Aircraft LSX revisited

#1

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

A couple of years ago I posted about my plans to use a LS1 in a P-51 replica and got quite a few good responses, especially from Dieselgeek (hi Scott) so I figured enough has changed to try it again. I figure another 8 months to a year before I need the actual engine, since I can mockup everything with the 6.0 that I already have.

Since the LS7 and L92 are out and parts will someday become available, I plan to use the block from one or the other and a combination of parts to achieve my goals, which are:

I need a fat powerband from 3200 to 4800 rpm. The engine will never see over 4800 due to propeller limitations. It will be geared using a chain drive of 2 to 1 ratio (widely used and proven to be reliable). The power loss through these drives is very low, less than 5% is a figure often used. I'd like over 350 max at 4800 and around 220-240 hp at 3400 rpm (sea level).

It will not have headers, only individual short stacks of around 12 inches long for two reasons: appearance, and the fact that there's no room inside the cowling for anything else. This also gets the heat overboard quickly. A good thing.

Firstly, does anyone have experience with engines running short stacks and if so, what cam specs minimize the power loss? I know ther'll be a loss, I'd just like to keep it small as possible.

I'm looking at using Megasquirt (dual) running in speed density mode.

I'm not sure whether to go with the new style (L92) heads or stay with the 6.0 vortec heads and intake. (I already have a LQ4 (new) longblock, intake, etc which I probably will end up selling unless I decide to use the heads and intake.) With the relatively low rpm, I'm not sure of any advantage to the L92 heads, and suspect the LS7 heads will be too big. Any thoughts?

The dry sump would be nice, with a custom oil tank to feed in unusual attitudes, but I haven't decided if it's worth it yet.

A number of LS1 based engines are flying, so there's no question they work. The operating profile is almost identical for a boat and an airplane. I'm just looking at thoughts on how to build an engine with the powerband I need with a displacement depending on which block I end up using.

Thanks for any ideas and thoughts.

ORG

Since the LS7 and L92 are out and parts will someday become available, I plan to use the block from one or the other and a combination of parts to achieve my goals, which are:

I need a fat powerband from 3200 to 4800 rpm. The engine will never see over 4800 due to propeller limitations. It will be geared using a chain drive of 2 to 1 ratio (widely used and proven to be reliable). The power loss through these drives is very low, less than 5% is a figure often used. I'd like over 350 max at 4800 and around 220-240 hp at 3400 rpm (sea level).

It will not have headers, only individual short stacks of around 12 inches long for two reasons: appearance, and the fact that there's no room inside the cowling for anything else. This also gets the heat overboard quickly. A good thing.

Firstly, does anyone have experience with engines running short stacks and if so, what cam specs minimize the power loss? I know ther'll be a loss, I'd just like to keep it small as possible.

I'm looking at using Megasquirt (dual) running in speed density mode.

I'm not sure whether to go with the new style (L92) heads or stay with the 6.0 vortec heads and intake. (I already have a LQ4 (new) longblock, intake, etc which I probably will end up selling unless I decide to use the heads and intake.) With the relatively low rpm, I'm not sure of any advantage to the L92 heads, and suspect the LS7 heads will be too big. Any thoughts?

The dry sump would be nice, with a custom oil tank to feed in unusual attitudes, but I haven't decided if it's worth it yet.

A number of LS1 based engines are flying, so there's no question they work. The operating profile is almost identical for a boat and an airplane. I'm just looking at thoughts on how to build an engine with the powerband I need with a displacement depending on which block I end up using.

Thanks for any ideas and thoughts.

ORG

#2

TECH Addict

I would really like to see that thing fly.

You could probably use a resleeved Ls2 block to keep the light weight of thae aluminum block. The L92 heads would work fine I would think, but the probleme there is going to be an intake manifold. As far as I know, there is only the truck manifold for it. and the truck manifolds usually have some real height associated with them.

A stroker LS1 would be nice. Real fat midragne torque, which is exactly where you need it.

You could probably use a resleeved Ls2 block to keep the light weight of thae aluminum block. The L92 heads would work fine I would think, but the probleme there is going to be an intake manifold. As far as I know, there is only the truck manifold for it. and the truck manifolds usually have some real height associated with them.

A stroker LS1 would be nice. Real fat midragne torque, which is exactly where you need it.

