Warhawk Progress

#1

Collections Removal

Thread Starter

Join Date: Jan 2006

Location: Long Island, NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

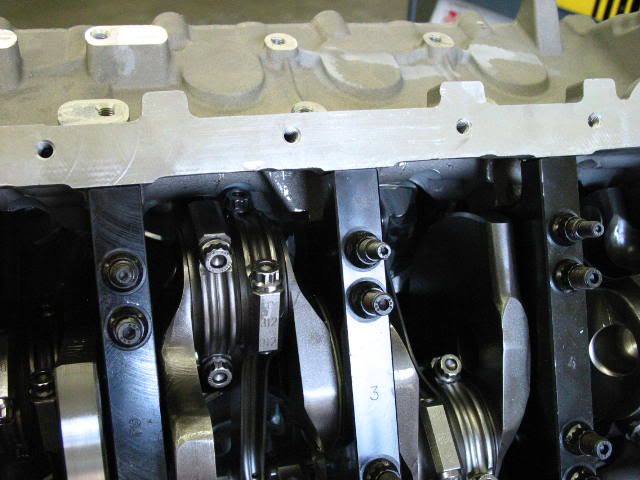

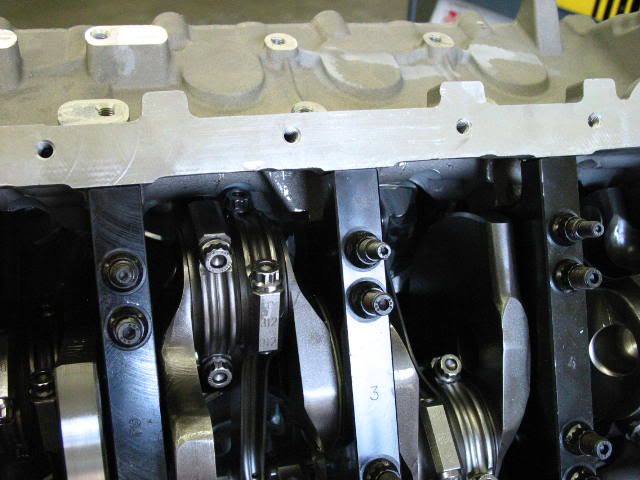

I've started this thread to display progress to date with our assembly check-out. We hope this answers some questions you have had and shows some of the internals of Warhawk.

It's important to remember that this is a "mule" block, used for clearance checking and feasibility study.

You're seeing a 9.24 deck block, with no jackets, some grinding and other un-pretty blems-but it is dimensionally accurate and serves it's purpose. I can tell you that production pieces are very pretty (we've seen some foundry pours) and we think, going to be bulletproof.

These shots show a 4.250" Callies, with Eagle rods and Manley pistons. You can see rod bolt notches machined in the galley bulge and sleeve bottoms. This all clears just fine. In fact we laid the 4.500" Callies in place (with no rods or pistons) and it swings perfectly without hitting anything. Remember this is the low deck. We know the rods bolts will hit the oil galley and an external line will be needed, but we're not that far along yet. We have indications that the tall decks will be here sooner than we thought and when they and the proper pin-height pistons arrive we'll do the 481 build.

Yes, we're taking our sweet time with this but we hope the the 9000 RPM or 2000 HP builders will appreciate that fact.

We should be filling the early orders at the very end of Sept. and by mid Oct., we'll be stacked in the warehouse with them.

Thanks for your interest and we'll keep you posted.

It's important to remember that this is a "mule" block, used for clearance checking and feasibility study.

You're seeing a 9.24 deck block, with no jackets, some grinding and other un-pretty blems-but it is dimensionally accurate and serves it's purpose. I can tell you that production pieces are very pretty (we've seen some foundry pours) and we think, going to be bulletproof.

These shots show a 4.250" Callies, with Eagle rods and Manley pistons. You can see rod bolt notches machined in the galley bulge and sleeve bottoms. This all clears just fine. In fact we laid the 4.500" Callies in place (with no rods or pistons) and it swings perfectly without hitting anything. Remember this is the low deck. We know the rods bolts will hit the oil galley and an external line will be needed, but we're not that far along yet. We have indications that the tall decks will be here sooner than we thought and when they and the proper pin-height pistons arrive we'll do the 481 build.

Yes, we're taking our sweet time with this but we hope the the 9000 RPM or 2000 HP builders will appreciate that fact.

We should be filling the early orders at the very end of Sept. and by mid Oct., we'll be stacked in the warehouse with them.

Thanks for your interest and we'll keep you posted.

Trending Topics

#9

TECH Enthusiast

iTrader: (4)

Join Date: Apr 2005

Location: Bremerton, WA

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

I'm still wondering about the front and rear covers? Will they be included with the price of the block or will they be a NECESSARY purchase? I remember reading somewhere that the warhawk uses their own front and rear covers, but I haven't seen anything else written about them since. Any info on other misc costs of this block would be extremely helpful in making my mind up over a Darton wetsleeved LS1 block.

#10

Collections Removal

Thread Starter

Join Date: Jan 2006

Location: Long Island, NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

Grn,

Herewith the needed and optional components for Warhawk, listed by part number and suggested retail price.

