My 355 is done and should fire today!!!

#81

Thread Starter

11 Second Club

iTrader: (17)

Joined: Jul 2008

Posts: 9,896

Likes: 1

From: Chicago area

yep on a 1.89 60ft. Now I have the 2 step and Hoosier QTPs and am a tad lighter so Im hoping to drop that 60ft to a 1.7 or better. I doubt it will trap any higher. I hope it just doest run any worse. DA will be pretty important.

#83

Looks nice and sounds great...Good luck at the track...The weather is cooling off nicely out here...Gonna get mine out soon myself...Still looking for that ever elusive 10.9X...Had Vig 3600 restalled to 4000, added a Spohn pro series rear bar, and 325 50 R15 M/T radials...If I can get the 60s anywhere in the 1.4s I should have it....Again good luck with everything...

--Alan

--Alan

#85

Thread Starter

11 Second Club

iTrader: (17)

Joined: Jul 2008

Posts: 9,896

Likes: 1

From: Chicago area

Looks nice and sounds great...Good luck at the track...The weather is cooling off nicely out here...Gonna get mine out soon myself...Still looking for that ever elusive 10.9X...Had Vig 3600 restalled to 4000, added a Spohn pro series rear bar, and 325 50 R15 M/T radials...If I can get the 60s anywhere in the 1.4s I should have it....Again good luck with everything...

--Alan

--Alan

Thanks!!!!

lol!! Ram air works even at idle!!! Thanks!

#88

. Seriously get some rear susp. pieces and some track time, that 60 ft will drop real fast. I know nobody likes them but I've had good luck with the QA1's on the 6 speed cars.....

. Seriously get some rear susp. pieces and some track time, that 60 ft will drop real fast. I know nobody likes them but I've had good luck with the QA1's on the 6 speed cars.....

BTW....sounds real good...we'll have to get together sometime before it gets crummy out here!

#90

Thread Starter

11 Second Club

iTrader: (17)

Joined: Jul 2008

Posts: 9,896

Likes: 1

From: Chicago area

LOL! ^^

For sure Chris im trying to make it up to GLD for RSD on Friday!!

Im going with the QA1s up front and later replace the rears. Rear suspension has LCAs, TA, and PHB. Still needs relocation brackets and shocks/springs

For sure Chris im trying to make it up to GLD for RSD on Friday!!

Im going with the QA1s up front and later replace the rears. Rear suspension has LCAs, TA, and PHB. Still needs relocation brackets and shocks/springs

#91

--Alan

#93

If you're on any kind of budget, the stock rear springs aren't bad...Just get a set of 12 way QA1s back there and play with stiffness settings....I run QA1 R series fronts with 275lb springs, stock rears with QA1 12 ways...Fronts on 2 rears on 8...But thats subject to changing track conditions obviously....

--Alan

--Alan

and it's a shame I work friday nights....I'd be there if I could. Let us know what she does!

#95

Thread Starter

11 Second Club

iTrader: (17)

Joined: Jul 2008

Posts: 9,896

Likes: 1

From: Chicago area

Just got back from the dyno.

Graph looks great and smooth. TQ curve is great. But the car is down a bit on power. It made 405.49/360.09. vs 413/366.00

Im sure once the motor loosens up it will make more. The reasons I think its down 9hp and 6 tq is the heavy *** Street twin, plus the forged pistons are heavier and the rockers also weigh a tad more. Not to mention the last dyno was late fall and alot cooler out.

I do think the advantages of the pistons, RRs & street twin out weigh the HP/TQ loss. Wont matter anyways once I can afford a kit for the car. !!!!

!!!!

Graph looks great and smooth. TQ curve is great. But the car is down a bit on power. It made 405.49/360.09. vs 413/366.00

Im sure once the motor loosens up it will make more. The reasons I think its down 9hp and 6 tq is the heavy *** Street twin, plus the forged pistons are heavier and the rockers also weigh a tad more. Not to mention the last dyno was late fall and alot cooler out.

I do think the advantages of the pistons, RRs & street twin out weigh the HP/TQ loss. Wont matter anyways once I can afford a kit for the car.

!!!!

!!!!

#96

Did you have speedinc. dynotune it? Cuz when I went there they said they couldn't tune my lt1 maybe cuz i have OB1? anyways that is one clean car, I'd like to see this car at GLD I maybe going next week on weds. just because it's $20 haha I hope to have numbers like that someday that is a really nice build

#97

cut it so it will look like this:

then make a plate like this:

paint it:

take the half with the heater motor in the car that you cut:

put them together and place them in the car and bolt it up:

#99

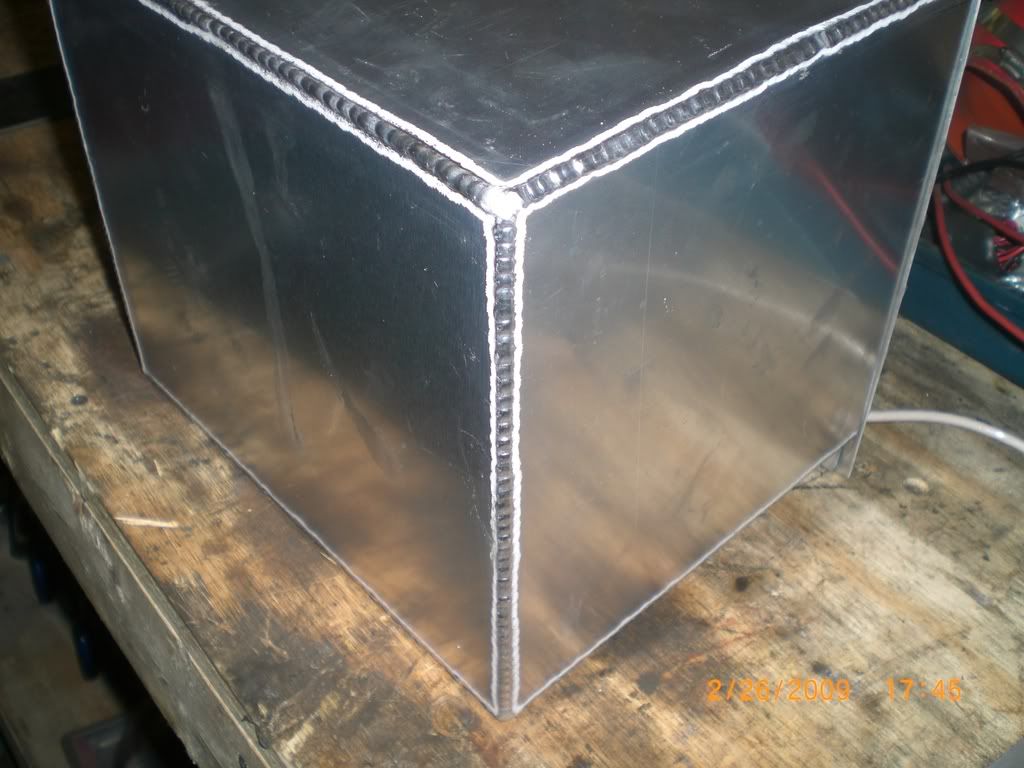

I could do it out of aluminum. I work with Stainless but that would look like hell because stainless likes to warp so damn bad. The one I made was out of 16 ga. The pop out I made for the blower motor has just enough clearance to miss the PCM connectors. I even made my own battery box, which fits better than anything I had boughten:

The dash part is easy, SEE:

Last edited by 94zgreenmachine; 09-18-2009 at 08:42 PM.