#3

i will be doin same thing in a seabee amphib.

ls7 looks by far the best. i will be running takeoff rpm of 4500 max. i have not looked for a cam yet but it will require changing.

headers, especially long tube will produce more power than straight stacks due to scavaging. again you will require a diff cam for straight stacks. stay with efi to prevent icing.

vesta has a good dual ecm with simple mixture control and timing control. when comparing engines keep in mind gm uses sae rating rather than stp rating for hp. almost 5 % difference. ls7 is rated with stock exhaust manifolds installed, water pump turning, and remainer of accessories rotating but not under load. ls2 is also excellent engine with top torque at 4400 rpm.

ls7 looks by far the best. i will be running takeoff rpm of 4500 max. i have not looked for a cam yet but it will require changing.

headers, especially long tube will produce more power than straight stacks due to scavaging. again you will require a diff cam for straight stacks. stay with efi to prevent icing.

vesta has a good dual ecm with simple mixture control and timing control. when comparing engines keep in mind gm uses sae rating rather than stp rating for hp. almost 5 % difference. ls7 is rated with stock exhaust manifolds installed, water pump turning, and remainer of accessories rotating but not under load. ls2 is also excellent engine with top torque at 4400 rpm.

#6

TECH Resident

Join Date: Oct 2004

Location: TAMPA by way of MIAMI!!!

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

I've thought about doing the same with an old SBC into a Velocity XLRG. I allways thought it would be badass and with a LSx it would be even better.

#7

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Keith, fortunately the truck intake will fit with an inch or so to spare. Right now an L92 block and heads with about 9-10 to 1 pistons look good. The crank options are stock, LS7 (if the dry sump ends up worth it), or stroker. Since the weight should be the same and the cost low, I'm very interested in this combo. Depending on cost and availability, the LS7 block/L92 heads combo also is interesting. The more cubic inches, the easier to get the low rpm power I need. My website http://home.comcast.net/~ogoodwin/Mustang.html has lots of pictures.

Originally Posted by Keith

I would really like to see that thing fly.

You could probably use a resleeved Ls2 block to keep the light weight of thae aluminum block. The L92 heads would work fine I would think, but the probleme there is going to be an intake manifold. As far as I know, there is only the truck manifold for it. and the truck manifolds usually have some real height associated with them.

A stroker LS1 would be nice. Real fat midragne torque, which is exactly where you need it.

You could probably use a resleeved Ls2 block to keep the light weight of thae aluminum block. The L92 heads would work fine I would think, but the probleme there is going to be an intake manifold. As far as I know, there is only the truck manifold for it. and the truck manifolds usually have some real height associated with them.

A stroker LS1 would be nice. Real fat midragne torque, which is exactly where you need it.

Trending Topics

#8

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

piusk, do you know Steve Lantz? He has a Seabee with a LS engine. I used to work with him. You're right about the headers, but I don't have the room and the short stacks are important on a replica type for sound and appearance. With the proper heads and cam, I hope I can minimize the losses in power. The FEW Mustang uses short stacks and a LS1. Apparently it works well. Does Vesta sell the ECM setup separately or just with an engine package?

Thanks

Thanks

Originally Posted by piusk

i will be doin same thing in a seabee amphib.

ls7 looks by far the best. i will be running takeoff rpm of 4500 max. i have not looked for a cam yet but it will require changing.

headers, especially long tube will produce more power than straight stacks due to scavaging. again you will require a diff cam for straight stacks. stay with efi to prevent icing.

vesta has a good dual ecm with simple mixture control and timing control. when comparing engines keep in mind gm uses sae rating rather than stp rating for hp. almost 5 % difference. ls7 is rated with stock exhaust manifolds installed, water pump turning, and remainer of accessories rotating but not under load. ls2 is also excellent engine with top torque at 4400 rpm.

ls7 looks by far the best. i will be running takeoff rpm of 4500 max. i have not looked for a cam yet but it will require changing.

headers, especially long tube will produce more power than straight stacks due to scavaging. again you will require a diff cam for straight stacks. stay with efi to prevent icing.

vesta has a good dual ecm with simple mixture control and timing control. when comparing engines keep in mind gm uses sae rating rather than stp rating for hp. almost 5 % difference. ls7 is rated with stock exhaust manifolds installed, water pump turning, and remainer of accessories rotating but not under load. ls2 is also excellent engine with top torque at 4400 rpm.