Required Parts:

# 832800-Cam retainer plate-$79.99

# 832820-Rear seal cover-$109.99

# 832821-Rear seal cover gasket- NA at this time

#061075-Valley cover plate-$109.99

#832560-Cylinder head stud kit (4 studs per cylinder)/9.240 deck-$279.99

#832563-Cylinder head stud kit (4 studs per cylinder)/9.800 deck-$279.99

Optional Parts:

#832561-Cylinder head stud kit (2 additional studs per cylinder)9.240 deck-$159.99

#832564-Cylinder head stud kit (2 additional studs per cylinder)9.800 deck-$159.99

If there is question why our parts are required, here's the answer.

Our cam retainer has two additional fasteners compared to OE due to our improved oiling crossover path. (Silicone sealant is applied rather than the imbedded rubber of the stock piece, which doesn't match our passages.)The rear seal cover also accomodates the difference in our oil system and requires our special gasket.The valley cover differs from OE in that our block is a "hybrid" - all our bolt locations are LS 2 driven; however the cam position sensor is rear-mounted as is the LS 1.

All stud kits are custom made for us by ARP, the options are only needed for the 6-bolt attachment of our heads.

We are currently sourcing a stainless bolt kit which we will use on the short block assemblies which we build. Builders may buy them at their discretion.

Hope this helps.

Herewith the needed and optional components for Warhawk, listed by part number and suggested retail price.

Required Parts:

# 832800-Cam retainer plate-$79.99

# 832820-Rear seal cover-$109.99

# 832821-Rear seal cover gasket- NA at this time

#061075-Valley cover plate-$109.99

#832560-Cylinder head stud kit (4 studs per cylinder)/9.240 deck-$279.99

#832563-Cylinder head stud kit (4 studs per cylinder)/9.800 deck-$279.99

Optional Parts:

#832561-Cylinder head stud kit (2 additional studs per cylinder)9.240 deck-$159.99

#832564-Cylinder head stud kit (2 additional studs per cylinder)9.800 deck-$159.99

If there is question why our parts are required, here's the answer.

Our cam retainer has two additional fasteners compared to OE due to our improved oiling crossover path. (Silicone sealant is applied rather than the imbedded rubber of the stock piece, which doesn't match our passages.)The rear seal cover also accomodates the difference in our oil system and requires our special gasket.The valley cover differs from OE in that our block is a "hybrid" - all our bolt locations are LS 2 driven; however the cam position sensor is rear-mounted as is the LS 1.

All stud kits are custom made for us by ARP, the options are only needed for the 6-bolt attachment of our heads.

We are currently sourcing a stainless bolt kit which we will use on the short block assemblies which we build. Builders may buy them at their discretion.

Hope this helps.

#12

Collections Removal

Thread Starter

Join Date: Jan 2006

Location: Long Island, NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

The first picture in this post shows the block interior and the galley bulge on the "driver" side of the block. The machined notches are for the rod bolts of the 4.25" assembly. Although the 4.50" crank itself clears the whole crankcase, the notches required for the rods would seriously weaken or breech the galley wall. We will drill, tap and mock-up a line outside the block to by-pass the rod interference area and safely route the oil past.

That's not an immediate priority though as; a.We don't have a tall deck block in the shop yet b. We're concentrating on the 427 and 454 assemblies right now. c. We need to get these out to the public.

I'm told by WorldTech, that his priority is to build and run-in for hours on our dynos, complete running engines (on carbs) purely to test all fits and geometrys

of block, heads, valvetrains etc. (No, NOT for power figures yet). He wants to get it right.

Stay tuned.

That's not an immediate priority though as; a.We don't have a tall deck block in the shop yet b. We're concentrating on the 427 and 454 assemblies right now. c. We need to get these out to the public.

I'm told by WorldTech, that his priority is to build and run-in for hours on our dynos, complete running engines (on carbs) purely to test all fits and geometrys

of block, heads, valvetrains etc. (No, NOT for power figures yet). He wants to get it right.

Stay tuned.

#14

TECH Fanatic

Join Date: Mar 2004

Location: Laguna Niguel, CA

Posts: 1,017

Likes: 0

Received 0 Likes

on

0 Posts

^ A 454 built in 2006 in the same package size(almost) as a small block.

The world of high-tech motors is getting better and better all the time.

The world of high-tech motors is getting better and better all the time.

Last edited by gun5l1ng3r; 08-18-2006 at 06:49 PM.

#16

FormerVendor

iTrader: (7)

Join Date: Jan 2002

Location: Toronto, Canada

Posts: 1,940

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by MerlinPro

Although the 4.50" crank itself clears the whole crankcase, the notches required for the rods would seriously weaken or breech the galley wall. .

#17

TECH Resident

iTrader: (1)

Join Date: Apr 2004

Location: Winchester,VA

Posts: 773

Likes: 0

Received 0 Likes

on

0 Posts

I know you can't just look at these things but that looks like an extremely tight tolerance. I've heard of someone designing a billet Gurdel to prevent torsion/twisting under high loads. I see how tight this is and can't help to wonder if there will be enough clearance where even if something such as that would not make a difference.