too big but I may be wrong, also I don’t believe it will put that much stress on the valve train that I will have to constantly replace parts.

#10

TECH Enthusiast

The following 2 users liked this post by grubinski:

68Formula (07-07-2024), Che70velle (07-07-2024)

#11

TECH Enthusiast

I also have people telling me that the cam is way too big for the engine and I will have constant issues with the valve train like eating lifters, breaking valve springs, wearing out cam bearings and cracking rockers and that I need to swap to a smaller camshaft. I don’t think the cam is too big but I may be wrong, also I don’t believe it will put that much stress on the valve train that I will have to constantly replace parts.

#12

lift is .621"/.604" they didn't say anything about the valvetrain besides recommending their .660" springs so I would assume it would be ok. Also what are you running with 8.89:1 dcr, pump gas?

#14

When it comes to octane sensitivity, a tight but safe quench is always better than sacrificing quench just to tradeoff compression. It more likely to be worse than better.

BSpeck82 is right. If you're running stock rotating assembly (like the steel pm rods and hypereutectic pistons) you can safely use .036" and that will get you more benefit. BUT, keep in mind, aluminum expands at a different rate. So aluminum pistons grow more depending on the alloy. For example, just within the common aluminum alloys the 2618 expands 15% faster than 4032 requiring tighter bore clearances and more quench. Your going to want to add some additional clearance. And as added precaution, some ARP rod bolts are good insurance.

Speaking of rods, stick with steel for any quench. Aluminum rods stretch and grow so much, that forget worrying about quench; getting the recommended deck clearance to account for growth at high rpm (that's the best you'll do), and make sure to run a very safe compression for the octane.

Also, crevice volume plays a role. So keep the gasket bore within .030-040" range over cylinder bore will reduce detonation effects from crevice volume. Too little will risk burning the gasket, but too much is similar effect to not enough quench distance.

BSpeck82 is right. If you're running stock rotating assembly (like the steel pm rods and hypereutectic pistons) you can safely use .036" and that will get you more benefit. BUT, keep in mind, aluminum expands at a different rate. So aluminum pistons grow more depending on the alloy. For example, just within the common aluminum alloys the 2618 expands 15% faster than 4032 requiring tighter bore clearances and more quench. Your going to want to add some additional clearance. And as added precaution, some ARP rod bolts are good insurance.

Speaking of rods, stick with steel for any quench. Aluminum rods stretch and grow so much, that forget worrying about quench; getting the recommended deck clearance to account for growth at high rpm (that's the best you'll do), and make sure to run a very safe compression for the octane.

Also, crevice volume plays a role. So keep the gasket bore within .030-040" range over cylinder bore will reduce detonation effects from crevice volume. Too little will risk burning the gasket, but too much is similar effect to not enough quench distance.

Last edited by 68Formula; 07-08-2024 at 05:35 AM.

#15

TECH Enthusiast

But under light load (cruising on the highway), I suspect the compression is part of what is getting me 31+ mpg.

#16

When it comes to octane sensitivity, a tight but safe quench is always better than sacrificing quench just to tradeoff compression. It more likely to be worse than better.

BSpeck82 is right. If you're running stock rotating assembly (like the steel pm rods and hypereutectic pistons) you can safely use .036" and that will get you more benefit. BUT, keep in mind, aluminum expands at a different rate. So aluminum pistons grow more depending on the alloy. For example, just within the common aluminum alloys the 2618 expands 15% faster than 4032 requiring tighter bore clearances and more quench. Your going to want to add some additional clearance. And as added precaution, some ARP rod bolts are good insurance.

Speaking of rods, stick with steel for any quench. Aluminum rods stretch and grow so much, that forget worrying about quench; getting the recommended deck clearance to account for growth at high rpm (that's the best you'll do), and make sure to run a very safe compression for the octane.

Also, crevice volume plays a role. So keep the gasket bore within .030-040" range over cylinder bore will reduce detonation effects from crevice volume. Too little will risk burning the gasket, but too much is similar effect to not enough quench distance.

BSpeck82 is right. If you're running stock rotating assembly (like the steel pm rods and hypereutectic pistons) you can safely use .036" and that will get you more benefit. BUT, keep in mind, aluminum expands at a different rate. So aluminum pistons grow more depending on the alloy. For example, just within the common aluminum alloys the 2618 expands 15% faster than 4032 requiring tighter bore clearances and more quench. Your going to want to add some additional clearance. And as added precaution, some ARP rod bolts are good insurance.

Speaking of rods, stick with steel for any quench. Aluminum rods stretch and grow so much, that forget worrying about quench; getting the recommended deck clearance to account for growth at high rpm (that's the best you'll do), and make sure to run a very safe compression for the octane.

Also, crevice volume plays a role. So keep the gasket bore within .030-040" range over cylinder bore will reduce detonation effects from crevice volume. Too little will risk burning the gasket, but too much is similar effect to not enough quench distance.

#17

Great information I had no clue about the headgasket possibly being to small and risking burning, still learning and relatively new to engine building. I have been under the impression staying on the higher side of the optimal quench was better to prevent unwanted piston and valve kissing as things begin to expand. I was aiming to get my quench as close to 0.040” as possible.

#18

We're not talking about PTV, that's a whole separate issue that needs to be verified. Going too tight on the quench about the piston colliding with the actual head when everything is at full operating temperature and high rpm. A little looser is of course safer (like .040"), but if you want to tighten it up to get more effect, you have to be aware of what parts you're putting into it because that changes what is "safe.". And you need super-precise machining on all applicable parts and assembly for flatness, along with precision calibers to verify the measurements on all cylinders. There are competitive race builders that with carefully selected parts, precision machining and assembly, and expensive measurement tools, have pushed it all the way down to as low as .028" with some witness marks where the pistons narrowly kissed the heads. But those are the guys where 5hp is worth the risk. On a home build, no need to go that tight. Just get it within the relm of effectiveness based on the components you're using.

#19

ok I’m currently trying to decide between a .030” thick head gasket, a .036” head gasket or a .040” thick head gasket. Right now I measured my deck clearance as .006” in the hole using a dial indicator and a magnetic base but am going to remeasure as I now have a deck bridge. I am leaning more towards the .030” thick head gasket putting my quench at .036” or the .036” to achieve a quench of .042”

So even though you may slightly increased the compression ratio because of a smaller gasket volume, by getting into a good quench distance and minimizing crevice volume, you'll make more power with less tendency for knock. And improved quench can also reduce the amount of timing advance needed for optimized burn, further reducing the possibility of knock. For example, if with poor quench (octane not being an issue) you found 32* was needed; now with good quench, it might make more power with 30* than with 32* (even if neither setting produces knock). That's why just getting into an effective quench window is better than using a poor quench distance to lower compression.