#9

i've seen steves seabee. nice plane.

vesta sells computer seperate or anything seperate for that matter. jason is pretty good. also has a nice monitor system for ls engines. sells rads and prop

as well.

vesta also has a tight fitting intercooled supercharger package.

what kind of psru are you planning?

vesta sells computer seperate or anything seperate for that matter. jason is pretty good. also has a nice monitor system for ls engines. sells rads and prop

as well.

vesta also has a tight fitting intercooled supercharger package.

what kind of psru are you planning?

#11

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

It's scaled, about .7. Max weight is about 2300 pounds. The speed will be lower than the original, but the climb will be at least comparable, based on other replicas of about the same size/power.

org

org

Originally Posted by GuitsBoy

Is this replica scaled down? Forgive me if im wrong but didnt the original mustang have 1600+ HP? I mean, I know you wont be carrying around armorment or ordinance, but if its full scale, will a 350 HP engine get you off the tarmac?

#12

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

You're right about the power, but I don't think I have room in the cowling. A supercharger would solve lots of problems, not the least of which is the lack of scavenging with the short stacks.

org

org

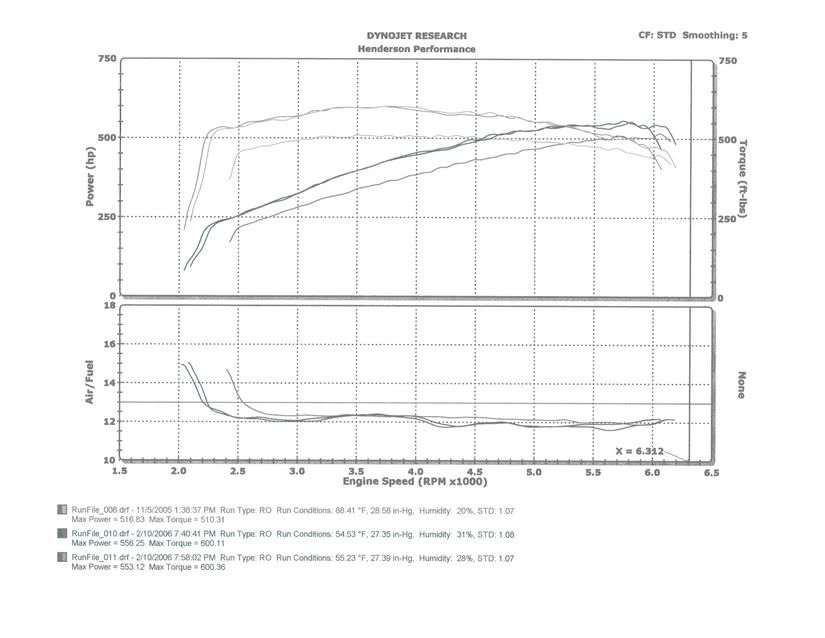

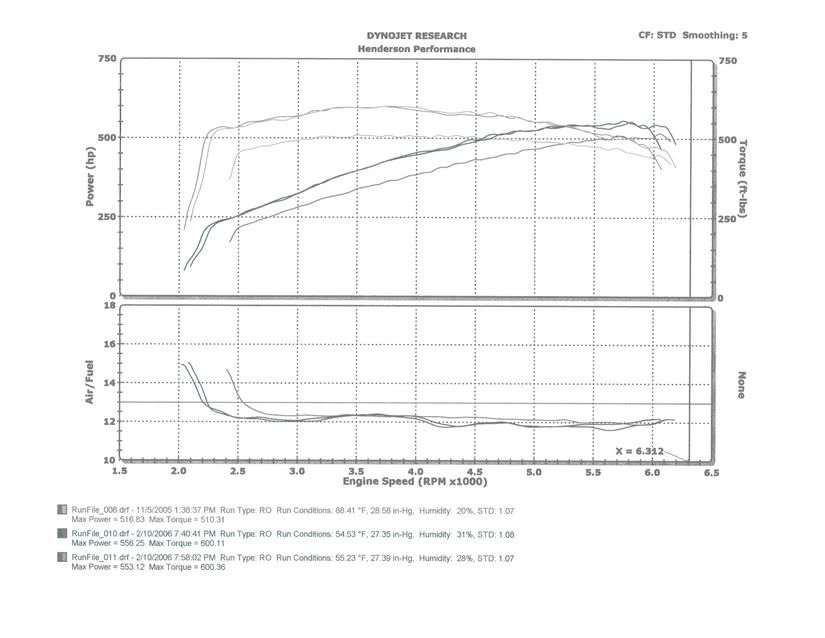

Originally Posted by M_T_0

take a ls2 put a KB blower on it and you will have all the power you can deal with between 3000-4800 rpm.

