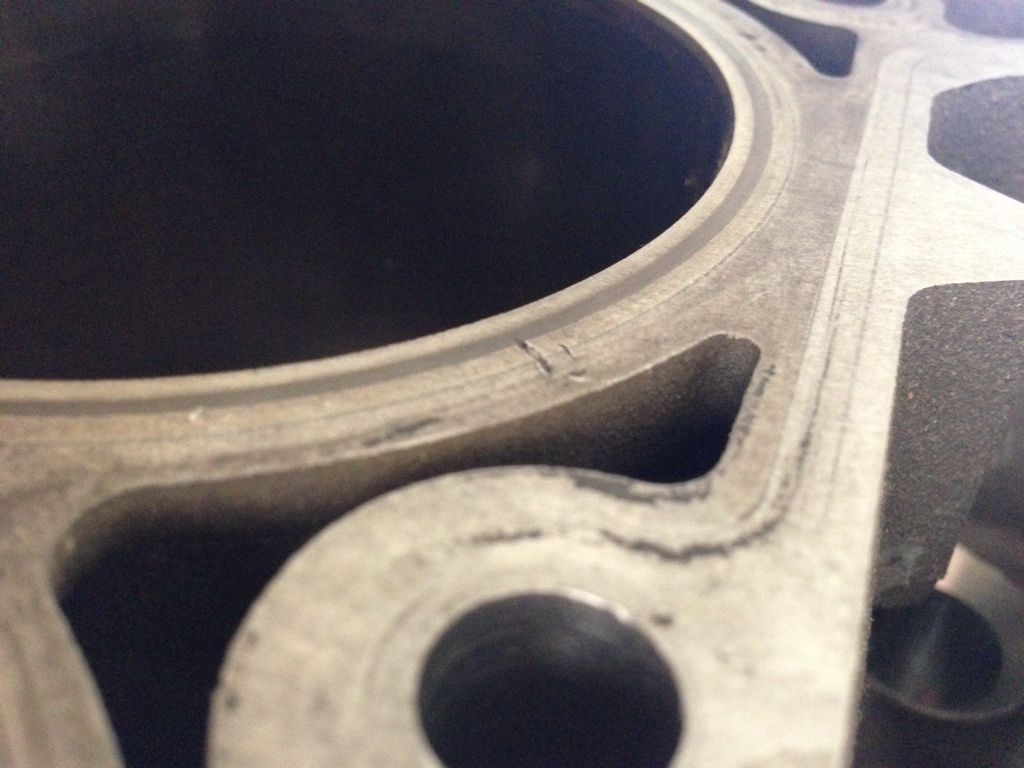

Scratch on deck of ls2 block repair

#3

Trending Topics

#8

#10

Also how does the copper help?

#12

As a last resort, the JB weld may work. I don't know if the heat will exceed it's limitations, but a small fill, scrape off the excess and hope for the best. Does the O-ring on the MLS gasket sit right on the damage or outside of it?

By the looks of it, I don't think a mill will even take it out unless you mill a lot. The picture makes it look pretty deep.

By the looks of it, I don't think a mill will even take it out unless you mill a lot. The picture makes it look pretty deep.

#18

Thanks, unfortunately I don't know of one in the immediate area and I wouldn't be able to get to one any time soon so I'll keep hoping someone here will be able to give me some more helpful advice. I don't plan on using jb weld.

#19

TECH Regular

iTrader: (2)

I just saw the new pics. Looking at the last pic that is taken directly over top of the nick, I wouldn't worry about it. You have enough surface on both sides to seal if the deck surface and head are flat. If combustion gases or coolant make there way to the nick they would eventually make there way to the other end.

#20

" If combustion gases or coolant make there way to the nick they would eventually make there way to the other end."

I'm trying to understand this part. Can you elaborate at all?

I'm trying to understand this part. Can you elaborate at all?

[/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG]  [/IMG]

[/IMG] [/IMG]

[/IMG]