this is a 346 ls1 with a maggie on it

More Than Zero

this is a 346 ls1 with a maggie on it

More Than Zero

#13

I flew a 1500 lb plane with 130 hp, so he'll be fine. I agree more HP would be impressive though. The LS1 is pretty heavy for a plane though.

Good luck with the build. Planes have a lot of considerations cars don't have to worry about, like changing altitude at 4000 ft/minute. On the other hand, you can take advantage of having to only really worry about a very small RPM band. I bet you'll get a lot of benefit from a well designed cam. Too bad about the exhaust, that could benefit from a fixed RPM too.

Is there a reason why you aren't using a higher RPM with a higher gear ratio?

Do you have room for a supercharger? All that cold air up there should allow a lot of boost at high altitude, as well as compensate some for pressure differences. If not, ram air should work nicely at 300 mph.

Good luck with the build. Planes have a lot of considerations cars don't have to worry about, like changing altitude at 4000 ft/minute. On the other hand, you can take advantage of having to only really worry about a very small RPM band. I bet you'll get a lot of benefit from a well designed cam. Too bad about the exhaust, that could benefit from a fixed RPM too.

Is there a reason why you aren't using a higher RPM with a higher gear ratio?

Do you have room for a supercharger? All that cold air up there should allow a lot of boost at high altitude, as well as compensate some for pressure differences. If not, ram air should work nicely at 300 mph.

#14

could you not run a centrifugal supercharger???? they worked VERY well on the merlin and griffith engines that the in the spitfires and (the Merlin) in the P-51's!

this would also hell with the presure diffrence and could be mounted behiund the engine so the profile wouldn't alter much!

thanks Chris.

this would also hell with the presure diffrence and could be mounted behiund the engine so the profile wouldn't alter much!

thanks Chris.

#15

TECH Enthusiast

iTrader: (3)

Join Date: Aug 2005

Location: Castle Rock, CO

Posts: 597

Likes: 0

Received 0 Likes

on

0 Posts

I would look at some sort of forced induction to compensate for the altitude changes, otherwise youre gonna have a really low power to weight ratio for that motor. A big single turbo would probably be the best solution, but I dont know much about planes.

What special considerations will you have to take into account with the oil in the oil pan? Some kind of uber dry-sump setup? With all that climbing and diving and rollings, oiling is going to be critical.

This sounds like an awesomely fun project...ive always wanted a P-51 myself

OPPS i jsut realized you want stock exhaust so the turbo might be out, LOL.

What special considerations will you have to take into account with the oil in the oil pan? Some kind of uber dry-sump setup? With all that climbing and diving and rollings, oiling is going to be critical.

This sounds like an awesomely fun project...ive always wanted a P-51 myself

OPPS i jsut realized you want stock exhaust so the turbo might be out, LOL.

#16

yeah i think compound turbo charging would be the best solution as you would get better boost at high altitude! but if you need to dump the exhaust quickly (what are the preblems that mean you ahve to do this org????) then you have to go for supercharging! now fixed displacment is great but you can shift more air with a centrifugal! and if you where to get really complex you could run a gear system so you increased SC rpm the higher you got!

just a thought!

thanks chris

just a thought!

thanks chris

#17

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Steel Chicken

I would look at some sort of forced induction to compensate for the altitude changes, otherwise youre gonna have a really low power to weight ratio for that motor. A big single turbo would probably be the best solution, but I dont know much about planes.

What special considerations will you have to take into account with the oil in the oil pan? Some kind of uber dry-sump setup? With all that climbing and diving and rollings, oiling is going to be critical.

This sounds like an awesomely fun project...ive always wanted a P-51 myself

OPPS i jsut realized you want stock exhaust so the turbo might be out, LOL.

What special considerations will you have to take into account with the oil in the oil pan? Some kind of uber dry-sump setup? With all that climbing and diving and rollings, oiling is going to be critical.

This sounds like an awesomely fun project...ive always wanted a P-51 myself

OPPS i jsut realized you want stock exhaust so the turbo might be out, LOL.

As for the pan, actually not a lot needs to be done, since all maneuvering can be kept to positive G...meaning the engine thinks it's upright no matter what the attitude really is. Bob Hoover used to demo a loop and roll with a glass of water sitting on the panel of his airplane and didn't spill a drop. Having said that, a dry sump would be very nice for the momentary changes in attitude involve n screwing up a maneuver, and the stock LS7 setup with a special tank is attractive in that respect. Most aircraft engines, however, don't have inverted capability either.

org

#18

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by chuntington101

yeah i think compound turbo charging would be the best solution as you would get better boost at high altitude! but if you need to dump the exhaust quickly (what are the preblems that mean you ahve to do this org????) then you have to go for supercharging! now fixed displacment is great but you can shift more air with a centrifugal! and if you where to get really complex you could run a gear system so you increased SC rpm the higher you got!

just a thought!

thanks chris

just a thought!

thanks chris

As for dumping the heat, there are really no problems except that this is a really tight cowling and will have minimal openings for air flow. Unlike the automotive engine bay, the radiator will be back under the belly and there' are big advantages (aerodynamic) to not allowing any more airflow through the cowling than necessary. The only planned opening will be the air inlet scoop for the induction and possibly an oil cooler (which will actually have a duct that doesn't allow air into the cowling, just through the cooler.) By dumping the heat overboard, all the electricals and lines will be lots happier. I figure quite a bit of the engine heat will be sucked out the openings for the stacks, too.

There are pictures of the installation of a LS1 on a similar airplane on my website (address above) along with pics of my airplane.

Thanks for the thoughts.

org

#19

On The Tree

Thread Starter

Join Date: Dec 2003

Location: Colorado

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by steve2001sh

I flew a 1500 lb plane with 130 hp, so he'll be fine. I agree more HP would be impressive though. The LS1 is pretty heavy for a plane though.

Good luck with the build. Planes have a lot of considerations cars don't have to worry about, like changing altitude at 4000 ft/minute. On the other hand, you can take advantage of having to only really worry about a very small RPM band. I bet you'll get a lot of benefit from a well designed cam. Too bad about the exhaust, that could benefit from a fixed RPM too.

Is there a reason why you aren't using a higher RPM with a higher gear ratio?

Do you have room for a supercharger? All that cold air up there should allow a lot of boost at high altitude, as well as compensate some for pressure differences. If not, ram air should work nicely at 300 mph.

Good luck with the build. Planes have a lot of considerations cars don't have to worry about, like changing altitude at 4000 ft/minute. On the other hand, you can take advantage of having to only really worry about a very small RPM band. I bet you'll get a lot of benefit from a well designed cam. Too bad about the exhaust, that could benefit from a fixed RPM too.

Is there a reason why you aren't using a higher RPM with a higher gear ratio?

Do you have room for a supercharger? All that cold air up there should allow a lot of boost at high altitude, as well as compensate some for pressure differences. If not, ram air should work nicely at 300 mph.

One of the nice things about EFI is the ability to compensate for the altitude changes. You still lose power with less air density, but the engine continues to run at peak efficiency. Another reason for using the computerized engine controls.

As for the rpm, I'm happier with the lower stresses on the engine at these speeds. I know the engine will last at higher rpm, but as long as I can get the performance I need without stressing it any more than necessary, I'll keep the rpm in this range. Another factor is that most reduction drives have been proven to work well at about that ratio. The reduction drives have proven to be the weak link in most conversions, so babying it is also a factor.

Do you have any thoughts on cam design for the short stacks? As noted, the operating range will be between 3000 and at most 4800 and all I need is the ability to accelerate from idle (probably 1200 rpm) into that range smoothly. Idle won't be really that important, within reason, since the engine will always have a load on it just to turn the prop, even at idle.

org

#20

I'm afraid I know very little about cam design, but enough to know you want someone experienced, someone who sees the potential for tuning an engine that doesn't really have a range to operate in, but 1 constant RPM.